10

Starting up the machine (fig, 5)

Turn the main switch (1) to position “1” in order to put the machine under tension, and ensure

that the Star-Delta switch (2) is set at the “Star” position.

To start up the motor push the start button (3), and after about 6 seconds switch over to the

“Delta” position.

This time delay of 6 seconds is needed to let the motor gain its full speed before switching over

to “Delta”.

When you forget to switch over from Star to “Delta”, the motor will reach its full speed but will

have no power, and can be damaged very easily.

By pushing the stop button (4) the saw motor is automatically stopped, and slowed down by the

automatic brake( only CE version machines ) within 10 seconds.

WARNING:

All fuses can be found inside the electrical cabinet, and each time this cabinet is

opened the machine must be disconnected from the main power supply.

Mounting of the sliding table (fig, 6)

Slide the guide rail onto the two brackets which are mounted at the side of the saw table, and

lock the two bolts (1).

The same two bolts (1) can be used to change the position of the guide rail relative to the saw

table, unlock and slide the guide rail in or out in function of the stroke of the sliding table

wanted.

The sliding table is to be slid onto the guide rail, and after this has be done put the guide rail

stop bracket at the front end of the guide rail, this in order to prevent the cross cut table from

falling off.

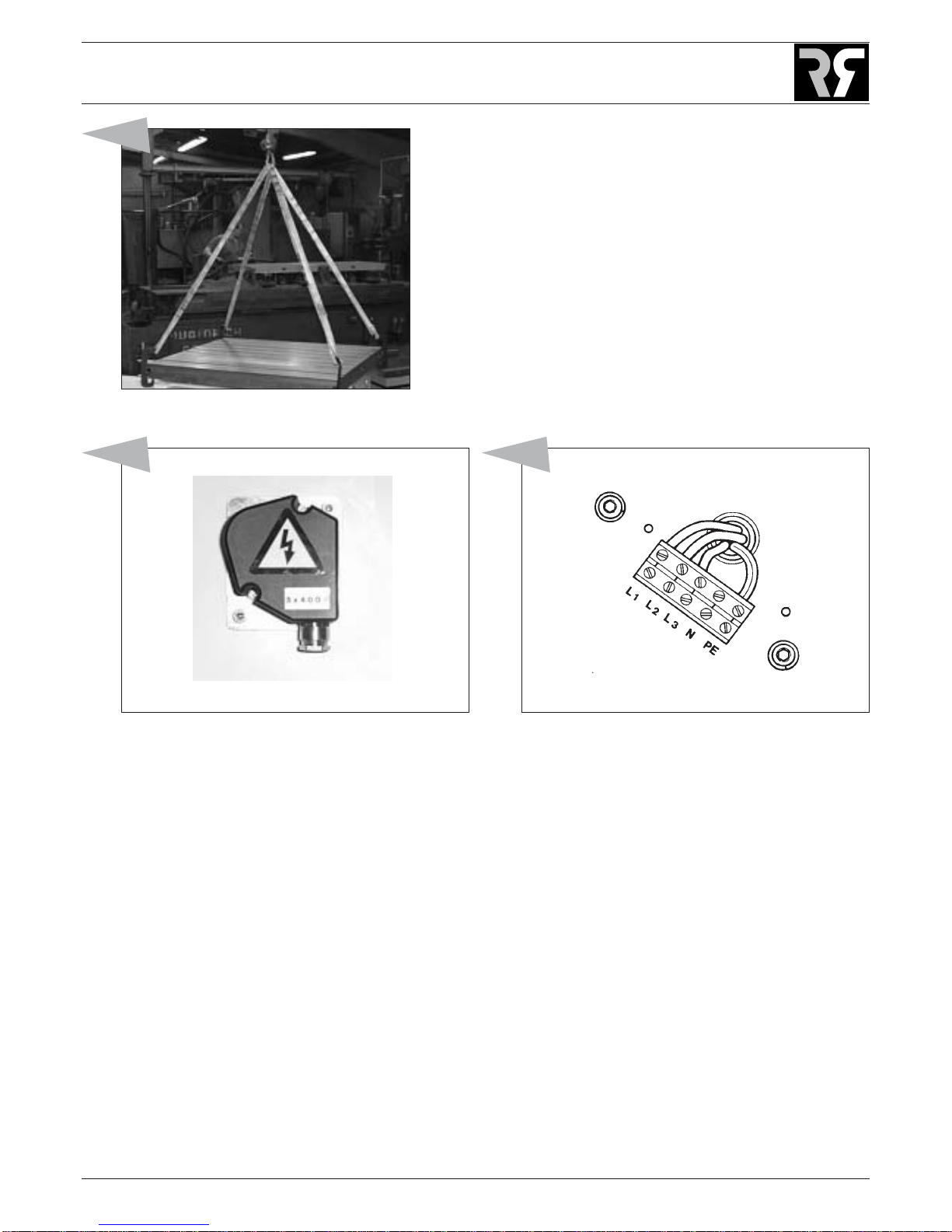

Changing sawblades (fig, 7, 7 bis)

WARNING: Before changing sawblades always disconnect the machine from the main

power supply by turning the main switch off.

Use only sawblades accordingly EN 847-1 specifications.

The wear of safety gloves when changing sawblades is highly recommended.

- Remove the table insert (3) and raise the saw arbor to its highest position, and turn the

saw arbor untill the locking pin (1) can be introduced into the bore of the saw table and

the saw arbor pulley.

- The easyest way to turn the saw arbor is to put the saw nut wrench (2) onto the nut and

turn the saw arbor using this wrench- Now unlock the nut: Warning: left hand thread.

- Before fitting the sawblade ensure that both sawblade body and flanges are clean, this

to prevent the sawblade from wobbling.

- Never forget, after the saw arbor nut has been tightened, to remove the locking pin from

the pulley before starting up the motor.

WARNING: All sawblades used on the machine must have two additional safety bores

in the sawblade body, these bores together with the two bolts in the saw flange prevent

the sawblade from coming off, when the sawblade is stopped by the brake motor.

The dimensions of these bores can be seen in fig, 7 bis.

Never remove the two safety bolts which are fixed in the saw arbor flange.