FORNI CLASSICO 80 User manual

www.stefanoferraraforni.it

WOOD OVEN

INSTALLATION AND OPERATING MANUAL

CLASSICO 80 – 90 – 110 – 120 – 130 – 140 – 150

MLF 80 – 90 – 110 – 120 – 130 – 140 – 150

SOMMA 80 – 90 – 110 – 120 – 130 – 140 – 150

VULCANO 80 – 90 – 110 – 120 – 130 – 140 – 150

PLEASE READ ALL INSTRUCTIONS BEFORE INSTALLING AND USING

THE APPLIANCE

A major cause of oven – related fire is failure to maintain required

clearances (air space) to combustible materials. It is of utmost

importance that this oven be installed only in accordance with these

instructions

SAVE THESE INSTRUCTIONS

Stefano Ferrara Forni S.R.L.

Forni artigianali napoletani

Neapolitan handmade brick ovens

Via Provinciale Pianura,2 – int.12

80078 Pozzuoli, Napoli

Tel./Fax: +39 081 876 1664

e-mail: info@stefanoferraraforni.it

P.IVA 06771801211

C.C.I.A.A. 838246

2

www.stefanoferraraforni.it

Table of content Page

- Introduction ............................................................................................................................................................. 3

- Installation operating and maintenance preface....................................................................................................... 5

- Features................................................................................................................................................................... 6

- Models and sizes ..................................................................................................................................................... 7

- Instruction for lifting and moving oven ..................................................................................................................... 9

- Packaging removing and placement oven on support stand ………………………………….... ................................ 11

- Installation procedures

•General information …………………………………………………………………………..... .......................... 12

•Stand covering installation (optional for Classico, Somma, Vulcano models)……………………………….. 13

•Stand covering installation for MLF model……………………………........................................................... 14

- Sanitation ................................................................................................................................................................ 18

- Oven venting …………………………………………………………………………………………….............................. 19

- Oven care during first fires …………………………………………………………………………… .............................. 20

- Oven management ................................................................................................................................................. 21

- Maintenance and cleaning ....................................................................................................................................... 22

3

www.stefanoferraraforni.it

INTRODUCTION

This manual has been made so that the user of the oven can work in complete safety.

THE USER HAS OBLIGATION TO READ CAREFULLY AND TO OBSERVE CAREFULLY THE

INSTRUCTIONS OF THE MANUAL.

Failure to comply with the instructions contained in this manual, means to operate in the conditions of use

not foreseen by the manufacturer.

THE MANUFACTURER IS NOT LIABLE FOR ANY DAMAGES CAUSED BY THINGS OR PERSONS,

DUE TO THE FAILURE TO OBSERVE THE INSTRUCTIONS AND THE RECOMMENDATIONS IN THIS

MANUAL.

The manual must be kept in good condition and must always be available for quick reference in case of

need.

THE MANUAL IS OF OWNERSHIP OF THE MANUFACTURER AND CANNOT BE REPRODUCED EVEN

PARTIALLY, AS WELL AS IT CANNOT BE DIFFUSED OR USED FOR ADVERTISING PURPOSE OR

SHARED WITH THIRD PARTIES.

ANY TRANSGRESSION WILL HAVE CIVIL AND PENAL SANCTIONS AS A CONSEQUENCE.

EXPLANATION OF SYMBOLS AND WARNINGS

SYMBOL DESCRIPTION

Symbol used to identify information of particular importance within the manual. The

information also concerns the safety of the personnel involved in the use of the

machine.

Symbol used to indicate passages of technical importance in the instructions and

warnings or procedures related to operator safety.

Symbol used to indicate warnings or procedures related to electricity.

NOTE ON THE PRODUCT

The aim of the manufacturing company is to make ovens that meet the current technical state. So we always

take care of our products even after delivery.

For any problems or inconveniences contact the service center:

Email: info@stefanoferraraforni.it - tel. +39 081 876 16 64

4

www.stefanoferraraforni.it

INTRODUCTION ABOUT INSTRUCTIONS OF WORKING

These instructions have the task of allowing and facilitating the safe and appropriate use of the OVEN and of

exploiting the regulatory use possibilities provided.

Their observance helps to avoid dangers, repair costs, to reduce off-duty times and to increase the lifespan

of the device.

Operating instructions are to be followed also taking in consideration the regulations on accident prevention

and environmental protection valid in the country of installation

BUYER'S OBLIGATIONS

The buyer is obliged to:

• Observe the national regulations concerning workplace safety;

• Observe the instructions contained in the manual.

5

www.stefanoferraraforni.it

INSTALLATION OPERATING AND MAINTENANCE PREFACE

WARNING

READ THIS ENTIRE MANUAL BEFORE YOU INSTALL THE OVEN. FAILURE TO

FOLLOW INSTRUCTIONS MAY RESULT IN PROPERTY DAMAGE, BODILY

INJURY, OR EVEN DEATH.

•When this oven is not properly installed, a fire may result. To reduce the risk of fire, follow the

installation instructions

•Contact your local building or fire officials for clarification on any restrictions on installation of this

oven in your area, or need for inspection of the oven installation.

•DO NOT close the oven door while a fire is in the oven.

•Place the door over the oven opening after cooking is completed at the end of the work day.

•Hot while in operation. Keep children, clothing and furniture away. Contact may cause skin burns.

•Do not burn garbage or flammable fluids.

•Smokes of the burning must be expelled through a flue system conform to the local rules.

•Do not connect the oven to a chimney flue serving another appliance.

•Keep children and pets away from hot oven.

•DO NOT USE products not specified for use with this oven.

•DO NOT USE liquid fuel (firelighter fluid, gasoline, lantern oil, kerosene or similar liquids) to start or

maintain a fire.

•DO NOT use water to dampen or extinguish fire in the oven.

•Keep a proper extinguisher (class A) close to the oven at all times.

•Instruct all personnel about location and use of the fire extinguisher and proper fire emergency

procedures.

•DO NOT pack required air spaces with insulation or other materials.

•DO NOT expose the oven to the weather, if the oven is installed outdoors to shelter it under a

canopy.

•The oven is meant only for cooking pizza and/or bread it is not recommended for cooking other food

or food in pan ,chafe of metal pans can get the floor soon damaged and grease spatter from

roasting can be absorbed from the floor that lose its correct properties of cooking.

•DO NOT pack required air spaces with insulation or other materials.

•Use only well dried wood.

•Use a metal shovel to remove the ashes and place them in a metal bin with a tightly fitting lid. The

container should be stored on a non-combustible surface, away from all combustible materials.

Ensure ashes are completely cold before disposing of them appropriately.

•DO NOT expose the oven to the weather, if the oven is installed outdoors to shelter it under a

canopy.

•The oven is meant only for cooking pizza and/or bread it is not recommended for cooking other food

or food in pan ,chafe of metal pans can get the floor soon damaged and grease spatter from

roasting can be absorbed from the floor that lose its correct properties of cooking

SAVE THESE INSTRUCTIONS

6

www.stefanoferraraforni.it

FEATURES:

Plain of cooking : Biscotto di Sorrento

Crown and dome :refractory bricks 60 mm. thick , they bear temperature of over 900°C (1650 F).

External hood :Santa Maria Bricks modeled by hand.

External covering : Mosaic tiles – palladiana marble

Alimentation : Wood

Wood consumption : 7 kg/h (15.50lbs/h)

Working temperature suggested : 400/450 °C ( 750/850 F)

Flue output : Ø 250 mm. ( 10 in)

Heat Output : 25000 Kcal – 29 Kw

Max heat output : 29000 Kcal – 34 Kw

Smokes temperature output : 190°C (374 F)

Extract air flow : 800 Mc/h (at starting)

650 Mc/h (at fully operating)

Required CFM : 470

Venting : Natural draft .

Oven employs an integral exhaust hood above the front opening. All flue gases exit the front opening

and drafts into the exhaust hood to be subsequently expelled through a flue pipe (250 mm O.D.)

located at the top of the oven. The flue pipe is intended to be connected to a natural draft chimney

system complying with NFPA96.

7

www.stefanoferraraforni.it

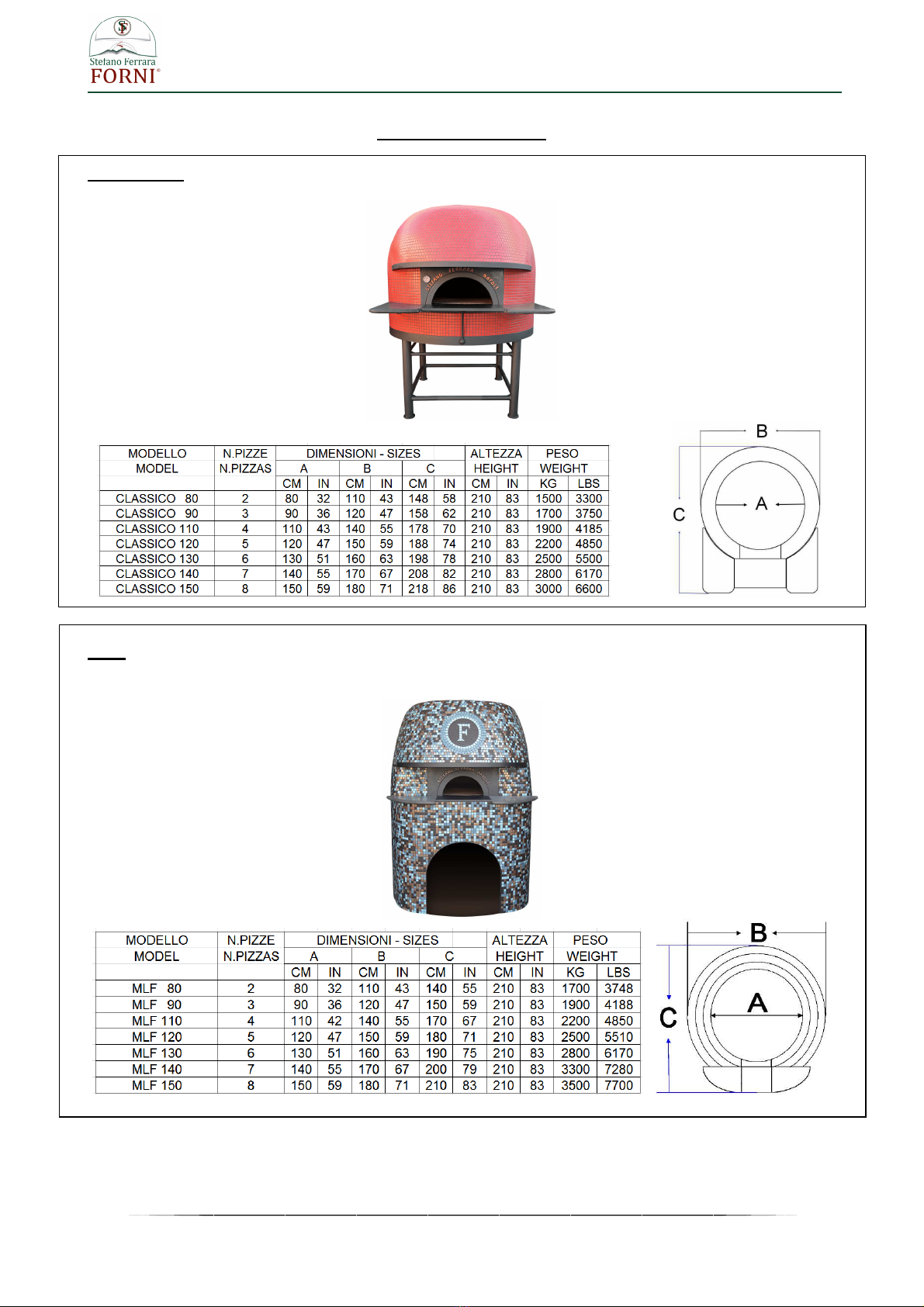

MODELS AND SIZES

CLASSICO

MLF

8

www.stefanoferraraforni.it

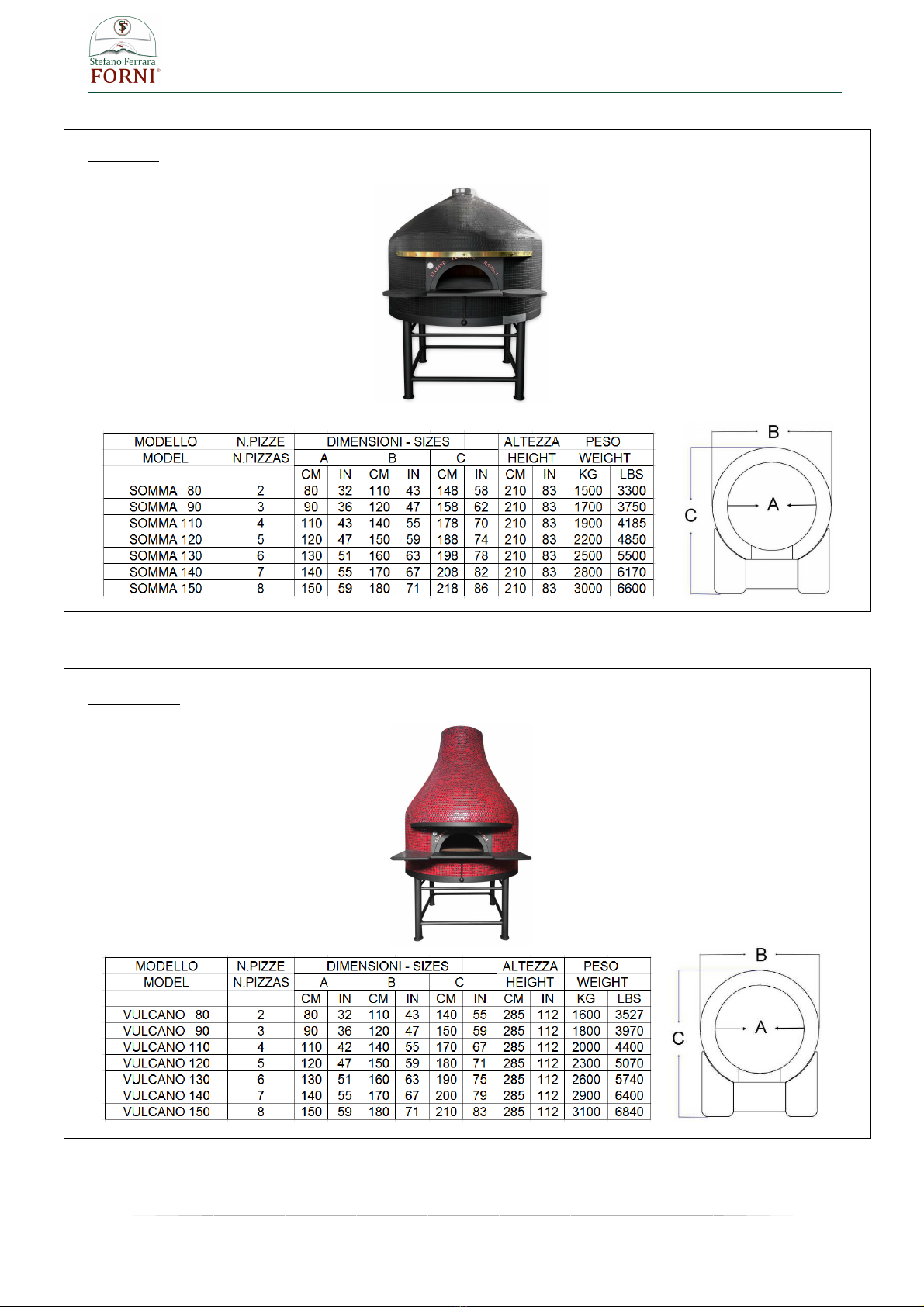

SOMMA

VULCANO

9

www.stefanoferraraforni.it

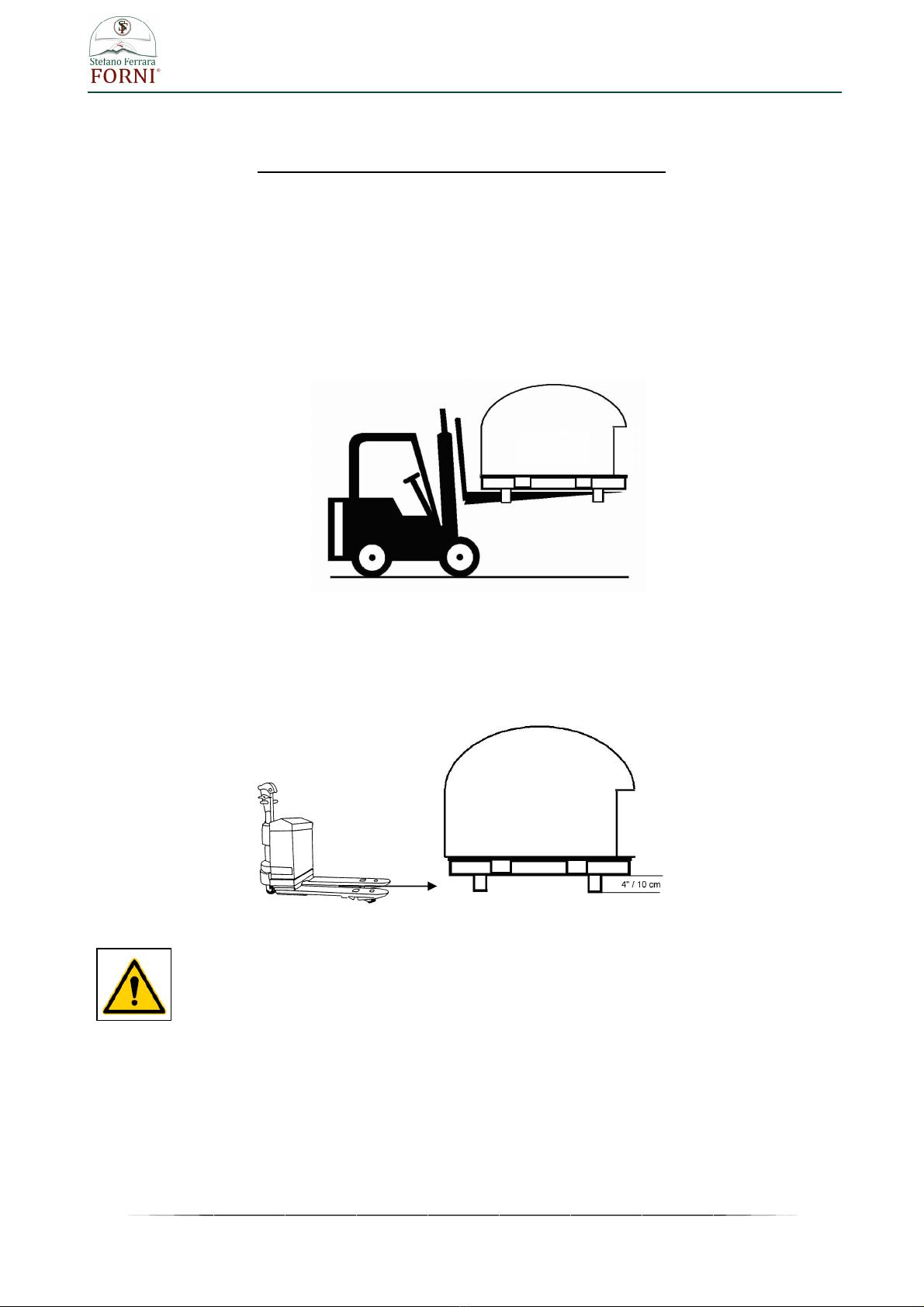

INSTRUCTIONS FOR LIFTING AND MOVING OVEN

FOR OVEN ALREADY INSTALLED ON THE SUPPORT STAND

1- USING A FORKLIFT

Determine if forklift capacity is sufficient to lift oven. (See pag. 7-8 for weights and sizes)

Prior to lifting, make sure the forks are long enough as whole diameter of the oven, if not fork extensions

should be used.

Keep forklift straight. Carefully place forks on the back of the oven through the stand legs

and position under the oven. Slowly lift and move the oven as needed

2- USING A PALLET JACK

Determine if pallet jack capacity is sufficient to lift oven. (See pag. 7-8 for weights and sizes)

Prior to lifting, make sure pallet jack is long enough to reach both horizontal angles at lower end of steel tube

support legs. Place pallet jack on the back of the oven , place the forks between tube steel support legs

under horizontal angles.

Carefully lift oven and move slowly.

10

www.stefanoferraraforni.it

INSTRUCTIONS FOR LIFTING AND MOVING OVEN

FOR OVEN SEPARATED FROM THE SUPPORT STAND

1- USING A FORKLIFT

Determine if forklift capacity is sufficient to lift oven. (See pag. 7-8 for weights and sizes)

Prior to lifting, make sure the forks are long enough as whole diameter of the oven, if not fork extensions

should be used.

Under the oven there are four little steel feet 4” (10 cm) high to permit placing of the forks.

Keep forklift straight. Carefully place forks on the back of the oven through the steel feet and position under

the oven. Slowly lift and move the oven as needed.

2- USING A PALLET JACK

Determine if pallet jack capacity is sufficient to lift oven. (See pag.7- 8 for weights and sizes)

Prior to lifting, make sure the forks are long enough as whole diameter of the oven.

Place pallet jack on the back of the oven, place the forks between the steel feet and position under the oven.

Carefully lift oven and move slowly.

WARNING : STRICTLY FORBIDDEN TO INVERT THE OVEN ALSO ON A SIDE , ONLY

VERTICAL LIFTING IS ALLOWED

11

www.stefanoferraraforni.it

PACKAGING REMOVING AND PLACEMENT OF THE OVEN ON SUPPORT STAND

On the bottom of the crate (front side and back side) there is the required space for insert the forks of the

forklift. (photo 1)

The crate is fixed to two metal brackets placed under the oven (photo 2)

photo 1 photo 2

Once removed the crate for removing the brackets , lifting the oven with a forklift and unscrewing the bolts.

Note: the removed bolts (17 mm. – 0.67 in. hexagonal head screw) will be the same to use for fixing the

oven on the support stand, so preserve them for the next use.

Lifting the oven with a forklift until a higher height than the metallic support stand

Let down carefully for inserting the steel feet placed under the oven into the legs of the support stand

respecting the marked letters :

- Front : A – A

- Back : B – B

Once placed the oven on the support stand to screw the furnished screws (17 mm.- 0.67 in. hexagonal head

screw) in the existing holes on the back of each stand leg.

12

www.stefanoferraraforni.it

INSTALLATION PROCEDURES

1. Be sure to have a sufficient space in the desired location for the oven.

See pag. 7 – 8 for minimum space required according the model

2. Place the oven on appropriate floor able to support the oven weight.

3. Any adjacent combustible floor which

projects in front of the oven opening must

be a minimum of 30 inches (75 cm) away

from each side of the door opening and

36 inches (90 cm.) from the front of the

door opening.

4. It is essential to maintain clearance space

between the oven components and any

combustible material, such as walls and

ceilings.

The oven must have a minimum 10” (25,5

cm.) clearance to combustibles from all

sides and 14" (35,5 cm) clearance to

combustibles from the top.

Warning : Don’t place any type type of

insulation in the required clearance

spaces surrounding the oven

13

www.stefanoferraraforni.it

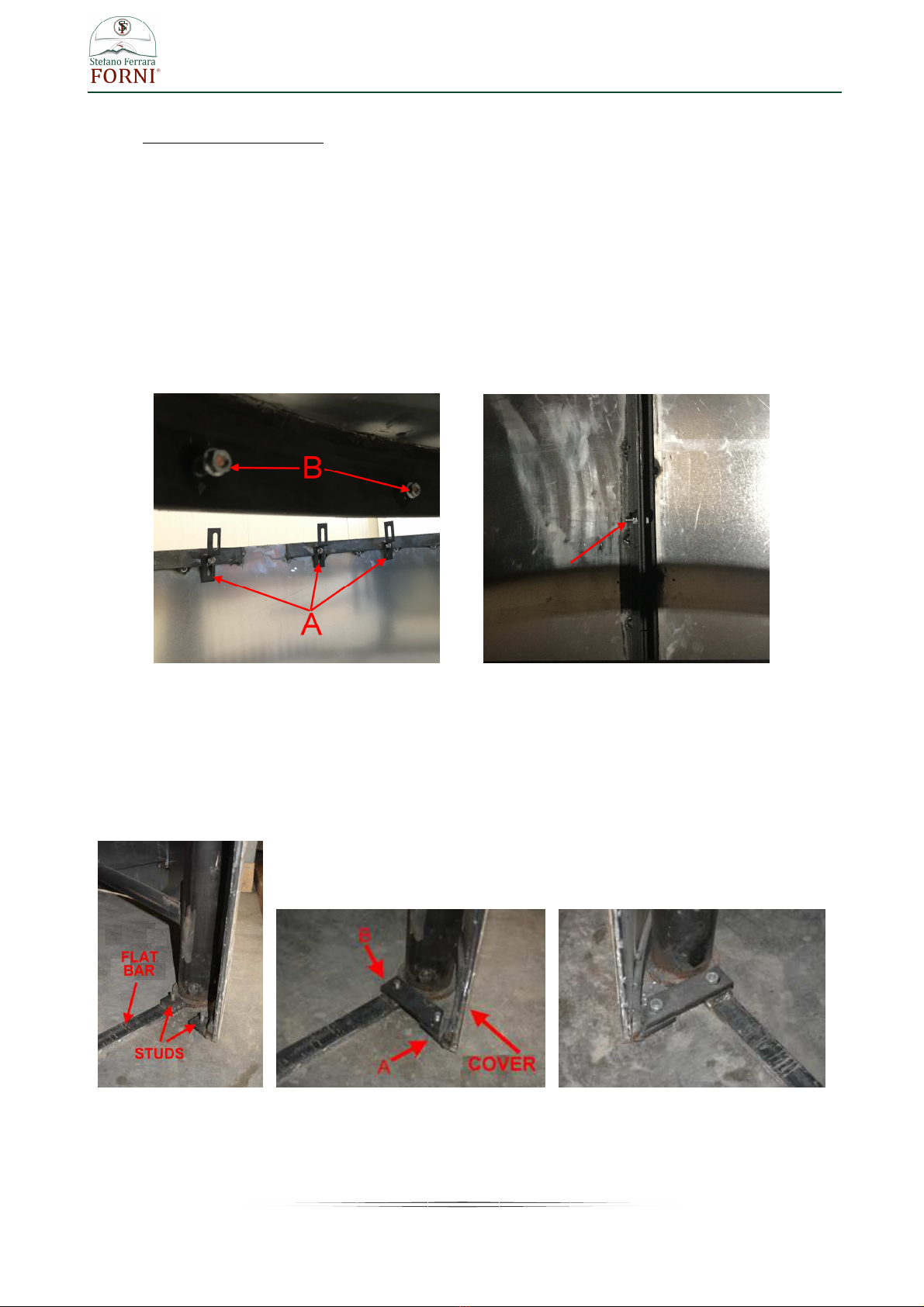

5. Stand covering installation (optional for models Classico, Somma e Vulcano)

For such working below listed tools are required:

a) Spanner for hexagonal head screws 13 mm. (0.51 in)

b) Spanner for hexagonal head screws 17 mm. (0.67 in)

The stand leg covering is provided of some small holed metallic bands (A - photo 1) to fix to the studs

installed at the oven bottom “B” photo 1 with hexagonal nuts 13 mm - 0.51 in

The cover is divided into two parts, place the right part and the left part surrounding the stand legs and join

the two parts by screwing the screws into the holes on the back.(photo 2)

Unscrew the hexagonal nuts from the studs on the oven bottom (B photo 1) , insert each metallic band (A

photo 1) into the correct stud and screw all the nuts

photo 1 photo 2

Fasten the front part of the cover to the flat bar of conjunction placed between the two front stand legs

The terminals of the flat bar and the bottom of the frontal cover arch are provided of pre welded studs,

connect these points with the bar ending 45 degree cut .

The 45 degree terminal of the bar (A) is to be fastened to the cover , the terminal with straight ending (B) is

to be fastened to the flat bar . Screw with the provided hexagonal nuts mm. 17 (0.67 in)

photo 3 photo 4 photo 5

On the top and internally to the front arch of the cover two metal fins are welded, insert hexagonal head

screw mm. 13 (0.51 in) and screw well so to get perfect joint of the edges

14

www.stefanoferraraforni.it

5.1 Installation of stand covering for MFL model

For such working below listed tools are required:

a) Spanner for hexagonal head screws 10 mm. (0.40 in)

b) Spanner for hexagonal head screws 13 mm. (0.51 in)

c) Spanner for hexagonal head screws 17 mm. (0.67 in)

Install the back paneling , it’s provided provided of some small holed metallic bands(photo 1) to fix at the

bottom of the oven with the furnished screws (Hex head self-threading screw mm. 10 – 0.40in)

photo 1 photo 2

Place the paneling getting the holes of the metallic bands and the holes of metallic ring underneath the oven

coincide between them (photo 2 previous page), to screw the provided screws. (Hex head self-threading

screw mm. 10 – 0.40 in)

Once installed the back panel install the front panel that is provided of junction points like shown on photo 3

photo 3

15

www.stefanoferraraforni.it

Install the front paneling getting its edges to coincide with the edges of the back panel already assembled

Match the hole of the point “1” (see photo above) with the holes of metallic ring underneath the oven and

screwing the provide screw (hex head self-threading screw mm. 10- 0.40in )

The paneling is provided of some studs on the top and on the sides (see point 2 and 5 photo 3) and the

same studs are welded on the internal side of the perimeter metallic ring underneath the oven and on the

sides of the back paneling.

Put the metallic bands into the studs (photo 4) and screwing the provided hexagonal nuts mm.13 – 0,51in

(photo 5)

photo 4 photo 5

Screw the stirrup with curved end (point “3” photo 6) to the iron tube of the oven stand (photo 7) using hex

head self-threading screw mm. 10 (0.40in)

photo 6 photo 7

16

www.stefanoferraraforni.it

Join the point 4 of the front stand cover (photo 8) to the stand using the metallic stirrup with 45 degrees end .

The stirrup side with 45 degree end must be fixed on the point 4 of the cover (photo 8) the other side with

straight end must be fixed to the prewelded screw on the junction band between the stand legs (photo 10 –

11)

For screwing use the provided hex nuts mm. 17 (0.67in)

photo 8 photo 9

photo 10 photo 11

17

www.stefanoferraraforni.it

Fasten the sides of the oven stand cover to the cross tubes of the same stand with the stirrup showed on the

photo 12

photo 12 photo 13

The curved end of the stirrup must be overlapped on the cross tube of the support stand (photo 13) , get

matched the hole existing on the stirrup and the hole existing on the tube then screwing with the provided

hex screw mm. 10 (0.40in)

The opposite terminal of the stirrup must be overlapped and fastened to the stirrup existing on the stand

cover (point 6 photo below) using the provided hex head 13 mm. (0.51in) screw .

6) Installation of lateral marbles

Lateral marbles come into a separate package

Fasten the marbles on the metallic plate existing at the sides of the oven mouth using some silicone and

waiting complete drying before use them as support shelf

18

www.stefanoferraraforni.it

SANITATION

The ovens are carry a NSF sanitation certification .

They are listed to NSF /ANSI Standard 4 .

This means that the oven interior and the surfaces of the oven which are meant to be left exposed have

been evaluated from the standpoint of sanitation and food safety and are compliant with NSF/ANSI Standard

4.

The ovens provided with the iron stand comply to the NSF requirements just if the stand legs are covered

upon installation.

For covering the stand legs don’t use any combustible material and in case of use of a metal enclosure be

sure the used metal is corrosion resistant .

The ovens provided with the inox steel stand are fully compliant to the NSF requirements so no other work is

requested after installation and the stand legs can be left exposed.

19

www.stefanoferraraforni.it

OVEN VENTING

The venting system of our wood burning ovens is to direct connection, exploiting the natural draught.

The oven employs an integral exhaust hood above the front opening. All flue gases exit the front opening

and drafts into the exhaust hood to be subsequently expelled through a flue pipe (250 mm / 10” in O.D.)

located at the top of the oven. The flue pipe is intended to be connected to a natural draft chimney system

complying with NFPA96 (for USA and Canada)

It’s requested a minimum of 18 “ clearance from combustible material around the flue opening existing on the

top of the oven .

For the flue system we recommend to use a building heating appliance chimney grease duct assembly , (UL

listed for USA and Canada or complying with the local regulations for other countries).

Stainless steel pipes single or twin-walled 250 mm/10 “ in diameter (meant as internal diameter in case of twin

walled pipes) to connect from the chimney connector existing on the top end of the oven up to the desired

place where the smokes will go out.

Installation shall be in accordance with the standard for ventilation control and fire protection of commercial

cooking operations – NFPA 96 (for USA and Canada)

Usually a single wall stainless steel pipe requires minimum of 18” clearance from combustible material , a

double wall pipe requires less clearance so for the right clearance to combustible material please refer to

the company from which you’ll buy the pipes ,as we don’t Know what type of pipes will be installed.

Induct the elements according to the toward of the smokes. The toward of the smokes is understood from

the “ masculine” to the “female” part.

Sew together the elements having care of not damage the seal inserted in the female part. It is advisable to

lubricate the masculine part with a light coat of fat, spray or liquid soap.

Mount and to shut the security wrappers for every junction.

WARNING !

The above information are just some suggestions , for building the flue system is of utmost

importance contact a specialized company and submit your venting plans to local

authorities before proceeding with installations.

The purchaser is responsible of the conformity, correct installation and correct working of

the flue system.

20

www.stefanoferraraforni.it

OVEN CARE DURING FIRST FIRES

As the oven has just been built, it is still damp and the mortar full of water which needs to dry out. Therefore,

it cannot be used immediately for baking but it needs a period of drying out. This can be achieved with one

week (around 8 hours daily) of keeping medium fires just to let it dry and at the same time "cook" both the

bricks and the baking surface.

It's important that you cure your oven slowly, by building a series of central increasingly larger fires. If you

begin building large fires in your oven right way, you could compromise your oven's longevity and ability to

cook well, and even to cause damage.

Place a small amount of wood and kindling on the hearth over a fire-starter block.

Light fire starter. At any time do not use more than four pieces of wood.

Get the oven working for at least 6/8 hours daily proceeding as follows:

Day 1- 2 - 3: The temperature should not exceed 150 °C (302 F).

It could happen that the temperature increases more than 150°C (302 F), this is normal and is due to the

heat retained by the refractory bricks.

During cooking pizzas, bricks absorb heat transferring some humidity to the oven with consequent balancing

of temperature; when no food is placed into the oven, there isn’t this balancing and all the heat is

accumulated and retained by the refractory bricks.

Any way, if the temperature increases more than 150 °C (302 F), get temperature decrease act as follows:

1- Do not add other wood.

If temperature doesn’t decrease:

2- Spread the wood or coals around on the cooking floor for getting less fire.

If also in this case there isn’t any temperature decreasing:

3- Remove some wood from the oven.

WARNING !

Take care during removing wood, wait until when it will be just coal, don't remove wood

with flame. Use a metal shovel for this operation and place the removed wood in a metal

bin with a tightly fitting lid placed on a non-combustible surface, away from any

combustible materials

Day 4: Get the oven work for the entire day at 200°C ( 392 F)

Day 5 through day 7: Increase the temperature of 50°C (122 F) per day

For a better a more sure temperature measurement you can use an infrared thermometer (non provided with

the oven)

During these days of first fires DO NOT CLOSE the door of the oven to the end of the day.

The door opened allows the expulsion of the vapours of the dampness, closing the door the vapours remain

trapped into the oven generating pressures can cause raising of the oven floor.

With the first fires the inside of the oven will become black due to the damp conditions, however after about

two days of baking, the bricks should start to become again clear and that indicates that the oven is finally

ready by to use.

Any cracks on the exterior decoration, normally in the filling between tiles, or on the external plaster for

ovens not provided with finishing of tiles ,it is generally due to the oven stabilization, and it is nothing to worry

about nor it compromise the correct functioning of the same oven.

Note : The week of oven care is sufficient if immediately after this first week the oven continue in working

daily. If for any reason, after the first time of care, the oven is left without building any fire for some days ,

when you will build again the fire you must not start with large fires but it’s good to start with low temperature

increasing it a bit for time .

As more time the oven has been without any fire , much more time you will need for increase of the

temperature

This manual suits for next models

27

Table of contents

Popular Wood Stove manuals by other brands

Ekol

Ekol Clarity 30 Boiler Installation and operating instructions

RIKA

RIKA Cult Plus instruction manual

Harman

Harman Oakwood Wood Stove owner's manual

Regency

Regency F2400M Owners & installation manual

NORFLAM

NORFLAM ARDENTE Installation instructions and operating manual

Dovre

Dovre ASTRO 3CBP Installation instructions and operating manual