RMG PGC 9300 User manual

Process Gas Chromatograph PGC 9300

MAINTENANCE LOGBOOK

Reliable Measurement of Gas

Status: 2018, JUNE 26TH

Version: 07

Contact

PGC9300 Maintenance Logbook · EN07 · 2018, June 26th

Manufacturer

Our customer service is available for technical queries

Address

RMG Messtechnik GmbH

Otto-Hahn-Straße 5

D-35510 Butzbach

Telefon switchboard

+49 6033 897 –0

Telefon service

+49 6033 897 –0

Telefon spare parts

+49 6033 897 –173

Fax

+49 6033 897 –130

E-mail

Original Document

The logbook PGC9300_maintenance_manual_en_07

from 2018, June 26th for the gas chromatograph

PGC9300 is the document translated first from the

German original version. Anyhow, this document may

serve as reference for translations into other languages.

Please use in case of any uncertainties the German

version as main reference.

Note

Unfortunately, paper is not updated automatically,

whereas technical development continuously advances.

Therefore, we reserve the right to make technical

changes in regard to the representations and

specifications of these operating instructions. The latest

version of this manual (and other devices) can be

downloaded at your convenience from our Internet

home-page

www.rmg.com

Date created

-

…

4th revision date

January 2016

5th revision date

March 2018

6th revision date

2018, June 26th

Document version and

language

Dokument

version

PGC9300_maintenance_manual_en_07

2018, June 26th

Language

EN

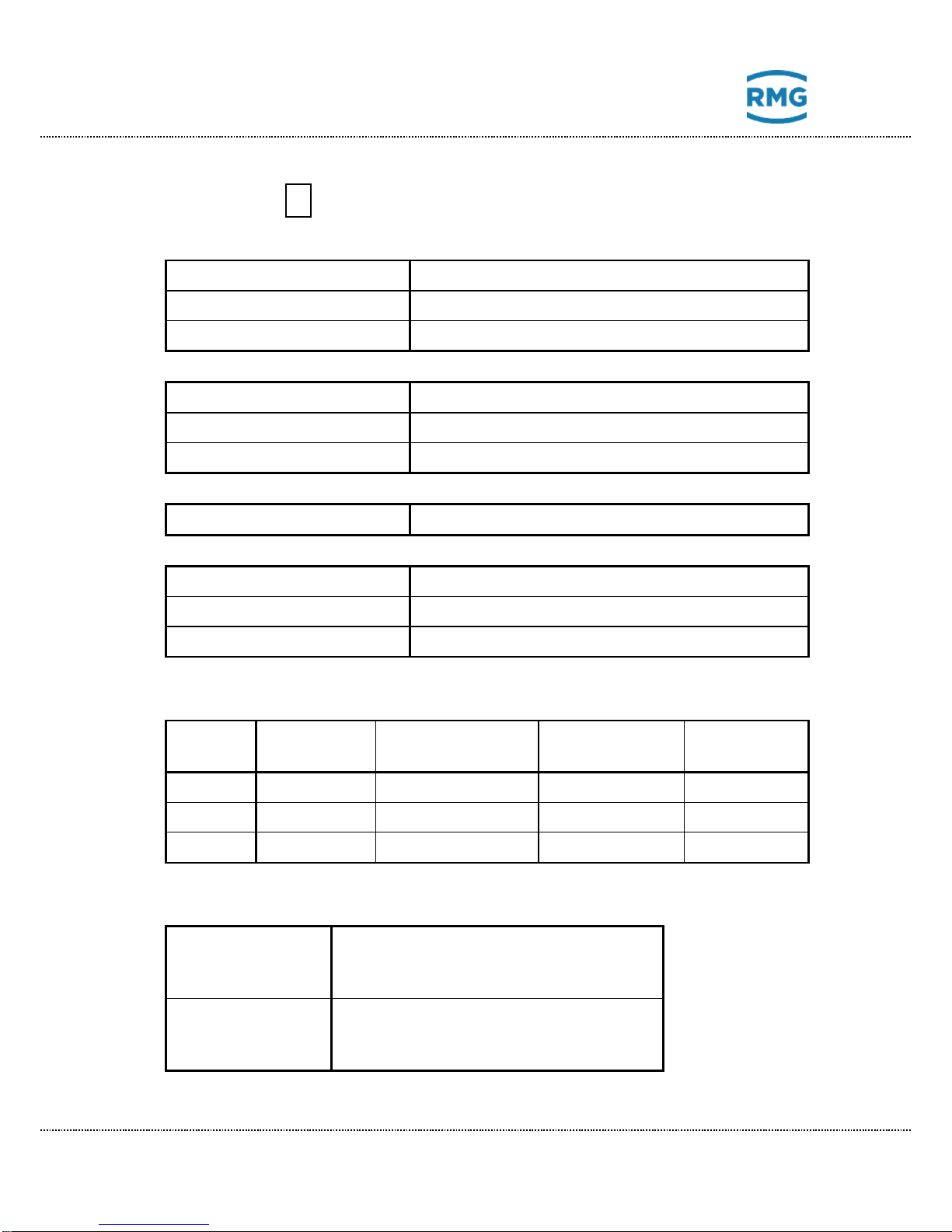

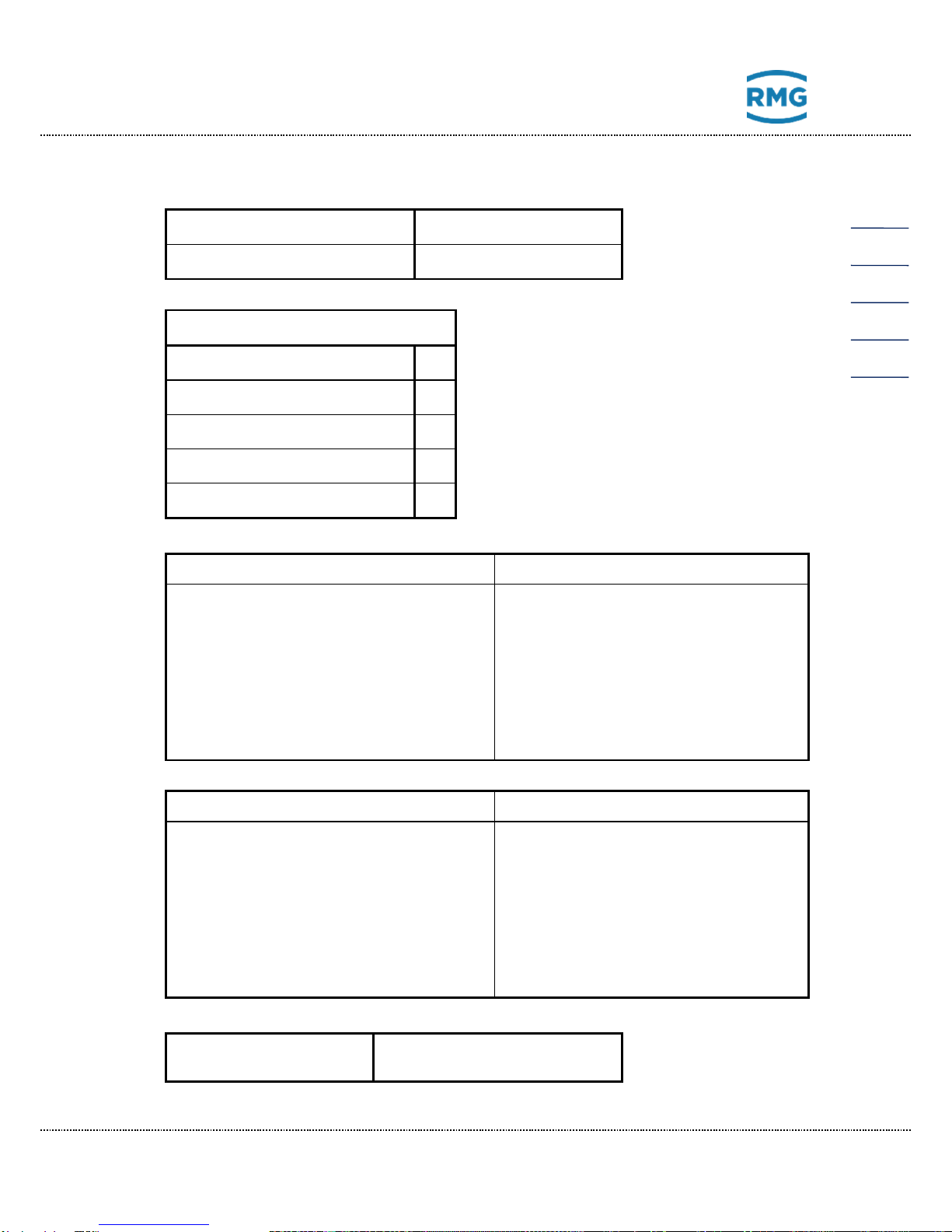

Your PGC9300

PGC9300 Maintenance Logbook · EN07 · 2018, June 26th

PGC 930 Maintenace Logbook

PGC manufacturer number

PGC year of manufacture

Meter serial number

GC 9300 manufacturer number

GC 9300 year of manufacture

GC 9300 software version

Approved for

Calorific value

Gas quality

Operator

Station

Commissioning

Type / carrier

gas

Column temperature

[°C]

Column pressure

[kPa]

Flushing time

[s]

Column A

Column B

Column C

Date

Signature

Contents

PGC9300 Maintenance Logbook · EN07 · 2018, June 26th

Inhalt

1. Instructions for Keeping the Maintenance Logbook .................................. 1

1.1. Inspection.................................................................................................... 1

1.1.1. Operating parameters on the GC 9300.................................................. 1

1.1.2. Cylinder pressures.................................................................................. 2

1.2. Maintenance by service technicians......................................................... 2

2. Manufacturer's requirements........................................................................ 3

2.1. Annual maintenance of the process gas chromatograph....................... 3

2.2. Metrological check / (re)calibration .......................................................... 3

Table Section 1..................................................................................................... 4

Cylinder pressures............................................................................................... 4

Table section 2 ..................................................................................................... 8

Maintenance measures, general......................................................................... 8

Table section 3 ................................................................................................... 19

Annual routine maintenance............................................................................. 19

Table section 4 ................................................................................................... 30

Test gas analyses............................................................................................... 30

1. Instructions for Keeping the Maintenance Logbook

PGC9300 Maintenance Logbook · EN07 · 2018, June 26th

1

1. Instructions for Keeping the Maintenance

Logbook

The maintenance logbook is part of the design approval and is used to monitor the

operation of the device. It is therefore mandatory that this maintenance logbook

should be kept. When a service callout is required, the original maintenance

logbook, or a copy, should be sent to the manufacturer.

The information on the first page and the relevant data in the table are entered by

the testing laboratory before the device is delivered. This documents the condition

of the device on delivery.

The device is to be inspected by the operator every 8 weeks until the first annual

routine maintenance check/recalibration (inspections). After the first annual

routine maintenance check/recalibration, it is sufficient for the operator to

perform an inspection every six months. The values listed in Table Section 1 of

this maintenance logbook must be documented during every inspection. Routine

maintenance should be performed once a year by qualified personnel according to

the manufacturer's instructions and should be documented in Table Section 3 in

the maintenance logbook. The data described in Table Section 4 of this logbook

should also be completed for each recalibration and similar check.

1.1. Inspection

1.1.1. Operating parameters on the GC 9300

The setpoints for the operating parameters are entered on the first page of this

book by the test laboratory during commissioning and shall remain unchanged

during operation, unless altered by an RMG service technician.

The actual values of the operating parameters can be checked at any time on the

GC 9300 analyser under the Status->Meter tab or using RMGViewGC. Because

these values are constantly monitored by the controller and because divergences

are officially recorded as “faults”, these parameters do not have to be documented

in the maintenance logbook. It is therefore necessary to check whether active or

inactive faults or warnings are displayed on the GC 9300 at every visit to the

station.

1. Instructions for Keeping the Maintenance Logbook

PGC9300 Maintenance Logbook · EN07 · 2018, June 26th

2

1.1.2. Cylinder pressures

The pressure in the gas cylinders is checked directly at the high-pressure gauges

of the relevant pressure reducing unit at regular intervals, in other words at every

maintenance check, and the information is then documented in the relevant table

in Table Section 1 of this logbook. If a cylinder has been changed or switched, this

should also be documented in the relevant column. If the PGC is found to be

malfunctioning, this fact should also be recorded.

The pressures should be checked for:

•Carrier gas 1

•Carrier gas 2 (if applicable)

•Internal calibration gas

1.2. Maintenance by service technicians

This section records all changes and measures carried out by service technicians.

This encompasses routine maintenance tasks, software updates and service

activities in the event of a malfunction. In the event of a malfunction, the operator

or service technician should enter a brief description of the problem in the

appropriate place.

It should be noted that this maintenance logbook is linked to a meter. In the event

of a serious malfunction that requires the meter to be replaced, a new

maintenance logbook must be started. This will be supplied with the new meter.

The old maintenance logbook, either a copy or the original, should be sent

to the manufacturer for analysis.

2. Manufacturer's requirements

PGC9300 Maintenance Logbook · EN07 · 2018, June 26th

3

2. Manufacturer's requirements

2.1. Annual maintenance of the process gas

chromatograph

The annual inspection of the PGC 930x must be carried out on the basis of the

checklist (Table Section 4) by persons who have received appropriate training

from RMG to provide such maintenance.

2.2. Metrological check / (re)calibration

Once the maintenance activities described in Section 2 are complete, the device

will subsequently undergo routine recalibration. A representative of the responsible

calibration authorities must be on hand for this purpose. The design approval and

the relevant guidelines and standards it contains are key to the technical

calibration of the system.

Recalibration entails:

•Checking the area around the existing power outputs

•Basic calibration of the PGC with internal calibration gas

•Verification with external calibration gasses with chromatogram

•Verification of power transmission and/or bus transmission of mandatory

calibration values

•Protokollierung aller durchgeführten Arbeiten, Eintragungen im Wartungsbuch

Following the verification of the official parameters to be set in the GC 9300 (tab: Detail),

metrological check begins with the opening of the calibration lock and the implementation

of a basic calibration (select tab: Detail->01-GC 9300->Mode->Basic Calibration).

Following basic calibration, the new response factors (tab: Detail->09 Calibration

Results->RFZ) and retention times (tab: Detail->09 Calibration Results->RTZ) are noted

down in Table Section 4. If the device is calibrated using the “new mathematics”, the

GLKs (tab: Detail->11 Component Parameters/ [component]->GLK) are to be noted down

instead of the RFZs. In addition, the chromatograms for the calibration gas are compared

with the sample chromatograms shown in the design approval. The chromatograms can

be analysed using the RMGViewGC software or on the basis of the chromatogram

displays in GC 9300 (tab: Graph->Chroms).

The metrological check of the device takes place subsequently. The test gases defined in

the design approval are analysed in succession. At least three analyses are required for

each gas. The result of the third analysis is to be used for the verification. The results of

these analyses are to be found in the GC 9300 (tab: Archives) and should be fully

recorded in the table provided for this purpose. The key parameters for the official

verification (according to the design approval) are indicated in the table. The setpoints can

be found in the certificates for the test gasses used and should also be noted. It is

recommended that the chromatograms of the test gasses should be checked.

Table section 1

PGC9300 Maintenance Logbook · EN07 · 2018, June 26th

4

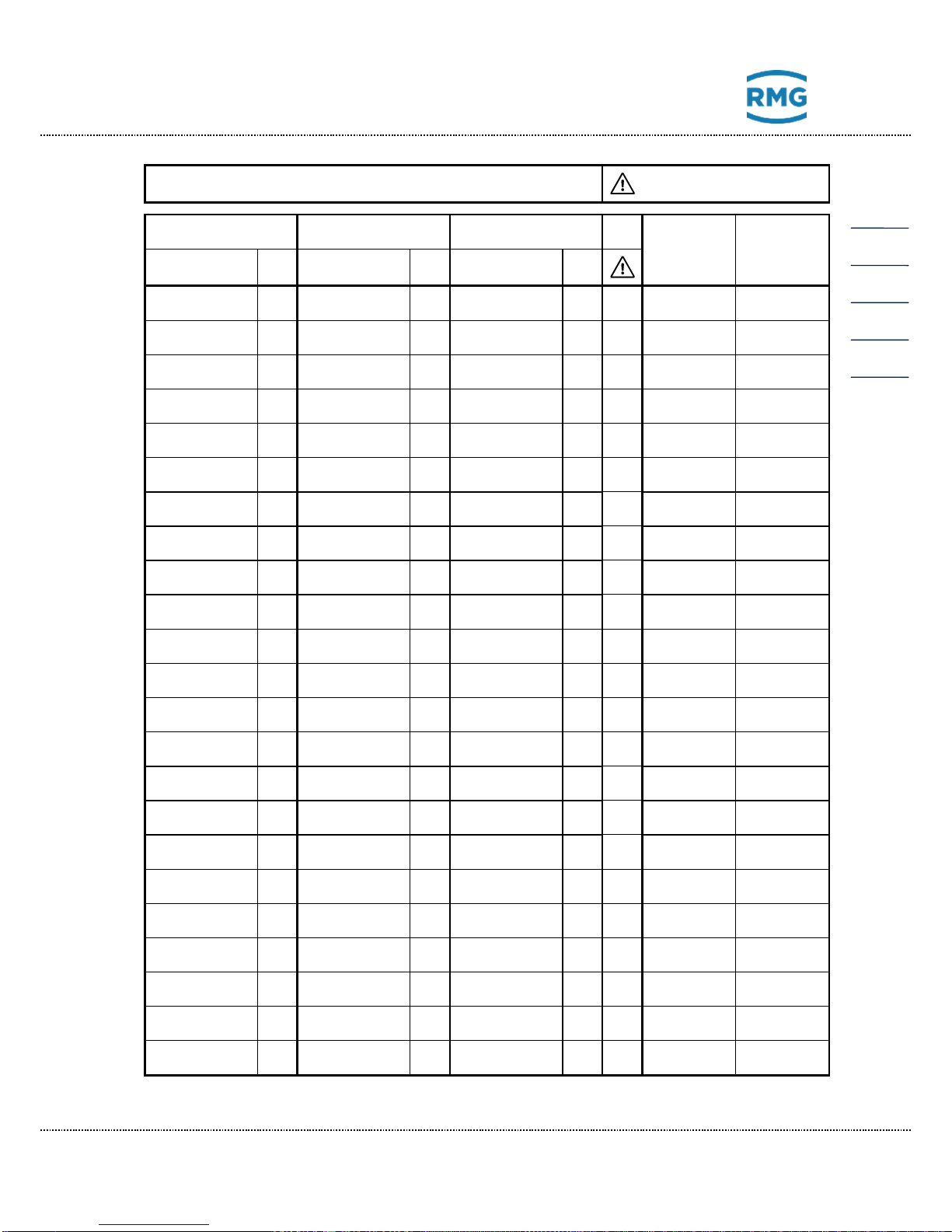

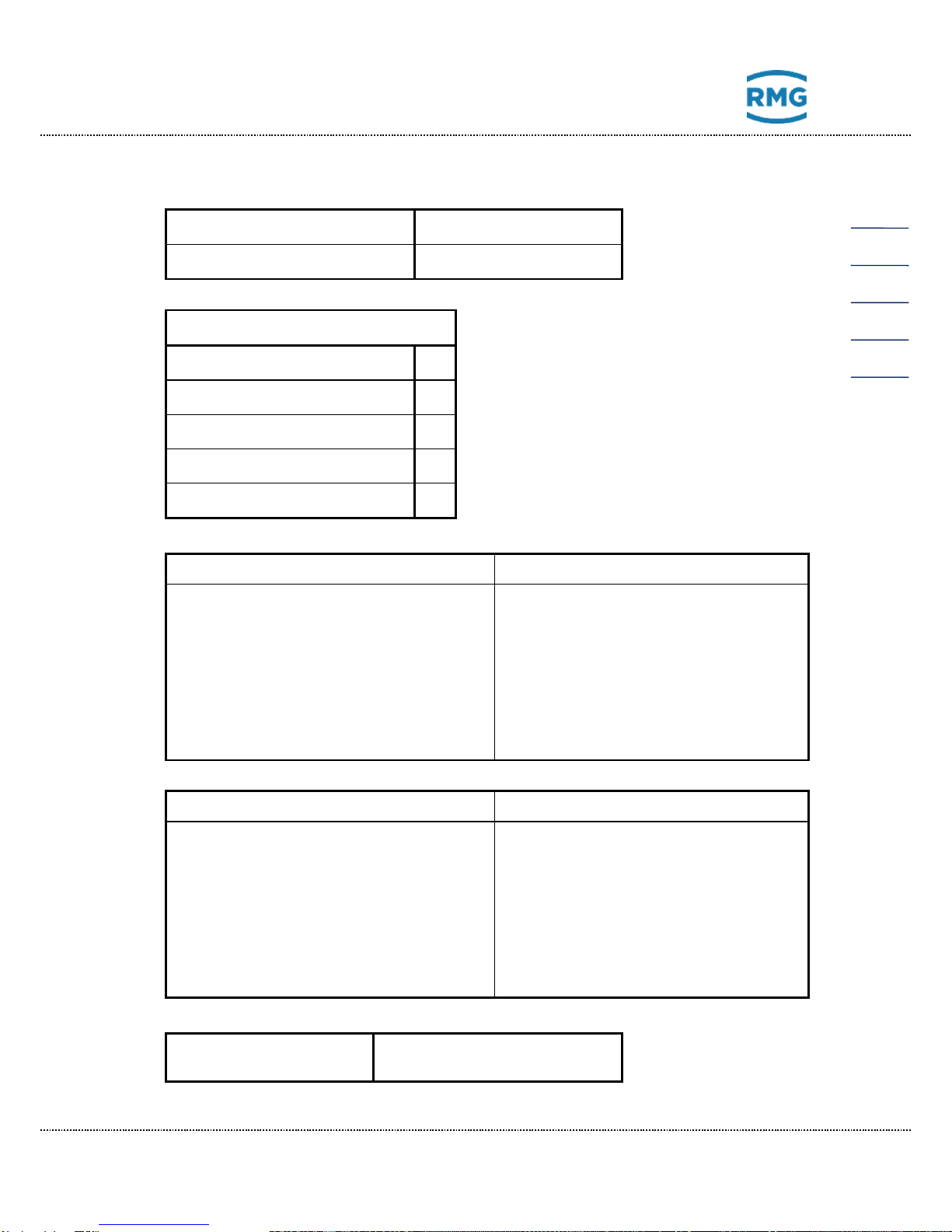

Table Section 1

Cylinder pressures

To be performed at:

•Every inspection

•Every maintenance

Entries made by:

•Operator

•RMG Service

Table section 1 / cylinder pressures

PGC9300 Maintenance Logbook · EN07 · 2018, June 26th

5

: Cylinder changed

: Device faulty

Carriergas I

Int. calibration gas

Carrier gas II

Date

Initials

Pressure / bar

Pressure / bar

Pressure / bar

Table section 1 / cylinder pressures

PGC9300 Maintenance Logbook · EN07 · 2018, June 26th

6

: Cylinder changed

: Device faulty

Carriergas I

Int. calibration gas

Carrier gas II

Date

Initials

Pressure / bar

Pressure / bar

Pressure / bar

Table section 1 / cylinder pressures

PGC9300 Maintenance Logbook · EN07 · 2018, June 26th

7

: Cylinder changed

: Device faulty

Carriergas I

Int. calibration gas

Carrier gas II

Date

Initials

Pressure / bar

Pressure / bar

Pressure / bar

Table section 2

PGC9300 Maintenance Logbook · EN07 · 2018, June 26th

8

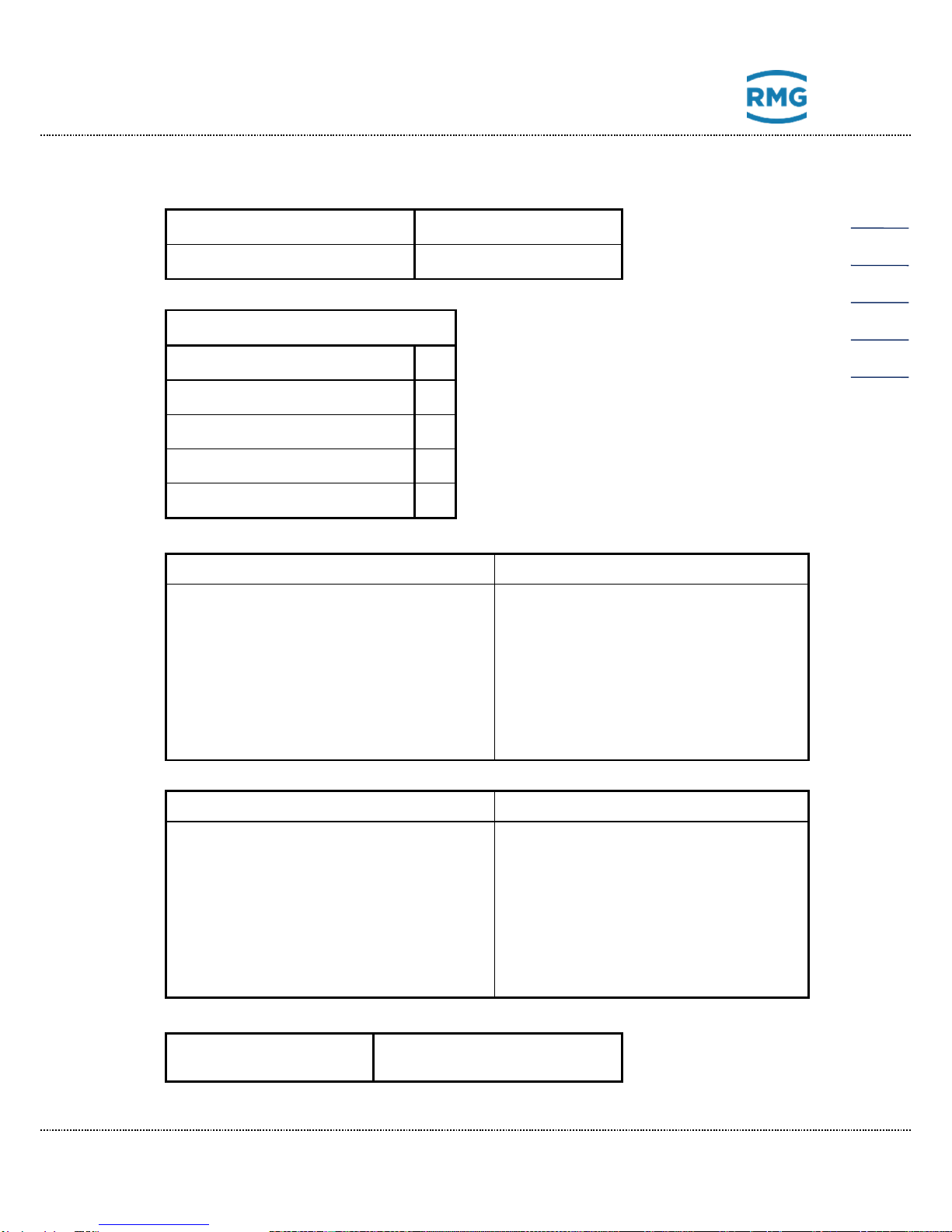

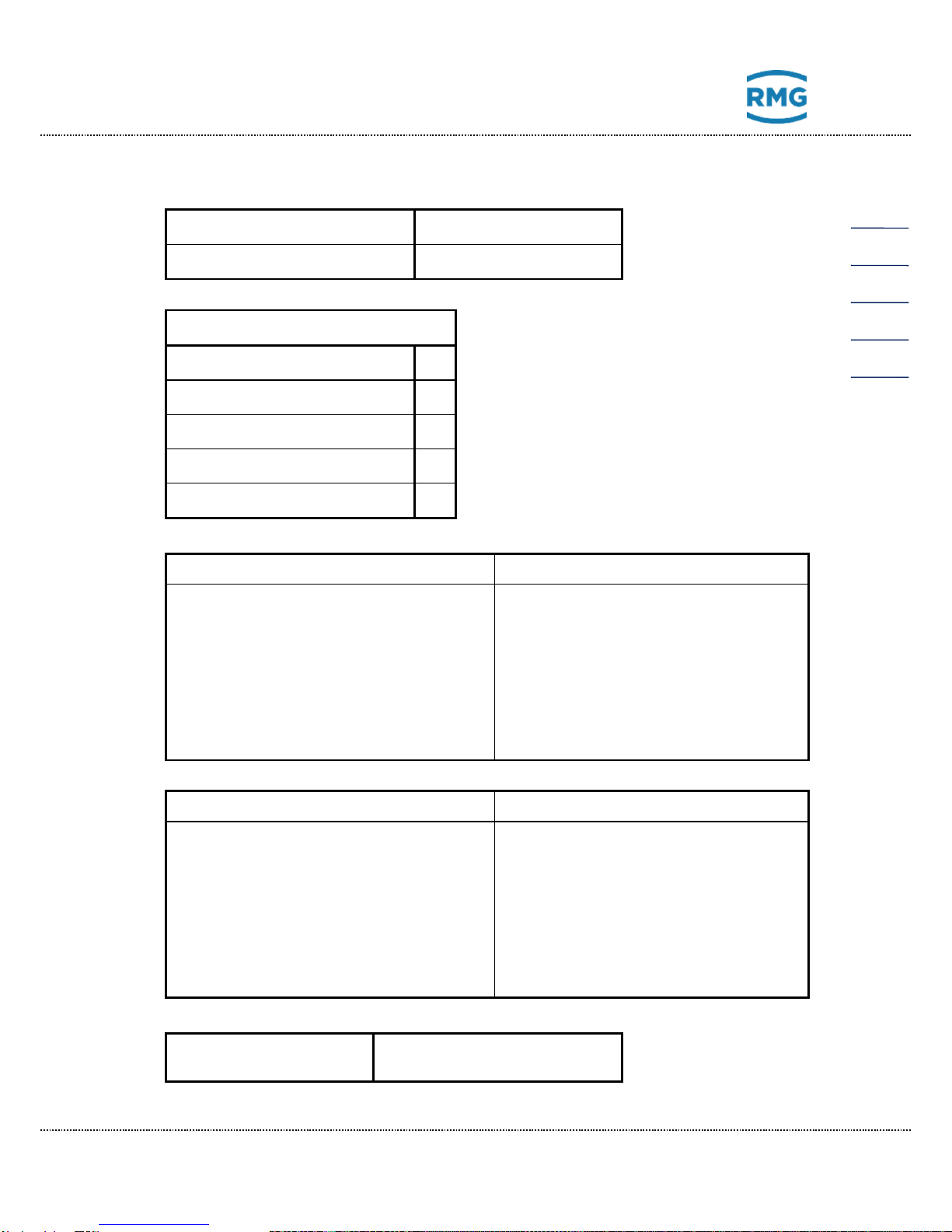

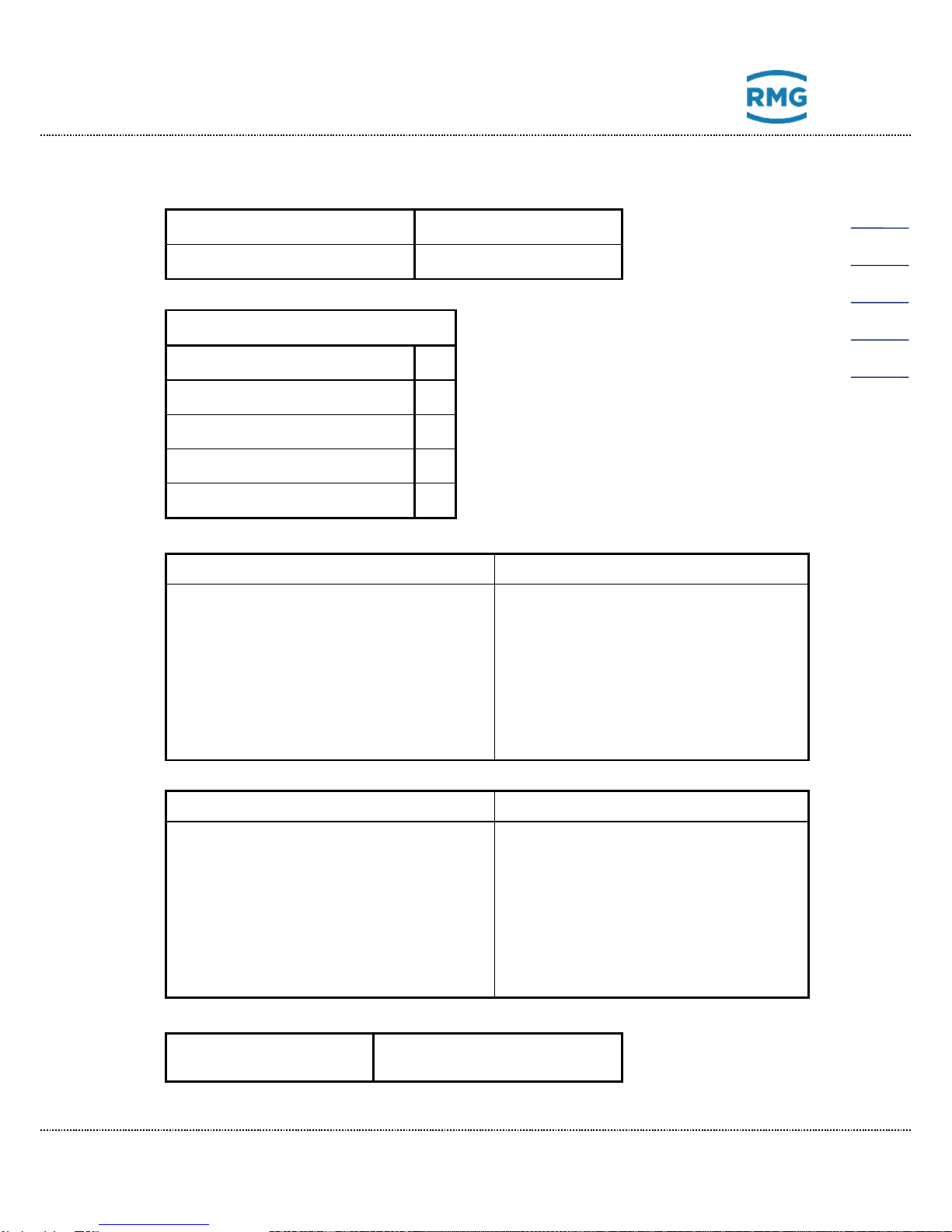

Table section 2

Maintenance measures, general

To be performed at:

•Annual routine maintenance

•Software update

•Metrological check

•(Re)calibration

•Repair

Entries made by:

•Trained personnel

•RMG Service

Table section 2 / maintenance measures, general

PGC9300 Maintenance Logbook · EN07 · 2018, June 26th

9

Maintenance measure

Performed by

Performed on

Measures performed

Routine maintenance

Table 3

Software update

Metrological check

Table 4

(Re)calibration

Table 4

Defect

See below

Description of problem

Measure

Description of problem

Measure

Signature

Table section 2 / maintenance measures, general

PGC9300 Maintenance Logbook · EN07 · 2018, June 26th

10

Maintenance measure

Performed by

Performed on

Measures performed

Routine maintenance

Table 3

Software update

Metrological check

Table 4

(Re)calibration

Table 4

Defect

See below

Description of problem

Measure

Description of problem

Measure

Signature

Table section 2 / maintenance measures, general

PGC9300 Maintenance Logbook · EN07 · 2018, June 26th

11

Maintenance measure

Performed by

Performed on

Measures performed

Routine maintenance

Table 3

Software update

Metrological check

Table 4

(Re)calibration

Table 4

Defect

See below

Description of problem

Measure

Description of problem

Measure

Signature

Table section 2 / maintenance measures, general

PGC9300 Maintenance Logbook · EN07 · 2018, June 26th

12

Maintenance measure

Performed by

Performed on

Measures performed

Routine maintenance

Table 3

Software update

Metrological check

Table 4

(Re)calibration

Table 4

Defect

See below

Description of problem

Measure

Description of problem

Measure

Signature

Table section 2 / maintenance measures, general

PGC9300 Maintenance Logbook · EN07 · 2018, June 26th

13

Maintenance measure

Performed by

Performed on

Measures performed

Routine maintenance

Table 3

Software update

Metrological check

Table 4

(Re)calibration

Table 4

Defect

See below

Description of problem

Measure

Description of problem

Measure

Signature

Table section 2 / maintenance measures, general

PGC9300 Maintenance Logbook · EN07 · 2018, June 26th

14

Maintenance measure

Performed by

Performed on

Measures performed

Routine maintenance

Table 3

Software update

Metrological check

Table 4

(Re)calibration

Table 4

Defect

See below

Description of problem

Measure

Description of problem

Measure

Signature

Table section 2 / maintenance measures, general

PGC9300 Maintenance Logbook · EN07 · 2018, June 26th

15

Maintenance measure

Performed by

Performed on

Measures performed

Routine maintenance

Table 3

Software update

Metrological check

Table 4

(Re)calibration

Table 4

Defect

See below

Description of problem

Measure

Description of problem

Measure

Signature

Table section 2 / maintenance measures, general

PGC9300 Maintenance Logbook · EN07 · 2018, June 26th

16

Maintenance measure

Performed by

Performed on

Measures performed

Routine maintenance

Table 3

Software update

Metrological check

Table 4

(Re)calibration

Table 4

Defect

See below

Description of problem

Measure

Description of problem

Measure

Signature

Other manuals for PGC 9300

1

Table of contents