4Eastwood Technical Assistance: 800.343.9353 >> techelp@eastwood.com

SET-UP

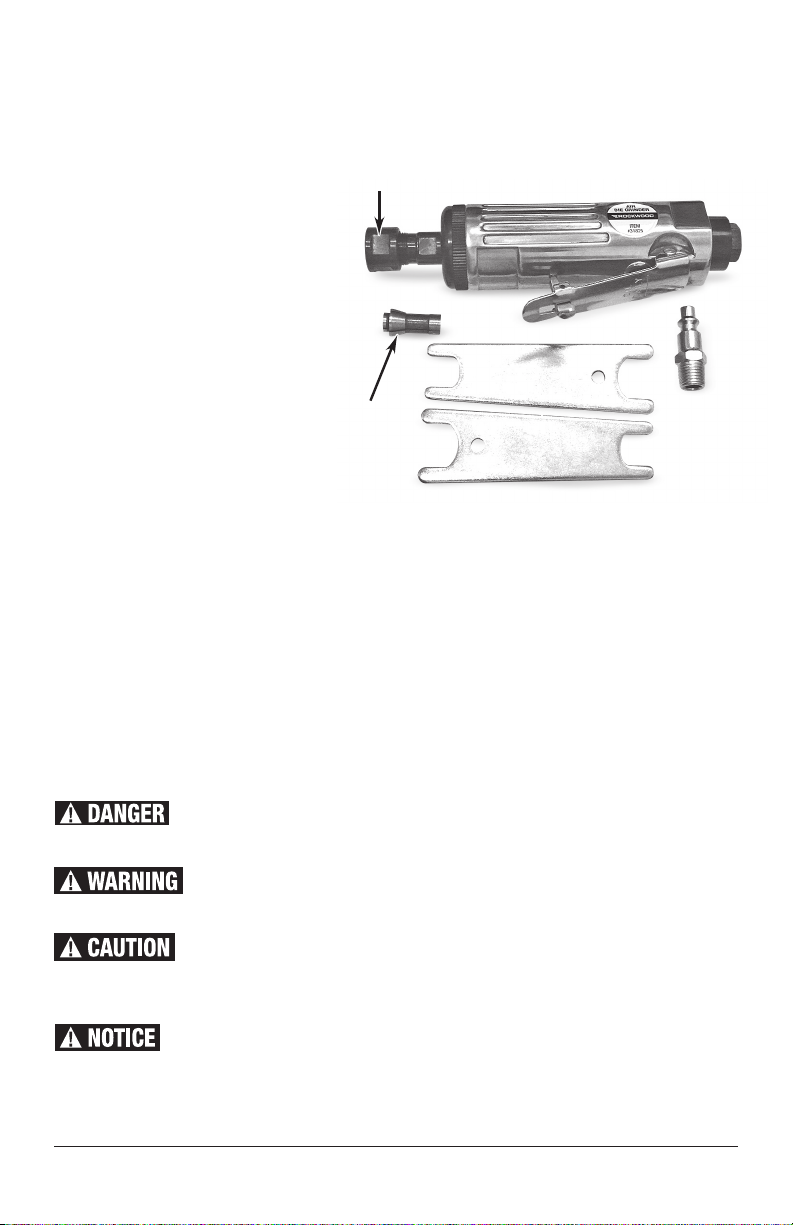

• Using a good quality Teflon sealing tape (not included), thread the 1/4” MNPT, Male quick

disconnect inlet fitting into the air inlet.

INJURY HAZARD!

To avoid injury, always disconnect air supply to Die Grinder before installing

or replacing accessories.

INJURY HAZARD!

To avoid injury, only use accessories rated for High-RPM,

(22,000 or greater) use.

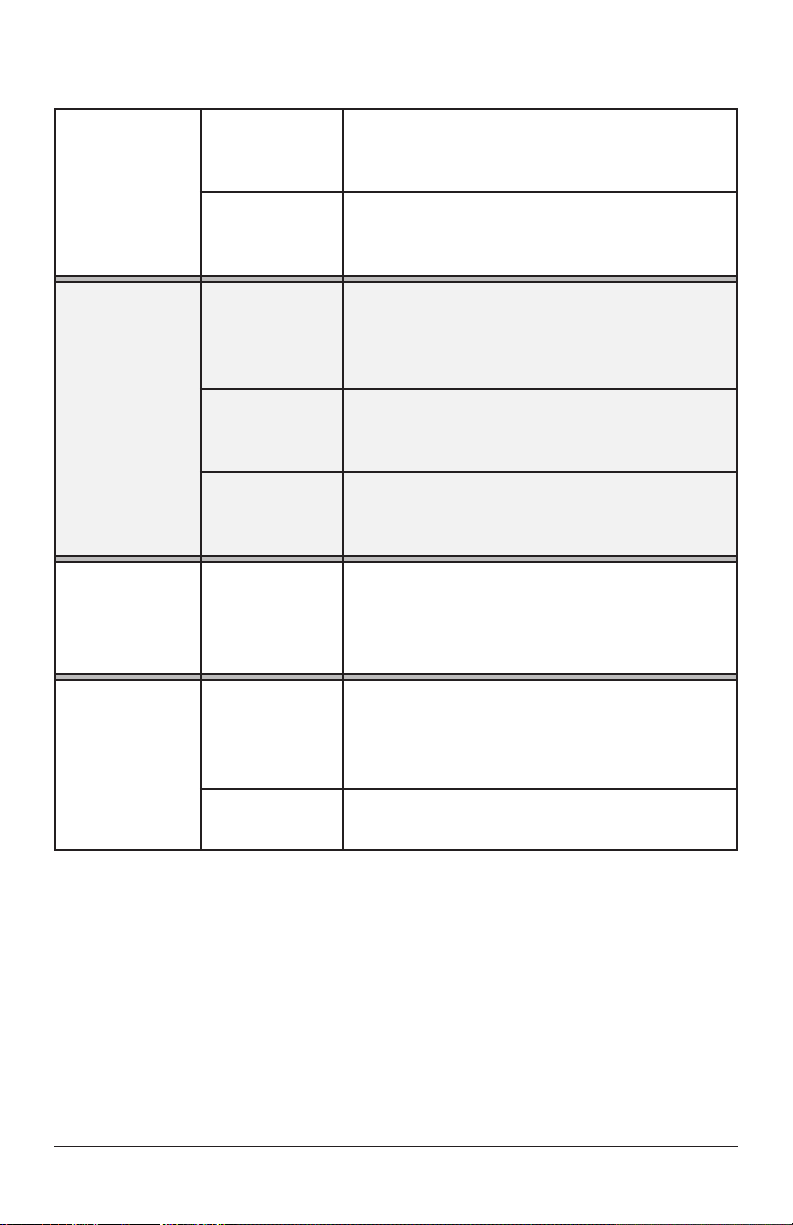

TO INSTALL OR SWITCH ACCESSORIES (not included)

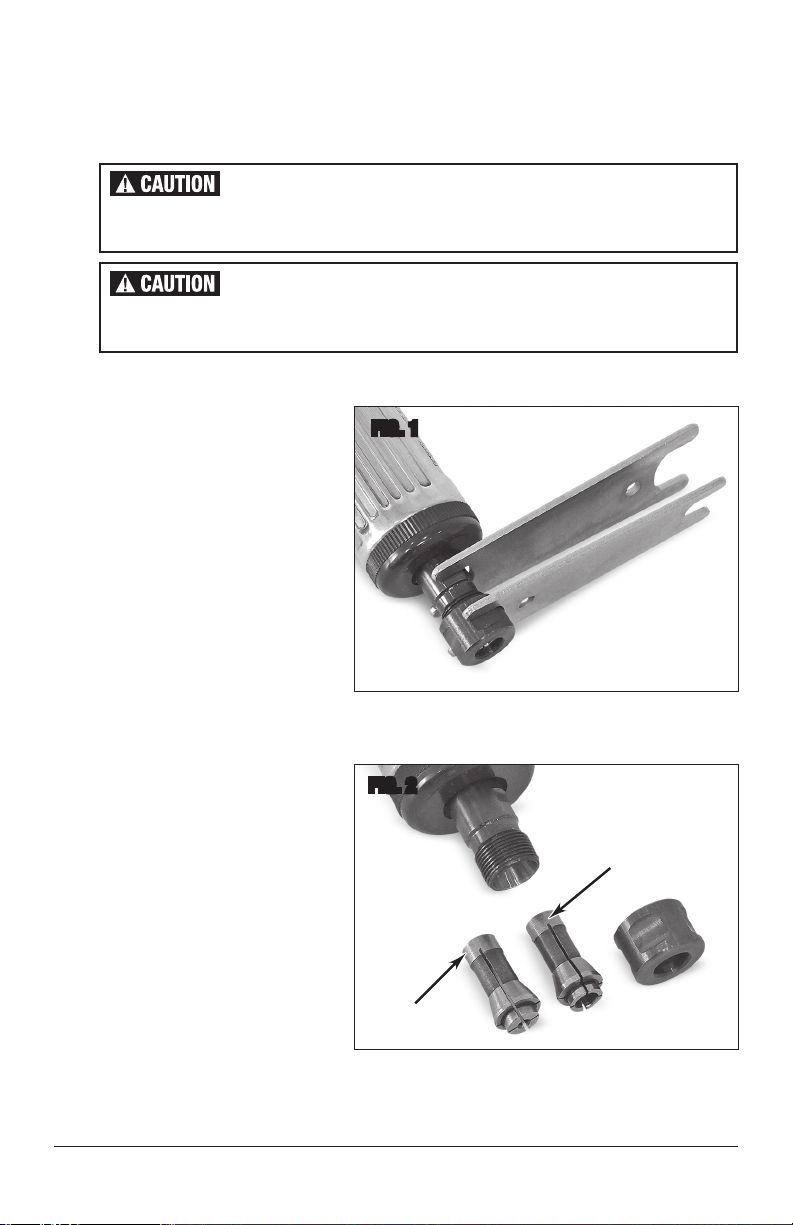

• With air supply disconnected,

Slide the smaller 14mm end of a

Collet Wrench over the flats of the

shaft and the larger 19mm end of

a Collet Wrench over the flats of

the Collet Retainer (FIG 1).

Loosen the threaded-on Collet

Retainer to release the Collet grip

on accessory then and pull out

the accessory. Replace accessory

with one of the same size shank

by sliding the shank into the

Collet then retighten securely.

TO SWITCH TO A COLLET OF ANOTHER SIZE

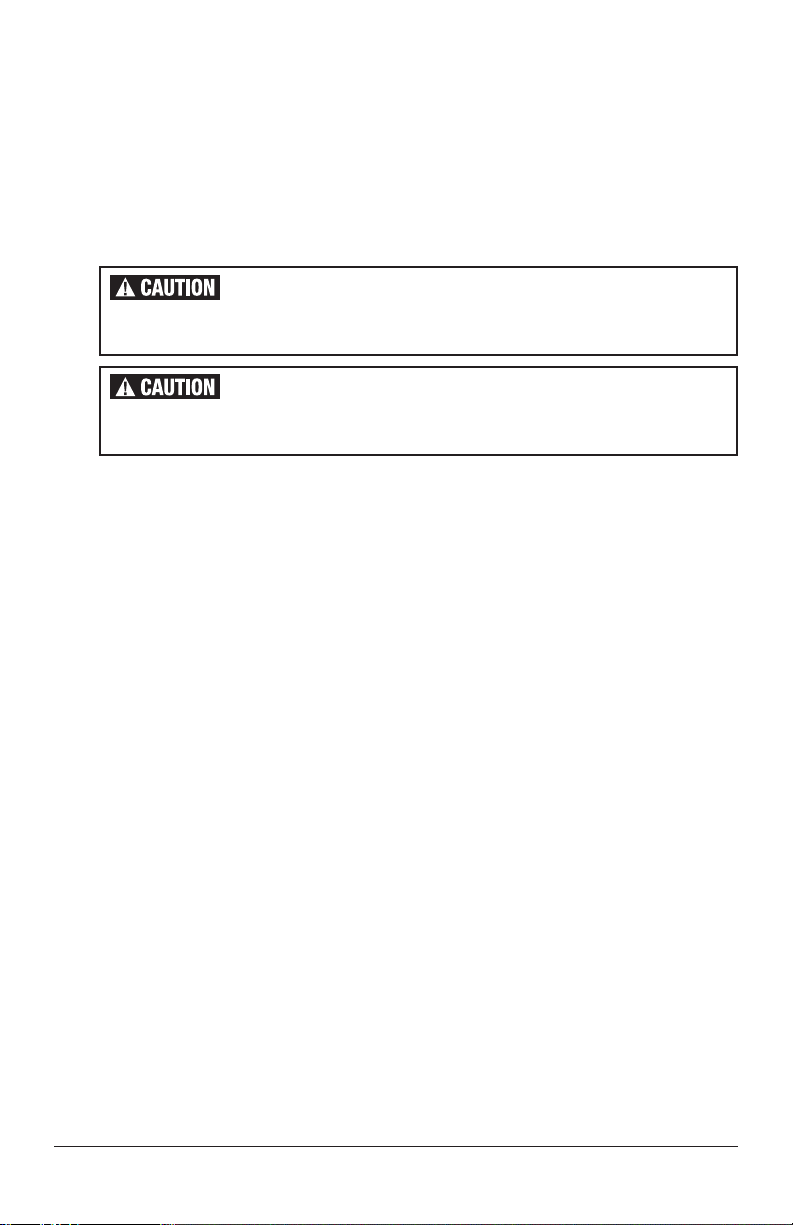

• With air supply disconnected,

Slide the smaller 14mm end of a

Collet Wrench over the flats of the

shaft and the larger 19mm end of

a Collet Wrench over the flats of

the Collet Retainer. Loosen then

remove the threaded-on Collet

Retainer and place it aside for

re-installation (FIG 2).

• Withdraw the accessory

(if installed) and the Collet.

• Install Collet into bore of Shaft.

• Place accessory (not included) into Collet.

• Replace Collet Retainer and tighten securely with included Wrenches.

1/8” Collet

FIG. 1

FIG. 2

1/4” Collet

Collet

Retainer