WM-020-379-10-en_BA Speedy basic S M L X Y.DOCX

STARK Spannsysteme GmbH – Roemergrund 14 - 6830 Rankweil - Austria

Tel.:+43 5522 37 400-0 - Fax.:+43 5522 37 400-700 - e-mail: info@stark-inc.com - www.stark-inc.com

2/15

1 Contents

1Contents ........................................................................................................................................................... 2

2Identification of the partly completed machinery ........................................................................................ 3

3User information .............................................................................................................................................. 3

3.1 Purpose of the document .................................................................................................................................. 3

3.2 Depiction of safety instructions ......................................................................................................................... 3

4Essential safety instructions.......................................................................................................................... 4

4.1 Proper use......................................................................................................................................................... 4

4.2 Foreseeable misuse .......................................................................................................................................... 4

4.3 On the use of rotating machine tools ................................................................................................................ 4

4.4 Modifications or changes .................................................................................................................................. 4

4.5 Spare parts, wear parts and auxiliary materials................................................................................................ 5

4.6 Obligation by the operator/owner ...................................................................................................................... 5

4.7 Residual risks .................................................................................................................................................... 5

4.7.1 Spring assembly........................................................................................................................................ 5

4.7.2 Malfunction in the hydraulic/pneumatic system during operation ............................................................. 5

4.7.3 Hazard due to overpressure...................................................................................................................... 6

4.7.4 Hazard due to incorrect mounting of the fast closing clamp ..................................................................... 6

4.7.5 Hazard on use in a rotating application..................................................................................................... 6

4.7.6 Aspects that may affect service life........................................................................................................... 6

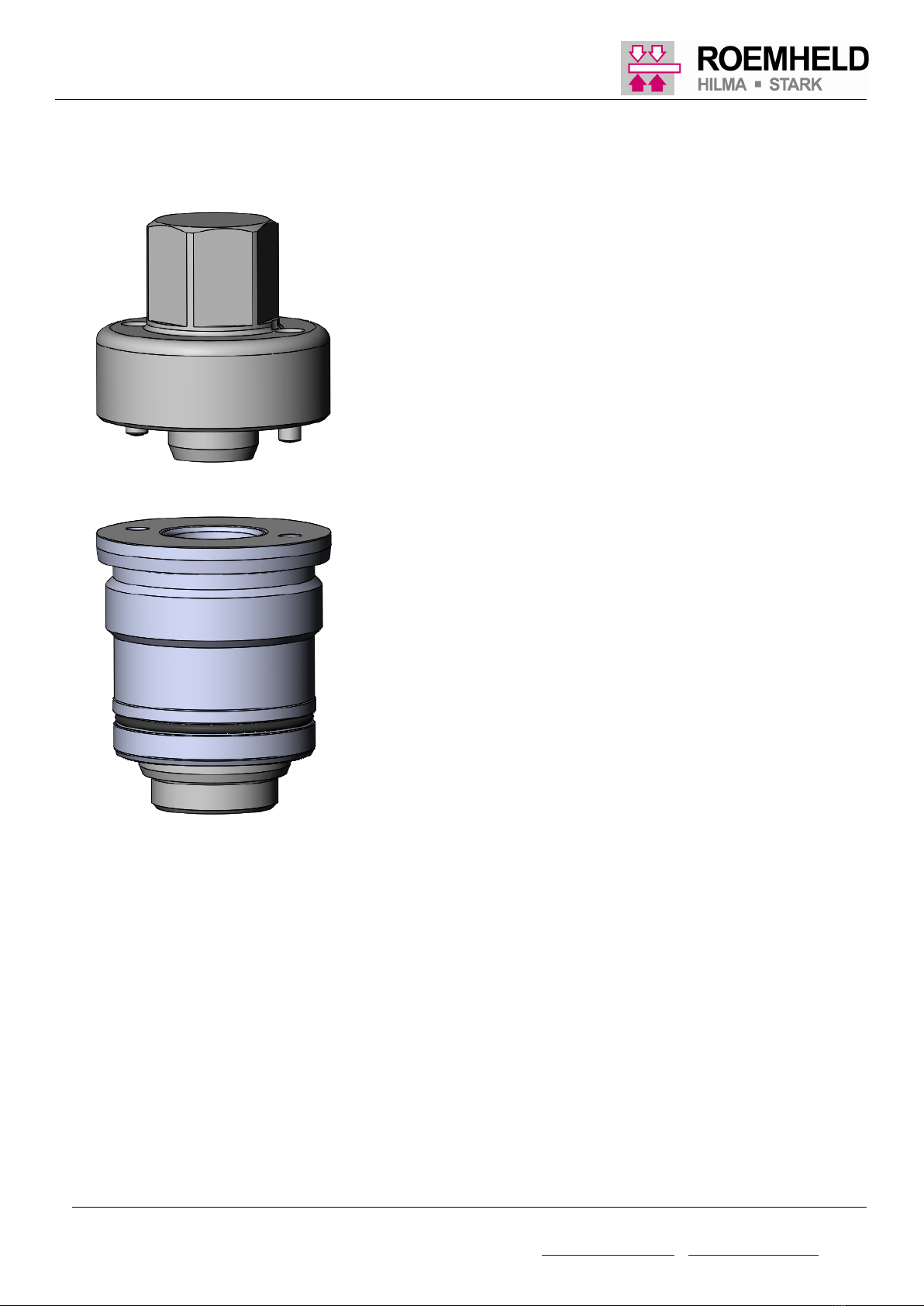

5Description of fast closing clamping device ................................................................................................ 7

5.1 General.............................................................................................................................................................. 7

5.2 Mounting and installation .................................................................................................................................. 7

5.2.1 SPEEDY basic S / M / L / X ...................................................................................................................... 7

5.2.2 SPEEDY basic L ....................................................................................................................................... 9

5.3 Removal of fast closing clamp .......................................................................................................................... 9

6Start-up, operating and operation................................................................................................................ 10

6.1 Putting in operation for the first time ............................................................................................................... 10

6.2 Function check ................................................................................................................................................ 10

6.3 Operating and operation ................................................................................................................................. 10

6.4 SPEEDYs with blow-out function and mount control ...................................................................................... 10

7Servicing and maintenance .......................................................................................................................... 11

7.1 Function check ................................................................................................................................................ 11

7.2 Maintenance interval of spring assembly........................................................................................................ 11

7.3 Cleaning .......................................................................................................................................................... 12

7.4 General cleaning ............................................................................................................................................. 12

7.5 Storage:........................................................................................................................................................... 13

7.6 Disposal / recycling: ........................................................................................................................................ 13

8Specifications ................................................................................................................................................ 14

9Manufacturer's declaration ........................................................................................................................... 15