7

vercal axis. It allows to correct centering between

the photocells in installaons with xing surfaces

that are parallel to each other.

For seng up the horizontal axis, loosen up the

two screws indicated with number 1 in the picture

6, adjust the movable part unl reaches the ideal

posion, then screw the two screws number 1

back. For seng up vercal axis, rotate the screw

indicated with number 2 in the picture 6, clockwise

or counterclockwise unl reaches the opmum

posion.

Control of the correct alignment between the

photocells

The photocell RX has one red led (indicated with L in

the pictures 1 and 2). Its brightness is proporonal

to the power of the received signal and at the same

me, it indicates the correct alignment between

the photocells. Bigger is the brightness, greater it

is the power received and therefore it is beer the

alignment. Even if the photocell RX works also with

low signal received, it is recommend to perform the

best alignment possible, to guarantee an ecient

funconing even in cases of fog, dust or rain.

Connecons of the outputs of the photocells RX

The outputs of the photocells RX are relays contacts

free of tension.

Cauon: by convenon the switches NC (normally

close) and NO (normally open) indicates in this

instrucon the reference to the photocells RX

acvated by the infrared ray.

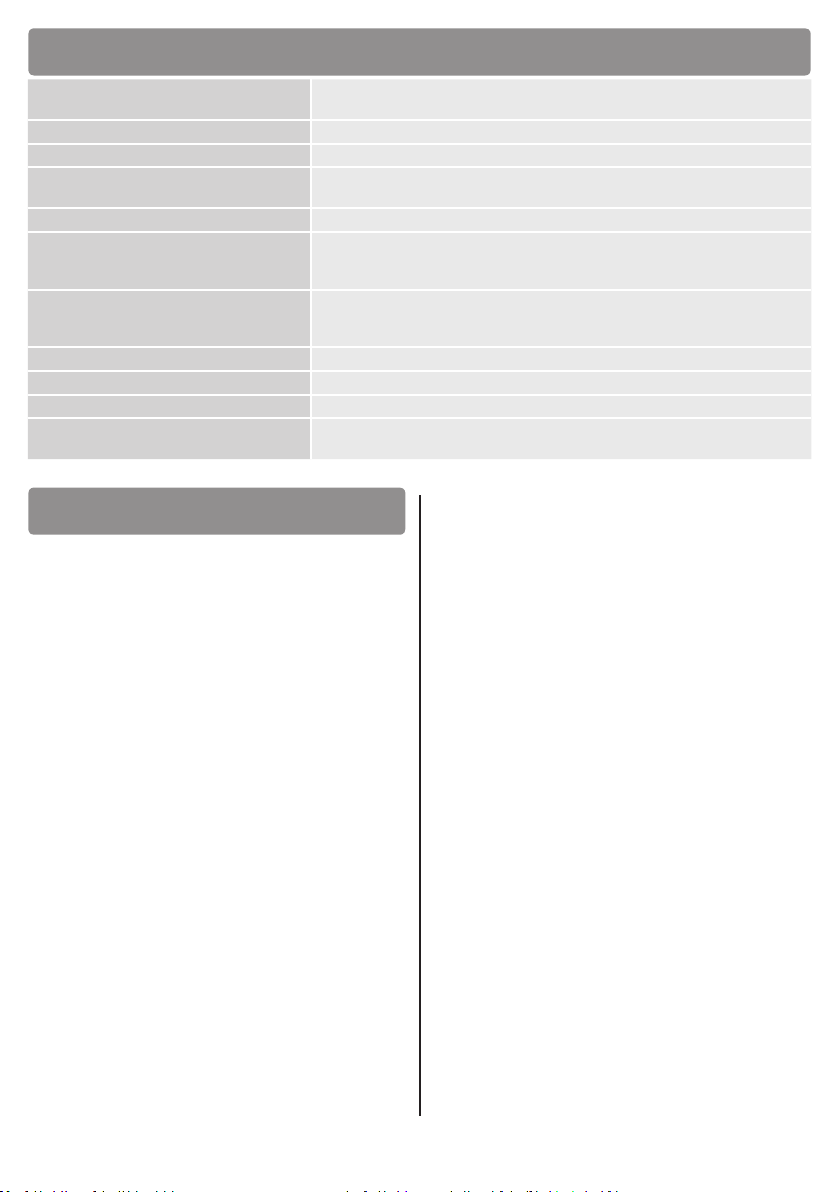

Descripon of the outputs of the terminal blocks:

– Terminal n°3 switch NC (normally close)

– Terminal n°4 switch COMUNE for the terminals

3 and 5

– Terminal n°5 switch NO (normally open)

Usually, for the automac entrances, switch NC

(terminals 3-4) is used because, if there is an

obstacle between the photocells, the switch NC

opens.

For the courtesy funcon, it is used the switch

NO (terminals 4-5) because, if there is an obstacle

between the photocells, the switch NO closes.

5 Tesng

Tesng of one pair of photocell

The tesng allows to verify the correct funconing

6 Maintenance

Do scheduled maintenance every 6 months, for

checking cleaning and funconing of all of the

photocells.

In case of dirt, wet, insects or anything else, clean

the photocell and run again the tesng process.

In case of oxide on the circuit board, please consider

the replacement.

7 Disposal

The product must be always uninstall by the technical

and qualied sta, using appropriate processes for the

correct removal of the product.

This product is made of dierent materials, some

of them could be recycled others must be disposed

through recycling or disposal systems established by

local regulaons for this product.

It is forbidden to dispose the product into the house

garbage. Make the “separate collecon” for disposal

according to the methods established by local

regulaons; otherwise return the product to the seller

when you buy the new equivalent product.

Local regulaons may provide for heavy penales for

illegal disposal of this product.

Cauon: some parts of the product may

contain pollutants and hazardous, if

thrown they may cause dangerous eects

to the environment and to the human

health.

of the photocells and the possible interference with

other transmission devices with infrared light that

are installed nearby.

Acvate the control device to which are connected

the photocells.

With something cylindrical of about 50mm of

diameter, break o many mes the beam of light

between the photocells. Repeat the same operaon

posioning near the photocell TX, near the

photocell RX and in the center between the two. If

the control device noce correctly each interrupon

at all points, the tesng is successfully completed. In

the case of two or more pairs of photocells installed,

repeat the same step taking care to verify possible

interferences between them.