- 4 -

SAFETY WARNINGS

READ AND UNDERSTAND ALL SAFETY WARNINGS BEFORE USING AIR COMPRESSOR

Hazard Level Potential of Hazard How to Avoid Hazard

Risk of Asphyxiation

Serious injury or death may occur from

inhaling compressed air. The air stream may

contain carbon monoxide, toxic vapors, or

solid particles.

Never inhale compressed air directly from the

pump, receiver, or from a breathing device

connected to the air compressor.

Sprayed materials such as paint, stucco,

insecticides, solvents, etc. contain harmful

vapors and poisons that may cause serious

injury or death if inhaled.

Operate compressor only in a well-ventilated

area. Use a respirator device and follow the

manufacturer’s recommendations for their

spray equipment. Keep compressor at least

25 feet away from spray equipment.

Serious injury or death may occur if the

exhaust from gas-powered small engines is

inhaled. Engine exhaust fumes contain

poisonous, carbon monoxide which is odorless

and colorless.

Operate gas-powered compressors only in a

well-ventilated area. Avoid inhaling engine

exhaust fumes, and never run a small gas-

powered engine in a closed building or

confined area without adequate ventilation.

Risk of Bursting

Serious injury or death may occur from an air

tank explosion if the air tanks are not properly

maintained or if modifications, alterations or

repairs are attempted to the air receivers.

Drain air tanks daily or after each use. Never

drill into, weld, patch or modify the air tanks.

If a leak develops, replace the tank

immediately or replace the entire compressor.

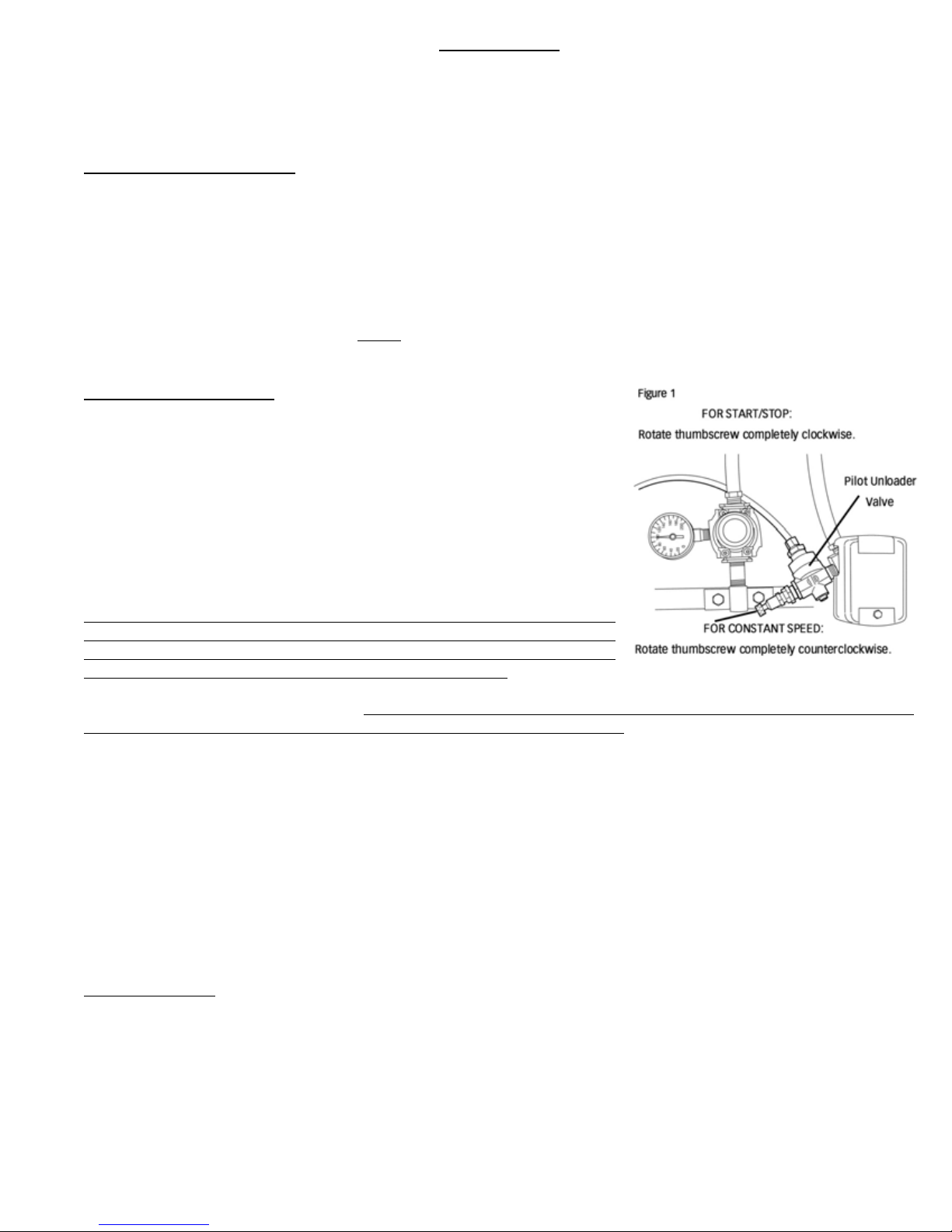

Serious injury or death may occur if

modifications are made to the pilot unloader

valve, pressure switch, safety relief valve or

other components that control the tank

pressure.

Never make adjustments to the components

that control tank pressure. Do not make

alterations to the factory operating pressure

settings. Check operation of the safety valve

on a regular basis and never operate without a

factory approved safety valve.

Serious injury may occur if accessories or

attachments are operated above the

manufacturer’s recommended pressure

ratings, causing them to explode or fly apart.

Do not use air tools or attachments before

reading the owner’s manual to determine the

maximum pressure recommendations. Never

exceed the manufacturer’s maximum

allowable pressure ratings. Do not use

compressor to inflate small low pressure

objects such as toys.

Risk of Electrocution or

Electrical Shock

Serious injury or death could occur if the air

compressor is not properly grounded.

Always plug compressor into a properly

grounded outlet which provides correct

voltage, proper grounding and adequate fuse

protection.

Electrical shock may occur if compressor is

not properly operated.

Never operate air compressor in wet

conditions or outdoors when it’s raining. Do

not allow electric cords to lay in water. Do not

operate with damaged power cord or with

protective electrical covers removed. Do not

touch plug with wet hands. Do not pull on

electric cord to disconnect from the outlet.

Serious injury or death may occur if electrical

repairs are attempted by unqualified

personnel.

Any electrical repairs or wiring performed on

this compressor should only be performed by

authorized service personnel in accordance

with the National and Local Electric Codes.

Risk of Explosion or Fire

Serious injury or death may result from normal

electrical sparks that occur within the motor

and/or pressure switch.

Always operate compressor in a well-

ventilated area free of combustible materials,

gasoline, flammable solvents or vapors.

Always locate compressor at least 20 feet

away from work area if spraying flammable

materials.

Serious injury may occur if a fire is caused by

overheating due to inadequate ventilation or

restrictions to any of the compressors

ventilation openings.

Never place objects against or on top of an air

compressor. Always operate air compressor

at least 18” away from any wall or obstruction.

Always operate in a clean, dry and well-

ventilated area.

Serious injury or death may occur from a fire

or explosion if spilled gas or vapors come in

contact with hot engine parts and ignite.

Never attempt to fill the gas tank while the

engine is hot or running. Add fuel outdoors in

a well-ventilated area. Do not fill gas tank near

lit cigarettes or near other sources of ignition.

WARNING

The engine exhaust from this product

contains chemicals known to the State

of California to cause cancer, birth

defects or other reproductive harm.