To order parts and supplies: 800.345.1178 >> eastwood.com 3

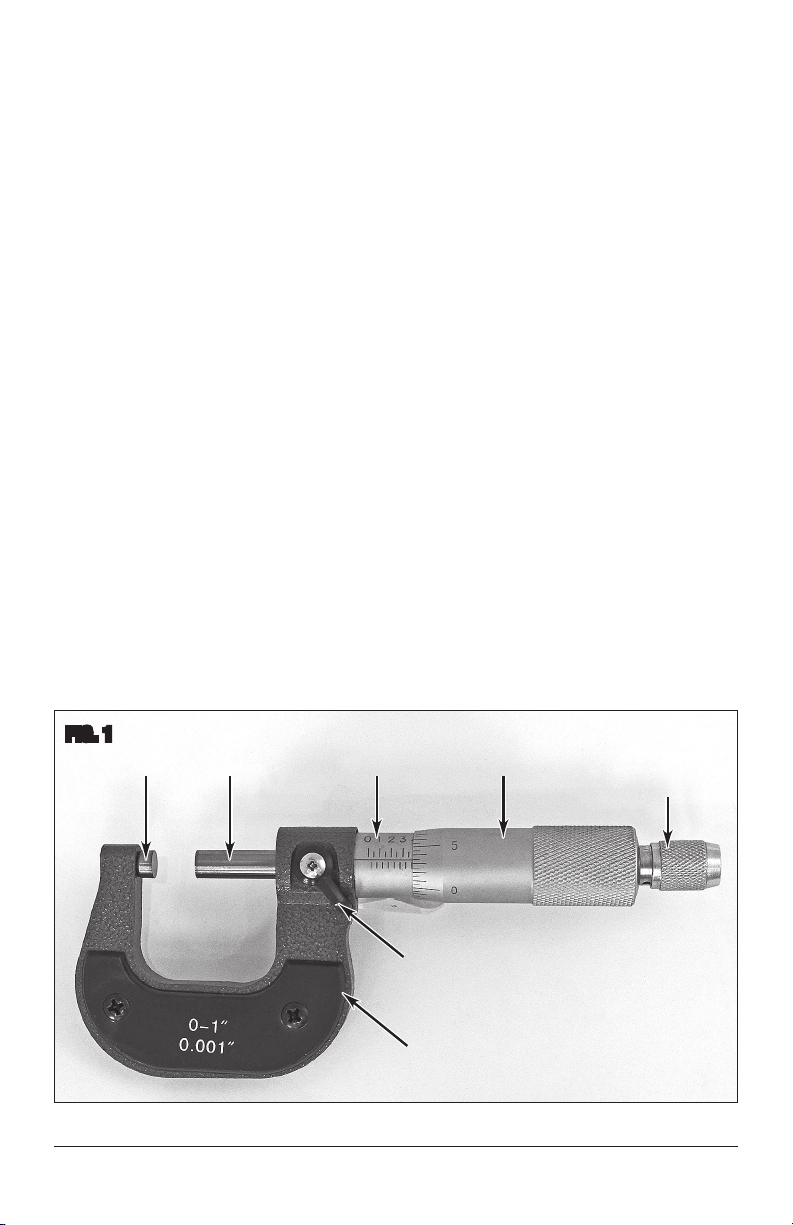

FIG. 1

Frame

Ratchet

Knob

ThimbleSleeveSpindleAnvil

Lock Lever

OPERATION

The accuracy of Micrometer measurement can be adversely affected by temperature. Micrometer and

part temperatures of 72°F [22°C] are ideal while warmer or colder extremes will cause expansion or

contraction which can produce inaccurate results.

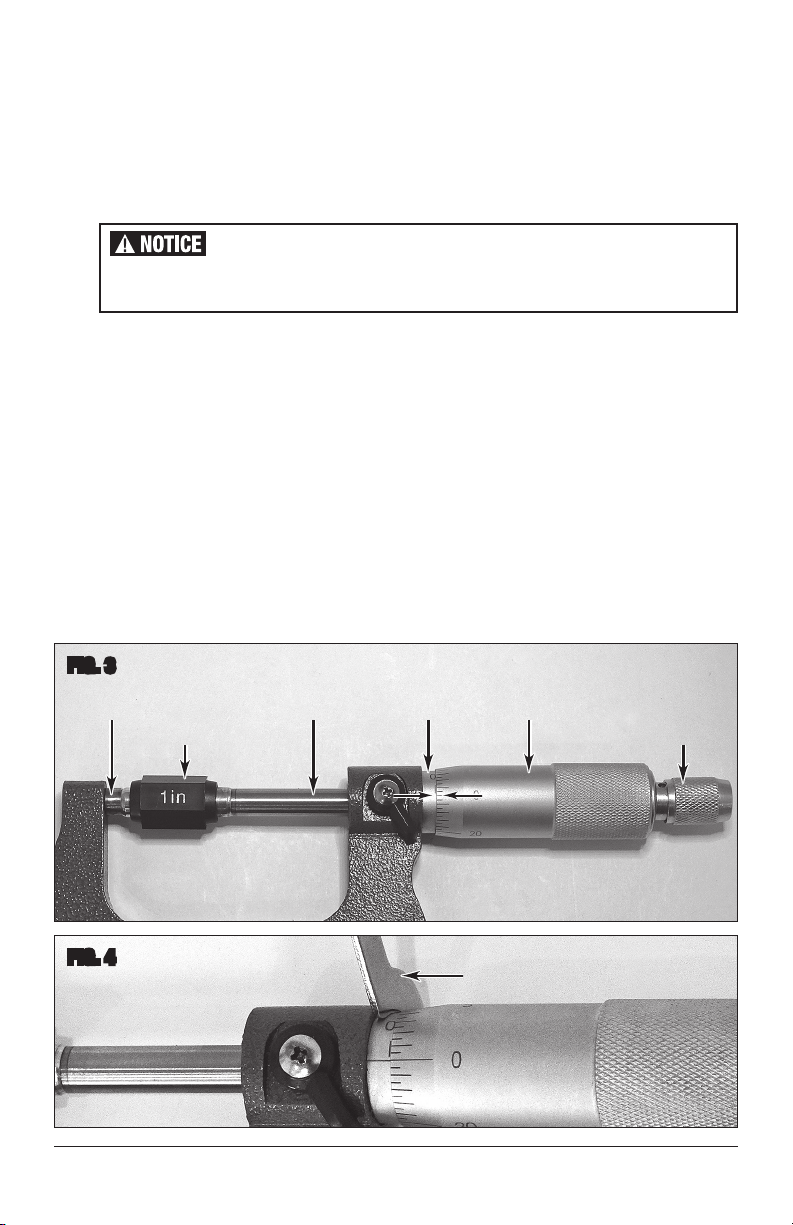

• Place the Micrometer in the palm of a hand, be sure the Spindle is unlocked, then rotate the

Thimble to open it slightly beyond the dimension of the part to be measured.

• Using care not to scratch the mirror polished Anvil and Spindle surfaces, place the part against

the Anvil first, then gently turn the Spindle inward until it makes contact with the part.

• Use only the Ratchet Knob to exert pressure on the part allowing 3 ratchet clicks to denote proper

tension. The dimension can now be read.

• To lock the Spindle at the desired dimension for easier reading, rotate the Locking Lever

15° Clockwise.

READING THE MICROMETER

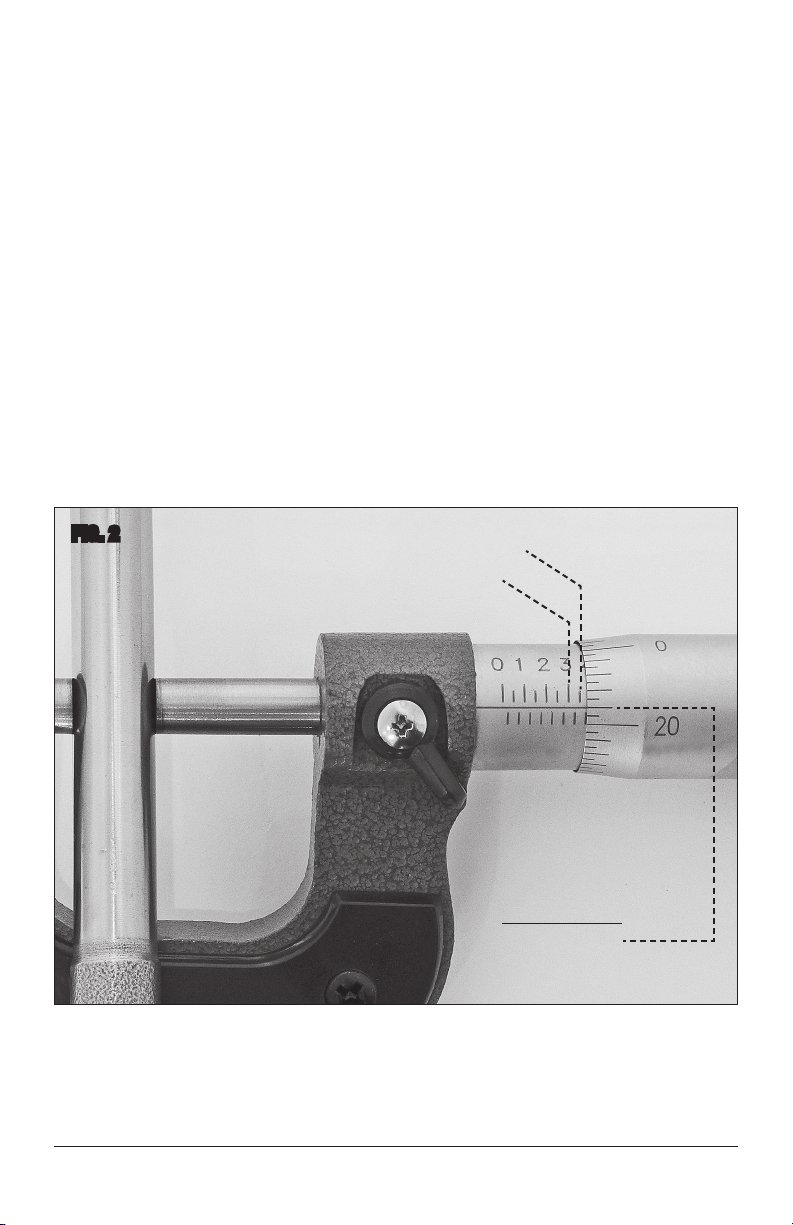

THE SLEEVE

• The Micrometer Sleeve is fixed and does not move (FIG 1).

• It has 10 markings, each of these markings is equal to 0.100” or 1/10” (1 tenth of an inch).

Viewed another way; The space on the sleeve between “0” and “1” equals .100”, the space

between “1” and “2” equals 0.200” and so on to 8, 9, 0.

• Each of these 10 markings is divided into 4 equal parts. (Note that 2 markings are above the

line while 2 are below).

• Each of those 4 markings is equal to .025” or 1/40” (1 40th of an inch).