2 / 14

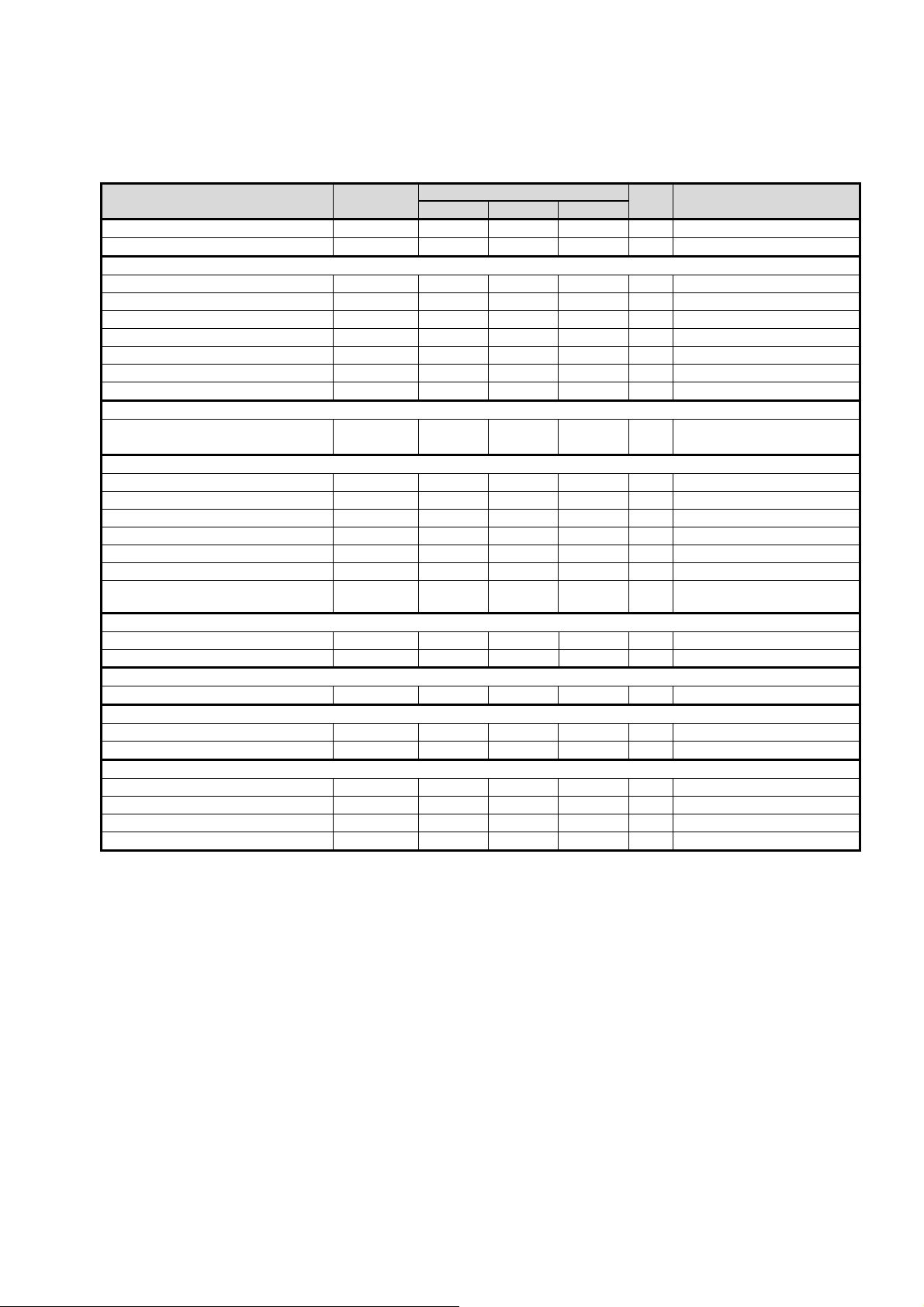

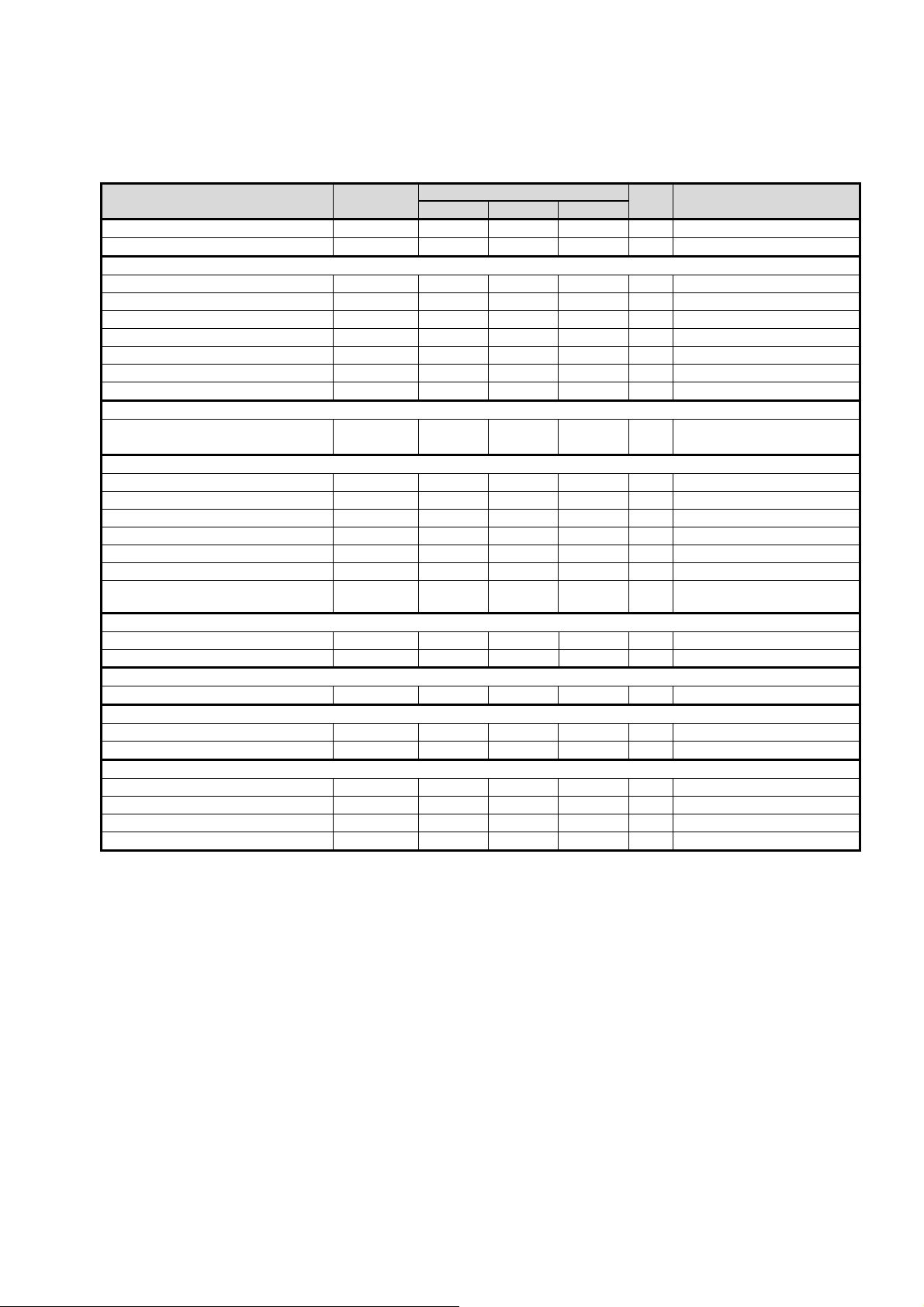

●Electric characteristic

(Ta=25℃, VCC=6.5V, GND=0V,CTL=6.5V unless otherwise specified.)

Parameter Symbol specification value UNIT Condition

MIN TYP MAX

Circuit current 1 IQ1 - 0 10 μA CTL=0V

Circuit current 2 IQ

- 3.4 - mA CTL=VCC

< Error amplifier part >

Standard voltage (VREF)V

RE

0.792 0.8 0.808 V Terminal FB and FC terminal short

Terminal FB Input bias current IFBB -1 0 1 μA VFB=0.9V

Terminal FC Clamping voltage H VFCH 1.8 - - V VFB=0.7V

Terminal FC Clamping voltage L VFCL - - 0.2 V VFB=0.9V

Terminal FC Sink current IFCSINK 0.5 - - mA VFB=0.9V, VF

=0.4V

Terminal FC Source current IFCSOURCE - - -70 μA VFB=0.7V, VF

=1.6V

Open loop gain AVER

- 100 - dB

<OSC part>

Oscillation frequency FOSC 400 500 600 kHz

When terminal RT 27kΩis

connected

<Soft start >

Charging current ISS -3 -2.5 -2 μA VSS=1.0V

Terminal SS Threshold voltage VSSTH 0.98 1.08 1.18 V VSS Volta

e

Terminal SS Clamping voltage VSSCLM 2.2 2.4 - V

Terminal SS Standby voltage VSSSTB 0.1 0.15 - V VSS Volta

e(L→H)

Terminal SS Discharge resistance RSS 49 70 91 kΩCTL=0V

Terminal SS Protection circuit start voltage VSSPON 1.0 1.1 1.2 V VSS Volta

e(L→H)

Terminal SS Protection circuit start voltage

Maximum hysteresis error VSSPON_HYS 10 100 200 mV VSS Voltage

< Low voltage, over voltage detection part>

Terminal FB Low voltage detection voltage VLV

0.51 0.56 0.61 V VFB Volta

e

Terminal FB Overvoltage detection voltage VOV

0.86 0.96 1.06 V VFB Volta

e

< Over current detection part>

Output current limitation threshold Ilm

VCC-0.9 VCC-0.7 VCC-0.5 V VSW Volta

e

<Power MOS>

Upper side MOS ON resistance RONU - 110 - mΩV

BOOT-VSW =5V

Lower side MOS ON resistance R

NL - 110 - mΩV

VREG

=5V

<Others>

Terminal PDET L output voltage VOL

DET - - 0.4 V IOL=100uA

Terminal CTL input voltage H level voltage VIH_CTL 2.0 - VCC V CTL terminal

Terminal CTL input voltage L level voltage VIL

CTL - - 0.5 V CTL terminal

Terminal CTL input current II

CTL - 60 90 μA CTL terminal, CTL=VCC

VFB : FB terminal voltage, VFC : FC terminal voltage, VSS : SS terminal voltage, VMONVCC : MONVCC terminal voltage

Not designed for radiation resistance.

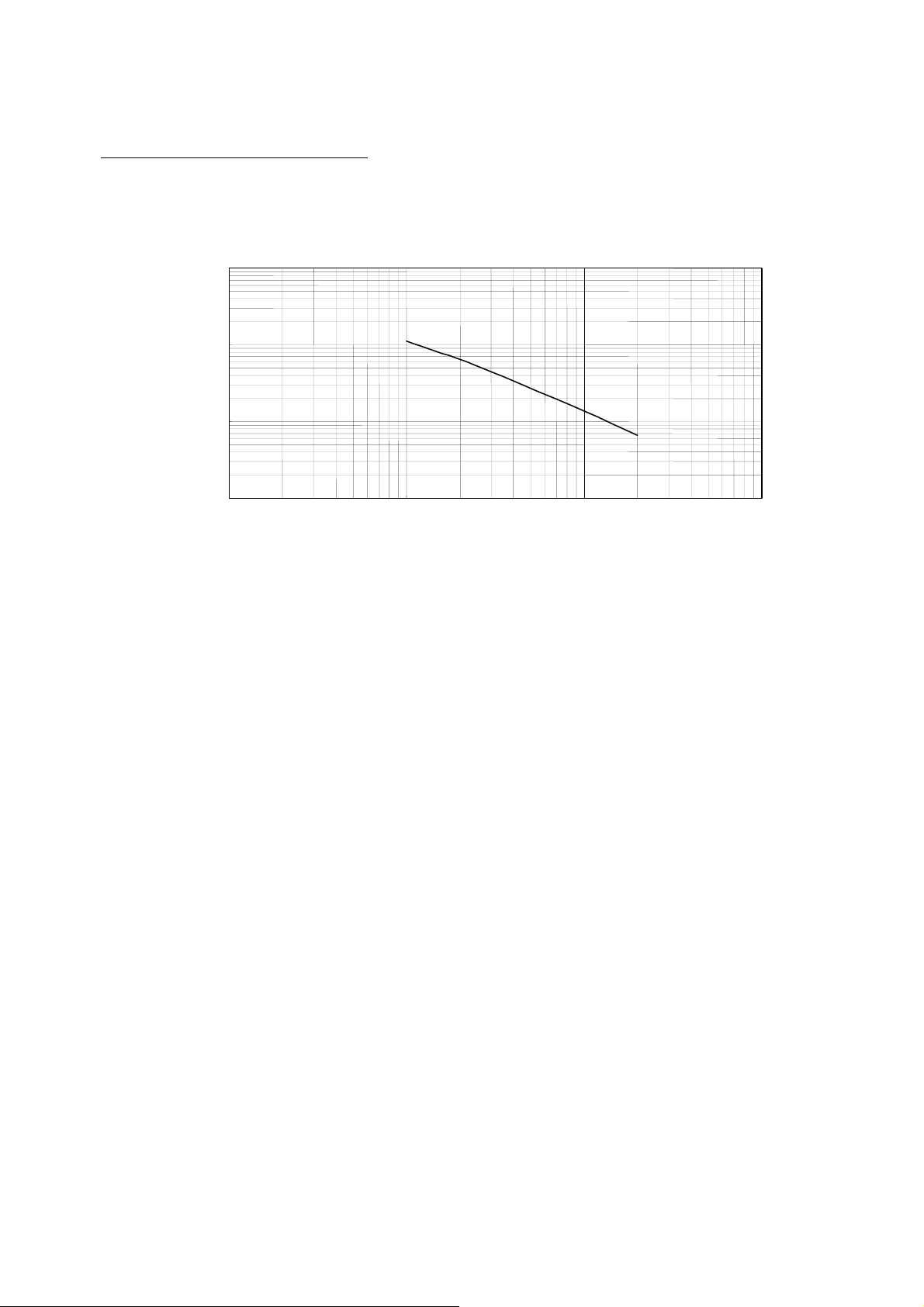

Current capability should not exceed Pd.