SI Analytics TitroLine 7500 KF User manual

TitroLine®

7500 KF

TITRATOR

OPERATING INSTRUCTIONS

Gebrauchsanleitung ...................................................................................................... Seite 5 ..... 72

Wichtige Hinweise: Die Gebrauchsanleitung vor der ersten Inbetriebnahme des Titrators TitroLine®7500 KF

bitte sorgfältig lesen und beachten. Aus Sicherheitsgründen darf der Titrator TitroLine®7500 KF ausschließlich

nur für die in dieser Gebrauchsanleitung beschriebenen Zwecke eingesetzt werden.

Bitte beachten Sie auch die Gebrauchsanleitungen für die anzuschließenden Geräte.

Alle in dieser Gebrauchsanleitung enthaltenen Angaben sind zum Zeitpunkt der Drucklegung gültige Daten. Es

können jedoch von SI Analytics sowohl aus technischen und kaufmännischen Gründen, als auch aus der

Notwendigkeit heraus, gesetzliche Bestimmungen der verschiedenen Länder zu berücksichtigen,

Ergänzungen am Titrator TitroLine®7500 KF vorgenommen werden, ohne dass die beschriebenen

Eigenschaften beeinflusst werden.

Operating Instructions ................................................................................................ Page 73.... 142

Important notes: Before initial operation of the Titration Unit TitroLine®7500 KF, please read and observe

carefully the operating instructions. For safety reasons the Titration Unit TitroLine®7500 KF may only be used

for the purposes described in these present operating instructions.

Please also observe the operating instructions for the units to be connected.

All specifications in this instruction manual are guidance values which are valid at the time of printing.

However, for technical or commercial reasons or in the necessity to comply with the statuary stipulations of

various countries, SI Analytics may perform additions to the Titration Unit TitroLine®7500 KF without changing

the described properties.

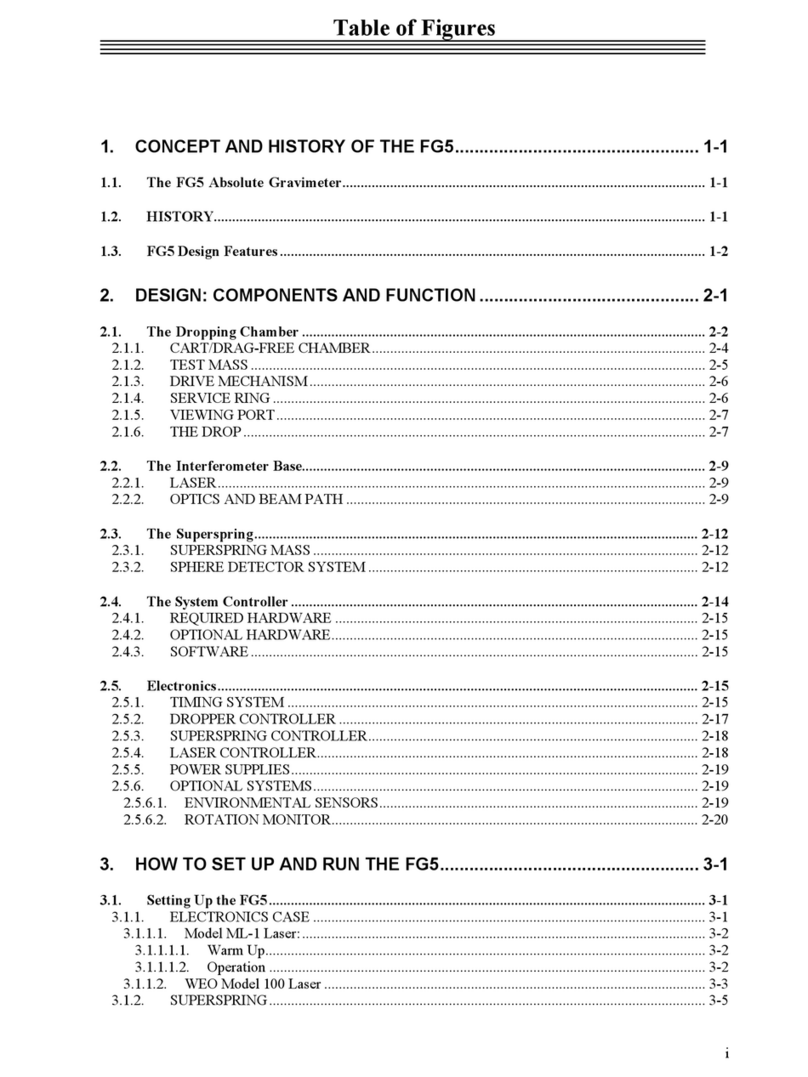

TABLE OF CONTENT PAGE

1. Technical Specifications of the Titrator TitroLine®7500 KF................................ 75

1.1 Summary............................................................................................................................75

1.2 Specifications Titrator TitroLine®7500 KF............................................................................76

1.3 Warning and safety information...........................................................................................79

2. Unpacking and First Operation .............................................................................. 80

2.1 Unpacking...........................................................................................................................80

2.2 Installation and Connection of the TM 235 KF titration stand and titration vessel..................80

2.3 Connecting the Titrator - Combination with Accessories and Additional Devices..................84

2.3.1 Back panel of the titrator TitroLine® 7500 KF ......................................................................84

2.3.2 Connection ports of the TitroLine® 7500 KF........................................................................84

2.3.3 Connecting a printer............................................................................................................84

2.3.4 Connecting a USB device (manual controller, keyboard, memory device, hub)....................84

2.3.5 Connection of analytical balances .......................................................................................85

2.4 Setting the Language of the Country ...................................................................................85

2.5 Interchangeable unit WA.....................................................................................................86

2.5.1 Installing the interchangeable unit.......................................................................................86

2.6 Positioning and Replacing an Interchangeable Unit.............................................................87

2.6.1 Placing an interchangeable unit...........................................................................................87

2.6.2 Removing an interchangeable unit ......................................................................................88

2.6.3 Programming the titration unit..............................................................................................88

2.7 Initial Filling or Rinsing of the Entire Interchangeable Unit....................................................90

2.8 Filling the titration vessel with solvent..................................................................................92

2.9 Replacing the Glass Cylinder and the PTFE Piston .............................................................92

3. Working with the Titrator TitroLine®7500 KF........................................................ 95

3.1 Front Keyboard...................................................................................................................95

3.2 Display................................................................................................................................95

3.3 Manual controller “mouse“...................................................................................................96

3.4 External PC Keyboard.........................................................................................................96

3.5 Menu Structure ...................................................................................................................97

3.6 Main Menu..........................................................................................................................99

3.6.1 Standard methods of KF Titration........................................................................................99

3.6.2 Automatic KF Titration.......................................................................................................100

3.6.3 Dosage.............................................................................................................................104

3.6.4 Preparing Solutions...........................................................................................................107

4. Method Parameters................................................................................................ 108

4.1 Method editing and new method........................................................................................108

4.2 Default methods................................................................................................................108

4.3 Copy Methods...................................................................................................................109

4.4 Delete Methods.................................................................................................................109

4.5 Print method .....................................................................................................................110

4.6 Change Method Parameters..............................................................................................110

4.6.1 Method type......................................................................................................................110

4.6.2 Result ...............................................................................................................................111

4.6.3 Titration parameters..........................................................................................................119

4.6.4 Titration end......................................................................................................................122

4.6.5 Dosing parameter..............................................................................................................124

4.6.6 Sample identification.........................................................................................................125

4.6.7 Documentation..................................................................................................................126

5. System settings ..................................................................................................... 127

5.1 Interchangeable Unit - Reagents.......................................................................................127

5.2 RS232 Settings.................................................................................................................129

5.3 Date and Time ..................................................................................................................131

5.4 Password..........................................................................................................................131

5.5 RESET..............................................................................................................................131

5.6 Printer...............................................................................................................................132

5.7 Device Information............................................................................................................132

5.8 System Tone.....................................................................................................................132

5.9 Software Update ...............................................................................................................133

6. Data Communication via RS232- and USB-B interface ...................................... 135

6.1 General Information ..........................................................................................................135

Meaning / Description........................................................................................................................135

6.2 Chaining multiple devices —“Daisy Chain Concept“ ..........................................................135

6.3 Instruction Set for RS-Communication...............................................................................135

7. Connection of Analytical Balances and Printers ................................................ 137

7.1 Connection of Analytical Balances.....................................................................................137

7.1.1 Balance TZ-Number..........................................................................................................137

7.2 Balance data editor...........................................................................................................138

7.3 Connection of Printers.......................................................................................................139

8. Maintenance and Care of the TitroLine®7500 KF ............................................... 140

9. Storage and transportation................................................................................... 141

10Recycling and Disposal......................................................................................... 141

11Index ....................................................................................................................... 142

Version 120829 US

75

Chapter 1 – Specifications Titrator TitroLine®7500 KF

1 Technical Specifications of the Titrator TitroLine®7500 KF

1.1 Summary

The TitroLine®7500 KF is suitable for the following applications:

The possible range of titrations includes volumetric KF and Dead stop titrations with a maximum of 50

memorisable methods.

The examples of possible use of the TitroLine®7500 KF include:

−KF titrations with 1-component KF reagents

−KF titrations with 2-component KF reagents

−Dead stop titrations such a bromine number and sulphur dioxide in

−Compatible with TitriSoft 3.0.

In addition, the TitroLine®7500 KF comes with following functionalities of the TITRONIC®500 piston burette:

−Dosing

−Preparation of solutions

Each method allows for the setting of a variety of dosing and filling rates.

Solutions to be used:

Virtually, any liquids and solutions with a viscosity of < = 10 mm² / s such as concentrated sulphuric acid may

be used. However, one has to avoid the use of chemicals that may attack glass, PTFE or FEP or that are

explosive, such as hydrofluoric acid, sodium azide or bromine! Suspensions containing high solids

percentages may clog or even damage the dosing system.

General provisions:

The safety guidelines that are applicable to the handling of chemicals have to be observed under all

circumstances. This applies in particular to inflammable and/or etching liquids.

Guarantee

We provide guarantee for the device described for two years from the date of purchase. This

guarantee covers manufacturing faults being discovered within the mentioned period of two years.

Claim under guarantee covers only the restoration of functionality, not any further claim for damages

or financial loss.

Improper handling/use or illegitimate opening of the device results in loss of the guarantee rights.

The guarantee does not cover wear parts, as lobes, cylinders, valves and pipes including the thread

connections and the titration tips. The breach of glass parts is also excluded. To ascertain the

guarantee liability, please return the instrument and proof of purchase together with the date of

purchase freight paid or prepaid.

76

Chapter 1 – Specifications Titrator TitroLine®7500 KF

1.2 Specifications Titrator TitroLine®7500 KF

Status July. 01th2012

CE sign:

EMC compatibility according to the Council Directive: 2004/108/EG;

applied harmonized standards: EN 61326-1:2006

Low-voltage directive according to the Council Directive 2006/95/EG

Testing basis EN 61 010, Part 1

Country of origin: Germany, Made in Germany

The following solvents/titration reagents are allowed to be used:

−All common titration solutions.

−As reagent water and all non-aggressive non-organic and organic fluids are allowed. If using combustible

fluids fire please adhere to the Guidelines for Explosion Protection and Prevention of the chemical industry.

−For fluids with higher viscosity (≥5 mm2/s), lower boiling point or affinity to outgas, the filling and dosage

speed can be adjusted.

−Fluids with viscosity over 20mm2/s cannot be dosed.

Measurement input: Karl-Fischer (Dead-stop) connector for double platinum electrode

Polarisation voltage variably adjustable from 40 … 220 mV.

Connector: 2 x 4 mm - sockets.

Measurement

range

Display resolution

Measurement

accuracy* withou

t

sensor probe

I [µA]

0 ... 100

0,1

0,2 ±1 Digit

* The measurement uncertainty of the sensor probe has to be taken into account as well.

77

Chapter 1 – Specifications Titrator TitroLine®7500 KF

Display: 3.5 inches -1/4 VGA TFT display with 320x240 pixels.

Inputs:Measurement input µA: (Dead-Stop-) connector for double platinum electrode

Connection sockets: 2 x 4 mm)

Power supply: power supply 90-240 V; 50/60 Hz, power input: 30 VA

RS232-C Interface:RS232-C interface separated galvanically through photocoupler

Daisy Chain function available.

Data bits: adjustable, 7 or 8Bit (default: 8 Bit)

Stop bit: adjustable, 1or 2 Bit (default: 1 Bit)

Start bit: static 1Bit

Parity: adjustable: even / odd / none

Baud rate: adjustable: 1200, 2400, 4800, 9600, 19200 (Default 4800 baud)

Address: adjustable, (0 to 15, default: 01)

RS232-1 for computer, input Daisy Chain

RS232-2 devices of SI Analytics, titrator TitroLine6000/7000/7500,

- Burettes TITRONIC500, TITRONIC110 plus, TITRONICuniversal,

- Balances of the types Mettler, Sartorius,

- Kern, Ohaus (for more, please contact SI Analytics)

- Exit Daisy Chain

USB Interface: 2 x USB-type A and 1 x USB-type B

USB –Typ B (“slave“) for connecting a PC

USB –Typ A (“master“) for connecting:

- USB keyboard

- USB printer

- USB “mouse“ (“mouse“),

- USB data media e.g. USB stick

- USB Hub

Stirrer/pump TMKF: 12V DC out,500mA

power supply for stirrer TM 235 and KF titration stand TM 235 KF

Housing material: Polypropylene

Front keyboard: polyester coated

Housing dimensions: 15.3 x 45 x 29.6 cm (W x H x D), height incl. interchangeable unit

Weight: ca. 2.3 kg for basic unit

ca. 3.5 kg for complete device incl. interchangeable unit (with empty reagent bottle)

Ambient conditions: Ambient temperature: + 10 ... + 40 °C for operation and storage

Humidity according to EN 61 010, Part 1:

Max. relative humidity 80 % for temperatures up to 31 °C,

linear decrease down to 50 % relative humidity at a temperature of 40 °

78

Chapter 1 – Specifications Titrator TitroLine®7500 KF

Status Aug. 23rd 2011

Interchangeable units

Compatibility: units are compatible to the titrators TitroLine®6000, TitroLine®7000, TitroLine®

7500 KF and Piston Burette TITRONIC®500

Recognition: automatically through RFID. Recognition of unit size and characteristics of the

Titration- or dosing solution

Valve: volume neutral cone valve made from fluorocarbon polymers (PTFE), TZ 3000

Cylinder: borosilicate glass 3.3 (DURAN®)

Hoses: FEP hose set, blue

Bracket for supply bottle: suitable for square glass bottle and misc. reagent bottles

Materials: borosilicate glass DURAN®, fluorocarbon polymers (PTFE), stainless steel,

polypropylene,

Dimensions: 15 x 34 x 22.8 cm (W x H x D) incl. reagent bottle

Weight: approx. 1.2 kg for interchangeable unit WA incl. empty reagent bottle

Dosing accuracy: after DIN EN ISO 8655, part 3

Accuracy: 0.15 %

Precision: 0.05 - 0.07 %

(Depending on the used interchangeable unit)

Dosing accuracy of the Titrator TitroLine®7500 KF with WA interchangeable units:

Interchangeable.

unit

type No.

Volume

[ml]

Tolerances of the Øi

of the glass cylinder

[mm]

Dosage error*

according to

100 % volume

[%]

Reproducibility

[%]

WA 05 5.00 ± 0.005 ± 0.15 0.07

WA 10 10.00 ± 0.005 ± 0.15 0.05

WA 20 20.00 ± 0.005 ± 0.15 0.05

WA 50 50.00 ± 0.005 ± 0.15 0.05

79

Chapter 1 – Specifications Titrator TitroLine®7500 KF

1.3 Warning and safety information

The TitroLine®7500 KF corresponds to protection class II. It was manufactured and tested according to DIN

EN 61 010, Part 1, Protective Measures for Electronic Measurement Devices and has left the factory in an

impeccable condition as concerns safety technology. In order to maintain this condition and to ensure safe

operation, the user should observe the notes and warning information contained in the present operating

instructions. Development and production is done within a system which meets the requirements laid down in

the DIN EN ISO 9001 standard.

For reasons of safety, the titrator TitroLine®7500 KF must be opened by authorised persons only; this means,

for instance, that work on electrical equipment must only be performed by qualified specialists.

!

In the case of nonobservance of these provisions the titrator TitroLine®7500 KFmay constitute a

danger: electrical accidents of persons or fire hazard. Moreover, in the case of unauthorised

intervention in the titrator TitroLine®7500 KF as well as in the case of negligently or deliberately

caused damage, the warranty will become void.

!

Prior to switching the device on it has to be ensured that the operating voltage of the titrator TitroLine® 7500

KF matches the mains voltage. The operating voltage is indicated on the specification plate. Nonobservance of

this provision may result in damage to the titrator TitroLine® 7500 KF or in personal injury or damage to

property.

If it has to be assumed that safe operation is impossible, the titrator TitroLine®7500 KF has to be put out of

operation and secured against inadvertent putting to operation. In this case please switch the titrator TitroLine®

7500 KF off, pull plug of the mains cable out of the mains socket, and remove the titrator TitroLine®7500 KF

from the place of work.

Examples for the assumption that a safe operation is no longer possible,

the package is damaged,

the titrator TitroLine®7500 KF shows visible damages,

titrator TitroLine®7500 KF does not function properly,

liquid has penetrated into the casing.

The titrator TitroLine®7500 KF must not be stored or operated in humid rooms.

For reasons of safety, the titrator TitroLine®7500 KF must only be used for the range of application described

in the present operating instructions.

In the case of deviations from the intended proper use of the device, it is up to the user to evaluate the

occurring risks.

!

The relevant regulations regarding the handling of the substances used have to be observed: The

Decree on Hazardous Matters, the Chemicals Act, and the rules and information of the chemicals trade. It

has to be ensured on the side of the user that the persons entrusted with the use of the titrator TitroLine®

7500 KF are experts in the handling of substances used in the environment and in titrator TitroLine®7500 KF

or that they are supervised by specialised persons, respectively.

During all work with titration solutions:

!

Please wear protective glasses!

!

The titrator TitroLine®7500 KF is equipped with integrated circuits (EPROMs). X rays or other high energy

radiation may penetrate through the device’s casing and delete the program.

For working with liquids, not beeing common titration solvents, especially the chemical resistance of the

construction materials of the titrator TitroLine®7500 KF have to be considered (please also refer to chapter

1.1).

For the use of liquids with high vapour pressure or (mixture of) substances not being mentioned in chapter 1.1

as allowed substances, the safe and proper operation of the titrator TitroLine®7500 KF has to be guaranteed

by the user.

When the piston moves upwards within the cylinder, a microfilm of dosing liquid or titration solution will always

remain adhered to the inner wall of the cylinder, but this has no influence on the dosing accuracy. This small

residue of liquid, however, may evaporate and thus penetrate into the zone underneath the piston, and if non-

admitted liquids are being used, the materials of the titrator TitroLine®7500 KF may be dissolved or corroded

(please refer also to chapter 8 “Maintenance and Care of the titrator TitroLine®7500 KF”).

80 Chapter 2. Unpacking and First Operation

2 Unpacking and First Operation

2.1 Unpacking

The titrator itself as well as all related accessory and peripheral parts have been carefully checked at the factory

to ensure their correct function and size. The TitroLine®7500 KF modules consists of:

•TitroLine®7500 basic unit

•An interchangeable dosing unit WA 05, WA 10 or WA 20

•The KF titration stand (pump and stirrer) TM 235 KF including waste (1 L clear bottle), solvent (1 L amber

bottle) and moisture bottle (100 ml) with all tubes.

•Titration vessel TZ 1770 including titration tip

•KF starter kit TZ 1789 with molecular sieve, glass wool and a set of syringes with needles.

•Electrode KF 1100

Please ensure that the small accessories are also removed in full from the packaging. For the scope of delivery,

please refer to the enclosed parts lists.

Fig. 1

2.2 Installation and Connection of the TM 235 KF titration stand and titration vessel

The titrator TitroLine®7500 KF and the TM 235 KF may be placed on any flat surface.

As a rule, the TM 235 KF titration stand is arranged to the right of the titrator.

The pump/stirrer is connected to the 12V out-socket at the rear panel of the TitroLine®7500 KF using the TZ

1577 connection cable (scope of delivery of the basic device) (cp. ‘Back panel’ illustration, chapter 2.4).

The stand rod (scope of delivery of the basic device) is screwed into the thread of the TM 235 KF.

The titration vessel TZ 1770 is mounted at the stand rod. Please take care that the metal clamp is adjusted as

shown in the attached photo:

81

Chapter 2. Unpacking and First Operation

Fig. 2

Put all three white inner plastic adapters at the waste, solvent and moisture bottle.

Fill the moisture bottle with molecular sieve.

Connect the PVC and PTFE plastic tubes as shown in the next pictures.

The PVC tubes are connected to the connectors at the back side of the TM 235 KF. The long PVC tube is used

for the connection of the waste bottle. The two shorter PVC ones are used to connect the moisture bottle and the

solvent bottle.

Fig. 3

82 Chapter 2. Unpacking and First Operation

The moisture bottle is connected to the right connector (view from above) of the TM 235 KF. The waste (clear)

bottle is connected to the left connector.

Fig. 4

The PTFE tube from the clear waste bottle is adjusted to the ground (tube 1) of the titration vessel. The PTFE

tube from the solvent bottle (tube 2) is adjusted as shown in the next two pictures:

Fig. 5

83

Chapter 2. Unpacking and First Operation

Fig. 6

The burette tip is placed into the left NS 14 opening and connected to the valve of the interchangeable unit.

Put first some glass wool and then molecular sieve in the plastic moisture tube. Place it to the other NS opening

as shown in the next picture.

Fig. 7

The electrode KF 1100 is connected to the µA input.

The keyboard is connected to one of the USB –A ports.

84 Chapter 2. Unpacking and First Operation

2.3 Connecting the Titrator - Combination with Accessories and Additional Devices

2.3.1 Back panel of the titrator TitroLine®7500 KF

Fig. 8

2.3.2 Connection ports of the TitroLine®7500 KF

The TitroLine® 7500 KF is equipped with the following connections:

1) µA measurement input for the connection of double platinum electrodes (KF 1100 or Pt 1200, Pt 1400)

2) USB-B interface for connection to a PC

3) On/Off switch

4) Two USB-A (“Master“) interfaces for connecting USB devices such as a keyboard, printer, manual control

unit, USB memory device etc.

5) ”in“: Connection of the external power pack

6) “out“: Connection of the TM 235 KF titration stand or TM 235 magnetic stirrer

7) Two RS232 ports, 4-channel (Mini-DIN):

RS1 for connection to the PC

RS2 for connection of a weighing balance and other devices from SI Analytics (burettes a.s.o.)

2.3.3 Connecting a printer

Printers with a USB interface are to be connected to one of the two USB-A interfaces. These printers have to

feature HP PCL emulation (3, 3GUI, 3 enhanced, 5, 5e). So-called GDI printers cannot be used!

Alternatively the thermo-compact printer Seiko S445 can be connected.

2.3.4 Connecting a USB device (manual controller, keyboard, memory device, hub)

The following USB devices can be connected to the USB-A interfaces:

•PC-keyboard

•TZ 3880 manual controller (in the following: ”mouse“)

•Printer

•USB storage devices, e.g. USB sticks

•USB hub

•USB barcode scanners

1

2

3

4

5

6

7

85

Chapter 2. Unpacking and First Operation

2.3.5 Connection of analytical balances

Analytical balances are to be connected to the RS232-2 using an appropriate cable

2.4 Setting the Language of the Country

The ex-factory default language setting is English. When the piston burette is switched on, the main menu will

appear once the boot sequence is completed:

Fig. 8

Using <SYS/<F7> or <MODE>, followed by <System settings> you navigate to the system settings. The very first

menu is to be used for setting the language of the country:

Fig. 9

Use <ENTER>/<OK> to call the menu. Select the national language using the <↑↓> arrow keys, confirm it with

<ENTER>/<OK>:

Fig. 10

The selected language will appear immediately. Pressing the <ESC> key twice will return the user to the main

menu.

86 Chapter 2. Unpacking and First Operation

2.5 Interchangeable unit WA

Fig. 11

1) TZ 3871 - suction hose

2) TZ 3872 - connection hose

3) TZ 3873 - dosing hose without dosing tip and holding bracket;

TZ 3874 - dosing hose with dosing tip and holding bracket

4) TZ 3801 - valve cover lid

5) TZ 3000 - 3/2-way valve

6) TZ 2003 - drying tube

7) TZ 3802 - threaded cap with borehole GL 45, incl. adapter with 2 openings for drying tube and suction

hose

8) TZ 3803 - 1 litre reagent bottle, brown

9) TZ 3900 - UV protection, blue transparent

10) TZ 3875 - shaft for titration tip and

TZ 3356 - titration tip unit, blue or micro titration tip white TZ 3285, adapter TZ 1525

11) TZ 1507 - plastic drip-down tubule

2.5.1 Installing the interchangeable unit

Fig. 11 shows a completely assembled interchangeable unit.

•Remove the valve with the attached hoses from the pack, and then push it on the valve support until it

snaps in position.

•Slip on the valve cover lid on the valve as is shown in the illustration.

•Insert the TZ 3872 connection hose in the threaded hole provided in the burette cylinder, and then tighten

it by hand.

•Insert the TZ 3871 suction hose into the threaded opening of the GL 45 or S 40 adapters, and then

tighten it manually.

•Remove the standard dosing hose TZ 3874 from the valve and connect the dosing hose including from

the KF titration vessel TZ 1770

6

3

1

2

4

5

7

8

9

11

87

Chapter 2. Unpacking and First Operation

2.6 Positioning and Replacing an Interchangeable Unit

The base unit comes with an RFID reader, and all the interchangeable units are equipped with an RFID

transponder. This transponder can be used to store the following information:

•Unit size (cannot be changed)

•Unit ID (cannot be changed)

•Reagent name (default: blank)

•Concentration (default: 1.000000)

•Concentration determined on: (Date)

•To be used until: (Date)

•Opened/Produced on: (Date)

•Test according to ISO 8655: (Date)

•Charge description: (default: no charge)

•Last modification: (Date)

Each time an interchangeable unit is pushed onto the base unit, the data is automatically read out of the

transponder.

2.6.1 Placing an interchangeable unit

The interchangeable unit is to be placed on the device unit as is shown in fig. 12 a-c; subsequently, it is to be

pushed downwards until the black button latches on the left side.

Fig. 12.a

Fig. 12.b

88 Chapter 2. Unpacking and First Operation

Fig. 12.c

2.6.2 Removing an interchangeable unit

Removing the interchangeable unit is done in reverse order:

•Depress the black button on the left, and then pull the interchangeable unit forward as is shown in fig. 12

c – 12 a.

!

Please note: Removing the interchangeable unit is only possible as long as the piston is in the lower

position (zero position). Possibly, it may be necessary to press the <FILL> key first.

!

2.6.3 Programming the titration unit

The data from the RFID transponder of the interchangeable unit will be read immediately (fig. 13).

Fig. 13

Following the reading operation, the input menu for the input of the reagents will be shown for approx. 10

seconds (fig. 14). The size of the interchangeable unit is displayed on the left side of the display (here 10 ml).

Fig. 14

89

Chapter 2. Unpacking and First Operation

When used for the first time, it is recommended to enter here at least the name of the reagent being used. To do

so, confirm the “Reagent“selection with <ENTER>, then type the name and possibly the concentration (fig. 12).

Fig. 15

Press <OK>/<ENTER> to confirm (fig. 15). Following the optional input of additional parameter, press <ESC> to

leave the reagents menu (fig. 16). The approximate concentration of the KF titrant (e.g. 5 or 2) should be entered

under concentration. Thereby the drift in µg/min can be calculated in the right dimensions.

Fig. 16

You will be prompted for a confirmation of the values (fig. 17):

Fig. 17

If you selected <Yes>, the values will be written into the interchangeable unit. You can see this from a message

in red colour displayed at the bottom. Upon completion, the left bottom corner of the display will show the new

name of the reagent (fig. 18). In the present case this is Titrant 5.

Table of contents

Other SI Analytics Laboratory Equipment manuals

Popular Laboratory Equipment manuals by other brands

Cascade Sciences

Cascade Sciences CVO-2-HT Installation and operation manual

Selecta

Selecta ULTRASONS-H manual

Keysight

Keysight PV8900 Series Operating and service guide

Upvel

Upvel UP-103I Quick installation guide

V&P Scientific

V&P Scientific SpinVessel VP 418SV2-2-50CB-CC operating instructions

Thermo Scientific

Thermo Scientific Antaris EX manual