RKC INSTRUMENT COM-K IMR01Z01-E9 User manual

®RKC INSTRUMENT INC.

A

ll Rights Reserved, Copyright ©2004, RKC INSTRUMENT INC.

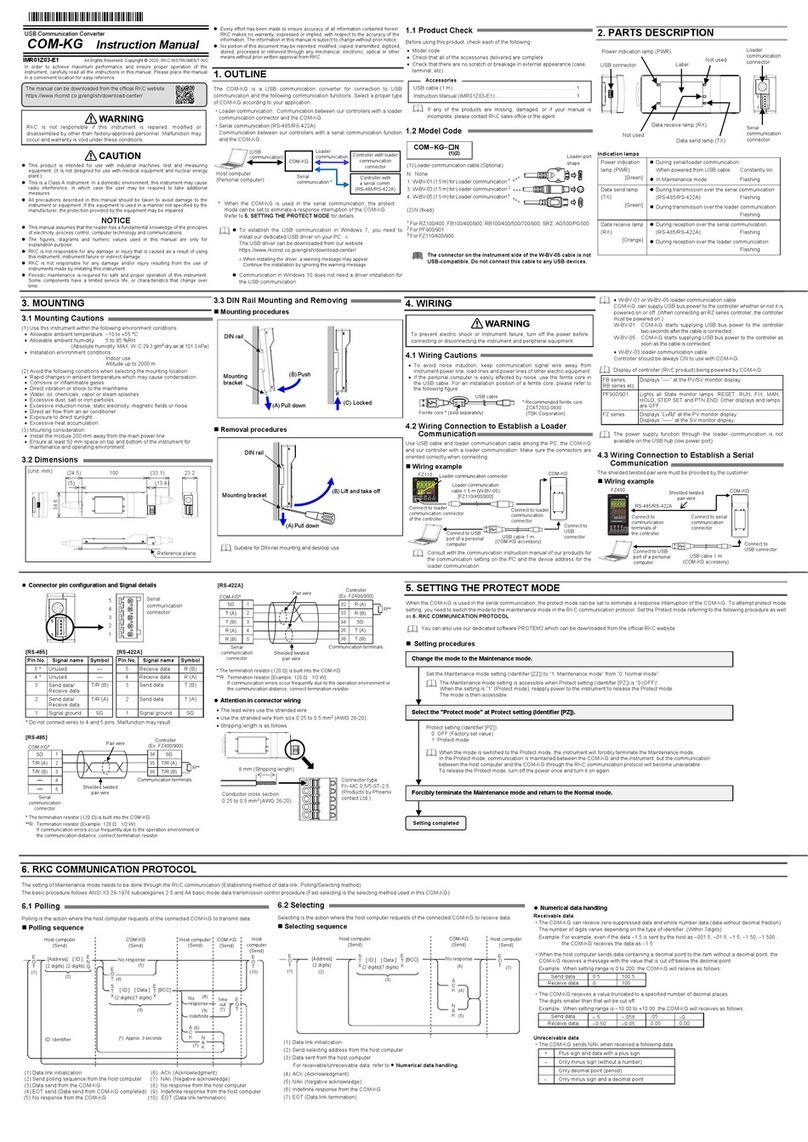

USB Communication Converter

COM-K Instruction Manual

IMR01Z01-E9

Thank you for purchasing this RKC product. In order to achieve maximum

performance and ensure proper operation of your new instrument, carefully read

all the instructions in this manual. Please place the manual in a convenient

location for easy reference.

This is a Class A instrument. In a domestic environment, this

instrument may cause radio interference, in which case the user

may be required to take adequate measures.

All precautions described in this manual should be taken to avoid

damage to the instrument or equipment.

NOTICE

This manual assumes that the reader has a fundamental knowledge

of the principles of electricity, process control, computer technology

and communications.

The figures, diagrams and numeric values used in this manual are

only for purpose of illustration.

RKC is not responsible for any damage or injury that is caused as a

result of using this instrument, instrument failure or indirect damage.

RKC is not responsible for any damage and/or injury resulting from

the use of instruments made by imitating this instrument.

Periodic maintenance is required for safe and proper operation of this

instrument. Some components have a limited service life, or

characteristics that change over time.

Every effort has been made to ensure accuracy of all information

contained herein. RKC makes no warranty expressed or implied,

with respect to the accuracy of the information. The information in

this manual is subject to change without prior notice.

No portion of this document may be reprinted, modified, copied,

transmitted, digitized, stored, processed or retrieved through any

mechanical, electronic, optical or other means without prior written

approval from RKC.

1. PRODUCT CHECK

Before using this product, check each of the following:

• Model code

• Check that all of the accessories delivered are complete.

• Check that there are no scratch or breakage in external appearance

(case, terminal, etc).

COM–K–

:Loader communication cable (Optional)

N:None

1: W-BV-01 cable (1.5 m) for loader communication

[For square shaped loader port]

3: W-BV-03 cable (1.5 m) for loader communication

[For round shaped loader port]

The USB device driver can be downloaded from the official

RKC website: http://www.rkcinst.com/english/soft/index.asp

If any of the products are missing, damaged, or if your manual

is incomplete, please contact RKC sales office or the agent.

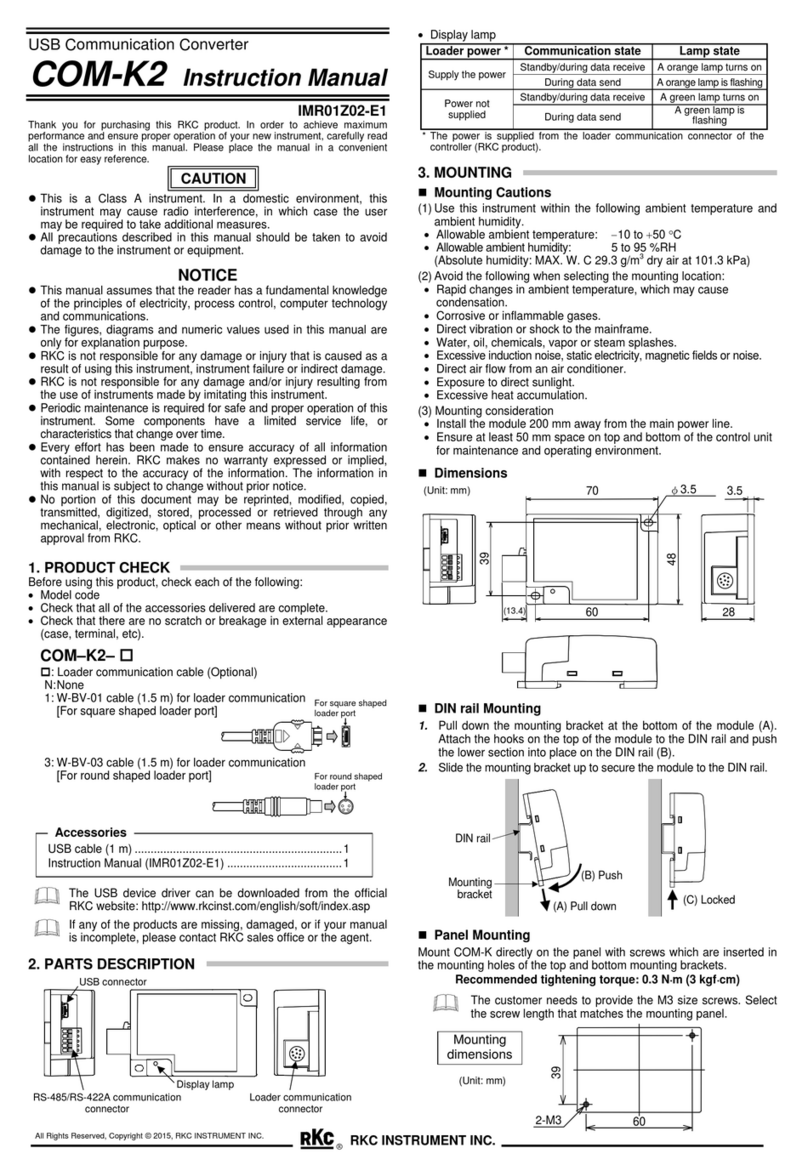

2. PARTS DESCRIPTION

USB connecto

r

RS-485/RS-422A communication

connecto

r

Displaylamp Loader communication

connector

• Display lamp

Loader power * Communication state Lamp state

Standby/during data receive A orange lamp turns on

Supply the power During data send A orange lamp is flashing

Standby/during data receive A green lamp turns on

Power not

supplied During data send A green lamp is

flashing

* The power is supplied from the loader communication connector of the

controller (RKC product).

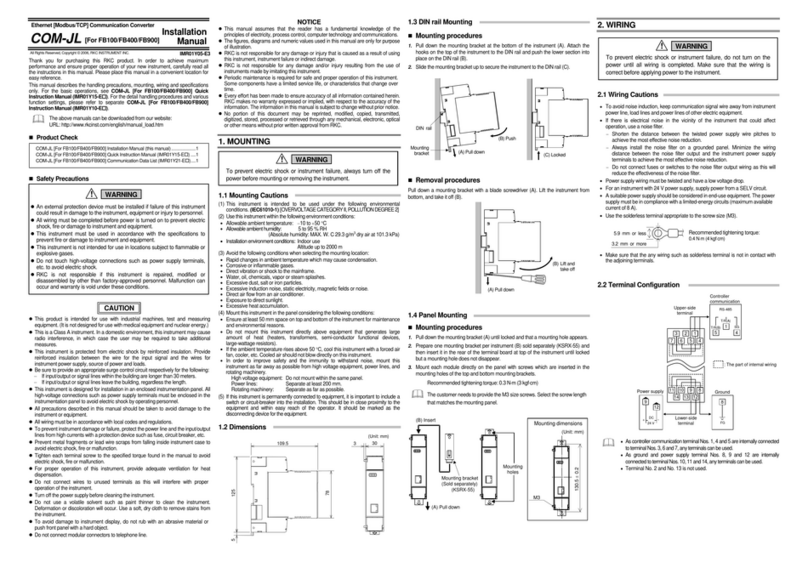

3. MOUNTING

Mounting Cautions

(1)Use this instrument within the following ambient temperature and

ambient humidity.

• Allowable ambient temperature: −10 to +50 °C

• Allowable ambient humidity: 5 to 95 % RH

(Absolute humidity: MAX. W. C 29.3 g/m3dry air at 101.3 kPa)

(2)Avoid the following when selecting the mounting location:

• Rapid changes in ambient temperature, which may cause

condensation.

• Corrosive or inflammable gases.

• Direct vibration or shock to the mainframe.

• Water, oil, chemicals, vapor or steam splashes.

• Excessive induction noise, static electricity, magnetic fields or noise.

• Direct air flow from an air conditioner.

• Exposure to direct sunlight.

• Excessive heat accumulation.

(3) Mounting consideration

• Install the module 200 mm away from the main power line.

• Ensure at least 50 mm space on top and bottom of the control unit

for maintenance and environmental reasons.

Dimensions 70 3.5

60 28

φ

3.5

(Unit: mm)

48

39

(13.4)

DIN rail Mounting

1. Pull down the mounting bracket at the bottom of the module (A).

Attach the hooks on the top of the module to the DIN rail and push

the lower section into place on the DIN rail (B).

2. Slide the mounting bracket up to secure the module to the DIN rail.

(C) Locked

(B) Push

Mounting

bracket

DIN rail

(A) Pull down

Panel Mounting

Mount COM-K directly on the panel with screws which are inserted in

the mounting holes of the top and bottom mounting brackets.

Recommended tightening torque: 0.3 N⋅m (3 kgf⋅cm)

The customer needs to provide the M3 size screws. Select

the screw length that matches the mounting panel.

CAUTION

Mounting

dimensions

60

2-M3

39

(Unit: mm)

USB cable (1 m) .................................................................1

Instruction Manual (IMR01Z01-E9) ....................................1

Accessories

For square shaped

loader port

For round shaped

loader port

The first edition: DEC. 2004 [IMQ00]

The ninth edition: JAN. 2011 [IMQ00]

®

RKC INSTRUMENT INC.

HEADQUARTERS: 16-6, KUGAHARA 5-CHOME, OHTA-KU TOKYO 146-8515 JAPAN

PHONE: 03-3751-9799 (+81 3 3751 9799) E-mail: info@rkcinst.co.jp

FAX: 03-3751-8585 (+81 3 3751 8585) JAN. 2011

4. WIRING

Wiring Cautions

• To avoid noise induction, keep communication signal wire away

from instrument power line, load lines and power lines of other

electric equipment.

• If the personal computer is easily affected by noise, use the

ferrite core in the USB cable. For an installation position of a

ferrite core, please refer to the following figure.

Ferrite core * (sold separately)

* Recommended ferrite core:

ZCAT2032-0930 (TDK Corporation)

USB cable

Method to connect

(1) For loader communication

Connected to loader communication

connector of the controller

Connected to USB

port of a personal

computer

USB cable

COM-K

Connected to USB connector

Connected to loader

communication

connector

Loader communication

cable [Optional]

W-BV-01 or W-BV-03

To avoid termination of the loader communication for

some versions of COM-K, do not turn the controller

(FB400/FB900 etc.) ON or OFF during operation by

loader communication.

W-BV-01 loader communication cable:

It is possible to use COM-K when controller is either ON or

OFF. COM-K starts supplying power to the connected

controller being OFF after approximately 2 seconds.

W-BV-03 loader communication cable:

Controller should be always ON to use with COM-K.

Display of controller (RKC product) being powered by COM-K

:

FB series,

RB series etc. Displays “-----” at the PV/SV monitor display.

PF900/901 Lights all State monitor lamps: RESET, RUN,

FIX, MAN, HOLD, STEP.SET and PTN.END.

Other displays and lamps are OFF.

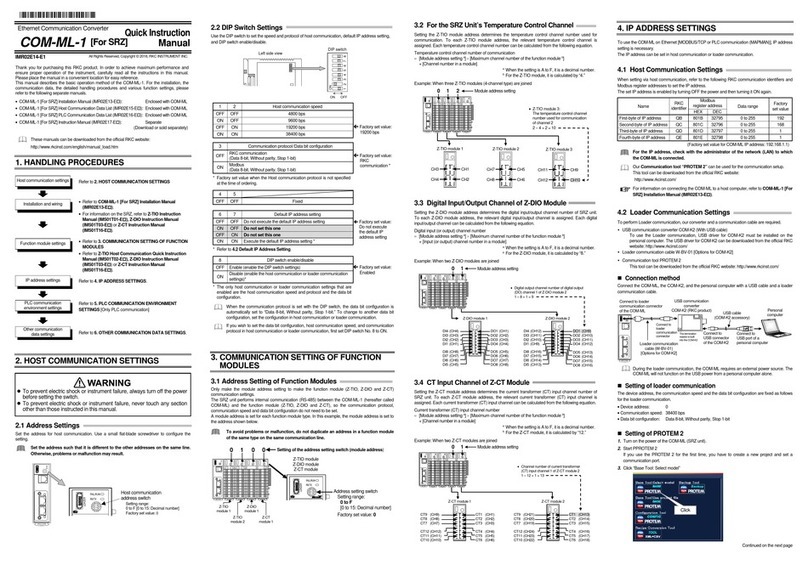

(2) For RS-485/RS-422A communication

The shielded twisted pair wire must be provided by the customer.

RS-485/RS-422A

Connected to USB

port of a personal

computer

USB cable

Connected to communication

terminals of controller

(Example: FB400/FB900)

Connected to USB connector

Connected to

RS-485/RS-422A

communication

connector

COM-K

Shielded twisted pair wire

Connector pin configuration

1 2 3 4 5

RS-485/RS-422A

communication

connector

[RS-485] [RS-422A]

Pin No. Signal name Symbol Pin No. Signal name Symbol

1 Signal ground SG 1 Signal ground SG

2 Send data/

Receive data T/R (A) 2 Send data T (A)

3 Send data/

Receive data T/R (B) 3 Send data T (B)

4 * Unused ⎯4 Receive data R (A)

5 * Unused ⎯5 Receive data R (B)

* Do not connect wires to 4 and 5 pins. Malfunction may result.

Connection diagram

Shielded twisted

pair wire

T/R (A)

T/R (B)

1SG 2R

Controller

(Example: FB400/FB900)

COM-K*

3

4

5

⎯

⎯

T/R (A)

T/R (B)

25 SG

26

27

RS-485/RS-422A

communication

connector

Communication terminals

(communication 1 side)

[RS-485]

R: Termination resistors (Example: 120

Ω

1/2 W)

If communication errors occur frequently due to

the operation environment or the communication

distance, connect termination resistors.

Shielded twisted

pair wire

T (A)

R (A)

1SG 2

Controller

(Example: FB400/FB900)

COM-K*

3

4

5

T (A)

R (A)

25 SG

26

27

RS-485/RS-422A

communication

connector

Communication terminals

(Communication 1 side)

[RS-422A]

28

29

T (B)

R (B)

T (B)

R (B)

* The termination resistor is built into the COM-K.

Attention in connector wiring

− The lead wires use the stranded wire.

− Use the stranded wire from size 0.25 to 0.5 mm2(AWG 26-20).

− Stripping length is as follows.

8 mm (Stripping length)

Conductor cross section:

0.25 to 0.5 mm2(AWG 26-20)

Connector type:

FK-MC 0,5/5-ST-2,5

(Products by Phoenix

contact Ltd.)

Installation of USB device driver

Installs an USB device driver in a personal computer before use.

1. Connect COM-K to USB port of a personal computer.

2. Install an USB device driver according to an on screen

instruction.

5. SPECIFICATIONS

USB function

Interface: Based on USB Ver. 2.0

Communication speed: Full speed (12 Mbps)

Connection: Connected by universal USB cable

(Mini-B connector)

Power source method: Bus power (The power is supplied from the

USB port on the personal computer side)

Compatible OS:

Windows XP/2000 Professional/Me/98 Second Edition

,

Windows 7 (32-bit, 64-bit)/Vista (32-bit, 64-bit)

Communication function

Interface: Based on RS-485, EIA standard

Based on RS-422A, EIA standard

Connection method: 2-wire system,

half-duplex multi-drop connection (RS-485)

4-wire system,

half-duplex multi-drop connection (RS-422A)

Synchronous method: Half-duplex start-stop synchronous type

Communication speed: 2400 bps, 4800 bps, 9600 bps, 19200 bps,

38400 bps

Data bit configuration: Start bit: 1

Data bit: 7 or 8

Parity bit: Without, Odd or Even

Stop bit: 1 or 2

Protocol: Protocol depends on application of the

personal computer side

Number of connecting controllers

Maximum 31 controllers (RS-485, RS-422A)

Termination resistor: Built-in termination resistor (120 Ω)

General specifications

Power supply voltage: 5 V DC ±5 %(Supplied by USB bus cable)

Current consumption: 150 mA max. (Loader communication)

60 mA max. (RS-485/RS-422A communication)

Allowable ambient temperature range:

−10 to +50 °C

Allowable ambient humidity range:

5 to 95 %RH (Non condensing)

Absolute humidity:

MAX.W.C 29.3 g/m3dry air at 101.3 kPa

Weight: Approx. 40 g

To prevent electric shock or instrument failure, turn off the

power before connecting or disconnecting the instrument

and peripheral equipment.

!WARNING

Table of contents

Other RKC INSTRUMENT Media Converter manuals

RKC INSTRUMENT

RKC INSTRUMENT COM-JG User manual

RKC INSTRUMENT

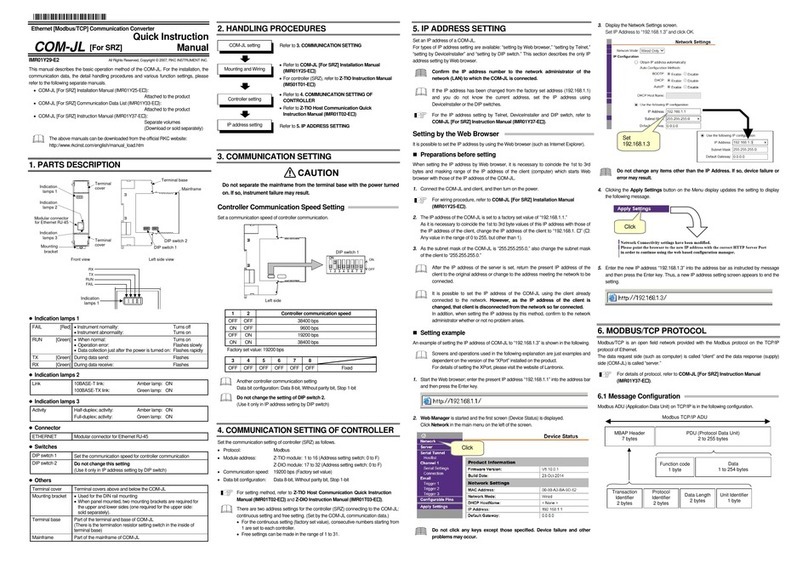

RKC INSTRUMENT COM-JL User manual

RKC INSTRUMENT

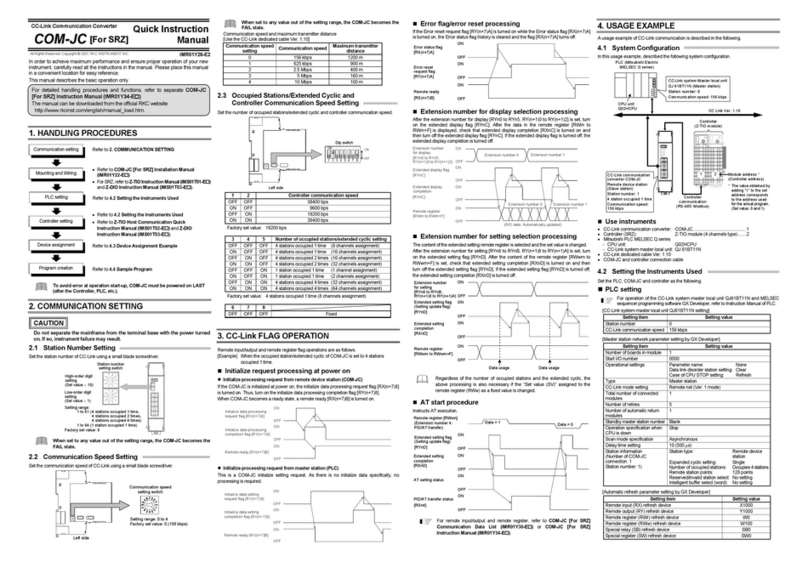

RKC INSTRUMENT COM-JC User manual

RKC INSTRUMENT

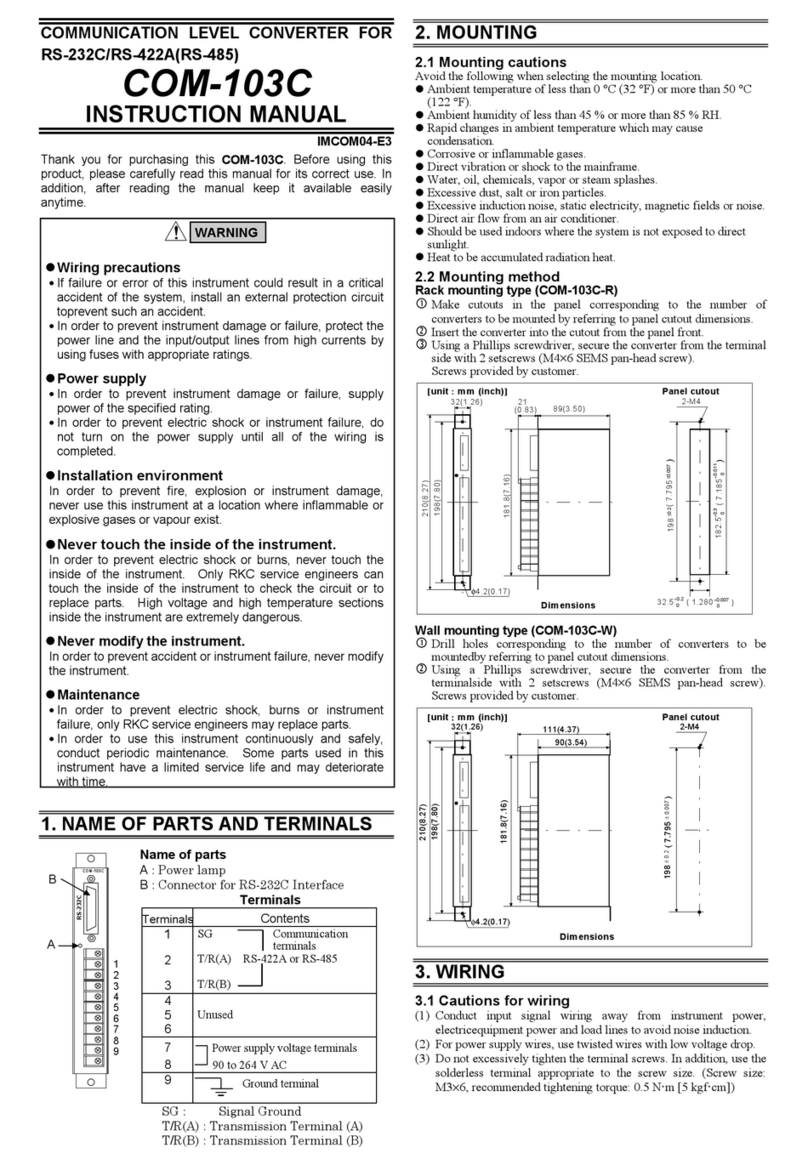

RKC INSTRUMENT COM-103C User manual

RKC INSTRUMENT

RKC INSTRUMENT DeviceNet COM-JH User manual

RKC INSTRUMENT

RKC INSTRUMENT COM-ML User manual

RKC INSTRUMENT

RKC INSTRUMENT COM-K2 User manual

RKC INSTRUMENT

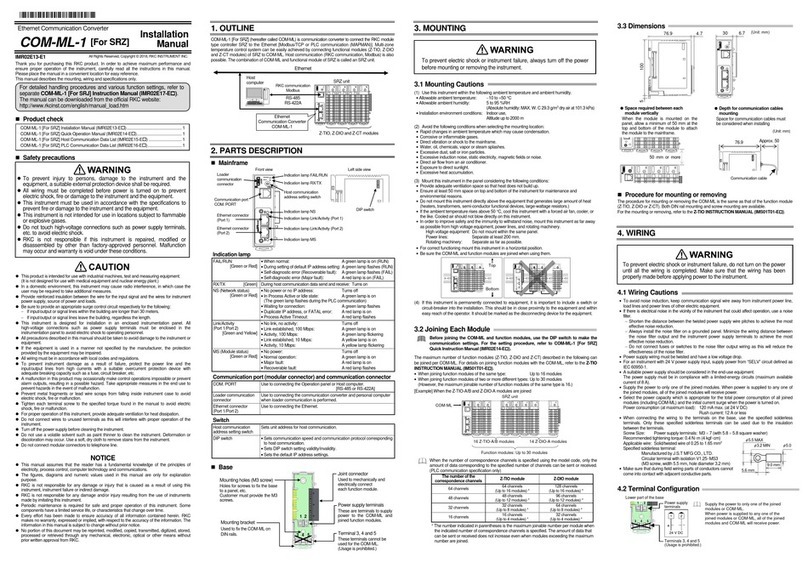

RKC INSTRUMENT COM-ML-1 User manual

RKC INSTRUMENT

RKC INSTRUMENT COM-JL User manual

RKC INSTRUMENT

RKC INSTRUMENT COM-ML-1 User manual