3.6. Screen 8

3.7. Mirror 8

3.8. Rear Cover (Upper) 8

3.9. Rear Cover (Bottom) 9

3.10. Disassembly For CRT Removal 9

4 Service Hints 11

4.1. Service position for Main chassis 11

4.2. Service Position for DG-Board 11

4.3. Service Position for K-Board 11

4.4. Service Position for KA-Board 11

4.5. Service Position for G-Board 12

5SelfCheck 13

6 Service Mode Function 14

6.1. How to enter SERVICE 1 14

6.2. How to enter SERVICE 2 14

6.3. Option Descrition 16

7 CRT Set Up 19

7.1. Dynamic Focus Adjustment 19

7.2. Electrical Focus Adjustment 19

7.3. Optical Lens Focus Adjustment 19

7.4. Centering Magnet Adjustment 20

7.5. Alignment magnet Adjustment 21

8 Deflection Adjustment 22

8.1. PAL 100Hz mode (100i) 22

8.2. PAL 100Hz V Comp mode (100i) 23

8.3. PAL Progressive mode (50p) 24

8.4. NTSC Progressive mode (60p) 24

8.5. 525p Deflection Adjustment / Confirmation 25

8.6. 625p Deflection Adjustment / Confirmation 25

9 Adjustment Procedure 26

9.1. Cut off Adjustment 26

9.2. Sub Contrast / G-Limit Adjustment 27

9.3. Sub Picture Contrast Adjustment 27

9.4. NTSC Tint Adjustment 28

9.5. Sub Color Adjustment 28

9.6. Blue Focus / Gamma Adjustment 29

9.7. White Balance Adjustment 29

9.8. Sub Bright Adjustment 30

9.9. Blue Limit Adjustment 30

10 Convergence Adjustment 31

10.1. Convergence Adjustment Sheet 31

10.2. Convergence Adjustment Procedure 32

10.3. Coarse Convergence Adjustment mode 33

10.4. Fine Convergence Adjustment 39

11 Location of Lead Wiring 43

11.1. Location of Lead Wiring (1) 43

11.2. Location of Lead Wiring (2) 43

11.3. Location of Lead Wiring (3) 43

11.4. Location of Lead Wiring (4) 44

11.5. Location of Lead Wiring (5) 46

11.6. Location of Lead Wiring (6) 48

11.7. Location of Lead Wiring (7) 48

11.8. Location of Lead Wiring (8) 49

11.9. Location of Lead Wiring (9) 49

12 Conductor Views 51

12.1. A-Board 51

12.2. D-Board 53

12.3. DC-Board 56

12.4. DG-Board 57

12.5. H-Board 61

12.6. LG, LR and LB Board 63

12.7. P-Board 64

12.8. SG-Board 66

12.9. SR and SB Board 67

12.10. U-Board 68

12.11. G, K and KA-Board 70

13 Block Diagram 71

13.1. Audio Block Diagram 71

13.2. Video Block Diagram 72

13.3. Power Block Diagram 74

13.4. Control Block Diagram 77

14 Schematic Diagram 79

14.1. Schematic Diagram Notes 79

14.2. A-Board (1 of 5) Schematic Diagram 80

14.3. A-Board (2 of 5) Schematic Diagram 81

14.4. A-Board (3 of 5) Schematic Diagram 82

14.5. A-Board (4 of 5) Schematic Diagram 83

14.6. A-Board (5 of 5) Schematic Diagram 84

14.7. D-Board (1 of 2) Schematic Diagram 85

14.8. D-Board (2 of 2) Schematic Diagram 86

14.9. DC-Board Schematic Diagram 87

14.10. DG-Board (1 of 6) Schematic Diagram 88

14.11. DG-Board (2 of 6) Schematic Diagram 89

14.12. DG-Board (3 of 6) Schematic Diagram 90

14.13. DG-Board (4 of 6) Schematic Diagram 91

14.14. DG-Board (5 of 6) Schematic Diagram 92

14.15. DG-Board (6 of 6) Schematic Diagram 93

14.16. H-Board (1 of 2) Schematic Diagram 94

14.17. H-Board (2 of 2) Schematic Diagram 95

14.18. LG-Board Schematic Diagram 96

14.19. LB and LR-Board Schematic Diagram 97

14.20. P-Board Schematic Diagram 98

14.21. SG-Board Schematic Diagram 99

14.22. SB and SR-Board Schematic Diagram 100

14.23. U-Board (1 of 2) Schematic Diagram 101

14.24. U-Board (2 of 2) Schematic Diagram 102

14.25. G, K and KA Board Schematic Diagram 103

15 Parts Location 105

16 Packing Exploded View 107

17 Mechanical Replacement Parts List 109

18 Electrical Replacement Parts List 110

18.1. Replacement Parts List Notes 110

18.2. Electrical Replacement Parts List 111

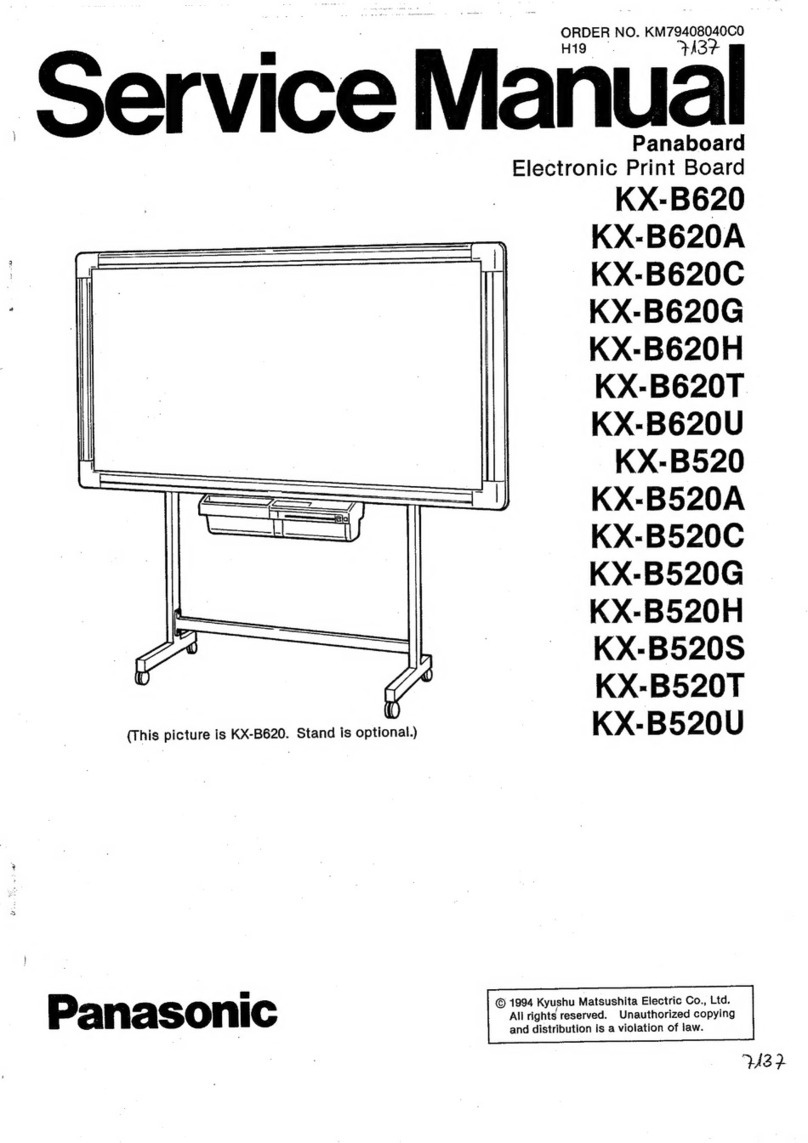

3

TX-47P800HQ / TX-47P800HZ