Roadmaster 766 User manual

Installation Instructions

Remote Battery Disconnect

part number 766

ROADMASTER, Inc. 6110 NE 127th Ave. Vancouver, WA 98682 800-669-9690 Fax: 360-735-9300 www.roadmasterinc.com

All specifications are subject to change without notice.

Note: Do not use this product on vehicles with diesel

engines, as they draw too much current and will cause non-

warranty failure of the solenoid — use the 767 Manual Battery

Disconnect instead.

CAUTION

Not for use with all vehicles. Intended only for use on

vehicles whose batteries must be disconnected for towing,

as per the owner’s manual.

Failure to verify the safety of disconnecting the battery

cables or failure to follow the owner’s manual instructions

for towing may cause non-warranty damage to the vehicle’s

components.

It is the owner’s responsibility to make certain that the

battery cable can be safely disconnected for towing, and

that all instructions in the vehicle owner’s manual regard-

ing towing are followed.

CAUTION

The Remote Battery Disconnect is a convenient way to

disconnect the vehicle’s battery; however, disconnecting

a vehicle’s battery will affect the vehicle’s electronics —

• You may need to reset dashboard presets, such as

radio presets or seat and brake pedal presets.

• You may need to re-wire aftermarket electrical acces-

sories, such as supplemental braking systems.

• Vehicles equipped with a Roadmaster braking sys-

tem will require a brake light switch connected to the

positive post on the vehicle’s battery. Otherwise, the

motorhome monitor will not indicate braking activity.

Severe damage to the towed vehicle’s brakes may result.

continued on next page

Time Tested • Time Proven

IMPORTANT NOTICE!

Safety Definitions

These instructions contain information that is very important to know and understand. This information is provided for

safety and to prevent equipment problems. To help recognize this information, observe the following symbols:

WARNING indicates a potentially hazardous situation

which, if not avoided, could result in property damage,

serious personal injury, or even death.

CAUTION indicates a potentially hazardous situation

which, if not avoided, may result in property damage,

or minor or moderate personal injury.

CAUTION

CAUTION used without the safety alert symbol in-

dicates a potentially hazardous situation which, if not

avoided, may result in property damage.

NOTE

Refers to important information and is placed in italic type.

It is recommended that you take special notice of these

items.

8 55 476 -11 0 6. 23

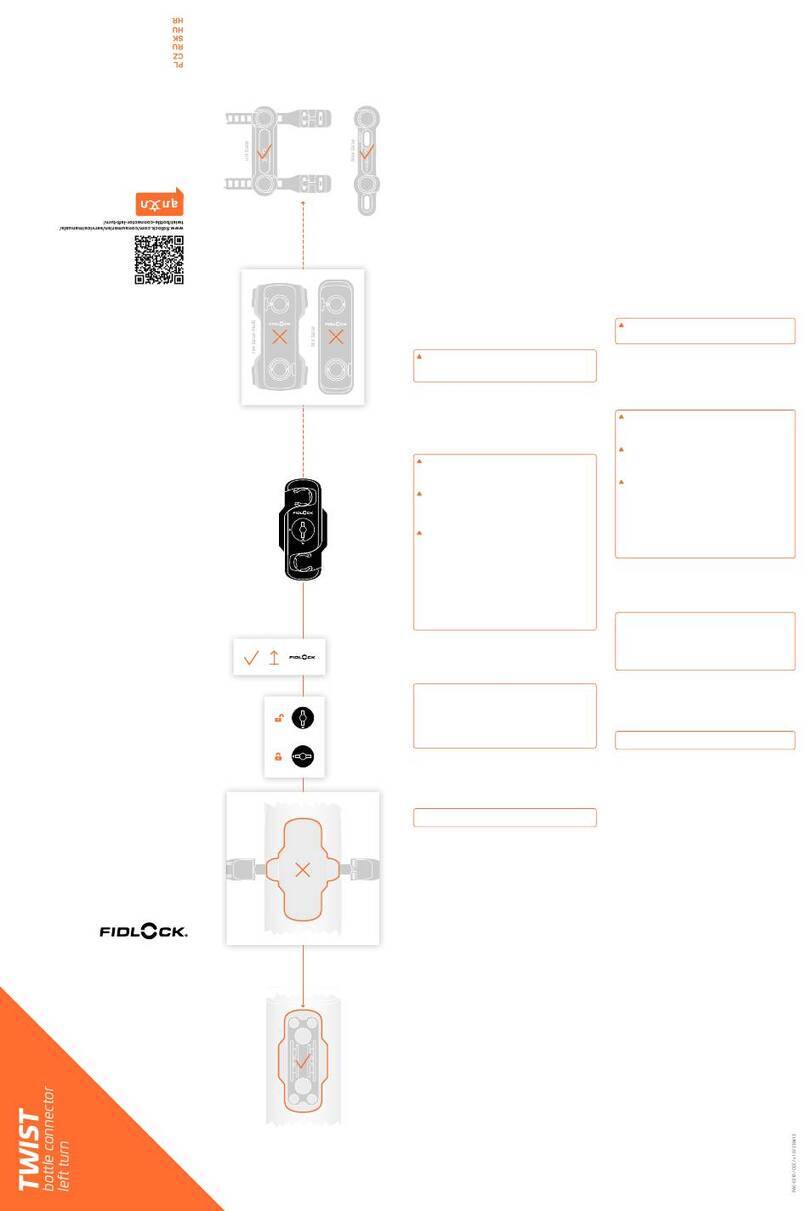

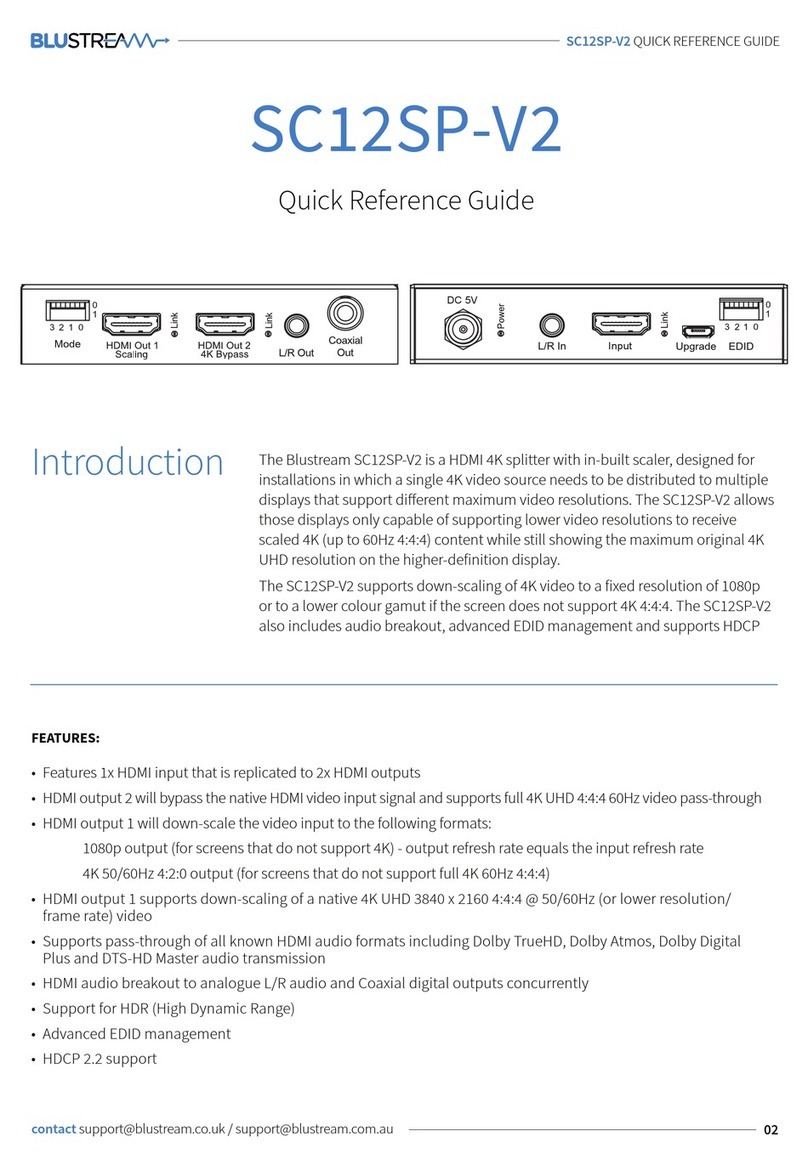

Remote Battery Disconnect wiring

Not to scale; please see the instructions

for complete information.

4. Disconnect the positive cable from the battery. Attach the

cable labeled “BATTERY POST” to the positive terminal on the

battery.

Note: If a stop light switch or other accessory must be

energized while towing, make sure to connect the accessory

to the positive side of the battery. DO NOT CONNECT ANY

ACCESSORIES TO THE SOLENOID.

5. Slide the provided section of shrink tubing (Figure 2) over

the cable labeled “POSITIVE CABLE.” Then attach this cable

to the positive cable you just removed from the battery: align the

two ends of the cables so they match. Connect the two cables

together as shown in Figure 2.

Note: It is imperative that the star washers are positioned

as shown.

Note: If the end of the vehicle’s battery cable has a diameter

smaller than 5/16", use a 5/16" drill to enlarge it.

Figure 1

continued from preceding page

Installation

1. Follow the vehicle manufacturer’s instructions to disconnect

the negative battery cable.

2. Choose a mounting location for the solenoid (Figure 1)

inside the engine compartment. This mounting location must

meet the following conditions:

• The mounting point must have a surface of sufficient

strength to hold the solenoid firmly in place.

• There are two cables attached to the solenoid. The end

of the cable labeled “BATTERY POST” must be within reach

of the vehicle’s positive battery post.

• The solenoid will be attached with the two included bolts

and nuts. Make certain that the bolts will not damage any com-

ponents on the other side.

• The solenoid must be grounded by using the provided

white ground wire. Make certain a good ground is available

within two feet of the solenoid.

• The solenoid must be mounted in a location where it is

protected from direct road spray.

• The black tip of the solenoid MUST be pointed downward.

3. Position the solenoid at the mounting location you have

chosen. Drill two ¼" holes for the bolts through the pre-drilled

holes (Figure 1) and attach the solenoid.

Also attach the white ground wire to any good chassis

ground with the included ring terminal and self-tapping screw.

If the cables must be rotated on the solenoid post, then

FOLLOW THESE INSTRUCTIONS CAREFULLY! Put a

wrench on the inside nut and use it to hold the inside nut in

position. Now, loosen the outside nut with a wrench, reposi-

tion the cable and retighten while carefully holding the inside

nut in position. Rotating the inside nut WILL CAUSE NON-

WARRANTY FAILURE of the solenoid.

CAUTION

You WILL destroy the solenoid unless you hold the in-

side nut stationary and ONLY rotate the outside nut. This

damage will not be covered by warranty.

Figure 3

Figure 2

6. Slide the shrink tubing

over the connection as shown

in Figure 3. Be certain no metal

is exposed. Seal the shrink tub-

ing with a heat gun or similar

device.

CAUTION

Make certain that no metal

is exposed on either side of

the shrink tubing. If metal is

exposed, a short circuit may

cause an electrical fire, which

may result in severe damage

to the vehicle.

7. Attach the provided protective loom to both cables.

CAUTION

In order to prevent damage from a short circuit,

cover both cables with the included protective loom. If the

cables are not covered, a short circuit may cause an electri-

cal fire, which may result in severe damage to the vehicle.

Note: Roadmaster recommends using an anti-corrosion

battery terminal spray on all exposed connections.

continued on next page

continued from preceding page

8. Look for a mounting surface for the switch (Figure 4) inside

the passenger compartment. This mounting surface must meet

the following conditions:

• Choose a location where the switch will not be turned on or

off accidentally, but where it will be accessible.

• There must be enough space for the switch and pigtail.

• You will remove the mounting nut to install the switch. You

must be able to reach behind the switch to reattach it.

• There must not be any metal, wiring or electrical compo-

nents directly behind the mounting location.

• Since the harness is 10 feet long, find a location within 10

feet of the solenoid.

9. Route the two-wire harness from the solenoid to the loca-

tion you have chosen for the switch. Cut the harness to length.

Then, using the schematic on page 1 as a guide, attach the

wiring harness to the pigtail using the two red butt connectors.

Route the wiring harness to avoid moving parts, sharp

edges, the fuel lines or hot components such as the engine

or exhaust system.

Wiring exposed by moving parts, sharp edges or hot

components may cause a short circuit, which can result in

damage to the vehicle’s electrical system as well as other,

consequential damage.

Wiring which is attached in close proximity to the fuel

lines may ignite the fuel.

Failure to follow these instructions may cause property

damage, personal injury or even death.

10. Remove the mounting nut from the switch.

11. Drill a 5/8" hole at the mounting location you have chosen.

With the mounting nut on the underside, route the two-wire har-

ness through the mounting nut and the hole. Plug the switch

into the pigtail as shown in the schematic on page 1. Secure it

with the mounting nut.

12. Use one or more of the included wire ties, if necessary, to

secure the harness in place.

13. Following the manufacturer’s instructions, reattach the

negative cable to the vehicle’s battery.

14. Insert the 7.5-amp fuse into the fuse holder (Figure 1).

Operating the battery disconnect…

1. Attempt to start the vehicle. If the vehicle starts, the battery

disconnect is in the “drive” mode. If it does not start, the battery

disconnect is in the “tow” mode.

Press the button to switch between “drive” and “tow.”

2. To tow the vehicle: follow the owner's manual instructions

to tow. At the point the manual instructs you to disconnect the

battery, push the button to “tow.”

To drive the vehicle: follow the owner's manual instructions

to reconnect the battery. At the point the manual instructs you

to reconnect the battery, press the button to “drive.”

Never operate the battery disconnect in any other way

except as instructed above. Pushing the battery disconnect

switch randomly may damage the vehicle's transmission,

electronics or other systems. Other consequential, non-

warranty damage may also occur.

If the vehicle is being driven, pushing the battery discon-

nect switch may cause a loss of vehicular control, resulting

in property damage, personal injury or even death.

To attach aftermarket accessories…

Attach aftermarket accessories, such as the BrakeMaster

break away switch, to the positive post on the vehicle's battery.

OWNER MUST READ AND FOLLOW THE

BELOW INSTRUCTIONS BEFORE

OPERATING THE BATTERY DISCONNECT

1. IMPORTANT! Never disconnect the battery while the

engine is running. This could result in the illumination of a

'Check Engine Light,' necessitating a dealership to reset it.

2. Do not turn the switch ON or OFF within a 30 second

time period. Many newer vehicles have diagnostic tests that

must be run during an initial start-up. If interrupted, this could

cause the system to malfunction.

3. When disconnecting the battery for dinghy towing, follow

the instructions in the vehicle owner's manual step by step.

At the point in which the manual instructs you to disconnect

the battery, turn the battery switch to the OFF position. When

the owner's manual directs you to reconnect the battery, only

then should you turn the switch to ON. Connecting or discon-

necting the battery out of the proper sequence can result in

significant, non-warranty damage to the vehicle's transmis-

sion or other important systems.

Failure to follow the procedures above may result in

significant, non-warranty damage to the vehicle.

CAUTION — DON'T LOCK YOURSELF

OUT OF THE VEHICLE!

If your vehicle has keyless entry or has other powered

features that could inadvertantly lock you out without

access once the battery has been disconnected, utilize a

manual key option or roll down the window first.

Refer to your owner's manual for information on how to

handle a dead battery situation, as this will be similar.

ROADMASTER manufactures a wide variety of components designed for vehicle-specic towing applications.

More components are available at tmaster.roadmasterinc.com, or call Technical Support at 800-669-9690.

Vehicle-specific components

— Advertisement —

Charge Line Kits

Brake light switches

Why do you need a brake light

switch? Brake light switches are

necessary only if you’re install-

ing a supplemental braking sys-

tem monitor, and the vehicle’s

OEM brake light switch doesn’t

work when the vehicle is in ‘tow’

mode.

This switch is only activated when the brake pedal is de-

pressed. No other manufacturer provides brake light switch-

es with this level of specicity. Why? When you know when

the towed vehicle’s brake pedal is depressed and released,

you know if the supplemental braking system is positioned

properly and working as it should.

• Works on any vehicle with a brake pedal.

• Works with any supplemental braking system that

moves the brake pedal.

• Works with any motorhome monitor

751000 Universal brake light switch

• Truly universal — works with all braking

systems that depress the brake pedal.

• Exceptional range and reliability — line-

of-sight transmission conrmed to 1,000

feet; proprietary send/repeat circuitry

conrms each signal at 100% reception.

• Protects the towed vehicle’s brakes —

reports any braking activity to the motorhome monitor; in-

cludes a low-battery alert, extended braking and break-away

alarms, and ve other audio and/or visual alarms and system

status notications.

• 30-minute installation, all at the towed vehicle; simply plug

the motorhome monitor into any 12-volt outlet.

• Automatic operation — activates only when the vehicles are

connected for towing.

Specications — frequency: 923 MHz; voltage: 12V; sleep

current: 30mA

9530 Universal supplemental braking system monitor

Wireless supplemental

braking system monitor

How about if you never had to spend another minute with your face on the oor

mat, gazing up into a black void, hunting for a miniscule piece of plastic playing hide

and seek? You don’t have to.

FuseMaster

76511

• You've spent enough time with your face on the oor mat.

• Adventures in electricity can be, well, electrifying.

• Chiropractors are expensive.

• Engine lubricant is not a fashion accessory.

FuseMaster eliminates the necessity of having to remove a fuse for towing, then hav-

ing to reinsert it for driving. After it’s installed, you simply ip a switch to accomplish

the same task.

76511 15-amp fuseholder 76512 Two 7.5-amp fuseholders

76514 Two 15-amp fuseholders 76515 30-amp fuseholder

76517 50-amp fuseholder

Many current vehicles have features that slowly drain the battery

while in tow mode.

These simple, easy-to-install kits help maintain the vehicle’s battery

charge while in tow, supplying up to 15 amps of current. They also

extend battery life by providing a constant maintenance charge (with-

out overcharging the battery) during towing. Installation hardware in-

cluded.

• Heavy-duty 14-gauge wire (156-25) or 12-gauge (156-75) wire

• Includes a thermal circuit breaker — no need to hunt down a

blown fuse

156-25 Towed vehicle charge line kit

156-75 Motorhome charge line kit

156-75

Popular Cables And Connectors manuals by other brands

Deutsch

Deutsch DT Series Technical manual

The Siemon Company

The Siemon Company MT-RJ Specifications

Xantrex

Xantrex power Inverter Stacking installation guide

WISKA

WISKA VaritainPushIn Rack 2x/x2 operating instructions

Campbell

Campbell 10164-L instruction manual

REUTLINGER

REUTLINGER 66 Original instruction manual

Raychem

Raychem TRACETEK TT3000 SERIES installation instructions

SAMCHULLY

SAMCHULLY BT Series instruction manual

Thetford

Thetford Aqua-Magic V quick start guide

Staubli

Staubli PV-ADB4-EVO 2 UR Series Assembly instructions

Bluestream

Bluestream SC12SP-V2 Quick reference guide

Volkswagen

Volkswagen VAS 5581/13 operating manual