Robinson R-66 Series Lithium-Ion User manual

R66 MAINTENANCE MANUAL

AND INSTRUCTIONS FOR CONTINUED AIRWORTHINESS

RTR 660 VOLUME I

Production Certificate Number 424WE

Type Certificate Number R00015LA

Robinson Helicopter Company Phone: (310) 539-0508

2901 Airport Drive Fax: (310) 539-5198

Torrance, California 90505-6115 Web: www.robinsonheli.com

United States of America

OFFICE HOURS

Monday through Friday, 7:30 a.m. to 4:30 p.m., Pacific Time.

Lunch hour is 11:30 a.m. to 12:30 p.m.

HOLIDAYS

Please visit www.robinsonheli.com for a complete list of holidays and company shutdowns.

CUSTOMER SUPPORT AND SPARES ORDERS

Please visit www.robinsonheli.com for a complete service directory.

Procure parts from any R66 Dealer or Service Center,

or order directly from RHC Customer Service via email, fax, or phone.

PUBLICATIONS

Please visit www.robinsonheli.com to view our publications electronically.

APR 2019 Introduction Page i

SUBSCRIPTION ORDER AND RENEWAL FORMS

Subscription order and renewal forms are located at www.robinsonheli.com.

WARRANTY INFORMATION

Helicopter and parts warranty information is located at www.robinsonheli.com.

Page ii Introduction APR 2019

CHAPTER LIST

Introduction

Chapter 1 General

Chapter 4 Airworthiness Limitations

Chapter 5 Inspections

Chapter 6 Dimensions and Descriptions

Chapter 7 Jacking and Hoisting

Chapter 8 Weight and Balance

Chapter 9 Ground Handling

Chapter 10 Parking and Storage

Chapter 11 Placards and Markings

Chapter 12 Servicing

Chapter 18 Track and Balance

Chapter 20 Standard Practices

Chapter 21 Environment Control

Chapter 22 Autopilot

Chapter 25 Furnishings

Chapter 28 Fuel System

Chapter 29 Hydraulics

Chapter 32 Landing Gear

Chapter 33 Lights

Chapter 52 Doors and Windows

Chapter 53 Fuselage

Chapter 62 Main Rotor

Chapter 63 Main Rotor Drive System

Chapter 64 Tail Rotor

Chapter 65 Tail Rotor Drive System

Chapter 67 Flight Controls

Chapter 71 Powerplant

Chapter 75 Engine Air Systems

Chapter 76 Engine Controls

Chapter 79 Engine Oil System

Chapter 90 Police Version

Chapter 92 E.N.G. Version

Chapter 95 Instrument System

Chapter 96 Electrical System

Chapter 97 Avionics

Chapter 98 Wiring Diagrams

Chapter 99 Special Tools

Chapter 100 Revision Log

JUL 2020 Introduction Page iii

Intentionally Blank

Page iv Introduction JUL 2020

APR 2017 Introduction Page v

TECHNICAL PUBLICATIONS

RECOMMENDED CHANGE REPORT

Please direct recommended changes to RHC Technical Publications via the email address

listed below, by phone, or by submitting a duplicate of this completed form by fax or mail.

Please include or have available the information detailed in this form.

Recommended changes may include but are not limited to general comments, corrections,

omitted information, or clarification of instructions.

Please send recommendations to:

Email: [email protected]

Phone: (310) 539-0508

Fax: (310) 539-5198

Robinson Helicopter Company

Attention: Technical Publications

2901 Airport Drive

Torrance, CA 90505-6115

UNITED STATES

Date: Publication:

Name: Chapter:

Company: Section:

Helicopter Model: Page:

Serial Number: Revision:

Phone:

Email:

COMMENTS:

Intentionally Blank

Page vi Introduction APR 2017

CHAPTER 1

GENERAL

Section Title Page

1-00 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.1

1-10 R66 Maintenance Manual Revisions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.1

1-20 R66 Maintenance Authorization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.2

1-30 Component Maintenance Authorization . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.2

1-40 Maintenance Record . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.2

1-50 Notations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.3

1-55 Maintenance Manual and Illustrated Parts Catalog References . . . . . . . . . . . . 1.3

1-60 Definitions and Abbreviations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.4

1-70 Service Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.4B

1-71 Part Designation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.4B

1-72 Returning Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.4B

1-73 Ordering and Shipping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.4B

1-74 Warranty Claims . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.4B

1-75 Customer Service Directory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.4B

1-80 Assembly Instructions for R66 Helicopter Crated for Export . . . . . . . . . . . . . 1.5

1-90 Helicopter Servicing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.11

1-91 Scheduled Maintenance and Inspections . . . . . . . . . . . . . . . . . . . . . . . . 1.11

1-92 Additional Component Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.12

JUL 2020 Chapter 1 General Page 1.i

Intentionally Blank

Page 1.ii Chapter 1 General JUL 2020

CHAPTER 1

GENERAL

1-00 Introduction

The R66 Maintenance Manual contains instructions necessary for proper maintenance,

servicing, and handling of the R66 helicopter. The R66 Instructions for Continued

Airworthiness (ICA) includes the R66 Maintenance Manual (MM), R66 Illustrated Parts Catalog

(IPC), R66 Service Bulletins (SB), R66 Service Letters (SL), RR300 Series Operation and

Maintenance Manual (OMM), applicable Rolls-Royce technical publications, and applicable

component manufacturer technical publications.

Service Bulletins are issued by Robinson Helicopter Company (RHC), Rolls-Royce, and

component manufacturers. RHC Service Bulletin compliance is mandatory; comply with

other applicable Service Bulletins as directed. RHC technical publications are available

online at www.robinsonheli.com. Rolls-Royce technical publications are available online at

https://fast.aeromanager-online.com.

Kit instructions are issued for field installation of either optional or mandatory (due to

Service Bulletin or parts obsolescence) equipment upgrades, or provisions for upgrades. Kit

instructions issued by RHC either implement approved type design data, or are approved

as type design data.

The R66 Maintenance Manual is formatted in Air Transport Association of America

Specification No. 100 (ATA-100). Style, content, and structure deviates from ATA-100

when necessary for clarity, and for logic of presentation. A list of chapters and a complete

list of contents is located in the Introduction. Chapters are separated by tab dividers and

chapter contents are listed in the chapter front pages.

CAUTION

Always read instructions completely before performing a task.

1-10 R66 Maintenance Manual Revisions

Before using the R66 Maintenance Manual, verify it consists of current effective pages.

The list of effective pages is located in the Revision Log in Chapter 100. When a new

manual is purchased, complete and submit the Subscription Order Form available online at

www.robinsonheli.com. Subscribers receive publication revisions for a two-year period.

Renew subscriptions annually. The revision status for all RHC technical publications is

available online at www.robinsonheli.com.

APR 2019 Chapter 1 General Page 1.1

1-20 R66 Maintenance Authorization

Only appropriately certificated mechanics who have successfully completed an R66

factory-sponsored maintenance course, or are under direct supervision of the above-

stated mechanic, are authorized to perform maintenance, repairs, or inspections on the

R66 helicopter. Annual inspections of U.S.-registered light helicopters must be performed

by holders of an Inspection Authorization (IA) certificate or by repair stations certificated

by the Federal Aviation Administration (FAA). The daily preflight and some preventive

maintenance may be performed by the above-stated mechanics, or by the pilot/owner after

receiving appropriate instruction in accordance with the R66 Pilot’s Operating Handbook

and applicable aviation regulations.

1-30 Component Maintenance Authorization

Only appropriately certificated mechanics who have successfully completed both a factory-

sponsored maintenance course and component maintenance course, and who possess

technical data supplied by RHC, are authorized to perform maintenance specified in the

Component Maintenance Manual (CMM). Component maintenance may only be performed

at an RHC-authorized Service Center that has required special tools.

1-40 Maintenance Record

The Airframe Maintenance Record is available online at www.robinsonheli.com.

Airframe Maintenance Record blank PDF forms may be used for R22-series, R44-series,

and R66 Turbine helicopters. Component Record blank PDF forms may be used for life-

limited or TBO components. Blank paper copies are available for purchase (P/N R8478

Airframe Maintenance Record and P/N R8479 Component Record [pack of 20]).

A Component Record is a maintenance record of the removals, installations, or maintenance

performed on a life-limited or TBO component. When a life-limited or TBO component is

installed in the helicopter, the Component Record card is inserted in the Airframe Maintenance

Record. When a life-limited or TBO component is removed from the helicopter, remove the

Component Record card and keep the card with the Component. Major assemblies may

contain one or more life-limited or TBO component.

RHC encourages operators to utilize Component Record cards to assist in tracking time on

interchangeable parts since service lives may be different between models.

RHC does not create Component Record cards for spares, however, operators may create

their own.

RHC’s Repair Station does not require a Component Record card in order to perform work

on a component, unlike a Component/Return Authorization form.

RHC recommends using a toner-based laser, or a pigment-based inkjet, color printer and 65

lb white (96 bright) premium card stock for Maintenance Record or Component Record card

production. Maintenance Record binders and tab sets are available separately (P/N R8656

Maintenance Record Binder and P/N R8650 Maintenance Record Tabs).

Page 1.2 Chapter 1 General APR 2019

1-50 Notations

The following notations will be found throughout the manual:

NOTE

A NOTE provides emphasis or supplementary explanation.

CAUTION

Equipment damage can result if a CAUTION is not followed.

WARNING

Personal injury or death can result if a WARNING is not followed.

1-55 Maintenance Manual and Illustrated Parts Catalog References

Maintenance Manual and Illustrated Parts Catalog Section and Figure references are subject

to relocation and renumeration. Effort will be made at the time of RHC technical document

revisions to correct superseded references, however, certain documents may not otherwise

require revision and superseded references may remain. A keyword or part number search

in online documents (Ctrl+F [PC] or Command+F [Mac]) may help to locate applicable data.

APR 2019 Chapter 1 General Page 1.3

Page 1.4 Chapter 1 General APR 2019

1-60 Definitions and Abbreviations

Refer to R66 Pilot's Operating Handbook (POH) Section 1 for additional definitions and

abbreviations.

A. Definitions

14 CFR § 27.602

Critical Part:

A part identified as a 14 CFR § 27.602 critical part within this

manual is subject to special inspection requirements. RHC

Technical Support must be notified whenever the part fails to meet

the special inspection requirements.

12 years: With respect to a 12 year inspection or life-limit, 12 years means 12

years from the date of the factory-issued airworthiness certificate

or factory-issued authorized release certificate (FAA Form 8130-3,

Airworthiness Approval Tag).

Annually: With respect to an annual inspection, annually means within the

preceding 12 calendar months.

Datum: An imaginary vertical plane from which all horizontal measurements

are taken for balance purposes with the aircraft in level flight

attitude. Refer to §6-20 for R66 datum location.

Empty Weight: Empty Weight includes the weight of the airframe, powerplant,

required and installed equipment, fixed ballast, unusable fuel, and

gearbox oil. Refer to R66 Turbine Type Certificate Data Sheet

(TCDS) in §4-30. Refer to Equipment List/Weight and Balance

Data Sheet (RF 134) and Weight and Balance Record in R66 POH

Section 6 for installed equipment.

Life-Limited Part: Refer to §4-10. Any part for which a mandatory replacement

limit is specified in the type design, the Instructions for Continued

Airworthiness, or the maintenance manual.

Time in Service: With respect to maintenance time records, time in service means

the time from the moment an aircraft leaves the surface of the

earth until it touches it at the next point of landing.

1-60 Definitions and Abbreviations (continued)

B. Abbreviations

14 CFR: Title 14 of the Code of Federal Regulations. The Federal Aviation

Regulations (FARs) are part of the CFR.

AOG: Aircraft on Ground

ATA-100: Air Transport Association of America Specification No. 100

BL: Butt Line Station locations

CRA: Component Return/Authorization

ELT: Emergency Locator Transmitter

EMU: Engine Monitoring Unit

FCU: Fuel Control Unit

FS: Fuselage Station locations

GCU: Generator Control Unit

HID: High Intensity Discharge

HS: Horizontal Stabilizer Station locations

ICA: Instructions for Continued Airworthiness

LBL: Left Butt Line Station locations

LED: Light Emitting Diode

LH: Left-hand

LRU: Line-Replaceable Unit

MRDS: Main Rotor Drive Shaft

MRGB: Main Rotor Gearbox

OEM: Original Equipment Manufacturer

PTG: Power Turbine Governor

R66 IPC: R66 Illustrated Parts Catalog

R66 MM: R66 Maintenance Manual

R66 POH: R66 Pilot’s Operating Handbook

RBL: Right Butt Line Station locations

RH: Right-hand

RHC: Robinson Helicopter Company

RR300 Series OMM: Rolls-Royce RR300 Series Operation and Maintenance Manual

RS: Rotor Station locations

SB: Service Bulletin

SL: Service Letter

TBO: Time Between Overhaul

TCDS: Type Certificate Data Sheet

TRDS: Tail Rotor Drive Shaft

TRGB: Tail Rotor Gearbox

TS: Tailcone Station locations

TSN: Time Since New

TSO: Time Since Overhaul

WL: Water Line Station locations

JUL 2020 Chapter 1 General Page 1.4A

Page 1.4B Chapter 1 General JUL 2020

1-70 Service Information

1-71 Part Designation

RHC parts are designated with an alphanumeric part number beginning with letter “A”,

“B”, “C”, etc., followed by three digits and a dash number.

A revision letter or letters follow(s) the stamped or ink-marked part number. Revision

progression is A thru Z, followed by AA thru AZ, followed by BA thru BZ, etc. Unless

otherwise specified, any revision of the same part number is interchangeable, such as

“A101-1 A” and “A101-1 D”.

A change in dash number indicates a change in form, fit, and/or function (e.g. part

number C339-1 is not interchangeable with part number C339-10 even though both are

jackshaft weldments for [hydraulic] R44s). Similarly, part numbers F049-6 and F049-06

are not interchangeable because the dash numbers are different.

1-72 Returning Parts

All parts shipped to RHC must include a signed Component Return/Authorization (CRA)

Form available online at www.robinsonheli.com.

1-73 Ordering and Shipping

Procure parts from any R66 Dealer or Service Center, or order directly from assigned RHC

Customer Service Representative via email, fax, or phone.

1-74 Warranty Claims

Complete CRA Form (refer to §1-72) and, in the Warranty Claim section, indicate if

rotorcraft or component is under warranty. If claim is for parts or for labor allowance

due to a Service Bulletin issued against rotorcraft or component, write in “per SB-XX”

adjacent to requested warranty action.

1-75 Customer Service Directory

Please visit www.robinsonheli.com for a complete service directory.

1-80 Assembly Instructions for R66 Helicopter Crated for Export

NOTE

Aircraft assembly to be performed by a certificated mechanic.

1. Remove top of cabin assembly crate. Remove wall marked “A” by removing lag bolts

painted black. Remove empennage assembly. Remove remaining walls. Remove all

parts, except cabin assembly, from crate base. Open crate containing blades, skid tubes,

and tailcone.

2. Refer to R66 Illustrated Parts Catalog (IPC) Figure 32-1. Install hardware securing forward

and aft strut assemblies (cross tubes installed) onto skid tubes. Standard torque bolts per

Section 20-32 and torque stripe per Figure 5-1.

3. Remove tailcone cowling per Section 53-23. Remove engine cowling per Section 53-21.

4. Remove shipping supports (ty-raps, foam, tape, etc.) from main rotor gearbox compartment,

but leave cannon plugs taped and fluid line dust caps installed. Remove engine air intake

cover by opening air filter bypass door and pulling string and cover through the door.

Remove main rotor gearbox mounting hardware, nylon spacers, and upper frame strut

assemblies.

5. Remove top of main rotor gearbox crate and position crate so gearbox is upright. Refer

to Section 7-20. Install hoisting equipment and lifting fixture or nylon rope on main

rotor hub. Remove hoist slack to support gearbox, remove lag bolts securing gearbox to

wooden divider, and carefully hoist gearbox from crate (do not damage pitot tube).

6. Install main rotor gearbox per Section 63-20 steps 1 thru 9, but do not remove hoisting

equipment and lifting fixture or nylon rope.

7. Perform (engine driveline) forward flex plate shimming per Section 63-11.

8. Refer to Section 7-20. Remove hoist slack to support cabin assembly, remove lag and

carriage bolts securing metal angles to crate, and hoist cabin & attached metal angles off

of crate base.

CAUTION

Do not lift helicopter and attached crate using main rotor hub;

damage to main rotor gearbox and frames could result.

9. Remove metal angles from cabin assembly landing gear attach points. Install landing gear

assembly per Section 32-10.

SEP 2012 R66 Maintenance Manual Chapter 1 General Page 1.5

Page 1.6 Chapter 1 General R66 Maintenance Manual SEP 2012

FIGURE 1-1 ASSEMBLY INSTRUCTIONS FOR R66 HELICOPTER CRATED FOR EXPORT

FIGURE 1-2 ASSEMBLY INSTRUCTIONS FOR R66 HELICOPTER CRATED FOR EXPORT

1-80 Assembly Instructions for R66 Helicopter Crated for Export (continued)

10. For air-conditioned ships:

a. Refer to Figure 1-1. Remove shipping supports (ty-raps, foam, tape, etc.) from G777-

1 compressor assembly. Install hardware securing G782-1 mount weldment to main

rotor gearbox. Standard torque hardware per §20-32 and torque stripe per Figure

5-1. Hook B774-3 spring in drilled hole of NAS1352-4H14 screw. Verify security.

b. Refer to Figures 1-1 and 1-2. Verify B173-5 v-belt is in good condition. Fit belt around

G779-1 pulley and compressor pulley, and install hardware securing compressor to

G782-1 mount weldment. Standard torque bolts per §20-32.

c. Refer to Figure 1-2. Install hardware securing compressor to G781-1 arm weldment.

Rotate compressor up and outboard to tension belt, then tighten hardware securing

compressor to weldment. Verify belt is properly aligned on both pulleys. Adjust belt

tension until 4.5-5.5 lb of force applied mid-span deflects belt 0.16-inch. Standard

torque bolts per §20-32.

d. Connect compressor assembly wiring to airframe harness at connectors and install

ty-raps as required. Cinch ty-raps until snug without over-tightening, and trim tips

flush with heads.

11. Refer to IPC Figure 79-1. Remove F237-1 tailcone frame weldment and F305-5 (aft)

inlet. Install tail rotor drive fan shaft (fanwheel installed) through scroll assembly. Install

hardware securing aft inlet to scroll assembly. Verify security.

12. Refer to IPC Figure 65-1. Install hardware securing C947-3 plate assembly to F908-1

yoke and tail rotor drive fan shaft. Standard torque bolts and palnuts per §20-32 and

torque stripe per Figure 5-1.

13. Remove shipping supports (ty-raps, foam, tape, etc.) from tailcone assembly, and install

tailcone per Section 53-40 steps 1 thru 7. Install strobe light. Install communication and

GPS antennas (if equipped).

14. Install empennage assembly per §53-50. Install aux stabilizer assembly per §53-52.

15. Service tail rotor gearbox per §12-21. Service main rotor gearbox per §12-11.

16. Remove hydraulic reservoir shipping plug. Install D487-3 vent assembly, special torque

vent to 100 in.-lb, and torque stripe per §Figure 5-1 (do not safety wire).

17. Install tail rotor assembly per §64-10. Match color-coded markings on blades with pitch

links.

18. Install main rotor blades per §62-10. Match color-coded markings on blades with

markings on hub and pitch links.

19. Inside engine compartment, remove anti-ice valve cap, starter-generator cap, inducer

bleed hose cover, exhaust pipe cover and desiccant, and combustion case drain valve

cap. Connect inducer bleed hose to box assembly and tighten clamp. Verify security.

MAY 2015 Chapter 1 General Page 1.7

1-80 Assembly Instructions for R66 Helicopter Crated for Export (continued)

20. If ship is equipped with attitude horizon, directional gyro, turn coordinator, and/or vertical

card magnetic compass:

A. Attitude Horizon, Directional Gyro, and Turn Coordinator Installation

CAUTION

Directional gyro mount screws must not exceed 1-inch in length.

1. Place a piece of foam under instrument face. Remove (6) screws securing face

to console and gently pull face forward. Remove hardware securing instrument

hole covers to face and remove covers. Install instruments and secure to face

with hardware provided.

2. Connect straight connector(s) to directional gyro and/or turn coordinator. Connect

angle connector to attitude horizon, ensuring strain relief points down. Ensure

connectors lock. Ty-rap excess wiring. Install screws securing instrument face

to console.

B. Vertical Card Magnetic Compass Installation

1. Locate airframe wiring (in windshield center bow), install 2-inch length of B158-3

heat shrink over wiring, and connect compass pins to airframe sockets (polarity

is not critical). Slide heat shrink over connection and apply heat. Install (4)

screws securing compass to mount, securing wiring atop compass.

21. Connect battery per §96-10.

NOTE

Check battery open circuit voltage and perform boost charging

or capacity tests as required per Concorde Battery Instructions

for Continued Airworthiness.

22. Perform pitot-static leak check per §95-10.

23. Install Emergency Locator Transmitter (ELT) per §25-61, as required. Install tailcone

cowling assembly per §53-23.

24. Install fire extinguisher per §25-62, as required.

25. Fuel helicopter per §12-41.

26. Verify all shipping supports (ty-raps, foam, tape etc.) have been removed from helicopter.

Refer to §6-70. Secure access panels and inspection doors.

NOTE

Flight checks to be performed by a qualified pilot and certificated

mechanic.

27. Perform ground check per §5-41 steps 2 thru 9.

Page 1.8 Chapter 1 General MAY 2015

1-80 Assembly Instructions for R66 Helicopter Crated for Export (continued)

28. Depreserve the engine after storage per RR300 Series Operation and Maintenance Manual

(OMM). Install starter-generator cooling hose. Install engine cowling per §53-21.

29. Install tail rotor dynamic balance equipment per §18-21.

30. Perform run-up per §5-42 steps 2 thru 16.

31. Perform tail rotor dynamic balance per §18-20.

32. Remove tail rotor dynamic balance equipment. Install main rotor balance equipment

per §18-11.

CAUTION

Mast fairing, cowlings, and panels must be installed for flight.

33. Perform hover checks per §5-43 step 1. DO NOT proceed into forward flight.

34. Track and balance main rotor per §18-12.

35. While climbing at maximum continuous torque, 60 KIAS:

a. Evaluate vibration level and controllability.

b. Perform momentary 30° left yaw to check for adequate directional control.

36. Level flight at 2000 feet density altitude (deviate as required for weather and terrain),

maximum continuous torque:

a. Evaluate longitudinal and lateral cyclic control forces.

b. Evaluate collective control forces.

37. Evaluate vibration level at maximum continuous torque and straight-and-level flight.

38. During autorotation at 50 KIAS and 90% rotor RPM, perform momentary 30° right

yaw to check for adequate directional control.

39. Check all instruments, gages, and avionics for proper operation.

JUL 2020 Chapter 1 General Page 1.9

*One-time maintenance after new or overhauled main rotor gearbox is installed.

** Recurring inspection not to exceed given interval.

*** See §1-60 Definitions and Abbreviations.

TABLE 1 SCHEDULED INSPECTIONS

Consult latest revision of listed

publications for specific applicability.

First 100 Hours*

100 Hours**

200 Hours**

300 Hours**

400 Hours**

600 Hours**

1000 Hours**

2000 Hours**

Annually***

12 Months**

24 Months**

3 Years**

5 Years**

6 Years**

12 Years**

15 Years**

3000 Cycles**

Replace main gearbox oil filter per §12-12. • •

Perform 100-hour / annual inspection per §5-45. • •

Perform main rotor blade tip maintenance per §

62-60. •

As required by RR300 Series Operation and

Maintenance Manual (OMM), perform maintenance

and inspection.

• • • • •

Service inlet barrier filter per § 71-21. • •

Replace main gearbox oil per §12-11. •

Drain and flush tail rotor gearbox per §12-23. •

Replace hydraulic filter per §12-32. •

Clean gearbox chip detectors per §12-13 & 12-22. • •

Lubricate swashplate bearings per §12-90. • •

Perform 2000-hour inspection per §5-50. •

Perform main gearbox internal visual inspection per

§ 5-74. •

Inspect emergency locator transmitter (ELT) per 14

CFR §91.207. •

Perform pop-out float leak check per §32-64 Part A. •

Test and inspect transponder per 14 CFR §

91.413. •

Perform pop-out float inflation check per §32-64

Part B. •

Peform pop-out float pressure cylinder hydrostatic

test. •

Perform 12-year inspection per §5-55. •

Pop-out float pressure cylinder maximum life. •

Page 1.10 Chapter 1 General JUL 2020

Other manuals for R-66 Series Lithium-Ion

4

Table of contents

Other Robinson Toy manuals

Popular Toy manuals by other brands

LeapFrog

LeapFrog Learn & Groove Rainbow Lights Piano instruction manual

Madcow Rocketry

Madcow Rocketry Mini Bomarc Assembly

Martha Stewart

Martha Stewart Farmer's Market Play Tent Assembly and care instructions

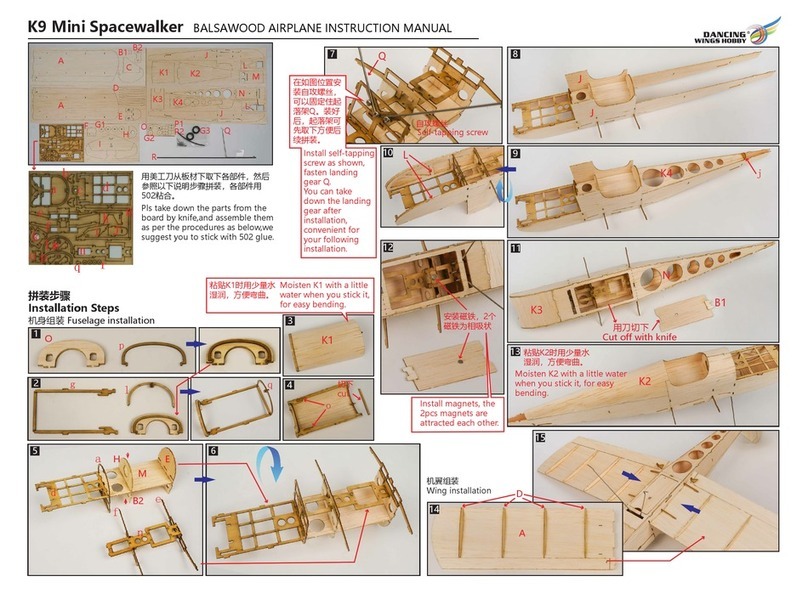

Dancing Wings Hobby

Dancing Wings Hobby K9 Mini Spacewalker instruction manual

Vollmer

Vollmer 45762 Mounting instruction

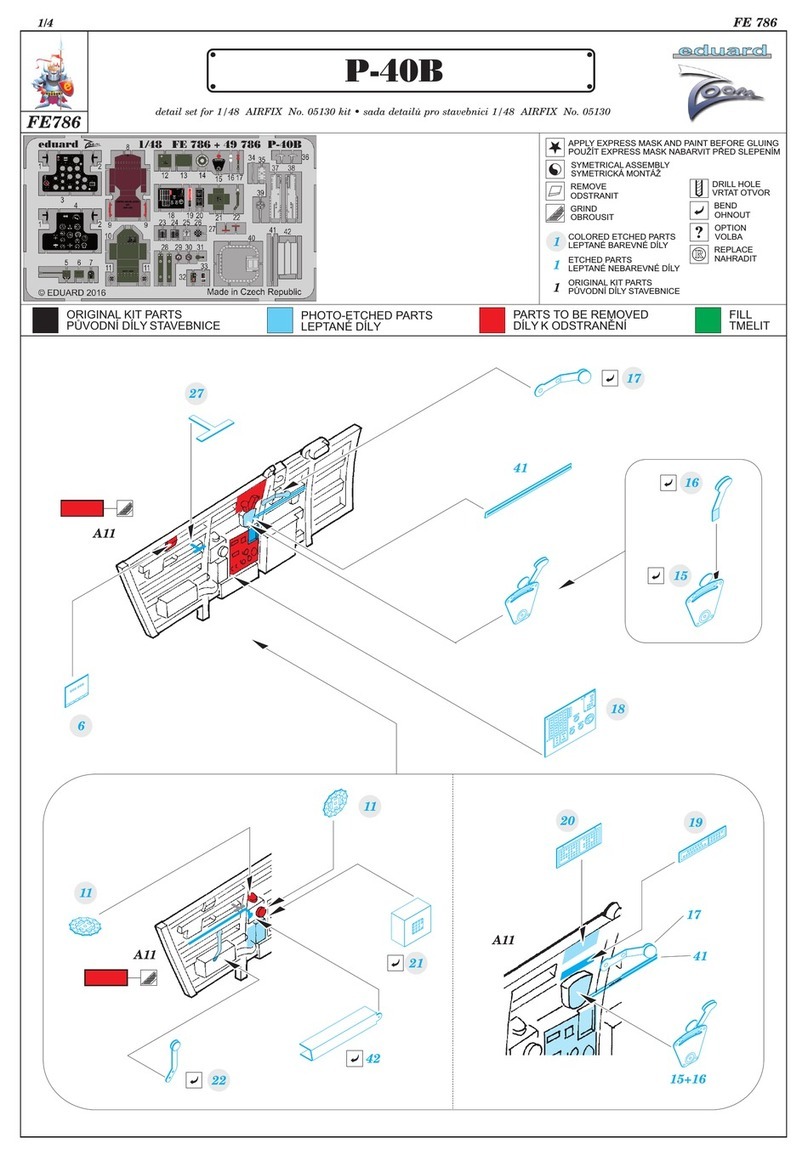

Eduard

Eduard 73405 instruction sheet