5

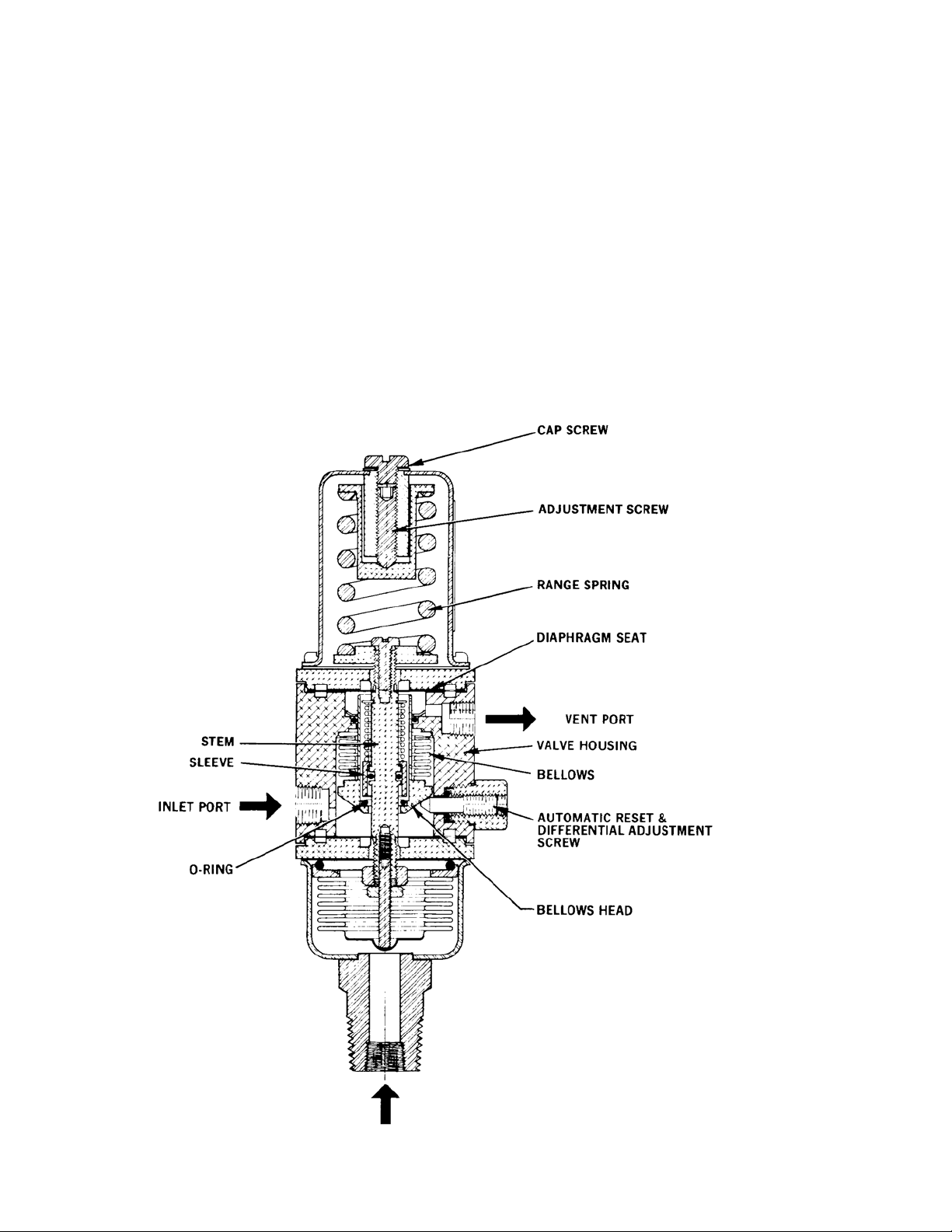

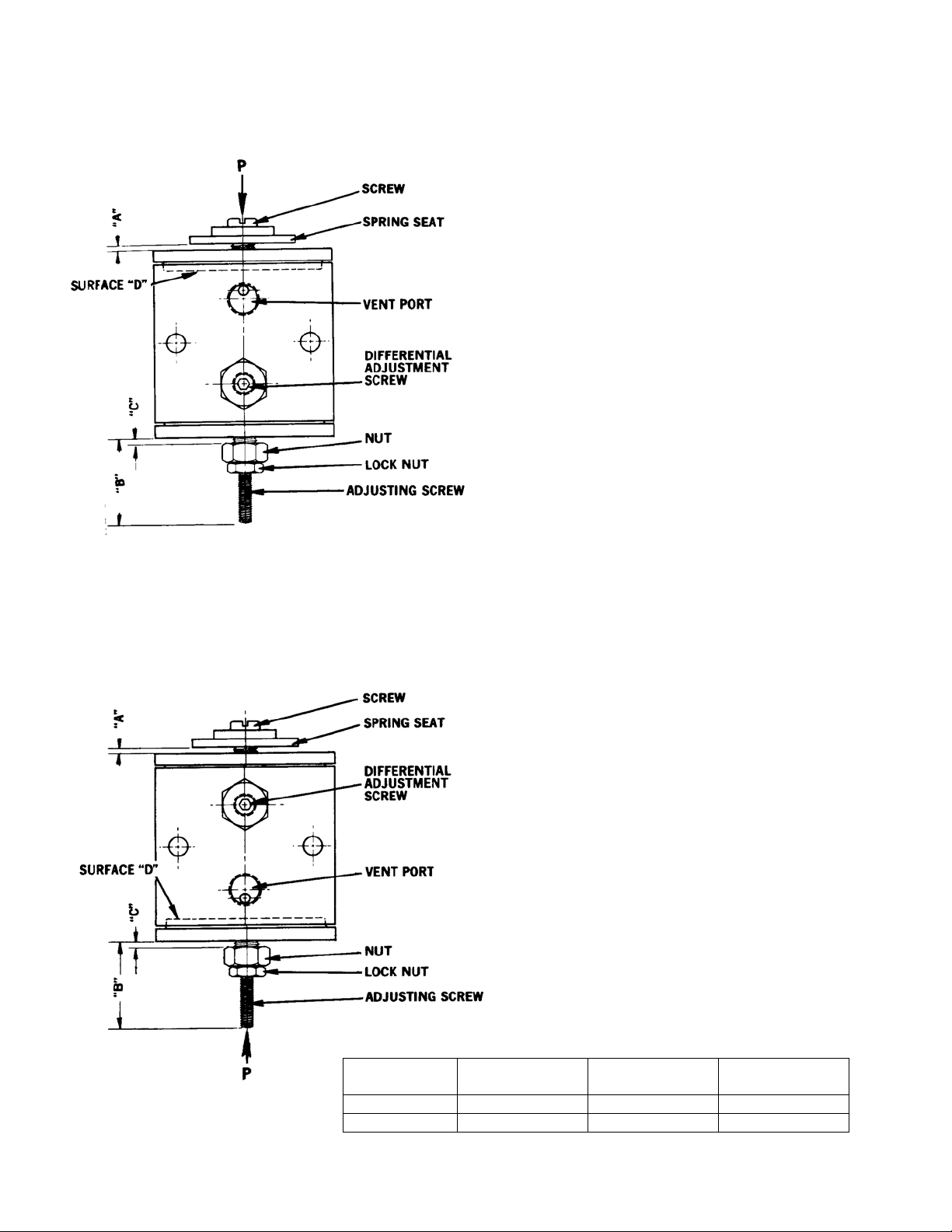

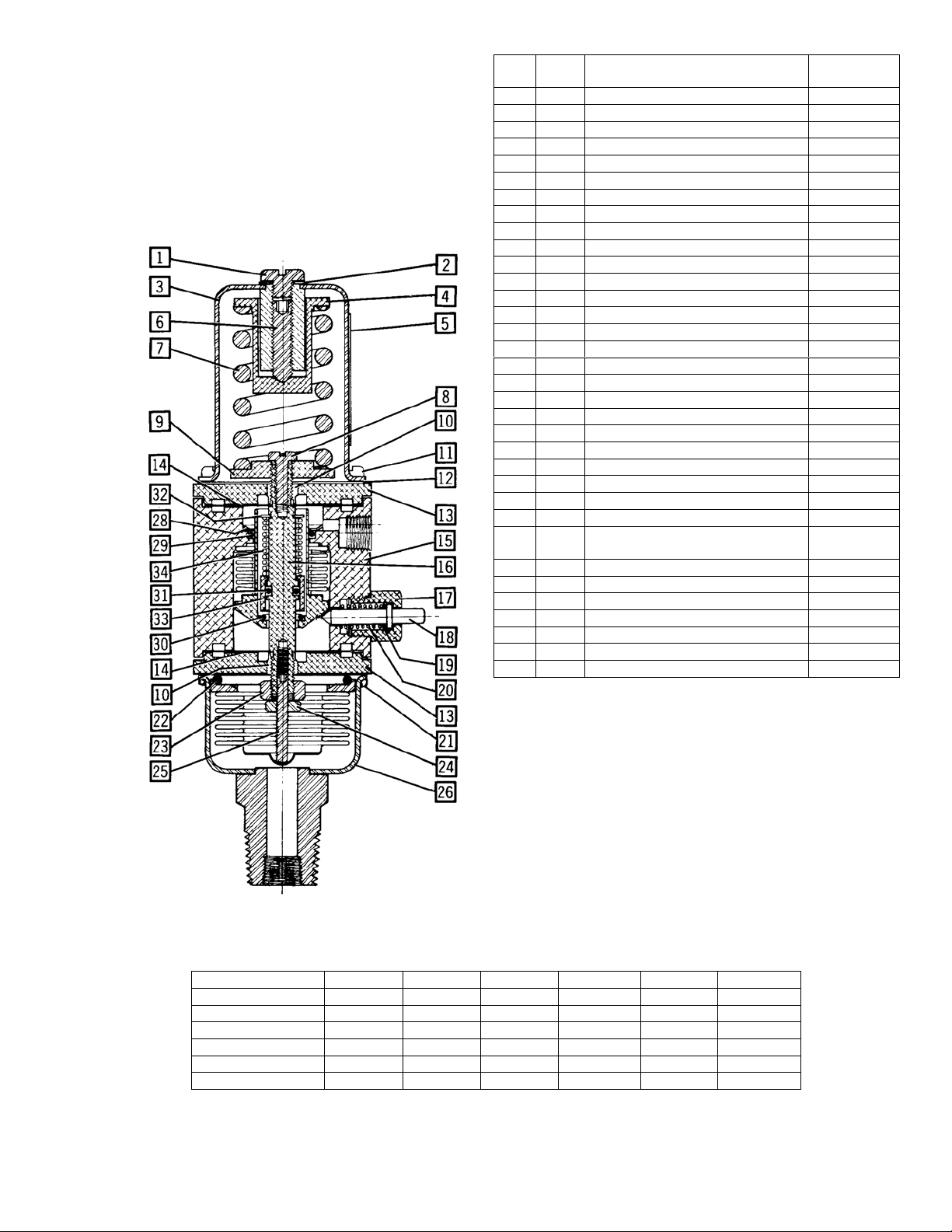

MAINTENANCE - See Figure 4

WARNING: USE CARE WHEN

DISASSEMBLING, SPRING FORCES PRESENT.

CAUTION: Do not subject O-rings, gasket, or

diaphragms to cleaning fluid, acetone, or any

halogenated hydrocarbons such as degrease liquids,

etc. Clean only with a soft, dry cloth. Metal parts can

be cleaned with a suitable solvent, and then dried

thoroughly before reassembly.

NOTE: Threads on screw (detail 8), diaphragm clamps,

spring housing screws (detail 11), bushing, and pressure

assembly screws (detail 21 should have Loctite Sealant

"H" or equivalent applied before reassembly. See * below.

Pressure Assembly

Remove four screws (detail 21) and O-ring (detail 22).

Replace defective pressure assembly, reassemble* and

recalibrate.

Bushing

To replace bushing O-ring (detail 19), remove bushing

and replace defective O-ring. Reassemble* unit and replace

in housing assembly. Recalibrate differential if unit is an

automatic reset model.

Housing Assembly and Stem

Remove cap screw and turn adjustment screw (detail 6)

counterclockwise to bring the range spring to free length.

Remove the four screws (detail 11), spring housing, spring

seat (detail 4), range spring and gasket. Remove the

pressure assembly as previously described. As applicable,

proceed with the Direct- or Reverse-Acting instructions

below.

Direct-Acting

Prevent the spring seat (detail 9) from rotating and back

the lock nut away (counterclockwise) from the nut several

turns. Preventing the spring seat (detail 9) from rotating,

remove the adjusting screw, nut, and lower flange.

Prevent the spring seat (detail 9) from rotating and

remove the exposed diaphragm clamp. Remove the

exposed diaphragm. Remove the stem by pulling the flange

from the valve housing.

To replace O-ring (detail 31) on stem, prevent spring

seat (detail 9) from rotating and remove screw (detail 8).

Prevent stem from rotating and remove spring seat (detail

9) and flange. Proceed with instructions designated Direct-

and Reverse-Acting below.

Reverse-Acting

Prevent the nut from rotating and remove the screw

(detail 8) and spring seat (detail 9). Remove the upper

flange.

Prevent the nut from rotating and remove the exposed

diaphragm clamp. Remove the exposed diaphragm. Remove

the stem by pulling the remaining flange from the valve

housing.

To replace O-ring (detail 31) on stem, prevent the nut

from rotating and back the lock nut away

(counterclockwise) from the nut several turns. Remove the

adjusting screw, nut, and flange. Proceed with instructions

designated Direct and Reverse-Acting below.

Direct- and Reverse-Acting

Remove remaining diaphragm clamp and diaphragm.

Remove retaining ring (detail 32,), spring (detail 34), and

sleeve. Remove defective O-ring (detail 31) and replace.

Reassemble sleeve, spring (detail 34) and retaining ring

(detail 32).

To replace O-ring (detail 29) in valve housing, remove

retaining ring (detail 28) and defective O-ring (detail 29).

Replace O-ring, then retaining ring.

To replace O-ring (detail 30) which seats against the

sleeve, remove the defective O-ring with a knife or other

sharp-pointed tool. Carefully remove any residue and clean

area from where O-ring was removed with a suitable

solvent. Dry thoroughly. Place a few drops of liquid Viton

(Pelmor Laboratories' PLV-2000 or equivalent) on the

seating area just cleaned. Take the replacement O-ring,

remove from it any dust, dirt or foreign matter, and bond it

to its seating area. Allow to cure for one or more hours.

With all O-rings, diaphragms, gaskets and defective

parts replaced, reassemble as follows:

On models with automatic reset, turn differential

adjustment screw into bushing clockwise until small end of

bellows head is even with surface "D" - see Figure 3. (On

models with manual reset, the reset plunger will need to be

held depressed to obtain surface "D" contact as explained

below).

Replace stem, diaphragms, and diaphragm clamps*.

Tighten clamps hand tight. While holding each clamp with

a wrench, tighten approximately 1/4 turn more.

Reassemble* remaining parts as shown in figure 3.

On models with manual reset, depress the reset plunger

to maintain small end of bellows head with surface "D"

contact while obtaining the following dimensions - see

figure 3.

Apply approximately one pound force (4.45 N) by finger

at point "P." Turn spring seat to obtain dimension "A" - see

Table 3. Lock spring seat in place with screw*.

With a gage in place to hold dimension "A," adjust

adjusting screw to dimension "B" and nut to dimension "C"

- see Table 3. Lock both in place with lock nut as shown in

figure 3.

Release reset plunger on manual reset models and turn

differential adjustment screw counterclockwise

approximately 3/4 turn on auto reset models.

Reassemble* remaining parts and recalibrate sensor.

FIELD REVERSAL

To change the sensor from direct- to reverse-acting or

vice versa, remove the spring seat (detail 9), adjusting

screw, and nut from stem. Reset bellows head to surface

"D" as explained in the Housing Assembly and Stem

Maintenance section. Reassemble spring seat (detail 9),

adjusting screw, and nut on appropriate end of stem using

figure 3 as a guide. Reset dimensions "A," "B" and "C" and

reassemble as explained in the Housing Assembly and Stem

Maintenance instructions. Recalibrate sensor when

assembled.