RMG GC 9300 User manual

Reliable Measurement of Gas

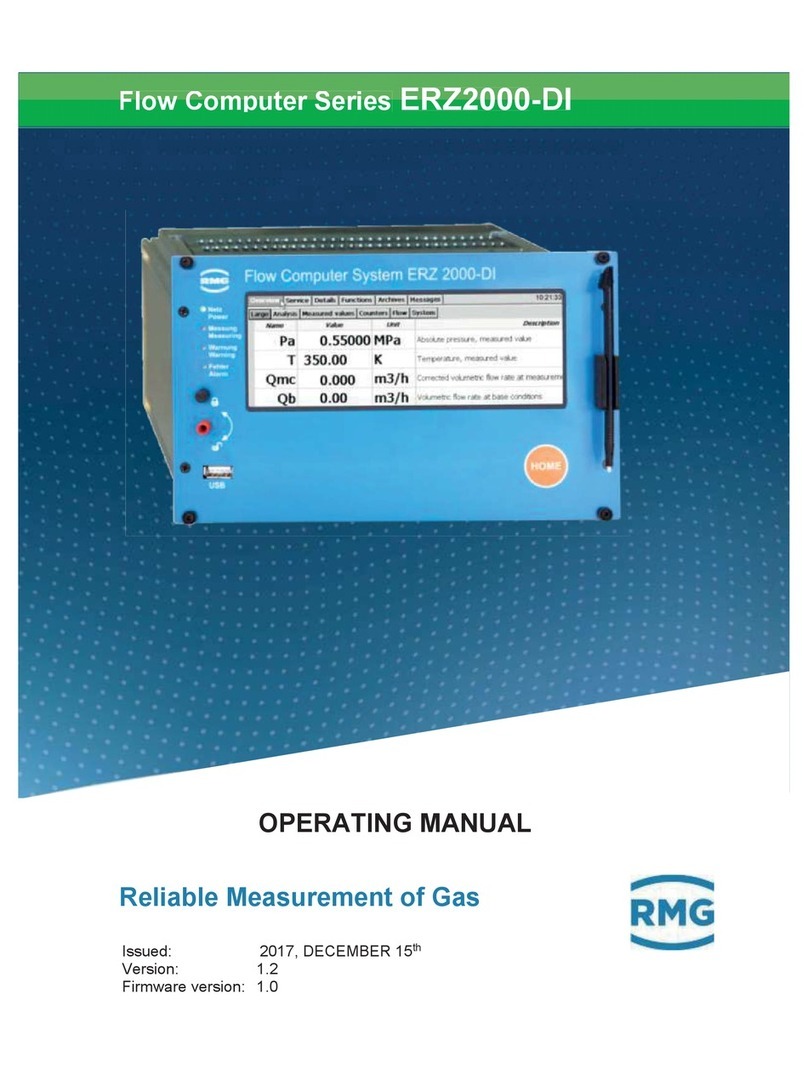

OPERATING MANUAL

Status: July, 24th 2018

Version: 14 EN

ANALYTICAL COMPUTER GC 9300

Contact

Manual GC 9300 EN14 July, 24th 2018

Manufacturer

Contact our customer service department for technical

information.

Address

RMG Messtechnik GmbH

Otto-Hahn-Straße 5

D-35510 Butzbach (Germany)

Main office

+49 6033 897 –0

Service

+49 6033 897 –0

Spare parts

+49 6033 897 –173

Fax

+49 6033 897 –130

Email

Translation of the

original document

The PGC9300_AC_manual_en_14 for the gas

chromatograph PGC 9300 from July, 24th 2018 is a

translation of the original German manual. Anyhow, this

document may serve as reference for translations into

other languages.

Remark

Please use in case of any uncertainties the German

version as main reference

Note

Unfortunately, paper is not updated automatically,

whereas technical development continuously advances.

Therefore, we reserve the right to make technical

changes in regard to the representations and specifica-

tions of these operating instructions. The latest version

of this manual (and the one other devices) can be

downloaded at your convenience from our Internet

page:

www.rmg.com

Created

July 2011

…

…

9. Revised

July 2015

10.Revised

January 2017

11.Revised

June 2017

12.Revised

June 2018

13.Revised

July, 24th 2018

Document version and

language

Document ver-

sion

PGC9300_AC_manual_en_14

July, 24th 2018

Language

EN

Contents

Manual GC 9300 EN14 July, 24th 2018

I

Contents

1ABOUT THIS MANUAL..................................................................1

1.1 Structure of this manual .............................................................................1

1.1.1 Abbreviations.........................................................................................................1

1.1.2 Symbols.................................................................................................................1

1.1.3 Structure of notices................................................................................................ 2

1.1.4 Working with the device.........................................................................................3

1.1.5 Risk assessment and minimization .......................................................................7

1.1.6 Applicability of the manual.....................................................................................8

1.1.7 Transport...............................................................................................................9

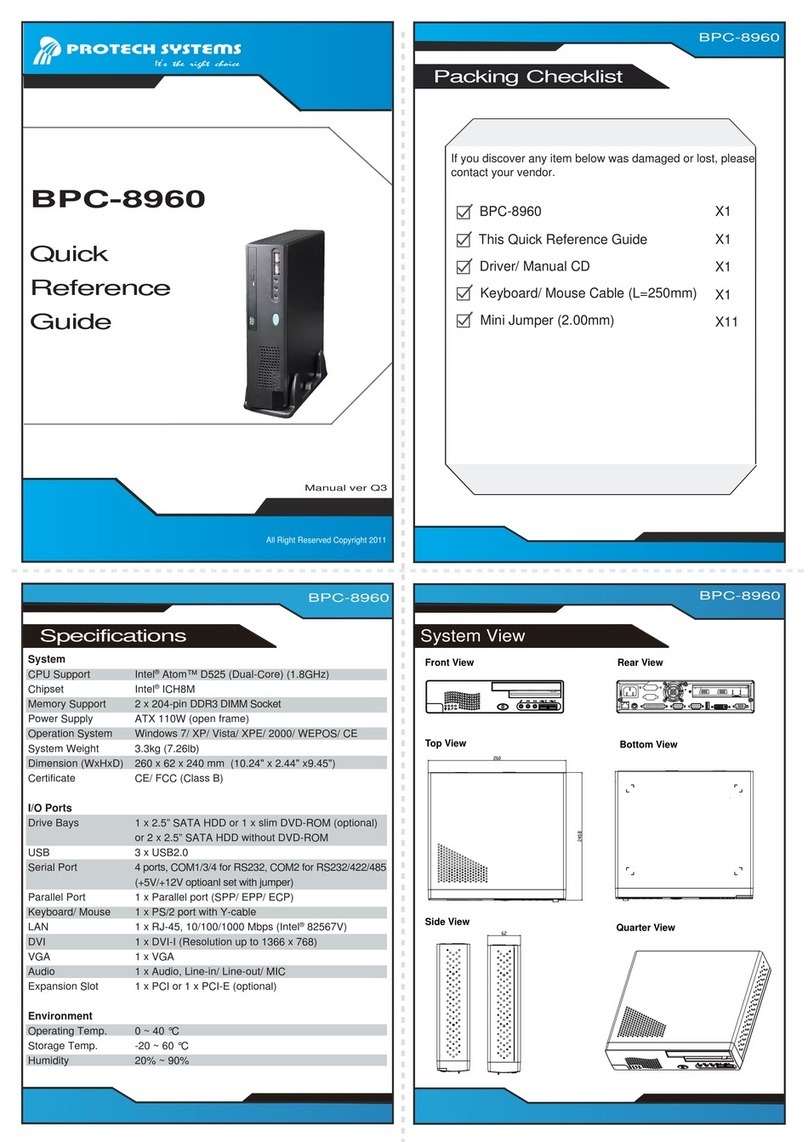

1.1.8 Scope of delivery.................................................................................................10

1.1.9 Disposal of packaging material............................................................................10

1.1.10 Storage................................................................................................................10

1.2 Structure of the manual ............................................................................11

1.3 Function .....................................................................................................12

1.4 Mode of operation .....................................................................................12

1.5 Area of applicability ..................................................................................13

2INTRODUCTION...........................................................................14

2.1 Touch screen.............................................................................................14

2.2 Operation....................................................................................................15

2.2.1 Operating modes................................................................................................. 15

2.3 Data storage...............................................................................................17

2.3.1 Archive according to the DSfG standard............................................................. 18

3INSTALLATION............................................................................19

3.1 Installation..................................................................................................19

3.2 Electrical connections ..............................................................................19

3.2.1 Connection assignment....................................................................................... 20

3.2.2 Power supply.......................................................................................................23

3.2.3 Interfaces............................................................................................................. 24

3.2.4 Additional external In- and Outputs..................................................................... 24

4COMMISSIONING........................................................................28

4.1.1 Establishing connection to the PC.......................................................................28

4.1.2 Switching on the device....................................................................................... 28

4.2 Gateway GC 9310 ......................................................................................28

4.2.1 GC 9310 commissioning ..................................................................................... 30

4.2.2 Interfaces and logs..............................................................................................32

4.2.3 Data storage........................................................................................................33

4.2.4 Electrical connections of the GC 9310 ................................................................34

Contents

Manual GC 9300 EN14 July, 24th 2018

II

5OPERATION.................................................................................39

5.1 Operation on the touch screen.................................................................39

5.1.1 Start screen.........................................................................................................39

5.1.2 Data: Results of the last analysis ........................................................................ 41

5.1.3 Graph - Trends: Trend display of arbitrary values............................................... 42

5.1.4 Graph - Chroms: Chromatogram of the last analysis.......................................... 42

5.1.5 Status - Measuring element: Status displays, e.g. column temperature .............43

5.1.6 Status –Dig. I/O: Status display of digital inputs and outputs............................. 44

5.1.7 Service: Service functions................................................................................... 44

5.1.8 User: User-specific display.................................................................................. 45

5.1.9 Detail: List of all measurements and parameters of the GC 9300....................... 46

5.1.10 Archive: Display of archive entries ......................................................................47

5.1.11 Log: Display of the log books .............................................................................. 48

5.1.12 DSfG - Archive: Display of the DSfG archive ...................................................... 49

5.1.13 DSfG - Delete: Deletion of the DSfG archive.......................................................49

5.1.14 Errors: Display of error messages with date and time......................................... 50

5.2 Operation examples ..................................................................................50

5.2.1 Enter code number.............................................................................................. 50

5.2.2 Change operating mode...................................................................................... 51

5.2.3 Program current output........................................................................................ 52

5.2.4 Read values for maintenance log entry............................................................... 52

5.3 Bake-out.....................................................................................................54

5.3.1 Bake-out process................................................................................................. 54

5.4 View and read archive via internet browser............................................59

5.5 Operation with RMGViewGC ......................................................................59

5.6 Error messages .........................................................................................60

6TECHNICAL DATA ......................................................................70

APPENDIX ...........................................................................................72

Appendix A: List of parameters...........................................................................72

Appendix B: Certificates.......................................................................................73

1 About this manual

Manual GC 9300 EN14 July, 24th 2018

1

1 About this manual

1.1 Structure of this manual

This manual provides information that is necessary for fault-free and safe opera-

tion.

The analytical computer GC 9300 was designed and produced according to the

state of the art and generally recognized safety standards and directives. Howev-

er, its use can entail dangers that are avoidable by complying with this manual.

The analytical computer GC 9300 must only be used as intended and in technical-

ly sound condition.

Warning

Unintended use voids all warranty claims and the analytical computer GC

9300 can also lose its approvals.

1.1.1 Abbreviations

The following abbreviations are used:

max.

Maximum

MID

Measurement Instruments Directive

min.

Minimum

e.g.

for example

1.1.2 Symbols

The following symbols are used:

1, 2, …

Identifies steps for work tasks

..

1 About this manual

Manual GC 9300 EN14 July, 24th 2018

2

1.1.3 Structure of notices

The following notices are used:

Danger

This warning notice informs you of imminently threatening dangers that can

arise due to misuse/operator error. If these situations are not avoided, death

or severe injuries can occur.

Warning

This warning notice informs you of potentially dangerous situations that can

arise due to misuse/operator error. If these situations are not avoided, minor

injuries can occur.

Caution

This notice informs you of potentially dangerous situations that can arise

due to misuse/operator error. If these situations are not avoided, damage to

the device or nearby property can occur.

Note

This notice informs you of potentially dangerous situations that can arise

due to misuse/operator error. If these situations are not avoided, damage to

the device or nearby property can occur.

This notice can provide you with helpful tips to make your work easier. This

notice also provides you with further information about the device or the

work process in order to prevent operator error.

1 About this manual

Manual GC 9300 EN14 July, 24th 2018

3

1.1.4 Working with the device

1.1.4.1 Safety notices Danger, Warning, Caution and Note

Danger

All of the following safety notices must be observed !!

Disregard of the safety notices can result in danger to the life and limb or

environmental and property damage.

Bear in mind that the safety warnings in this manual and on the device cannot

cover all potential dangerous situations, because the interaction of various condi-

tions can be impossible to foresee. Merely following the instructions may not suf-

fice for correct operation. Always remain attentive and consider potential conse-

quences.

•Read this operating manual and especially the following safety notices care-

fully before working with the device for the first time.

•Warnings are provided in the operating manual for unavoidable residual

risks for users, third parties, equipment or other property. The safety in-

structions used in this manual do not refer to unavoidable residual risks.

•Only operate the device in fault-free condition and in observance of the op-

erating manual.

•Compliance with local statutory accident prevention, installation and as-

sembly regulations is also mandatory.

Note

All notices in the manual must be observed.

Use of the analytical computer GC 9300 is only permitted in accordance with

the specifications in the operating manual.

RMG assumes no liability for damages arising due to disregard of the oper-

ating manual.

1 About this manual

Manual GC 9300 EN14 July, 24th 2018

4

Danger

Service and maintenance tasks or repairs that are not described in the oper-

ating manual must not be carried out without prior consultation with the

manufacturer.

Changes to the analytical computer GC 9300 are not permitted.

The technical specifications must be observed and followed for safe opera-

tion (Chapter 6 Technical data). Performance limits must not be exceeded.

For safe operation, the analytical computer GC 9300 must only be used in

the scope of the intended use (Chapter 1.3 Function to 1.5 Area of applicabil-

ity)

The GC 9300 complies with current standards and regulations. However,

danger can arise with misuse and the measuring element of the PGC can be

destroyed due to operator error.

1.1.4.2 Dangers during commissioning

Initial commissioning

The initial commissioning must only be carried out by

specially trained personnel (training by RMG) or RMG

service personnel.

Note

An acceptance test certificate must be created during the commissioning.

This, the operating manual and the CE Declaration of Conformity must be

stored so that they are always readily available.

All sharp edges on the device were removed, insofar as possible. However,

suitable personal protective equipment provided by the operator must be

worn during all work.

1 About this manual

Manual GC 9300 EN14 July, 24th 2018

5

Danger

This symbol is used in the manual as a warning of the danger

of explosion; observe the instructions following the symbol.

With the danger of explosion, the following must be observed,

in particular:

The analytical computer GC 9300 is not approved or designed for use in ex-

plosion-prone areas. Installation must only take place in safe rooms. The

analytical computer is intended for installation in a control cabinet in an

electronics room.

Install the device as specified in the operating manual. If the device is not

installed as specified in the operating manual, there may be a risk that other

connected devices have adequate explosion protection.

Inadequately qualified persons working on the equipment are unable to cor-

rectly estimate dangers. Explosions can be triggered. Only work on the

equipment if you have the appropriate qualifications.

Components can be damaged if you do not use suitable tools and materials.

Use tools that are recommended for the respective work in the operating

manual.

Mechanical installation

Mechanical installation must only be performed by appro-

priately qualified technicians.

Electrical installation

Installation on electrical components must only be carried

out by qualified electricians.

Mechanical and/or elec-

trical installation

These qualified personnel require training specifically for

work in explosion-prone areas. Qualified personnel are

persons who have training / education in accordance with

DIN VDE 0105, IEC 364 or comparable standards.

Note

•Before connecting the voltage supply, ensure that all gas lines to the

measuring element and the measuring element itself have been flushed. If

there is still air in the line system or the measuring element, the measur-

ing element will be destroyed. For this reason, you must also observe the

operating manual for the PGC measuring element CP 4900!

1 About this manual

Manual GC 9300 EN14 July, 24th 2018

6

Danger

•In general, the replacement of an analytical computer GC 9300 must only

be carried out by RMG Service.

1.1.4.3 Dangers during maintenance and repair

Operating personnel

The operating personnel use and operate the device in

the scope of the intended use.

Maintenance personnel

Work on the device must only be carried out by qualified

personnel who can carry out the respective tasks on the

basis of their technical training, experience and familiarity

with the applicable standards and requirements. These

qualified personnel are familiar with the applicable statu-

tory regulations for accident prevention and can inde-

pendently recognize and avoid potential dangers.

Maintenance and clean-

ing

Maintenance and cleaning must only be performed by

appropriately qualified technicians.

Danger

Inadequately qualified persons working on the equipment are unable to cor-

rectly estimate dangers. Explosions can be triggered.

Danger

The device can be damaged if it is not cleaned as specified in the operating

manual. Only clean the device as specified in the operating manual.

Components can be damaged if you do not use suitable tools.

- Only clean the device with a slightly damp cloth!

1 About this manual

Manual GC 9300 EN14 July, 24th 2018

7

1.1.4.4 Qualification of personnel

Note

In general, the following is recommended for all persons working with or on

the analytical computer GC 9300:

•Training / education for work in explosion-prone areas.

•The capacity to be able to correctly estimate dangers and risks when

working with the analytical computer GC 9300 and all connected devices.

•Training / education by RMG for work with gas measuring devices.

•Education / instruction in all national standards and directives to be com-

plied with for the work to be carried out on the GC 9300 analytical com-

puter.

1.1.5 Risk assessment and minimization

According to assessment by qualified employees of RMG, the analytical computer

GC 9300 is subject to risks during its use. Risks can arise, for instance, during use

outside of the permissible temperature range. Impermissible current and voltage

values can trigger explosions in explosion-prone areas. Naturally, work must only

be carried out by trained personnel (see chapter 1.1.4.4 Qualification of person-

nel), who are also trained to recognize suitable tools and use them exclusively.

These risks were summarized alongside development and measures were taken

to minimize these risks.

Measures for risk minimization:

- The maximum permissible temperature range is specified on the type plate

of the analytical computer GC 9300. Operation of the device is only permit-

ted within these specified ranges.

1 About this manual

Manual GC 9300 EN14 July, 24th 2018

8

Danger

- The wiring from and installation of the analytical computer GC 9300 in

explosion-prone areas must only be carried out by trained personnel

in accordance with EN60079-14 and in observance of national regula-

tions.

- Qualified persons must satisfy the definitions in accordance with DIN

EN 0105 or IEC 364 or directly comparable standards.

- Only trained and instructed personnel are permitted. Work on the

measuring system must only be carried out from qualified persons

and inspected by responsible qualified supervisors.

- Qualified persons have been authorized by the person responsible for

safety of personnel to carrying out such work on the basis of their

training, experience or instruction and familiarity with applicable

standards, provisions, accident prevention regulations and system

conditions. It is essential that these persons are able to recognize and

avoid potential dangers in good time.

1.1.6 Applicability of the manual

This manual describes the analytical computer GC 9300. The analytical computer

GC 9300 is only part of a complete system. The manuals of the other components

of the system must be observed. If you find contradictory instructions, contact

RMG and/or the manufacturers of the other components.

Note

Ensure that the power data of the current connection matches the specifica-

tions on the type plate. Observe any applicable national regulations in the

country of use. Use cable that is appropriate for the cable fittings.

Danger

Only work on the equipment if you have the appropriate training and qualifi-

cations.

1.1.6.1 Danger during operation

Observe the specifications of the system manufacturer and/or system operator.

1 About this manual

Manual GC 9300 EN14 July, 24th 2018

9

1.1.6.2 Dangers of operation in EX areas

The analytical computer GC 9300 is not intended for use in explosion-prone areas.

Only operate the analytical computer GC 9300 in fault-free and complete condi-

tion.

If you make technical changes to the device, safe operation can no longer be

guaranteed.

Danger

•Only use the analytical computer GC 9300 in its original condition.

•When connecting the measuring element, an external oxygen sensor or

additional equipment in explosion-prone areas, ensure that the appropri-

ate explosion protection is provided for these components.

•They are intrinsically safe devices for which galvanic isolation must be

provided with connection of these devices.

1.1.6.3 Responsibility of the operator

As the operator, you must ensure that only adequately qualified personnel work on

the device. Ensure that all employees who work with the device have read and

understood this manual. You are also obligated to train personnel regularly and

inform them of the dangers. Ensure that all work on the device is carried out ex-

clusively by qualified persons and inspected by responsible qualified supervisors.

The responsibilities for installation, operation, fault rectification, maintenance and

cleaning must be clearly regulated. Instruct your personnel with regard to the risks

involved with working with the device.

1.1.7 Transport

The device is packaged specific to the transport requirements for each customer.

Ensure safe packaging that absorbs light impact and vibrations is used for any

further transport. Nevertheless, inform the transport company that all types of im-

pact and vibrations should be avoided during transport.

1 About this manual

Manual GC 9300 EN14 July, 24th 2018

10

1.1.8 Scope of delivery

The scope of delivery can differ depending on the optional orders. The following is

“normally” included in the scope of delivery:

Part

Quantity

Analytical computer GC 9300

1

Optional:

Gateway GC 9310

1

Manual

1

…

…

1.1.9 Disposal of packaging material

Dispose of the material in an environmentally friendly manner in accordance with

national standards and directives.

1.1.10 Storage

Avoid extended periods of storage. Inspect the analytical computer GC 9300 for

damage and correct function after storage. Contact the RMG service department

to arrange for inspection of the device after a storage period of longer than one

year. For this purpose, send the device to RMG.

1 About this manual

Manual GC 9300 EN14 July, 24th 2018

11

1.2 Structure of the manual

The introduction of this manual comprises two parts. The first part lists general

specifications; the symbols used in the manual and the structure of notices are

presented and a risk assessment is provided. It also includes specifications for

transport and storage of the analytical computer GC 9300. The second part de-

scribes how the GC 9300 works and its intended purpose.

The second chapter explains the basic function and operation of the GC 9300 and

data storage –taking place in accordance with the DSFG standard, in particular.

The electrical connections, inputs, outputs and interfaces are explained in the third

section.

The fourth chapter describes the commissioning and how the GC 9300 is con-

nected to a PC. It also explains that the number of DSFG interfaces can be in-

creased using a gateway –the GC 9310. The fifth chapter covers the operation of

the GC 9300 and explains the individual menus in detail.

Chapter six summarizes the technical specifications. The Appendix provides an

extensive list of parameters and some additional details about the GC 9310.

1 About this manual

Manual GC 9300 EN14 July, 24th 2018

12

1.3 Function

The analytical computer GC 9300 is a component of the process gas chromato-

graph PGC 9300, which analyzes natural gas and biogas and provides the neces-

sary measurement values to determine the energy content and calculate the com-

pressionability factor. As a control computer, it determines the progress of the

analysis and delivers measurement results. It stores all operating parameters and

is also used for operation.

In addition to analysis control, the GC 9300 provides the following functions:

•Calculation of calorific value, heat value, standard density, and Wobbe in-

dex from the percentages of individual gas components in accordance with

ISO 6976, and the optional calculation of the methane number.

•Storage of analysis results in archives.

•Comprehensive communication functions.

•Operating mode settings for inspection purposes and analysis of gas sam-

ples.

1.4 Mode of operation

The analytical computer GC 9300 is the controller for the process gas chromato-

graph PGC 9300 and controls the analysis process in the measuring element CP

4900. In normal operation, an analysis begins as soon as the preceding analysis is

finished, wherein each analysis lasts about 3-4 minutes, depending on the variant.

The series of analyses proceeds without interruption by automatic calibrations. A

calibration, whether it takes place automatically or is started manually, 4 or 5 cali-

brating gas analyses and takes between 12 and 16 minutes depending on the de-

vice type. The calibration interval of 1 day is specified in the PTB approval.

A calibration can also be started manually at any time.

The PGC 9300 can be designed as a single stream unit for analysis of the gas

from one extraction point or as a multi-stream unit for up to 4 extraction points.

With multi-stream units, the measured gases changes with each analysis in the

standard setting.

The basis of an analysis is the signal curve of the sensor for each column unit,

which is called a chromatogram. Each peak in this chromatogram marks a gas

component. In the evaluation, the area under the peaks are determined, from

which polynomials are derived to calculate the proportion of gas components in

1 About this manual

Manual GC 9300 EN14 July, 24th 2018

13

mol%. The polynomial coefficients are determined in the factory calibration in

which a correction factor (response factor) is calculated for each component in

the automatic and manual calibration.

A basic calibration is carried out during commissioning and after various repair

and service tasks. The response factors derived from this do not change during

running operation and serve for comparison with the current response factors used

for the evaluation. As a result, it can enable recognition of a drift of the measuring

element due to an enrichment of moisture or heavy carbon dioxide. If the deviation

is greater than 10%, an alarm message appears and the column modules must be

heated to gas out. Basic calibration is not permitted during running operation.

In addition to the custody transfer parameters calorific value and standard density,

which were already mentioned, the analytical computer calculates the heating val-

ue, density ratio and Wobbe index, and, optionally, the methane number as a non-

custody-transfer factors from the individual components. The calculation takes

place in accordance with ISO 6976 (except for the methane number).

1.5 Area of applicability

The analytical computer GC 9300 is an essential element of the overall measuring

unit, which analyzes natural gas and biogas and provides the necessary meas-

urement values to determine the energy content and calculate the compression

ability factor. The analytical computer GC 9300 is the controller, or control com-

puter, for the process gas chromatograph PGC 9300 and controls the analysis

process in the measuring element CP 4900. It stores all operating parameters and

is also used for operation. It records and calculates the measurements, enables

display of the measurement results and calculation factors and stores and trans-

mits this data.

The PGC9300_ME_manual_en_06 (and the English manual) describes the differ-

ent types that are used in different areas. The PGC 9301 is designed for use in

"normal" natural gas. It works with 2 column modules. The PGC 9302 is designed

for use in biogas. It works with 2 column modules (A and C). The PGC 9303 al-

lows the determination of further gas components in "normal" natural gas. It works

with 3 column modules (A, B and C). The PGC 9304 allows the determination of

further gas components in "normal" natural gas. It works with 3 column modules

(A, B and C), whereby argon is used as carrier gas in column C. The PGC 9305

complies with the PGC 9301. For this PGC there will be a separate approval ac-

cording to Russian regulations, the GOST. The differences are described in more

detail in the Russian manual.

The permissible environmental temperatures, current and voltage values for safe

operation are specified in chapter 6 Technical data.

2 Introduction

Manual GC 9300 EN14 July, 24th 2018

14

2 Introduction

2.1 Touch screen

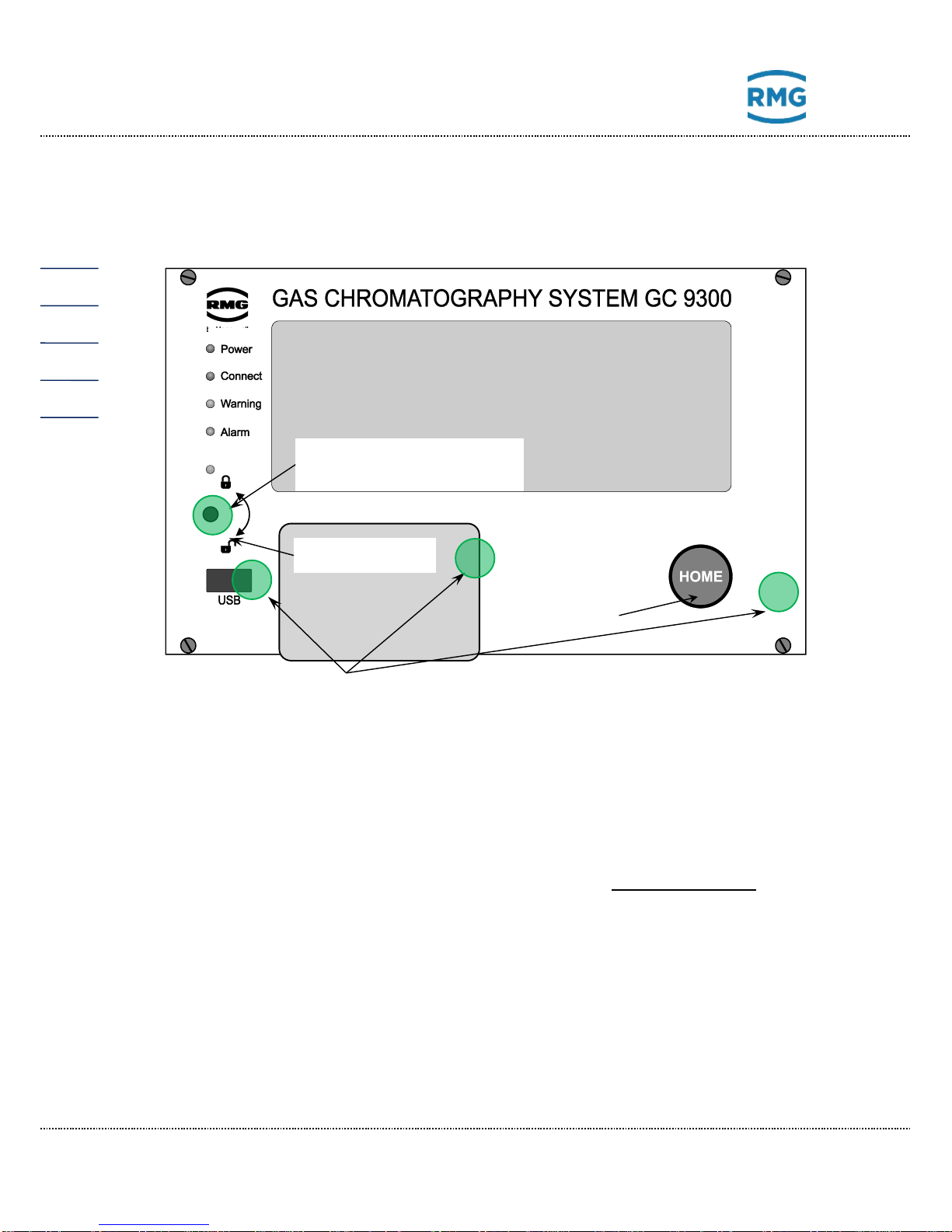

The following display and operating elements are located on the front panel:

Green LED

(Power)

Continuously illuminated: Voltage indicator.

Blinking light: Open custody transfer switch and/or open user lock.

Orange LED

(Connect)

Continuously illuminated: The measuring element is connected and

active.

Yellow LED

(Warning)

Continuously illuminated: A warning has been issued

Blinking light: Warning: Current fault of non-custody-transfer function(s)

Red LED

(Alarm)

Continuously illuminated: An alarm has been issued

Blinking light: Alarm: Current fault of custody transfer function(s)

Custody transfer

switch

Sealable rotary switch; the custody transfer lock is opened at the me-

chanical limit stop (in clockwise direction).

USB interface

For connection of USB components (e.g. a mouse), sealed in custody

transfer mode.

HOME button

To switch between the start screen and error screen.

Touch screen

Display and control panel of the analytical computer.

Touch screen

Home button

Custody transfer switch

as a rotary switch

Type plate

Sealing

Safety marks

2 Introduction

Manual GC 9300 EN14 July, 24th 2018

15

Operation via the touch screen is possible with an easy to understand menu. A PC

connected via the network interface enables the following types of operation:

1. Operating software RMGViewGC.

2. Any internet browser for viewing and storing of non-custody-transfer archives.

Further operating possibilities are available via DSfG bus with RMG software

products such as the PGC revision program AKA-II.

2.2 Operation

Operation takes place on the analytical computer GC 9300 and enables the follow-

ing actions:

•Reading of analysis results

•Starting of a manual calibration

•Switchover of the analysis from measuring gas to testing gas (reference

gas)

•Displaying and changing operating parameters

•Viewing of archives and log books

•Display of chromatograms

•Display of error messages

•Display of the device status

Note

Entry of the code number and/or opening of the custody transfer switch is

necessary for nearly all actions other than the display functions.

2.2.1 Operating modes

The following operating modes are available for the PGC 9300 in the “Details”

screen under “GC 9300 mode”:

•AUTORUN Normal analysis mode with automatic calibrations

•STOP Analysis mode is stopped

•BASIC CALIB. Basic calibration

(protected against inadvertent triggering)

2 Introduction

Manual GC 9300 EN14 July, 24th 2018

16

•NORMAL CALIB. Manually started calibration

(equivalent to automatic cal.)

•REF GAS Test gas analysis (reference gas)

Table of contents

Other RMG Desktop manuals