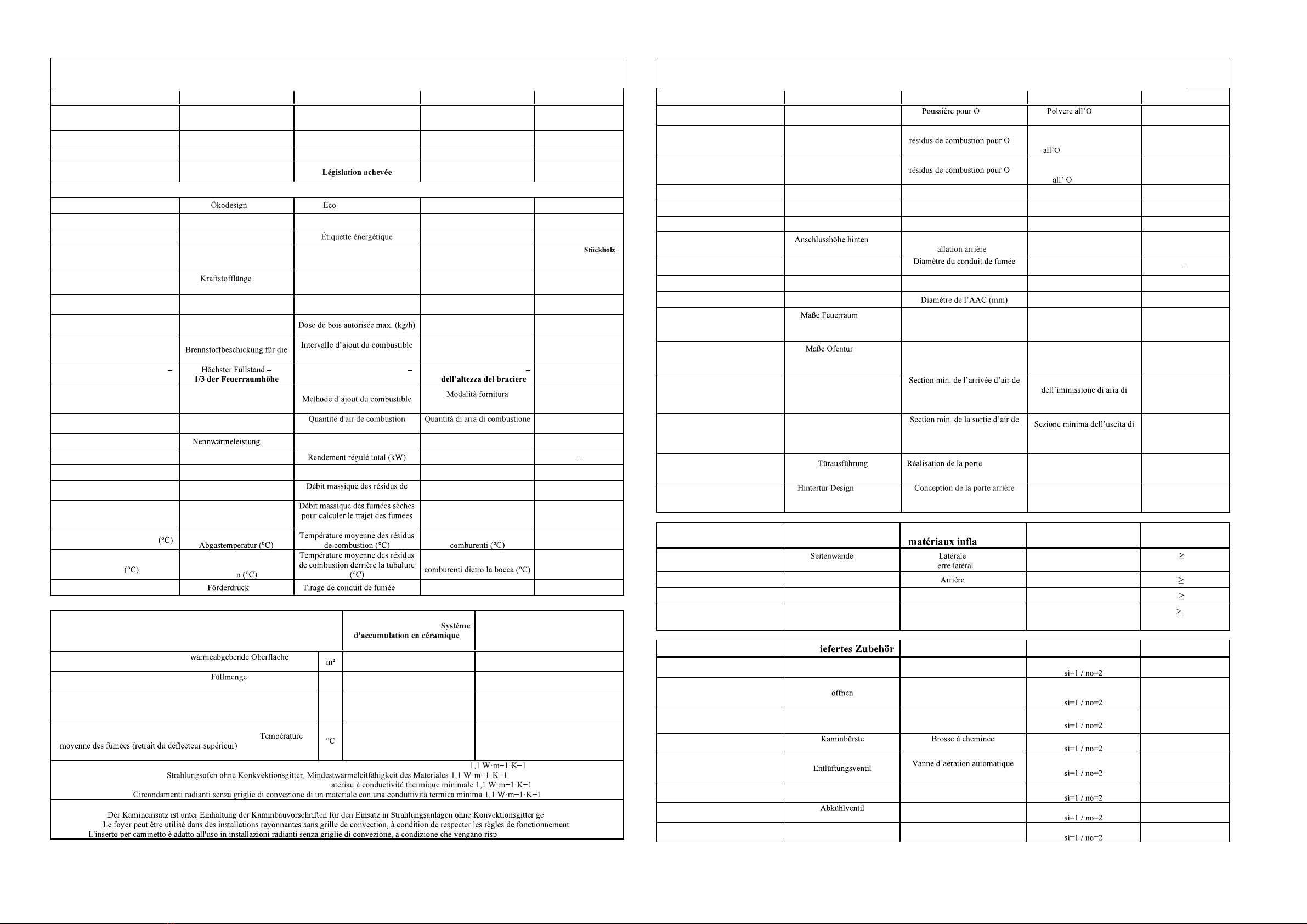

EN DE FR IT

Product name Produktbezeichnung Nom du produit Nome del prodotto Dynamic B 2G

66.50.13N

Dimensions HxWxD (mm) Abmessungen HxBxT (mm) Dimensions HxLxP (mm) Dimensioni AxLxP (mm) 1091 x 720 x 464

Weight (kg) Gewicht (kg) Poids (kg) Peso (kg) 179

Completed legislation Abgeschlossene

Gesetzgebung Legislazione completata -

EN 13 229 / 15a B-VG / DIN plus / BImSch V 1 / BImSch V 2

Eco-design (%) (%) -conception (%) Eco-design (%) 75,6

EEI EEI EEI EEI 113,7

Energy Label Energielabel Etichetta energetica A+

Prescribed fuel Vorgeschriebener Brennstoff Combustible prescrit Combustibile prescritto Piece wood /

Morceau de bois / Pezzo

di legno

Fuel length (mm) (mm) Longueur de carburant (mm) Lunghezza del carburante

(mm) 330

Average wood consumption (kg/h)

Durchschnittlicher

Holzverbrauch (kg(h) Consommation de bois moyenne

(kg/h) Consumo medio di legna

(kg/ora) 1,33

Max. allowed wood batch (kg/h) Max. erlaubte Holzzuladung

(kg/h)

Dose massima di legna

consentita (kg/ora) 1,9

Fuel supply interval for the rated

output

Zeitabstand der

Nennleistung pour la puissance nominale

Intervallo fornitura

combustibile per potenza

nominale

ora

The greatest height of the filling

1/3 of the firebox Hauteur maximale de la charge

1/3 de la hauteur du foyer Altezza massima caricamento

1/3 -

Fuel delivery method Art der Brennstoffbeschickung

combustibile

manually, von Hand,

manuellement,

manualmente

Amount of combustion air (m3/h) Menge an Verbrennungsluft

(m3/h)

(m3/h) (m3/h) 16,9

Nominal heat output (kW) (kW) Puissance nominale (kW) Potenza nominale (kW) 4,8

Total regulated output (kW) Reg. Gesamtleistung (kW) Potenza totale regolata (kW) 2,4 6,2

Efficiency (%) Wirkungsgrad (%) Rendement (%) Efficienza (%) 84,64

Mass flow rate of dry flue gases

(g/s) Massendurchfluss der

trockenen Abgase (g/s) combustion secs (g/s) Flusso peso combustib

(g/s) 4,1

Dry flue gases mass flow to

calculate the flue path (g/s)

Massendurchfluss von

trockenen Abgasen den

Schornsteinpfad berechnen(g/s)

(g/s)

Portata massica dei fumi secc

per calcolare il percorso dei

fumi (g/s) 6,1

Average flue-gas temperature

Durchschnittliche Temperatura media gas

208

Average flue gas temperature after

Flue pipe

Durchschnittliche

Abgastemperatur hinter dem

Stutze

Temperatura media gas

241

Flue draught (Pa) (Pa) (Pa) Tiraggio del camino (Pa) 10

Ceramic accumulation system /

Keramisches Zugsystem / /

Sistema di accumulo di ceramica

Accumulation rings / Aufsatzspeicher

Set Ringe / Anneaux de l'ensemble de

rangement des accessoires / Set di

archiviazione degli attacchi Anelli

Minimum radiant area / Mindest- /

Surface radiante minimale / Area radiante minima 3,5 ---

Maximal load of wood / Maximal Brennstoff- /

du bois / Carico massimo di legno kg 3,5 ---

Total heat output of the fireplace chamber / Feuerungsleistung / Puissance

thermique totale de la chambre du foyer / Potenza termica

del camino kW

11,0 ---

Average flue gas temperature (upper deflector removal) / Durchschnittliche

Rauchgastemperatur (Entfernen des oberen Deflektors) /

/ Temperatura media

dei gas di scarico (rimozione del deflettore superiore)

375 ---

Radiant surrounds without convection grids from a material with minimal thermal conductivity

Enveloppes rayonnantes sans grilles de convection en m

The fireplace insert is suitable for use in radiant fireplaces without convection grilles if the stove rules and regulations are followed.

eignet.

ettate le regole della stufa.

EN DE FR IT

Dust at O2 = 13%

(mg/Nm3) Staub bei O2= 13 %

(mg/Nm3) 2= 13%

(mg/Nm3) 2= 13 %

(mg/Nm3) 24

The concentration of CO

gases at O2= 13% (mg/Nm3)

CO Konzentration in den

Abgasen bei O2= 13%

(mg/Nm3)

Concentration en CO dans les

2=

13% (mg/Nm3)

Concentrazione CO nei gas

comburenti

= 13 % (mg/Nm3) 1130

The concentration of CO

in the flue gases

at O

= 13% (%)

CO Konzentration

in den Abgasen

bei O

= 13% (%)

Concentration en CO dans les

2=

13% (%)

Concentrazione CO

nei gas comburenti

= 13 % (%) 0,0900

CO2 (%) CO2 (%) CO2 (%) CO2 (%) 9,54

OGC - 02=13% (mg/m3) OGC - 02=13% (mg/m3) OGC - 02=13% (mg/m3) OGC - 02=13% (mg/m3) 37

NOx - 02=13% (mg/m3) NOx - 02=13% (mg/m3) NOx - 02=13% (mg/m3) NOx - 02=13% (mg/m3) 118

Connection height for rear

installation (mm) (mm) Hauteur de raccordement pour

l'inst (mm) Altezza di collegamento per

l'installazione posteriore (mm)

-

Flue pipe diameter (mm) Rauchabfuhrdurchmesser (mm)

(mm) Diametro del condotto fumi

(mm) 150 200

Flue throat (mm) Flue Hals (mm) Flue la gorge (mm) Fumi gola (mm) 200

CAI diameter (mm) CPV-Durchmesser (mm) Diametro ACA (mm) 150

Dimensions of the

chamber HxWxD

(mm)

HxBxT

(mm) Dimensions de la chambre de

combustion HxLxP

(mm)

Dimensioni della camera di

combustione AxLxP

(mm)

457 x 574 x 180

Dimensions of the furnace

door HxWxD

(mm)

HxBxT

(mm) Dimensions de la porte du four

HxLxP

(mm)

Dimensioni della porta del

forno AxLxP

(mm)

456 x 619

Min. cross section of convect air

inlet for nominal output

(cm2)

Min. Querschnitt der

Konvektionsluftzufuhr f. die

Nennleistung

(cm2)

convection pour rendement

nominal

(cm2)

Sezione minima

convezione per la potenza

nominale (cm2)

500

Min. cross section of convect air

outlet for nominal output

(cm2)

Min. Querschnitt des

Konvektionsluftausgangs f. die

Nennleistung (cm2)

convection pour rendement

nominal

(cm2)

aria di convezione per la

potenza nominale (cm2) 700

Door design

(Right=1 / Left=2 / Sliding =3)

(Rechts=1/Links=2/Schieben

(

Gauche=2 / Coulissant = 3)

(Destra=1 / Sinistra=2 /

estraibile = 3) 2

Back door design (No=0 /

/ Left=2 / Sliding =3)

(Nein=0 /

Rechts=1 / Links=2 / Schieben

= 3)

(Non =0 / Droite=1 / Gauche=2 /

Coulissant = 3)

Design della porta posteriore

(No=0 / Destra=1 / Sinistra=2

estraibile = 3) 1,2

Distance from flammable

materials Abstand von

Brennstoffen Eloignement des

mmables Distanza da materiali

infiammabili

Side (mm)

Side with glass (mm) (mm)

Seitenglas (mm) (mm)

V (mm) Laterali (mm)

Vetro laterale (mm) X 400

-

Back (mm) Hinterwand (mm) (mm) Posteriore (mm) Z 400

Front (mm) Frontwand (mm) Frontale (mm) Anteriore (mm) Y800

From the ceiling (mm) Von der Decke (mm) Du plafond (mm) Dal soffitto (mm) V1000

Supplied accessories

Mitgel

Accessoires fournis

Accessori forniti

Protective glove

yes=1 / no=2 Schutzhandschuh

ja=1 / nein=2 Gant de protection

oui=1 / non=2 Guanto protettivo

1

Hook to open the ashtray

yes=1 / no=2

Haken um den Aschenbecher

ja=1 / nein=2

Crochet pour ouvrir le cendrier

oui=1 / non=2

Agganciare per aprire il

posacenere

1

Ashtray

yes=1 / no=2 Aschenbecher

ja=1 / nein=2 Cendrier

oui=1 / non=2 Portacenere 1

Chimney brush

yes=1 / no=2

ja=1 / nein=2

oui=1 / non=2 Spazzola camino

2

Automatic

ventilation valve

yes=1 / no=2

Automatisches

ja=1 / nein=2

oui=1 / non=2 Valvola di scarico a

2

Cooling loop

yes=1 / no=2 Thermischen Ablaufsicherung

ja=1 / nein=2 Boucle de refroidissement

oui=1 / non=2 Ciclo di raffreddamento

2

Cooling valve

yes=1 / no=2

ja=1 / nein=2 Vanne de refroidissement

oui=1 / non=2 Valvola di raffreddamento

2

Cover with insulation

yes=1 / no=2 Abdeckung mit Isolierung

ja=1 / nein=2 Couvert avec isolation

oui=1 / non=2 Copertura con isolamento

2

Technical Sheet, Technisches Datenblatt, Fiche technique, Scheda tecnica Technical Sheet, Technisches Datenblatt, Fiche technique, Scheda tecnica