RFTSeries|6AxisForceTorqueSensor

©ROBO

T

OUS

Co.,Ltd.www.robotous.com|[email protected]2

Contents

1. Caution ·························································································································································· 4

1.1. Notices ···································································································································································································4

1.2. Warning ·································································································································································································4

2. Installation ···················································································································································· 5

2.1. Overview ·······························································································································································································5

2.2. Power Supply Specifications ·························································································································································6

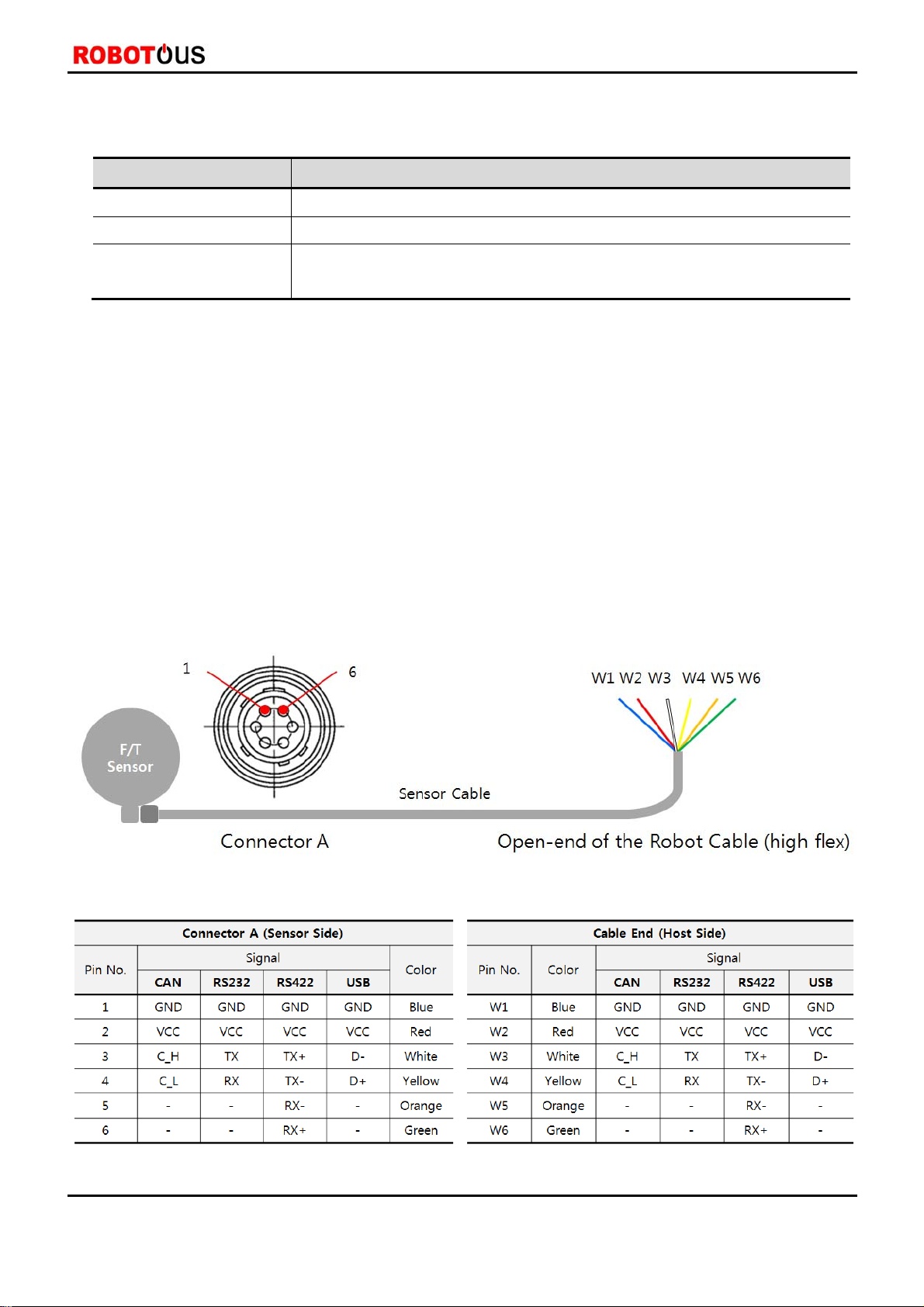

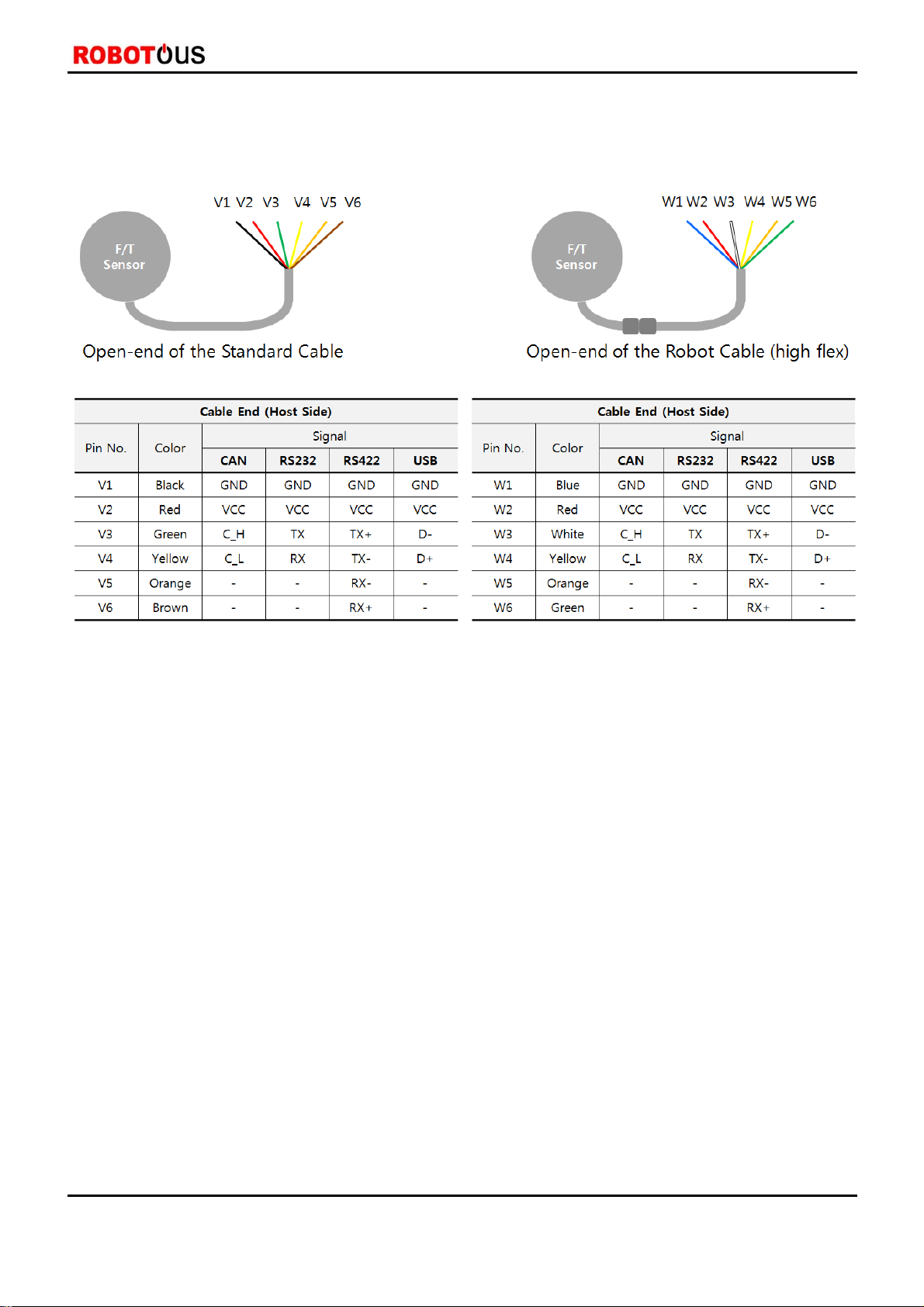

2.3. Wiring ····································································································································································································6

3. Operation ······················································································································································ 8

3.1. F/T Sensor Output Interfaces ·······················································································································································8

3.2. Communication Packets ·································································································································································8

3.3. Basic Operation ··················································································································································································8

3.4. Default Setting of Communication ············································································································································9

3.5. Packet Structure ·············································································································································································· 10

3.5.1. Packet Structure of CAN Interface ······················································································································································· 10

3.5.2. Packet Structure of UART interface······················································································································································ 10

3.6. Packet Definition ············································································································································································ 11

3.6.1. Summary of command packets ···························································································································································· 11

3.6.2. Read Model Name ······················································································································································································ 11

3.6.3. Read Serial Number ··················································································································································································· 12

3.6.4. Read Firmware Version ············································································································································································· 12

3.6.5. Set Communication ID (for CAN only) ·············································································································································· 12

3.6.6. Read Communication ID (for CAN only) ··········································································································································· 13

3.6.7. Set Baud-rate (for UART only) ······························································································································································· 13

3.6.8. Read Baud-rate ····························································································································································································· 1 4

3.6.9. Set Filter ·········································································································································································································· 14

3.6.10. Read Filter Setting ···················································································································································································· 15

3.6.11. Read F/T Data (once) ·············································································································································································· 15

3.6.12. Start F/T Data Output ············································································································································································· 17

3.6.13. Stop F/T Data Output ············································································································································································· 17

3.6.14. Set Data Output Rate ············································································································································································· 17

3.6.15. Read Data Output Rate ·········································································································································································· 18

3.6.16. Allowable Data Output Rate ································································································································································ 18

3.6.17. Set Bias ·········································································································································································································· 19