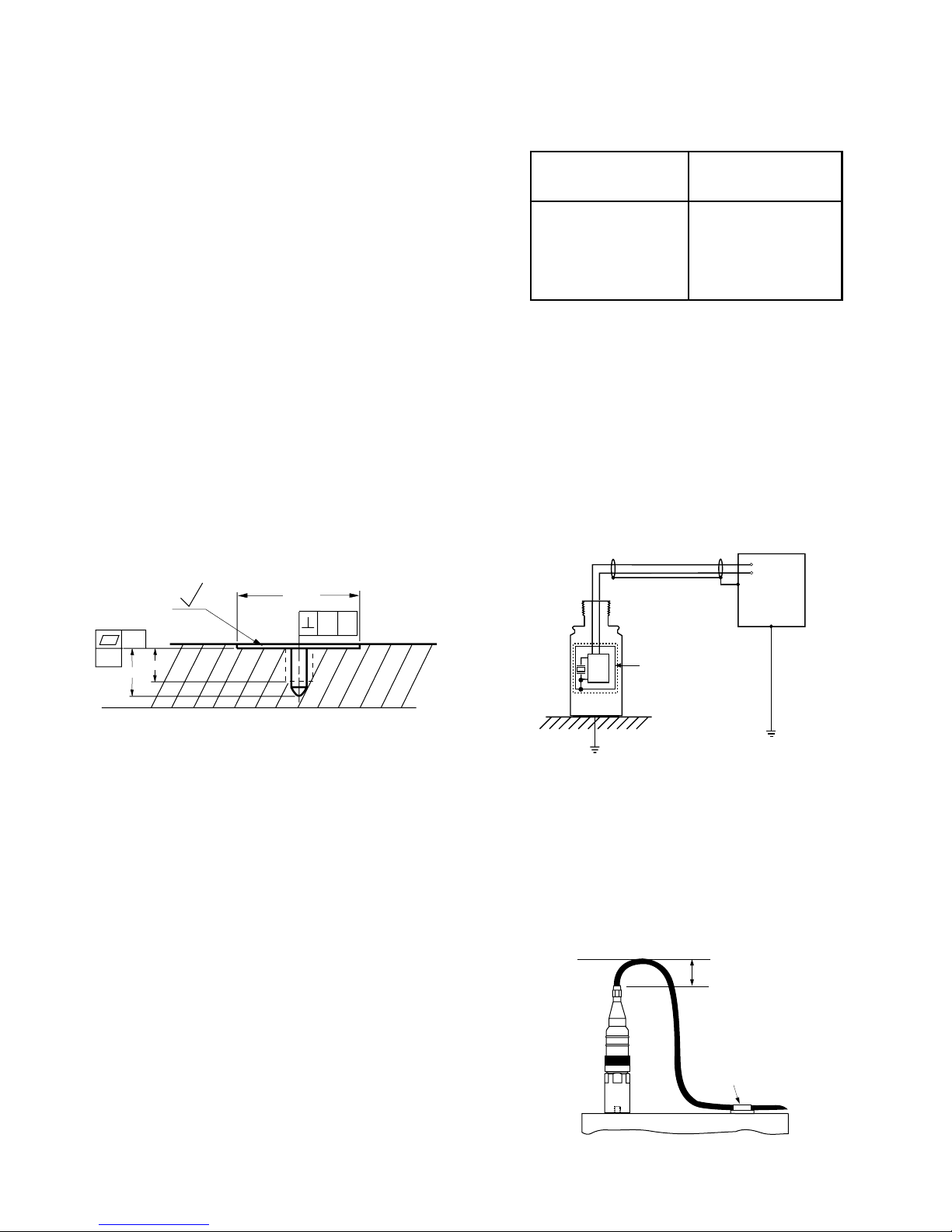

Mounting Instructions

The mounting point on the structure should be faced to a

diameter of 1.25 inches. For measurements involving

frequencies above 1 kHz, the surface should be flat within 1

mil and have surface texture no greater than 32 microinches.

The tapped hole must be perpendicular to the mounting

surface and at least two threads deeper than the stud. This will

prevent a gap between the sensor and the mounting surface–

producing optimum frequency response. (see Figure 1).

Proper screw torque on the mounting stud is also required.

Under-torquing the sensor reduces the stiffness of the

coupling. Over-torquing can cause permanent damage to the

sensor. It is recommended that 1/4-28 stud be torqued to a

maximum value of 30 inch-pounds.

Before stud mounting the sensor, a coupling fluid should be

applied to the mating surfaces. The coupling fluid protects the

mounting surface and optimizes the frequency response by

increasing the coupling stiffness. Suggested coupling fluids

are machine oil or vacuum grease. It is recommended that a

thread adhesive such as Loctite 222 be used.

Cable Routing and Electromagnetic Interference

Walkie-talkies, power lines, or even electrical sparks may

cause signal interference. The following guidelines will

eliminate many measurement errors due to electromagnetic

radiation and electrostatic discharge (ESD).

Assure that high quality, well shielded cables are used. If

cable splices are made, complete shielding must be

maintained.

Proper cable routing is imperative. Never run sensor cable

alongside AC power lines; cables must cross AC power lines

at right angles. Where possible, provide a separate grounded

conduit to enclose the sensor cable. In addition, route the

cable away from radio transmission equipment, motors/

generators, and transformers. Finally, avoid routing the cable

through areas prone to ESD. Even though Robertshaw

sensors are protected against ESD failure, temporary

distortion signals may appear at the output.

Cable Grounding and Ground Loops

In order to provide proper shielding and prevent ground

loops, cable grounding should be carefully considered.

For sensors using two conductor/shielded cable, the power is

carried on one lead and the return on the other. The cable

shield serves to protect the signal from ESD and

electromagnetic interference (EMI). The shield should be

grounded at only one point. Figure 2 shows a typical cable

connection scheme.

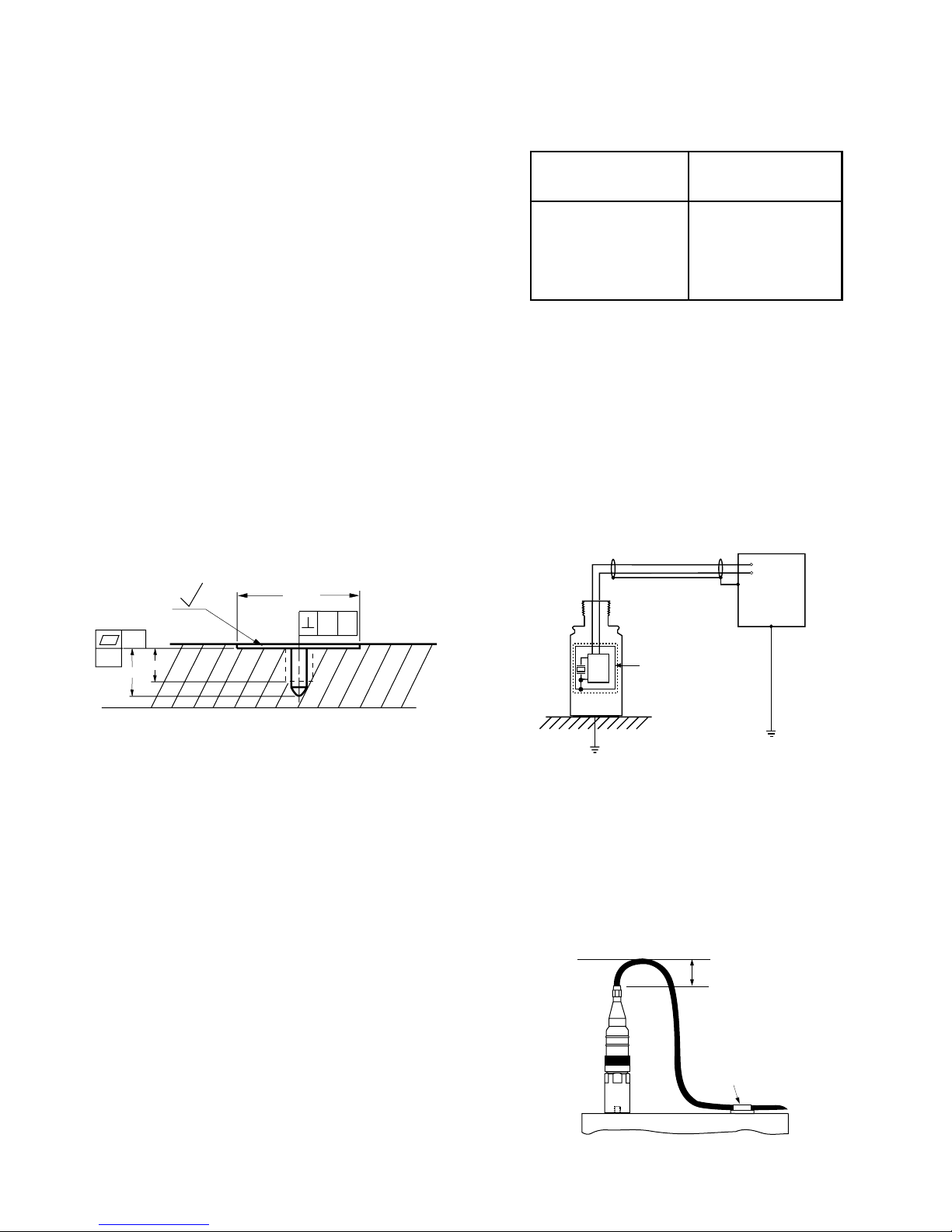

Cable Anchoring

After mounting the sensor, the cable should be anchored to

reduce stress at the cable terminations. When securing the

cable, leave enough slack to allow free movement of the

sensor. Figure 3 shows a recommended cable anchoring

technique.

Cable

Clamp

Machine Surface

Figure 3: Cable Anchoring

Allow 2 inches

minimum bend

radius

Table 1: Cable versus Cable Length

Figure 2: Multiconductor/Shield Configuration

Internal Shield

Isolated from Housing

Readout

Equipment

+

–

Electronics

Part Number NEMA 4X

Cable Length

086568A0016 16 Ft.

086568A0032 32 Ft.

086568A0064 64 Ft.

086568A0112 112 Ft.

Note: IP68 cable available by special order.

.004 A

.001

—A—

1.25" min.

.25

.35

32

Figure 1: Stud Mounting: Surface Preparation

Surface

Facing