COMMUNICATION LEVEL CONVERTER FOR

RS-232C/RS-422A(RS-485)

COM-103C

INSTRUCTION MANUAL

IMCOM04-E3

Thank you for purchasing this COM-103C. Before using this

product, please carefully read this manual for its correct use. In

addition, after reading the manual keep it available easily

anytime.

z

Wiring precautions

• If failure or error of this instrument could result in a critical

accident of the system, install an external protection circuit

toprevent such an accident.

• In order to prevent instrument damage or failure, protect the

power line and the input/output lines from high currents by

using fuses with appropriate ratings.

z

Power supply

• In order to prevent instrument damage or failure, supply

power of the specified rating.

• In order to prevent electric shock or instrument failure, do

not turn on the power supply until all of the wiring is

completed.

z

Installation environment

In order to prevent fire, explosion or instrument damage,

never use this instrument at a location where inflammable or

explosive gases or vapour exist.

z

zz

z

Never touch the inside of the instrument.

In order to prevent electric shock or burns, never touch the

inside of the instrument. Only RKC service engineers can

touch the inside of the instrument to check the circuit or to

replace parts. High voltage and high temperature sections

inside the instrument are extremely dangerous.

z

Never modify the instrument.

In order to prevent accident or instrument failure, never modify

the instrument.

z

Maintenance

• In order to prevent electric shock, burns or instrument

failure, only RKC service engineers may replace parts.

• In order to use this instrument continuously and safely,

conduct periodic maintenance. Some parts used in this

instrument have a limited service life and may deteriorate

with time.

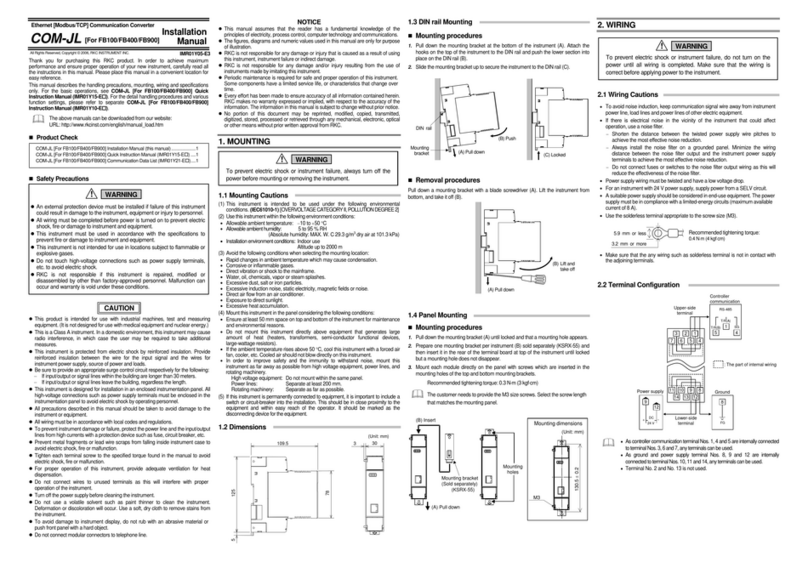

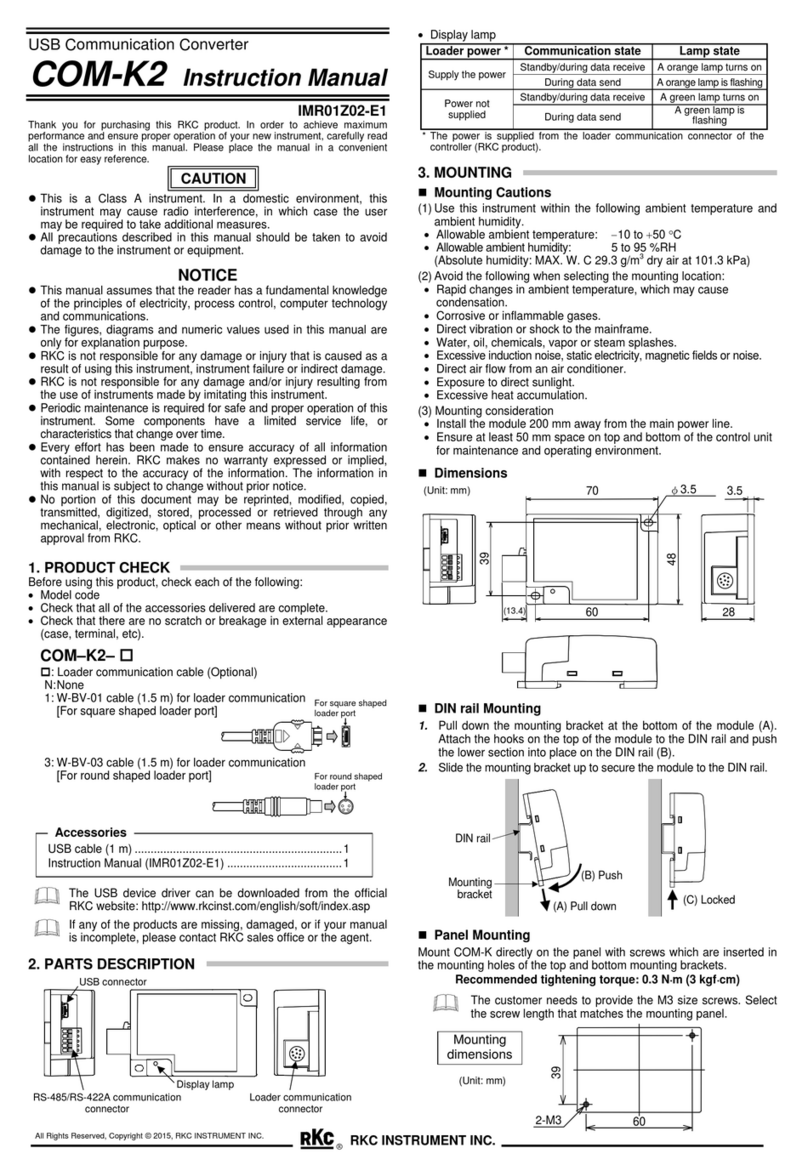

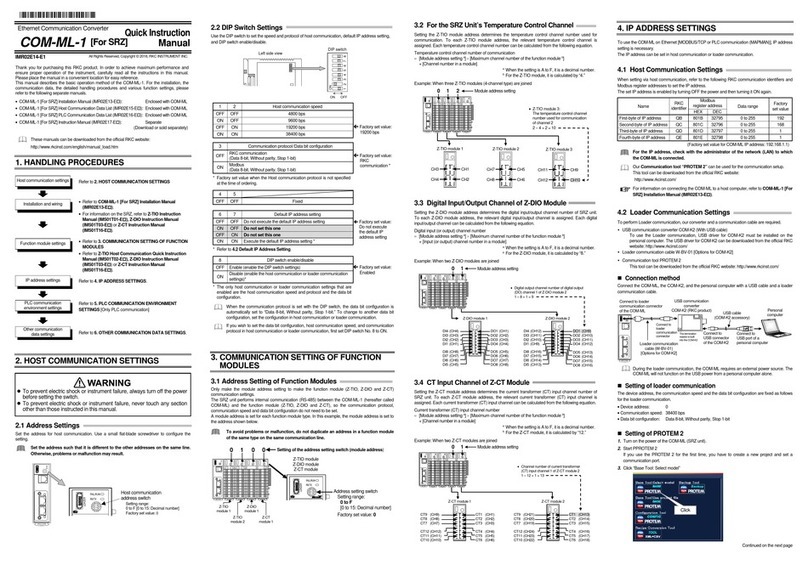

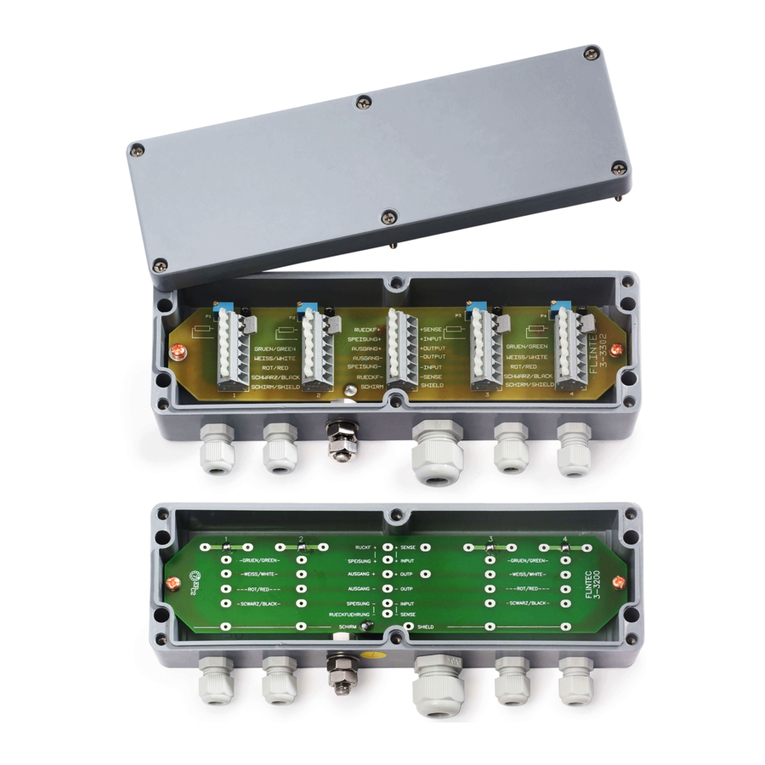

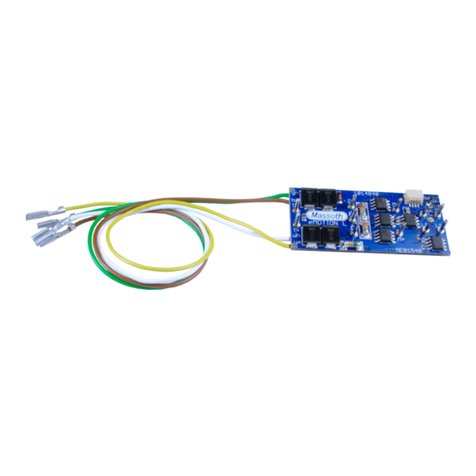

1. NAME OF PARTS AND TERMINALS

RS-232C

1

A

B

COM-103C

2

3

4

5

6

7

8

9

2. MOUNTING

2.1 Mounting cautions

Avoid the following when selecting the mounting location.

z

Ambient temperature of less than 0 °C (32 °F) or more than 50 °C

(122 °F).

z

Ambient humidity of less than 45 % or more than 85 % RH.

z

Rapid changes in ambient temperature which may cause

condensation.

z

Corrosive or inflammable gases.

z

Direct vibration or shock to the mainframe.

z

Water, oil, chemicals, vapor or steam splashes.

z

Excessive dust, salt or iron particles.

z

Excessive induction noise, static electricity, magnetic fields or noise.

z

Direct air flow from an air conditioner.

z

Should be used indoors where the system is not exposed to direct

sunlight.

z

Heat to be accumulated radiation heat.

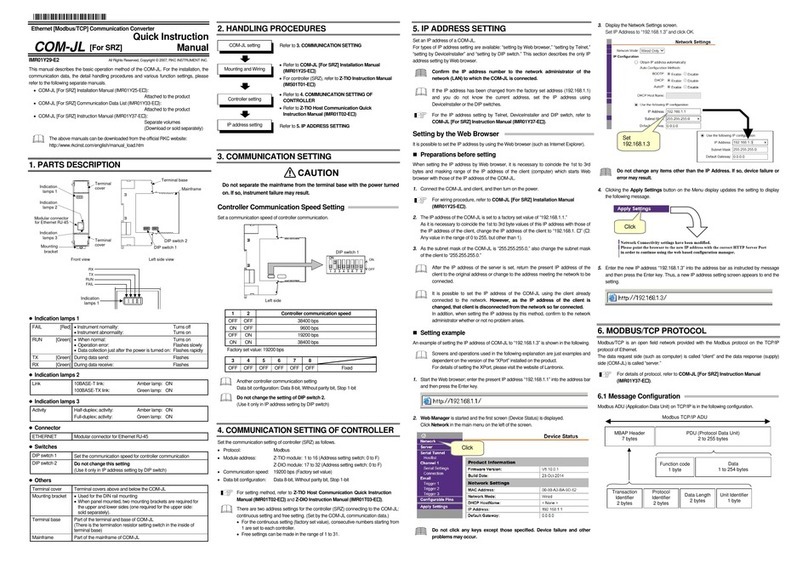

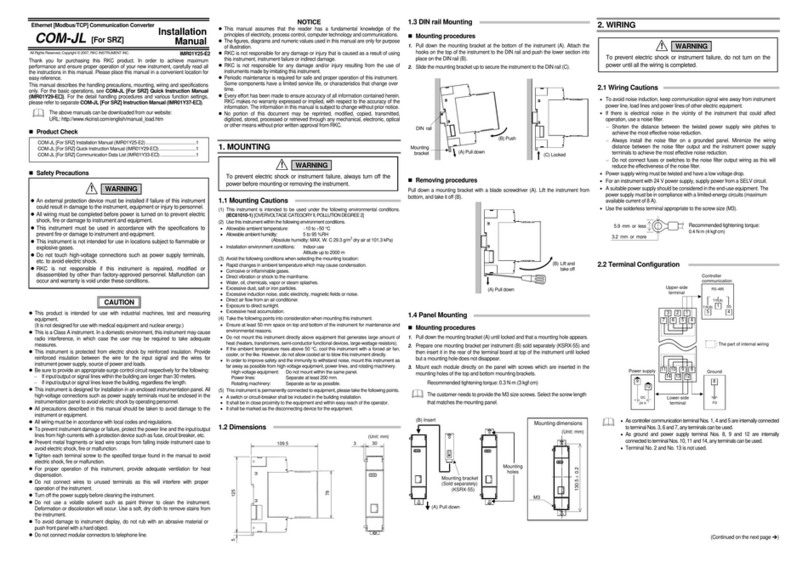

2.2 Mounting method

Rack mounting type (COM-103C-R)

cMake cutouts in the panel corresponding to the number of

converters to be mounted by referring to panel cutout dimensions.

dInsert the converter into the cutout from the panel front.

eUsing a Phillips screwdriver, secure the converter from the terminal

side with 2 setscrews (M4×6 SEMS pan-head screw).

Screws provided by customer.

32(1.26) 21

(0.83) 89(3.50)

2-M4

210

8.27

198

7.80

181.8

7.16

198 ±0.2( 7.795±0.007

182.

+0.3

0( 7.185+0.011

0

4.2

0.17

32.5+0.2

0( 1.280 0

+0.007 )

[

[[

[unit :

:::mm (inch)]

]]

]

Panel cutout

Dimensions

Wall mounting type (COM-103C-W)

cDrill holes corresponding to the number of converters to be

mountedby referring to panel cutout dimensions.

dUsing a Phillips screwdriver, secure the converter from the

terminalside with 2 setscrews (M4×6 SEMS pan-head screw).

Screws provided by customer.

32(1.26) 111(4.37)

90(3.54)

2-M4

210(8.27)

198(7.80)

181.8(7.16)

198 ±0.2 ( 7.79

±0.007 )

φ4.2(0.17)

[

[[

[unit :

:::mm (inch)]

]]

]

Panel cutout

Dimensions

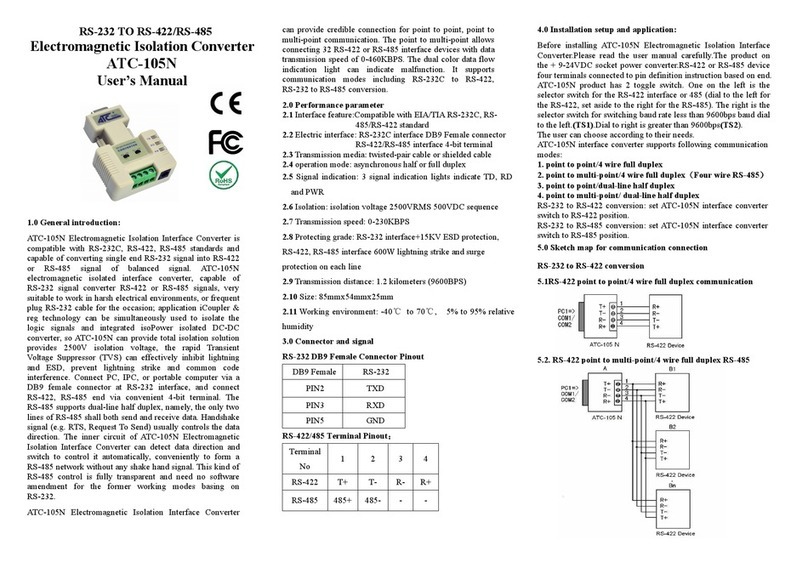

3. WIRING

3.1 Cautions for wiring

(1) Conduct input signal wiring away from instrument power,

electricequipment power and load lines to avoid noise induction.

(2) For power supply wires, use twisted wires with low voltage drop.

(3) Do not excessively tighten the terminal screws. In addition, use the

solderless terminal appropriate to the screw size. (Screw size:

M3×6, recommended tightening torque: 0.5 Nxm [5 kgfxcm])

WARNING

Name of parts

A: Power lamp

B: Connector for RS-232C Interface

Terminals

Terminal

Contents

1

2

3

SG Communication

terminals

T/R(A) RS-422A or RS-485

T/R(B)

4

5

6

Unused

7

8

Power supply voltage terminals

90 to 264 V AC

9Ground terminal

SG : Signal Ground

T/R(A):TransmissionTerminal(A)

T/R(B):TransmissionTerminal(B)