Page 6of 14

Zipscreen Installation Manual | v4.2| August 2019

2019 ©Copyright All Rights Reserved Rollease Acmeda

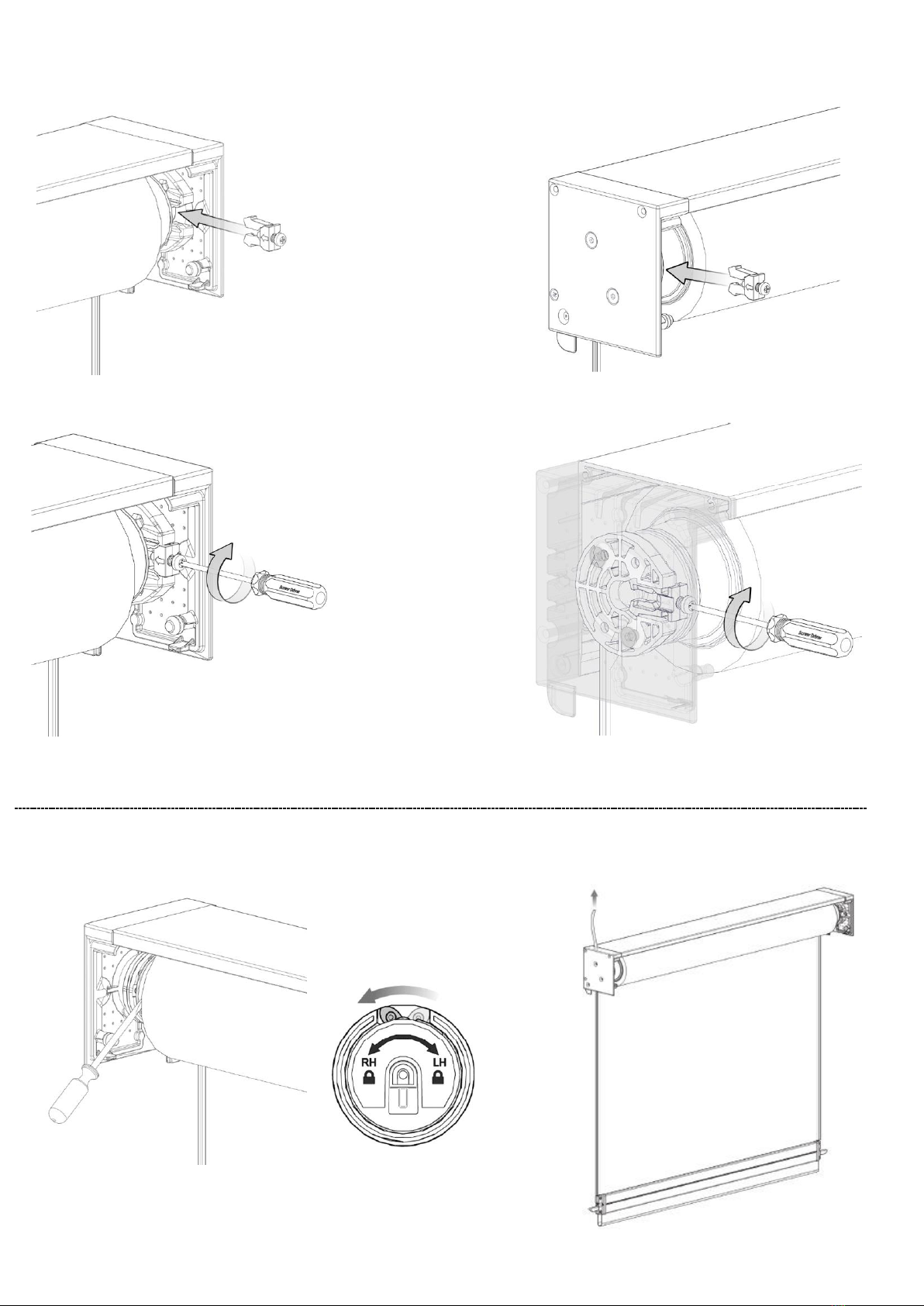

STEP 3 –ADD ADDITIONAL PRE-TURNS REQUIRED

Note: Gradually increase the number of pre-turns required. Only remove the pre-tension spanner when the spring tension is held by the internal

mechanism, immediately after a ‘click’ is heard.

STEP 4 –UNLOCK PRE-TENSION HEAD STEP 5 –RE-INSTALL AND TEST BLIND

Note: When the weight bar is pulled down, the tension in

the spring will be released.

If too many pre-turns are added, the blind will automatically raise.

Note: Re-install and secure Retainer Clip when complete.

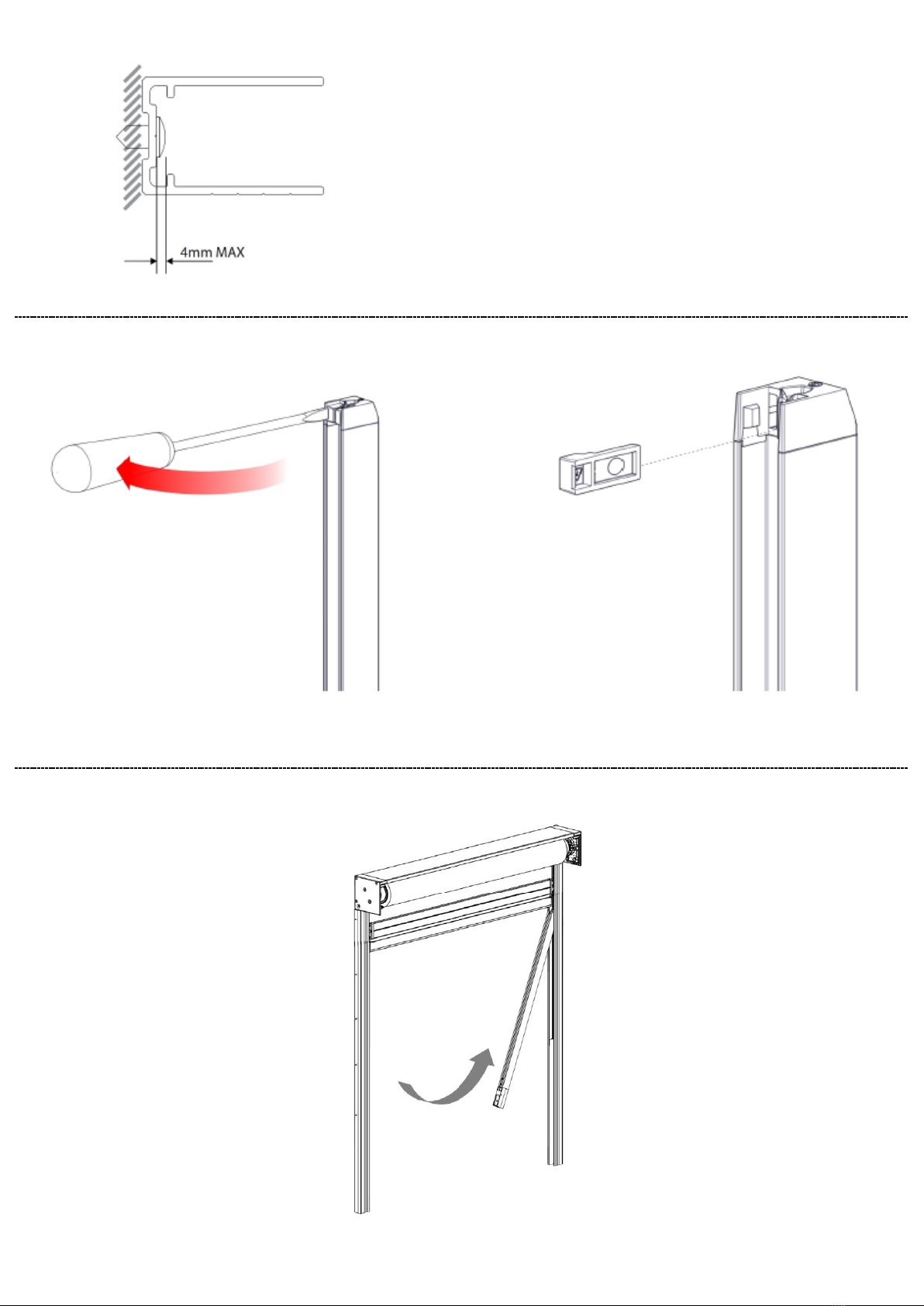

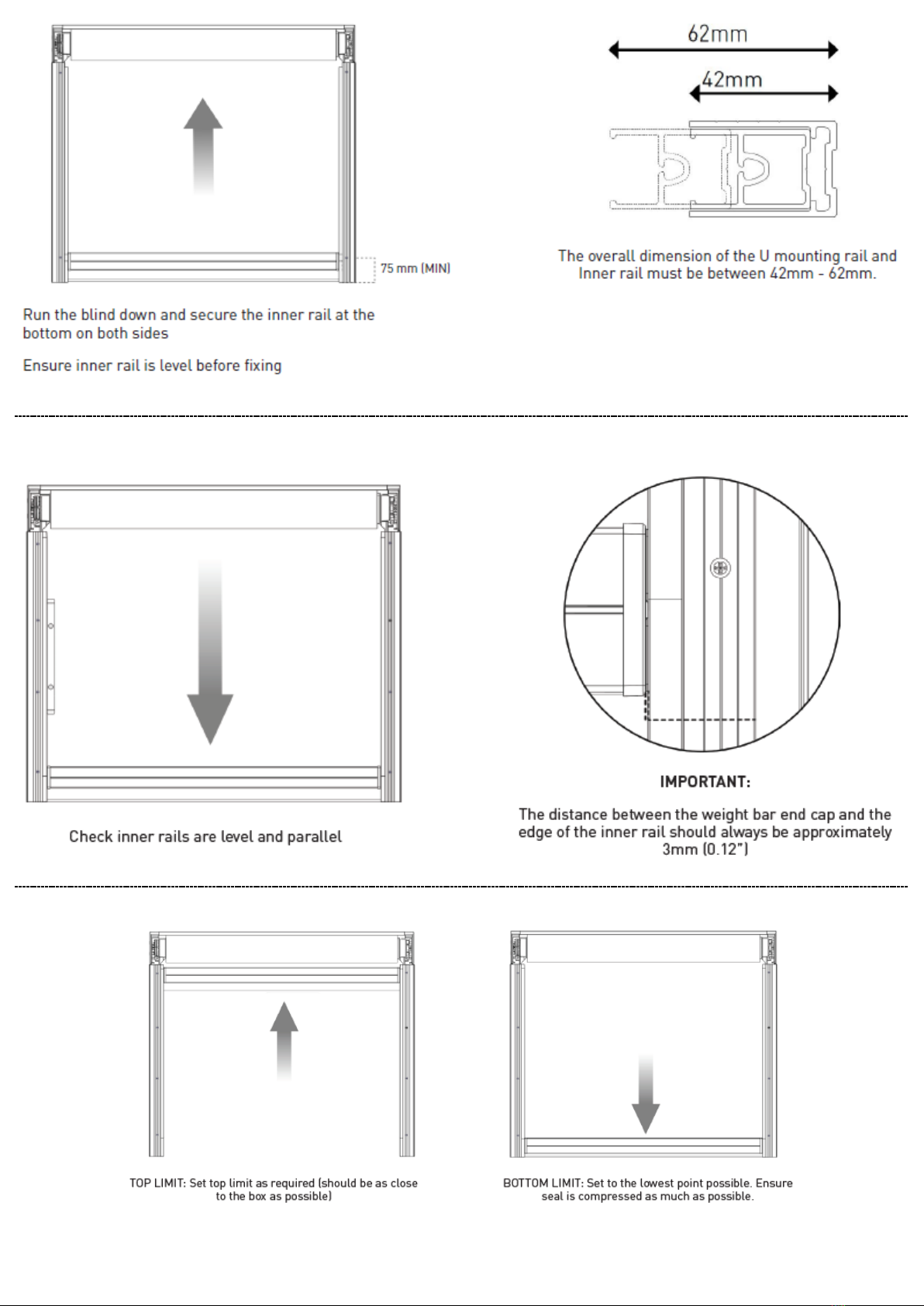

PART I –SIDE GUIDE INSTALLATION

STEP 1 –MARK OUT SIDE GUIDE POSITION AND ALIGN RAIL (FOR OPEN BRACKET ONLY)

Note: Use Open Bracket Template (RE01- Use thickness of Open Bracket Template Rail to sit flush to bracket

3012-033000) to assist