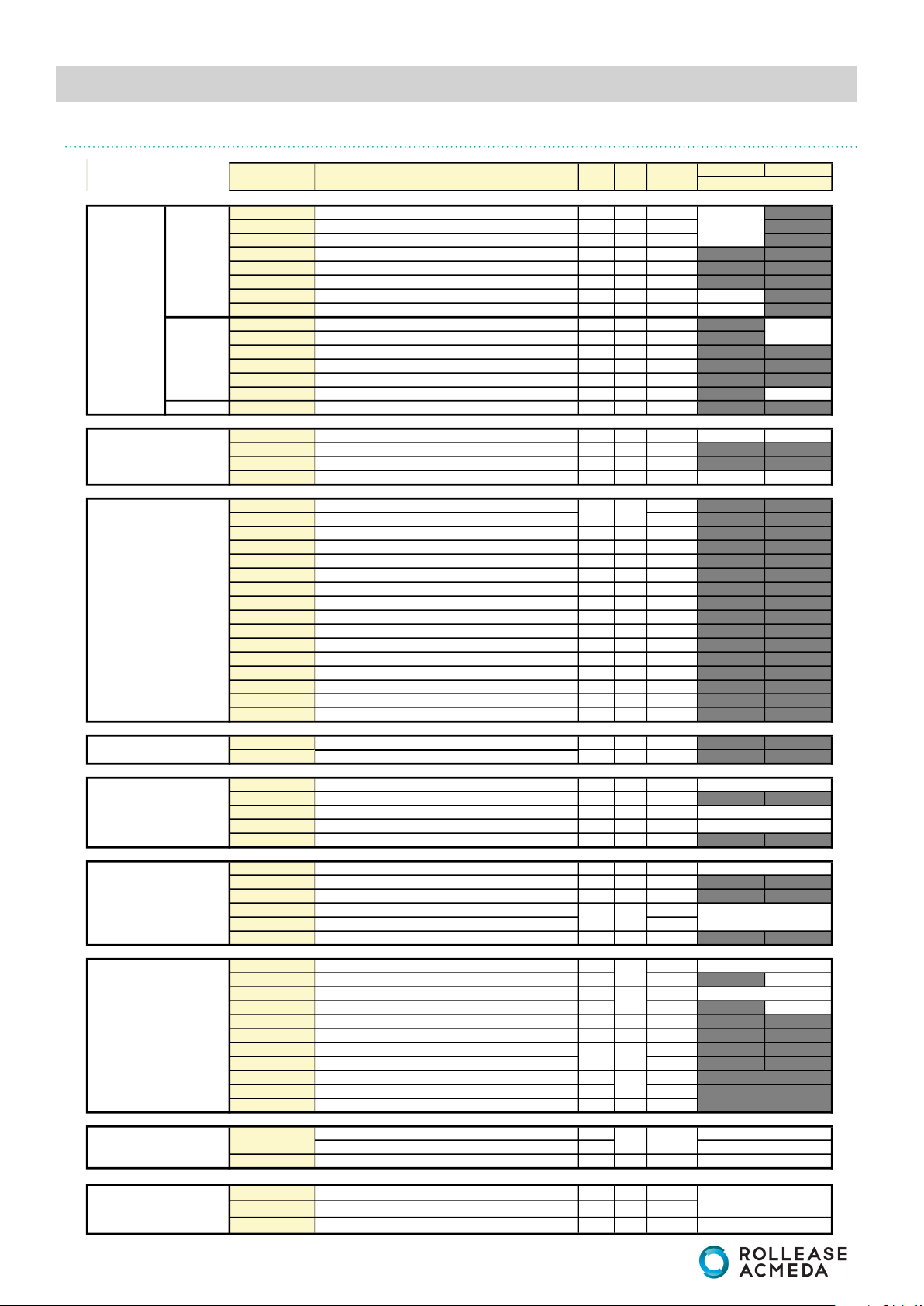

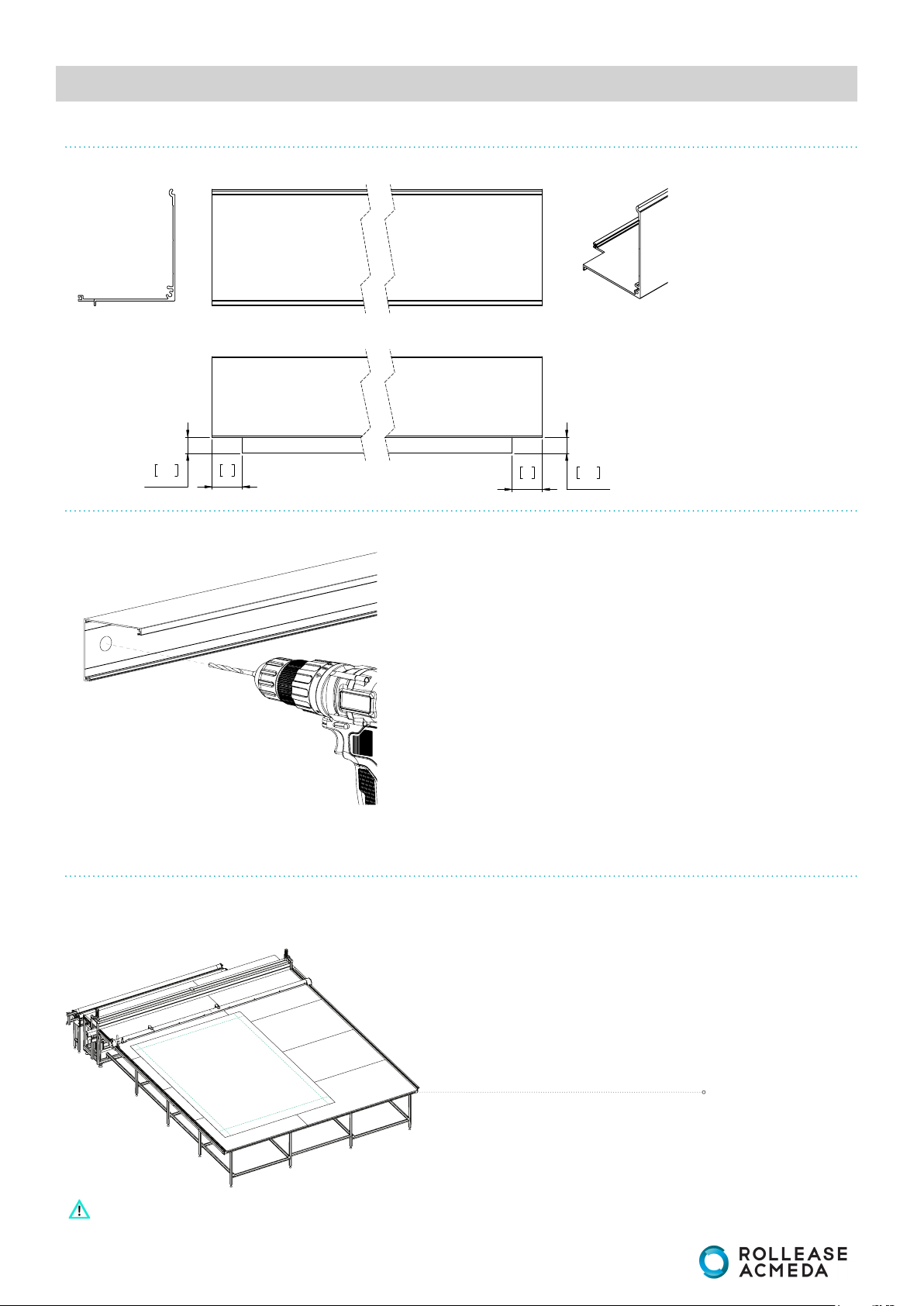

SB01-1010-xxxLLL Box Square 100 Back mm [in] 2 GL

SB01-1030-xxxLLL Box Square 100 Top mm [in] 2 GL

SB01-1025-xxxLLL Box Square 100 Cover mm [in] 2 GL

SB02-1001-xxx020 Box 100 - Universal End Plate Set - With Ears - 1 GL

SB02-1001-xxx010 Box 100 - Universal End Plate Set - WithOUT Ears - 1 GL

SB02-1020-xxx020 Box 100 End Plate Cover Set - 2 GL

SB91-0011-050LLL Fabric Brush - T-Slot Fit - 5mm High x 4.8mm Wide mm [in] 2 GL W - 11 [0.43]

SB91-0201-050100 Edge Strip D-Section mm [in] 2 GL W - 115 [4.53]

SB01-1326-xxxLLL Box 120 - Cover, 'SH-33' Square - 5.8mt Length mm [in] 2 GL

SB01-1340-xxxLLL Box 120 - TOP & BACK - 5.8mt Length mm [in] 2 GL

SB02-1201-025020 Box 120 - Universal End Plate Set - With Ears - 1 GL

SB02-1201-025010 Box 120 - Universal End Plate Set - WithOUT Ears - 1 GL

SB02-1220-xxx020 Box 120 'SH33' End Plate Cover - 2 GL

SB91-0011-050LLL Fabric Brush - T-Slot Fit - 5mm High x 4.8mm Wide mm [in] 2 GL W - 11 [0.43]

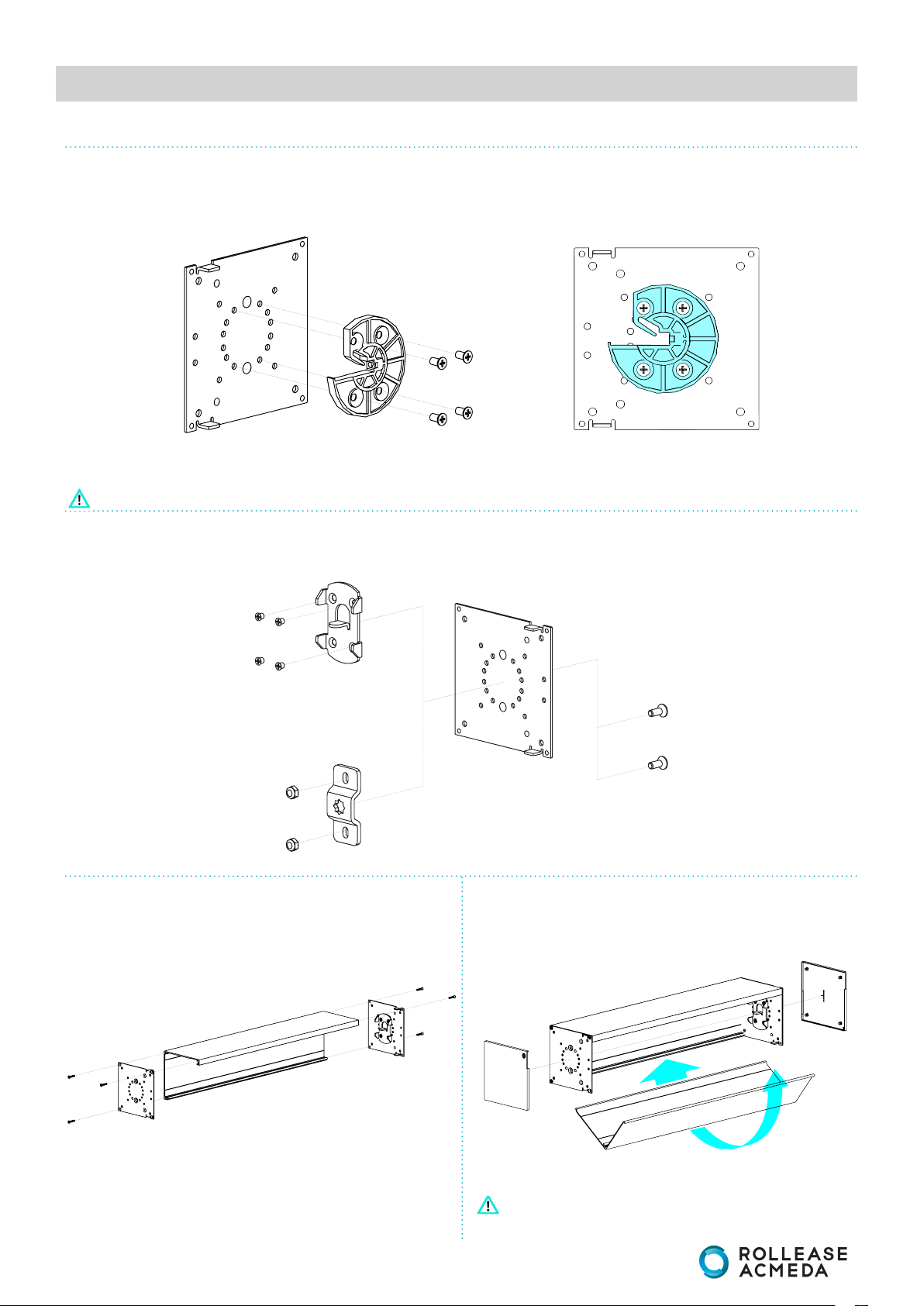

RB10-6400-xxx001 RB10 Idler Head Bracket Adapter & Screws | S60 - 3 GL

SB04-0702-xxxLLL ZIPSCREEN - 'U' Mounting Rail mm [in] 2 GL D - 203 [7.99] D - 243 [9.57]

SB05-1411-050001 Zipscreen | Inner Rail Funnel & Stop Set - 2 GL

SB05-1611-xxx001 Skylight Zipscreen Inner Rail End Cap + Screw - 2 GL

SB04-0701-xxxLLL Zipscreen - Zip Inner Rail mm [in] 2 GL D - 223 [8.78] D - 265 [10.43]

MT01-1145-050001 AUTOMATE | ARC FT 15Nm Motor w/ Adaptor Bracket AU, EU

MT01-1145-06900x AUTOMATE | ARC FT SLIM Motor US

RB56-0701-xxx508 AUTOMATE | S60 Motor Adapter Set - 1 AU, EU

RB56-0711-050509 AUTOMATE | Motor Head Plate | S60 - 1 AU, EU

RB56-0136-050508 AUTOMATE | Crown Wheel S60 - 1 AU, EU

RB56-0105-050518 AUTOMATE | Drive Wheel | S60 - 1 AU, EU

RB56-0721-069518 AUTOMATE | ARC Motor Adapter Set | S60/S80 - 1 US

RB56-0336-050502 AUTOMATE | Crown & Drive Set |S60 - 1 US

MTCLIP-35-45 Motor Drive Clip for 35/45mm Motors - 1 US

Not Supplied Somfy M50 Motor (Round/Star Head) - 1 -

RE01-0604-025000 Somfy M50 Round Head Motor Adaptor & Bracket + Screws - 1 AU, EU

RE01-0601-025000 AUTOMATE | Veue 45mm Motor Bracket Adaptor + Screws - 1 US

RE01-0602-025000 Somfy M50 Round Head Motor Adaptor + Screws - 1 US

RB56-0763-014050 Universal Zamack Adapter with Lock Ring & Screws - 1 GL

RB56-0236-050501 M50 Crown Wheel | 60STD (Somfy Sonesse 50) - 1 GL

RB56-0205-050511 M50 Drive Wheel | 60STD (Somfy Sonesse 50) - 1 GL

RB10-6400-050001 RB10 Idler Head Bracket Adapter & Screws | S60 - 3 GL

RB10-6200-050001 RB10 Bearing Idler - 2 GL

RE15-0111-xxxLLL F72 HD Weight Bar mm [in] 1 GL

RE15-0511-xxx000 F72 HD Weight Bar End Caps - 1 GL

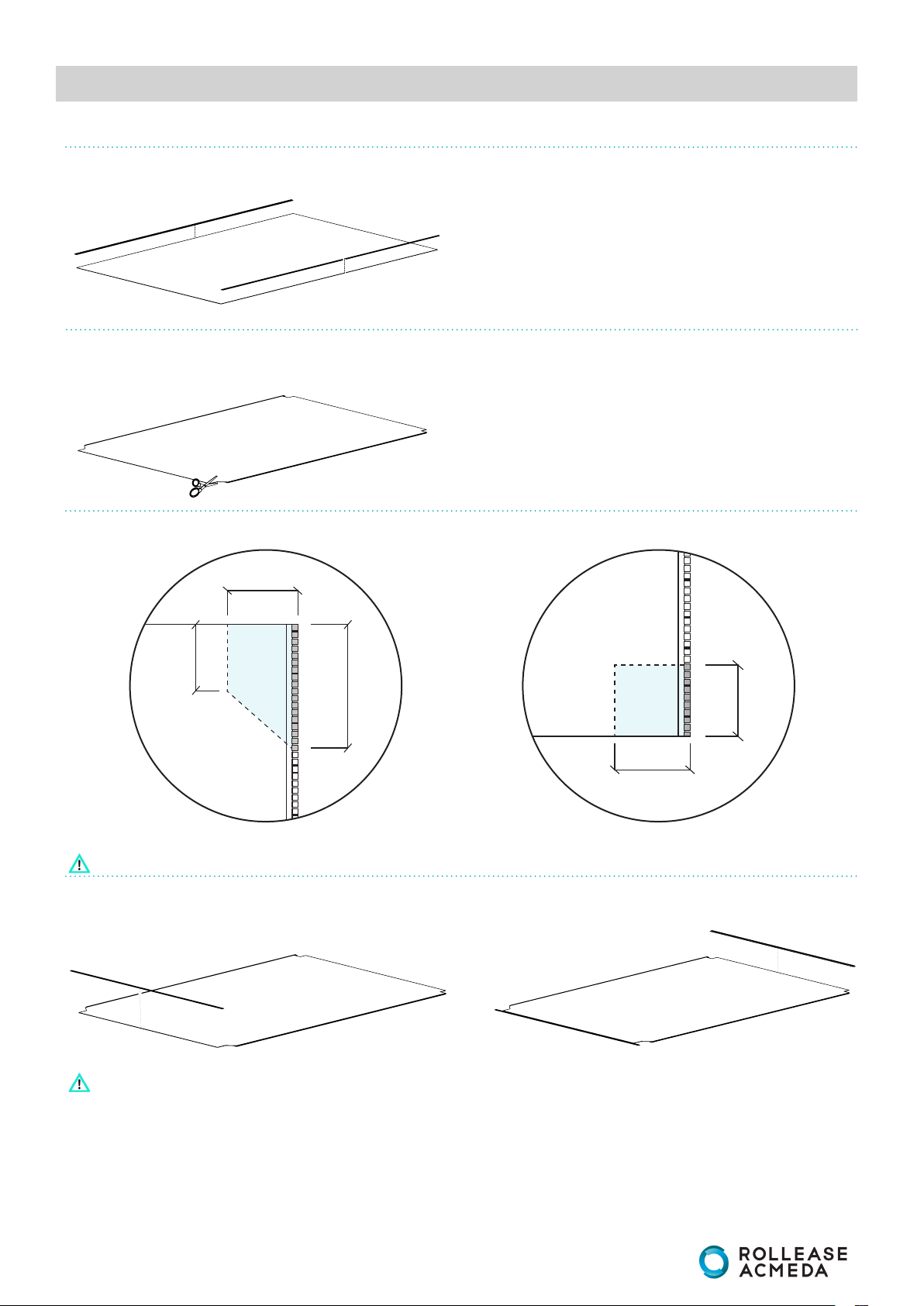

SB91-0001-050580 Bubble Seal Strip mm [in] 1 GL

SB91-0408-001015 7.2mm Spline with 15mm Tail mm [in] 1 GL

SB06-1332-060020 Wire Guide Ceramic Block - 2 GL

RB91-0260-000LLL SYS60 | 60-STD Aluminium Tube | OD 60.0mm mm [in] 1 GL

RB10-6000-050060 RB10 Tube Adapter | 60mm Tube - 1 GL

RB10-6200-050001 RB10 Bearing Idler Head - 2 GL

SS95-6038-050500 Lift Tape, Outdoor, 6.0mm wide x 0.38mm thick, Black GL

AC02-1500-050500 Cord, Braid PET HT Core with Dyneema, 1.5mm GL

SS48-1061-xxx090 SKYLIGHT Tape Spool - 9mm Tape + Fixing Screw | SYS60 - 2 GL

RB91-0260-000LLL SYS60 | 60-STD Aluminium Tube | OD 60.0mm mm [in] GL

RB91-0280-000LLL SYS60 | 80HD Aluminium Tube | OD 80.0mm mm [in] GL W - 121 [4.76]

RB92-0902-001075 9mm ACM Flat Spline - D/S MP-HR TAPE - 75 Lm Roll mm [in] GL

SH91-0135-050200 ZIP / No. 6 Gauge - Double Sided | 200mt Roll (Spline) mm [in] GL W - 82 [3.23]

RB10-6200-050001 RB10 Bearing Idler - 1 GL

RB10-6220-050001 RB10 Pre-Tension Idler (LH) - 1 GL

RB10-6040-050051 RB10 Retro-Fit Booster Extra Heavy (LH) GL

RB10-6040-050161 RB10 Retro-Fit Booster Short (LH) GL

SB11-0813-050360 ZIP - Tube Reducer - Medium (60mm to 45mm) - GL

SB11-0815-050580 ZIP - Tube Reducer - Long (80mm to 60mm) - GL

RB10-6000-050060 RB10 Tube Adapter | S60 - 2 GL

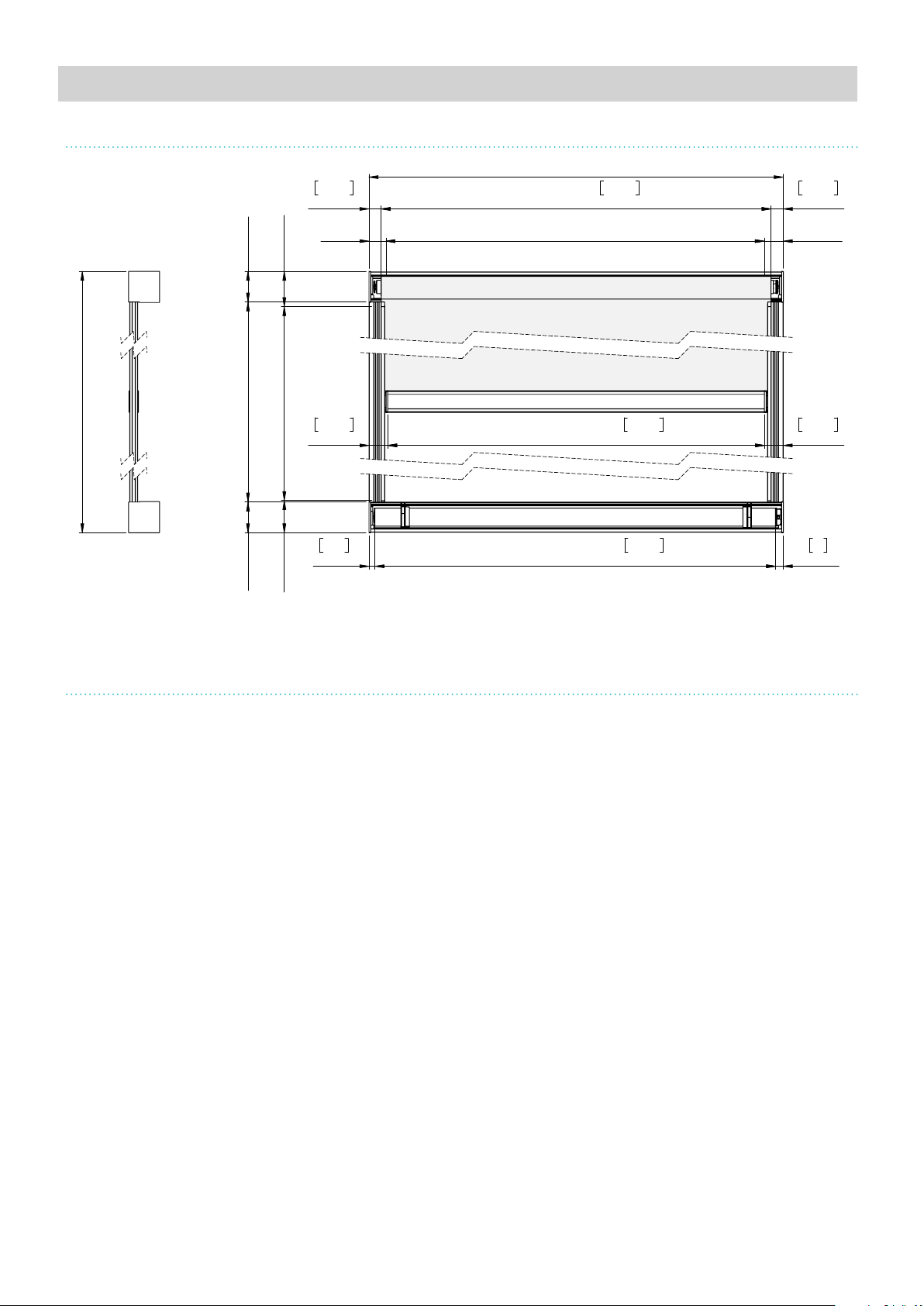

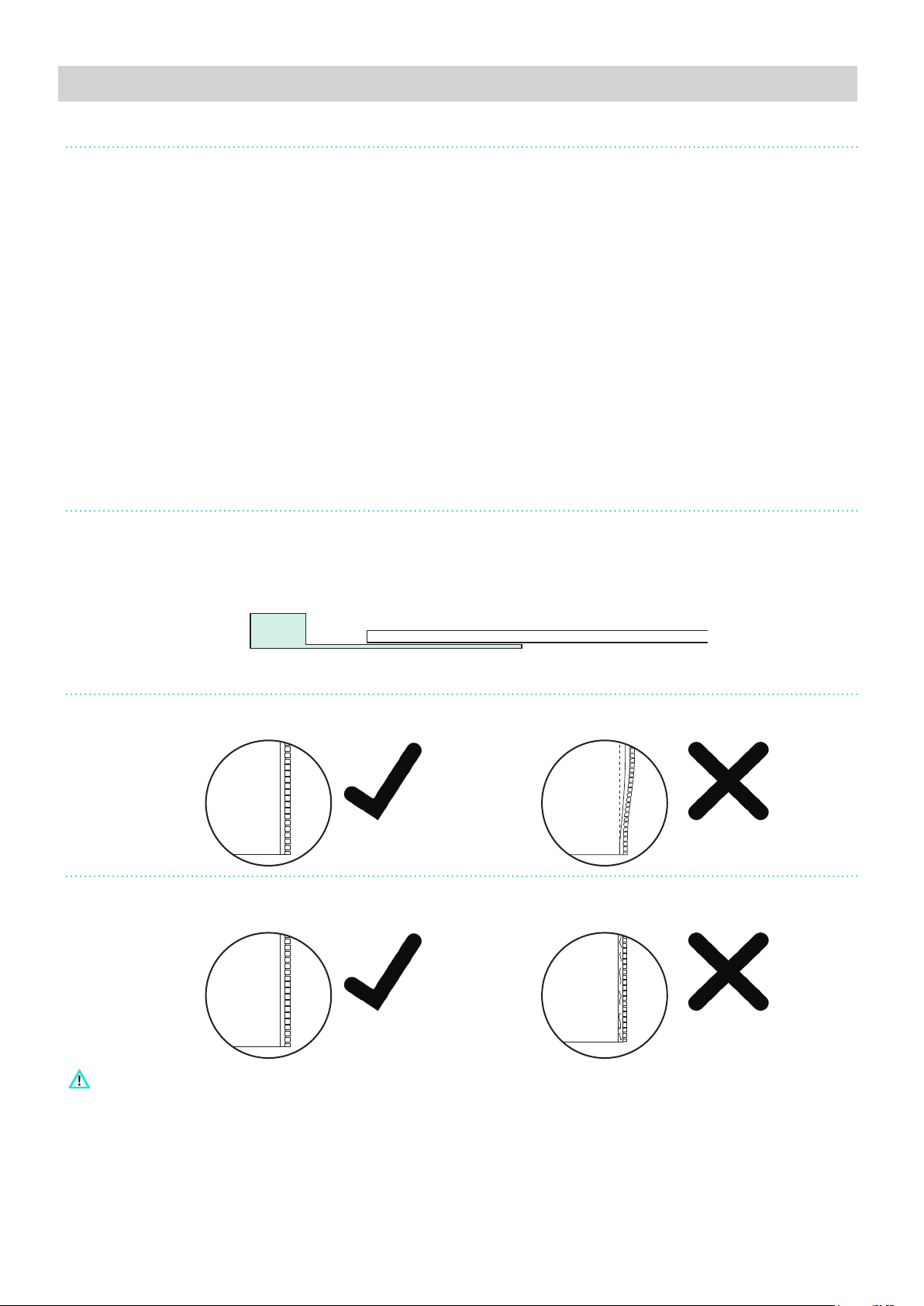

Fabric Width mm [in]

Fabric Drop mm [in]

SH91-0135-050200 ZIP / No. 6 Gauge - Double Sided | 200mt roll mm [in] 1 GL

MT01-1145-050001 AUTOMATE | ARC FT 15Nm Motor w/ Adaptor Bracket mm [in] - AU, EU

Not Supplied Somfy M50 Motors (Round Head / Star Head) mm [in] - -

MT01-1145-06900x AUTOMATE | ARC FT SLIM Motor mm [in] - US W - 61 [2.40]

W - 73 [2.87]

CONTROL

-1

SPOOL / MOTOR TUBE

IDLER

WEIGHT BAR

W - 124 [4.88]

W - 106 [4.17]

W - 82 [3.23]

SEE SPOOL TUBE DEDUCTIONS

mm [in]

Zipscreen - Skylight BOM & DEDUCTIONS

PART NUMBER DESCRIPTION U.O.M QTY REGION

BOX 100

BOX 120

ZIPSCREEN ATTACHMENT

W - 11 [0.43]

W - 11 [0.43]

BOX OPTIONS

FABRIC / SPRING TUBE

1W - 120 [4.72]

1W - 82 [3.23]

-1

2BOX 100 ONLY

BOX 120 ONLY

W - 82 [3.23]

Shade Drop (D) + 100 [4]

W - 82 [3.23]

1 (D x 2) + W

SPOOL TUBE DEDUCTIONS

FABRIC Not Supplied 1 -

Page. 02 Zipscreen Skylight Assembly Manual | November 2018

2018 ©Copyright All Rights Reserved Rollease Acmeda

BILL OF MATERIALS

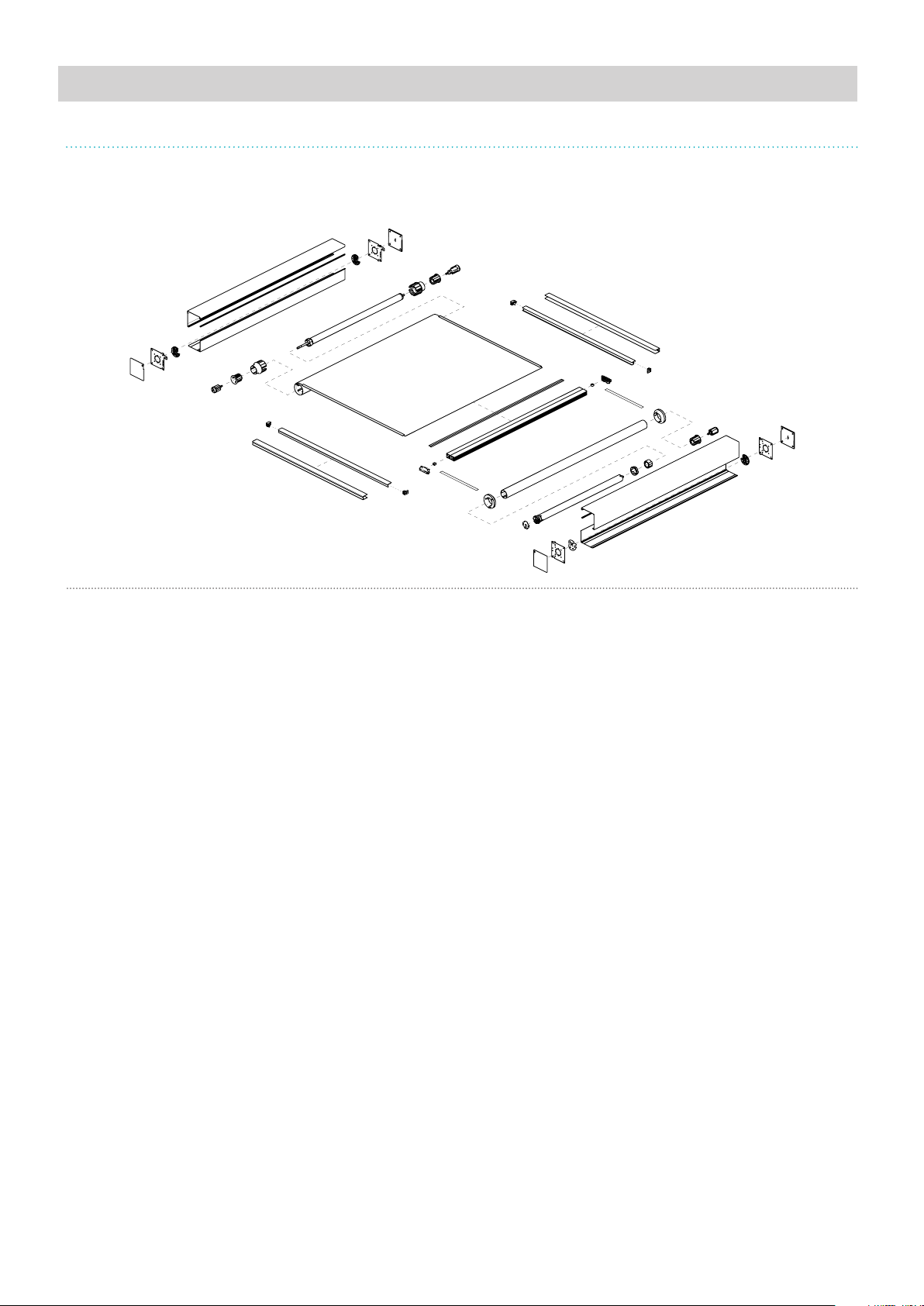

SECTION A: | OVERVIEW