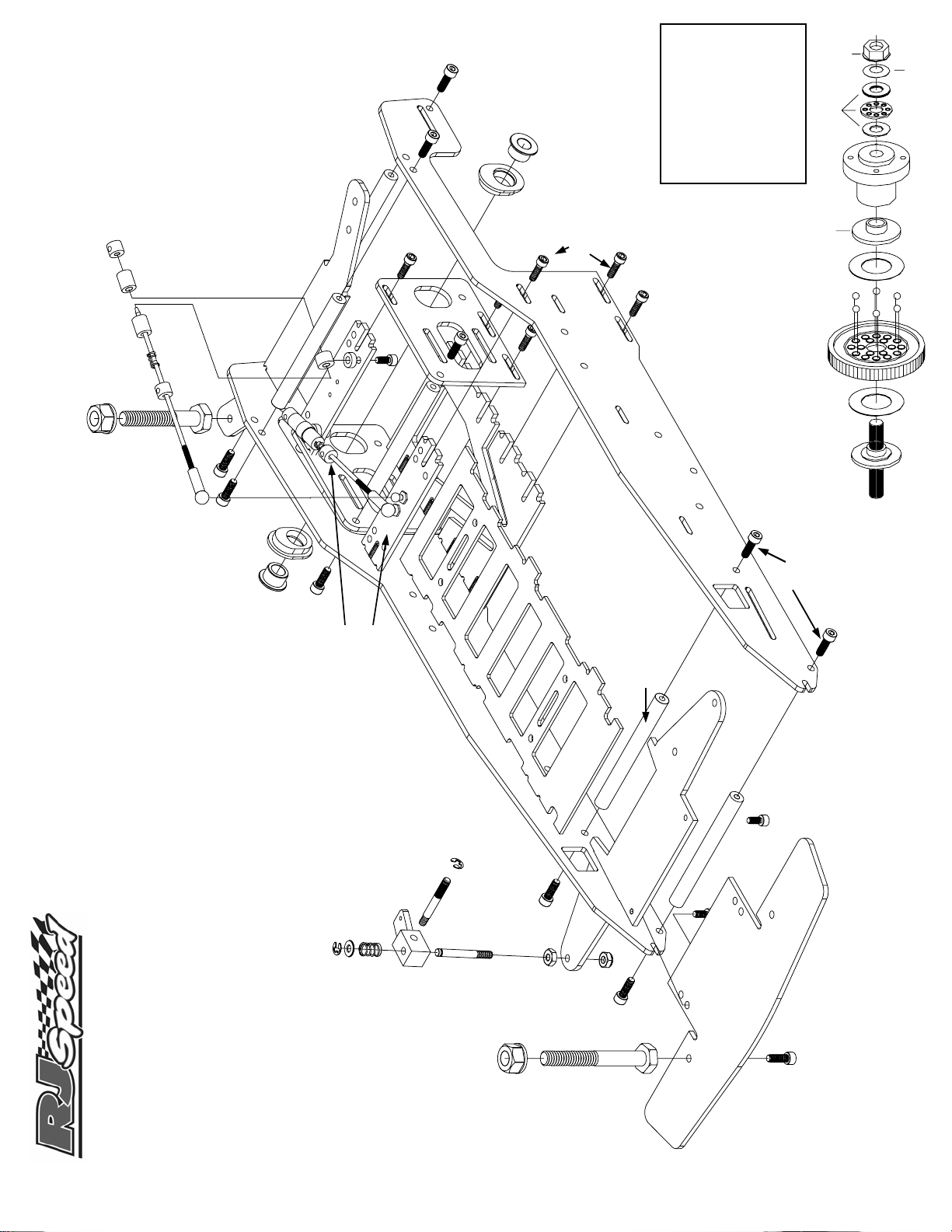

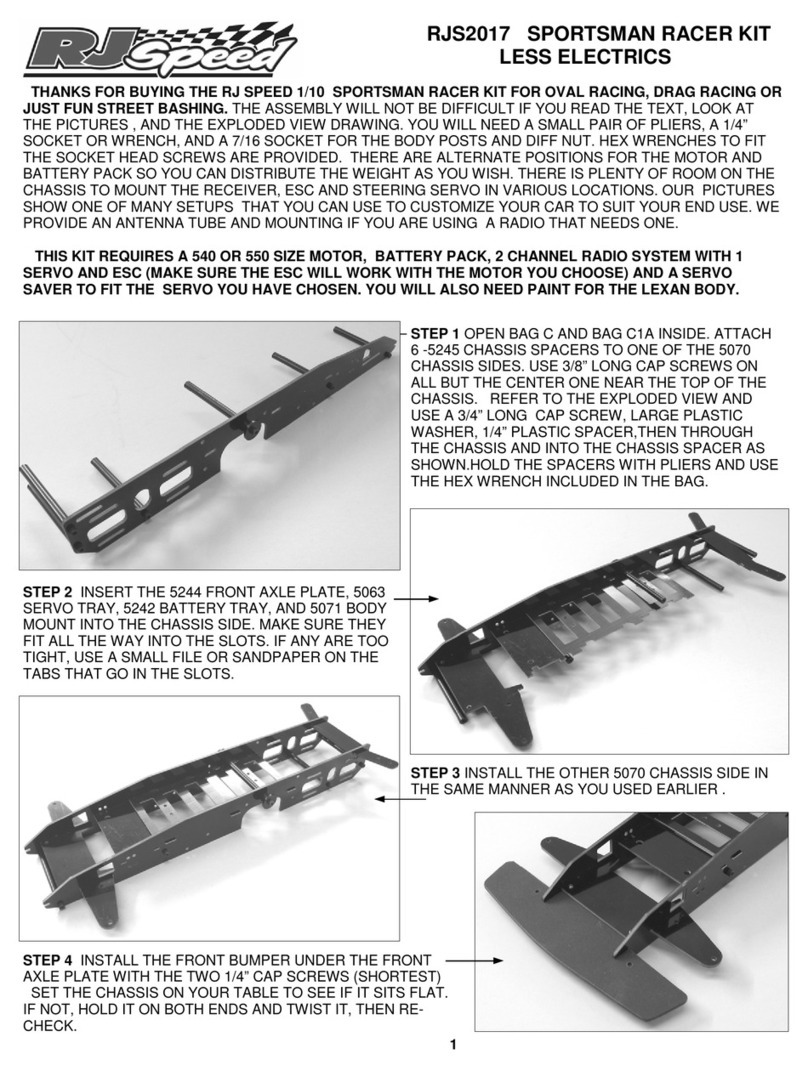

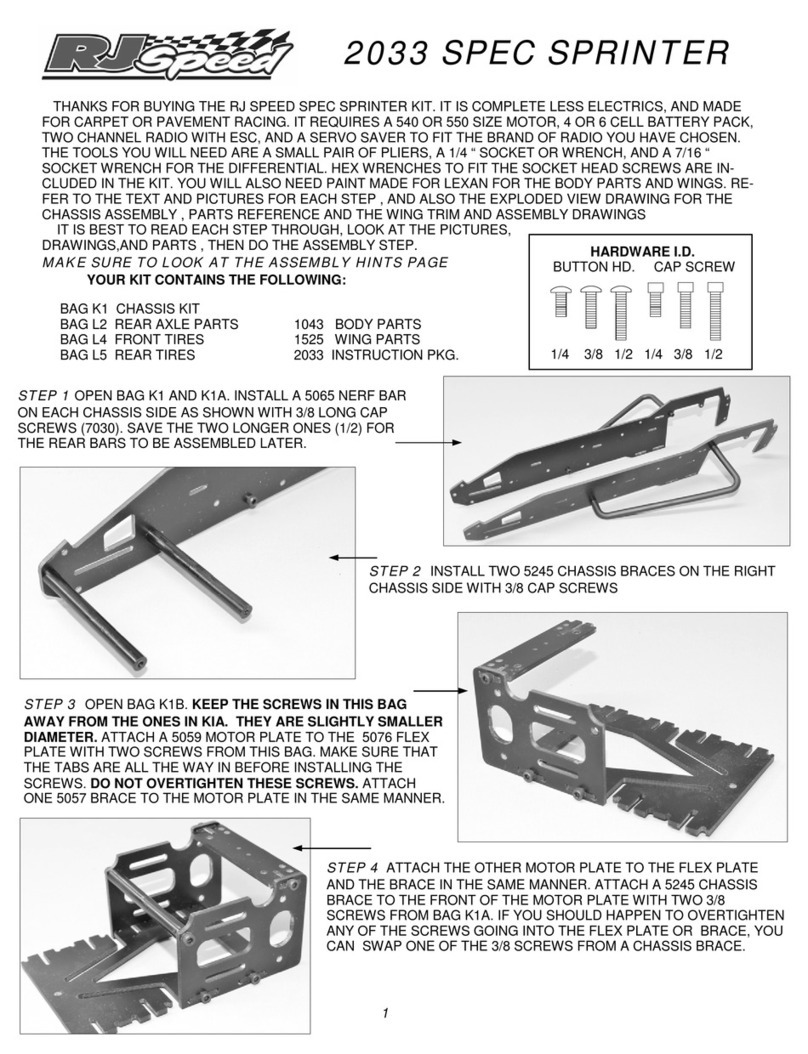

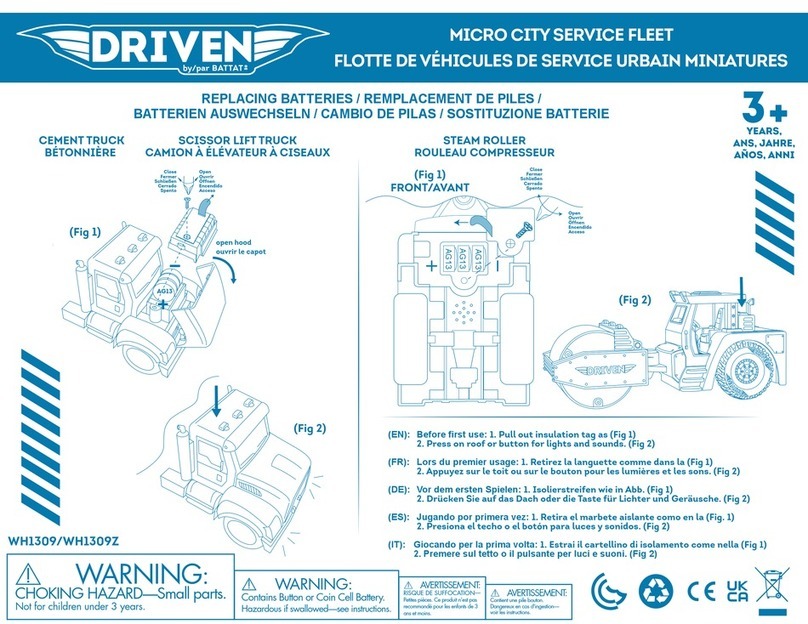

HINT –THREAD THE HOLES IN ALL OF THE 5245 CHASSIS SPACERS WITH A 4-40 TAP IF YOU

HAVE ONE AVAILABLE TO MAKE THE SCREWS HOLD BETTER.

HINT: BEFORE INSTALLING, HOLD THE 5377 KINGPIN BY THE THREADED END IN A HAND DRILL

AND USE VERY FINE SANDPAPER, THEN METAL POLISH TO MAKE THE SURFACE OF THE KINGPIN

SMOOTHER FOR A MORE CONSISTENT SUSPENSION. KEEPING THEM CLEAN AND RE-LUBED

WITH SILICONE GREASE ALSO WILL MAKE THE HANDLING BETTER.

. HINT: RUN A 1/8 DRILL THROUGH THE HOLE IN THE 5351 STEERING BLOCK S AFTER INSERTING

THE 5364 STUB AXLES AND/OR TRIM THE OUTER EDGES OF THE HOLES WITH A SHARP HOBBY

KNIFE. MAKE SURE THEY SLIDE FREELY ON THE KINGPINS. ADD A LITTLE LIGHT GREASE OR SILI-

CONE LUBE, INSTALL THE STEERING BLOCKS, THEN THE SPRINGS, WASHERS, AND E-CLIPS

HINT: GET YOUR AXLE THROUGH THE BUSHINGS, ATTACH A DRILL TO ONE END, LUBE THE

BUSHINGS WITH LIGHT OIL AND RUN IT FOR A WHILE TO BREAK THE BUSHINGS IN TO THE SUR-

FACE OF THE AXLE. MAKE SURE TO KEEP IT OILED. AND SLIDE IT BACK AND FORTH A SMALL

AMOUNT WHILE RUNNING. ADD THE OTHER SPACERS AND THE SET SCREW HUB.

HINT: TIGHTEN THE SETSCREW LIGHTLY, REMOVE THE HUB AND GRIND OR FILE A FLAT SPOT

WHERE THE SET SCREW HITS THE AXLE SO THE HUB WON’T SPIN ON THE AXLE UNDER LOAD.

THIS IS A MUST IF YOU UPGRADE TO HYBRID OR ALUMINUM SET SCREW HUBS.

HINT: YOU CAN SCRATCH THE INSIDE SURFACE OF THE DIFF HUB WHERE IT TOUCHES THE

ALUMINUM ADAPTOR A LITTLE WITH COARSE SANDPAPER AND USE A LITTLE SUPER GLUE TO

KEEP THE HUB FROM SLIPPING ON THE ADAPTOR. ALSO TRIM AROUND THE EDGE OF THE

HOLE IN THE OUTSIDE OF THE HUB TO MAKE SURE THE BALL THRUST BEARING SITS FLAT. YOU

CAN ALSO SCUFF ONE SIDE OF EACH DRIVE RING TO KEEP THEM FROM SLIPPING AGAINST THE

AXLE HUB OR ADAPTOR, BUT YOU WILL NOT BE ABLE TO TURN THEM OVER AND USE THAT SIDE

AFTER THE BALLS WEAR A GROOVE IN THEM.

ASSEMBLY HINTS AND SUGGESTIONS

FRONT END

REAR AXLE AND HUBS

RACING & SETUP SUGGESTIONS

ALL CARS ARE SLIGHTLY DIFFERENT DUE TO VARIATIONS IN PARTS AND ASSEMBLY CARE

AND TECHNIQUES , BUT THESE GENERAL SUGGESTIONS WILL APPLY.

TRY YOUR CAR OUT WITH CLEAN TIRES WITH SOME TRACTION COMPOUND OR WD-40 AP-

PLIED TO THE REAR TIRES. IT’S BETTER TO START WITH A CAR THAT IS STABLE THAN ONE

THAT HAS SEVERE OVERSTEER. IF YOUR CAR TRIES TO ROLL OVER IN THE CORNERS, YOU

NEED TO REDUCE THE PRESSURE ON THE RIGHT REAR TIRE. YOU CAN MAKE A SMALL AD-

JUSTMENT BY TIGHTENING THE LEFT COLLAR AND SPRING ON THE DAMPER AND TIGHTEN

THE RIGHT REAR SILICONE TUBE & COLLAR, OR LARGER ADJUSTMENT BY ADDING A SHIM ON

TOP OF THE RIGHT FRONT SUSPENSION SPRING.

THIS INCREASES THE CROSS WEIGHT ON THE LEFT REAR AND RIGHT FRONT TIRE, REDUCING

THE TENDENCY OF THE RIGHT REAR TO BITE TOO HARD AND FLIP THE CAR.

ALL ADJUSTMENTS VARY ACCORDING TO THE SURFACE YOU ARE RACING ON AND THE TYPE

OF TRACTION COMPOUND IN USE THERE AND HOW MUCH OF IT IS ON THE TRACK.

THERE ARE DIFFERENT FRONT SPRINGS AVAILABLE FROM SOME RC MANUFACTURERS AND

OUR REAR SPRINGS ARE THE SAME SIZE AS ONES USED BY ASSOCIATED RC ON THEIR PAN

CARS.

BALL BEARING SETS ARE AVAILABLE FROM SEVERAL RC SOURCES AND OUR CARS

REQUIRE 4 –1/8 X 5/16” FLANGED BEARINGS FOR THE FRONT WHEELS AND 2– 1/4 X 3/8

FLANGED BEARINGS FOR THE REAR AXLE.