EN DE FR IT

Product name Produktbezeichnung Nom du produit Nome del prodotto BARACCA 10

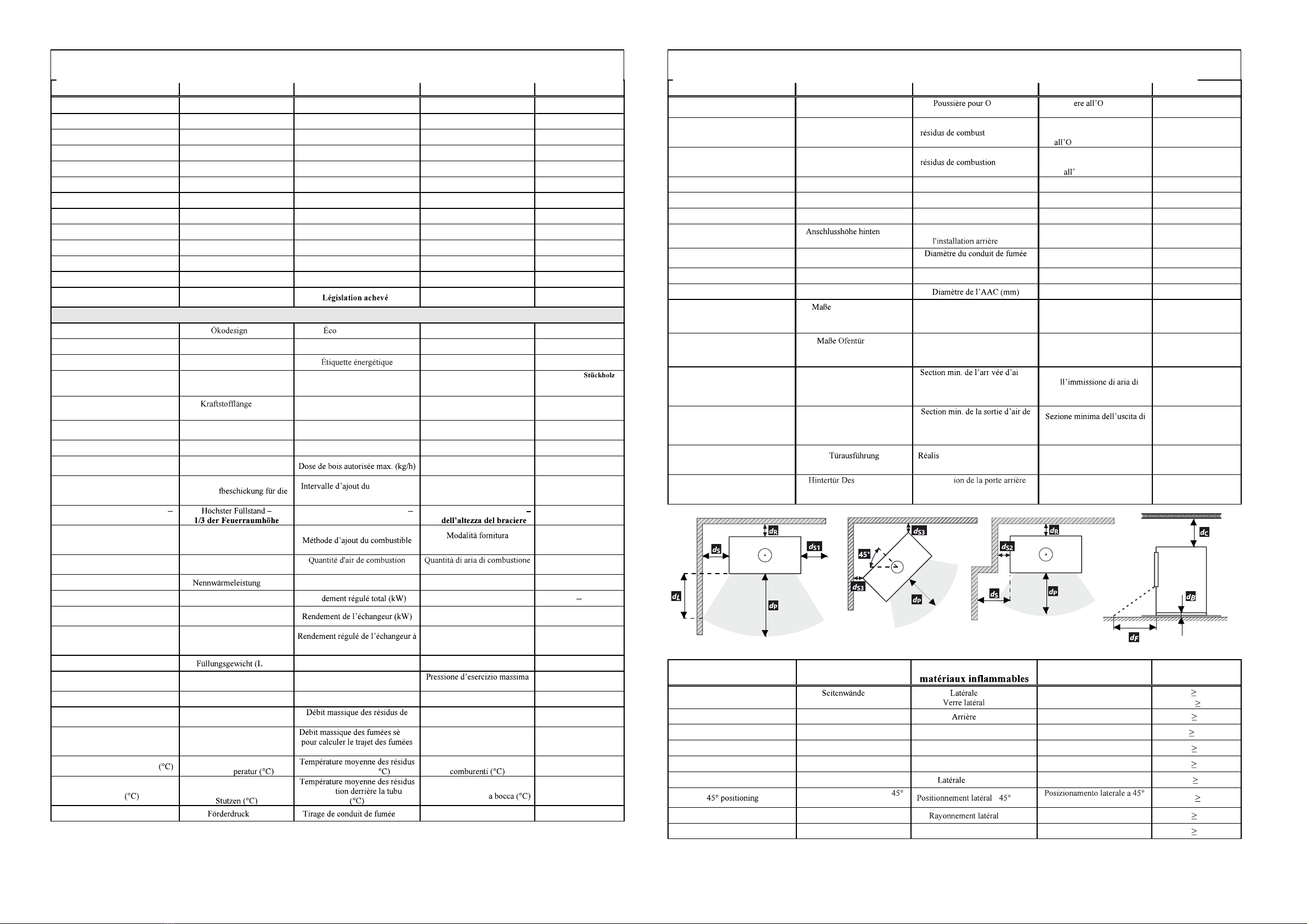

Dimensions HxWxD (mm) Abmessungen HxBxT (mm) Dimensions HxLxP (mm) Dimensioni AxLxP (mm) 1462 x 854 x 525

Weight (kg) Gewicht (kg) Poids (kg) Peso (kg) 291

Product name Produktbezeichnung Nom du produit Nome del prodotto BARACCA 11

Dimensions HxWxD (mm) Abmessungen HxBxT (mm) Dimensions HxLxP (mm) Dimensioni AxLxP (mm) 1462 x 854 x 525

Weight (kg) Gewicht (kg) Poids (kg) Peso (kg) 320

Product name Produktbezeichnung Nom du produit Nome del prodotto BARACCA 10 H

Dimensions HxWxD (mm) Abmessungen HxBxT (mm) Dimensions HxLxP (mm) Dimensioni AxLxP (mm) 1749 x 854 x 525

Weight (kg) Gewicht (kg) Poids (kg) Peso (kg) 323

Product name Produktbezeichnung Nom du produit Nome del prodotto BARACCA 11 H

Dimensions HxWxD (mm) Abmessungen HxBxT (mm) Dimensions HxLxP (mm) Dimensioni AxLxP (mm) 1749 x 854 x 525

Weight (kg) Gewicht (kg) Poids (kg) Peso (kg) 354

Completed legislation Abgeschlossene

Gesetzgebung eLegislazione completata -

EN 13 240 / EN 16 510 - 1 / 15a B-VG / DIN + / BImSch V 2 / Ecodesign / Flamme Verte 7* / Aria Pulita 4*

Eco-design (%) (%) -conception (%) Eco-design (%) 70,1

EEI EEI EEI EEI 106,1

Energy Label Energielabel Etichetta energetica A

Prescribed fuel Vorgeschriebener Brennstoff Combustible prescrit Combustibile prescritto Piece wood /

Morceau de bois / Pezzo

di legno

Fuel length (mm) (mm) Longueur de carburant (mm) Lunghezza del carburante

(mm) 180 - 350

Average wood consumption (kg/h)

Durchschnittlicher

Holzverbrauch (kg(h) Consommation de bois moyenne

(kg/h) Consumo medio di legna

(kg/ora) 1,78

Input achieved (kW) Erreichte Leistungsaufnahme

Puissance obtenue (kW) Potenza ottenuta (kW) 7,4

Max. allowed wood batch (kg/h) Max. erlaubte Holzzuladung

(kg/h)

Dose massima di legna

consentita (kg/ora) 2,3

Fuel supply interval for the rated

output

Zeitabstand der

Brennstof

Nennleistung

combustible

pour la puissance nominale

Intervallo fornitura

combustibile per potenza

nominale

ora

The greatest height of the filling

1/3 of the firebox Hauteur maximale de la charge

1/3 de la hauteur du foyer Altezza massima caricamento

1/3 -

Fuel delivery method Art der Brennstoffbeschickung

combustibile

manually, von Hand,

manuellement,

manualmente

Amount of combustion air (m3/h) Menge an Verbrennungsluft

(m3/h)

(m3/h) (m3/h) 22,6

Nominal heat output (kW) (kW) Puissance nominale (kW) Potenza nominale (kW) 5,9

Total regulated output (kW) Reg. Gesamtleistung (kW) Ren Potenza totale regolata (kW) 3,0 7,7

Exchanger output (kW) Austauscherleistung (kW) Potenza dello scambiatore

-

Regulated output of the hot water

exchanger (kW) Reg. Leistung des

Warmwassertauschers (kW) eau chaude (kW)

Potenza regolata dello

scambiatore ad acqua calda

-

Filling volume (litres) iter) Volume du remplissage (litres) Volume del riempimento (litri)

-

Max. operating overpressure (kPa)

Max. Betriebsdruck (kPa) Surpression de fonctionnement

max. (kPa) (kPa) -

Efficiency (%) Wirkungsgrad (%) Rendement (%) Efficienza (%) 80,1

Mass flow rate of dry flue gases

(g/s) Massendurchfluss der

trockenen Abgase (g/s) combustion secs (g/s)

Flusso peso combustibile secco

(g/s) 5,6

Dry flue gases mass flow to

calculate the flue path (g/s)

Massendurchfluss von

trockenen Abgasen den

Portata massica dei fumi secchi

per calcolare il percorso dei

7,6

Average flue-gas temperature

Durchschnittliche

Abgastem de combustion ( Temperatura media gas

252

Average flue gas temperature after

Flue pipe

Durchschnittliche

Abgastemperatur hinter dem

de combus

Temperatura media gas

comburenti dietro l

262

Flue draught (Pa) (Pa) (Pa) Tiraggio del camino (Pa) 12

EN DE FR IT

Dust at O2 = 13%

(mg/Nm3) Staub bei O2= 13 %

(mg/Nm3) 2= 13%

(mg/Nm3) Polv 2= 13 %

(mg/Nm3) 24

The concentration of CO

gases at O2= 13% (mg/Nm3)

CO Konzentration in den

Abgasen bei O2= 13%

(mg/Nm3)

Concentration en CO dans les

ion pour O2=

13% (mg/Nm3)

Concentrazione CO nei gas

comburenti

= 13 % (mg/Nm3) 837

The concentration of CO

in the flue gases

at O

= 13% (%)

CO Konzentration

in den Abgasen

bei O

= 13% (%)

Concentration en CO dans les

pour O2=

13% (%)

Concentrazione CO

nei gas comburenti

O

= 13 % (%) 0,0670

CO2 (%) CO2 (%) CO2 (%) CO2 (%) 9,19

OGC - 02=13% (mg/m3) OGC - 02=13% (mg/m3) OGC - 02=13% (mg/m3) OGC - 02=13% (mg/m3) 25

NOx - 02=13% (mg/m3) NOx - 02=13% (mg/m3) NOx - 02=13% (mg/m3) NOx - 02=13% (mg/m3) 100

Connection height for rear

installation (mm) (mm) Hauteur de raccordement pour

(mm) Altezza di collegamento per

l'installazione posteriore (mm)

1352

Flue pipe diameter (mm) Rauchabfuhrdurchmesser (mm)

(mm) Diametro del condotto fumi

(mm) 150

Flue throat (mm) Flue Hals (mm) Flue la gorge (mm) Fumi gola (mm) 150

CAI diameter (mm) CPV-Durchmesser (mm) Diametro ACA (mm) 125

Dimensions of t

chamber HxWxD

(mm)

Feuerraum HxBxT

(mm) Dimensions de la chambre de

combustion HxLxP

(mm)

Dimensioni della camera di

combustione AxLxP

(mm)

340 x 506 x 210

Dimensions of the furnace

door HxWxD

(mm)

HxBxT

(mm) Dimensions de la porte du four

HxLxP

(mm)

Dimensioni della porta del

forno AxLxP

(mm)

-

Min. cross section of convect air

inlet for nominal output

(cm2)

Min. Querschnitt der

Konvektionsluftzufuhr f. die

Nennleistung

(cm2)

i r de

convection pour rendement

nominal

(cm2)

Sezione minima

de

convezione per la potenza

nominale (cm2)

-

Min. cross section of convect air

outlet for nominal output

(cm2)

Min. Querschnitt des

Konvektionsluftausgangs f.

Nennleistung (cm2)

convection pour rendement

nominal

(cm2)

aria di convezione per la

potenza nominale (cm2) -

Door design

(Right=1 / Left=2 / Sliding =3)

(Rechts=1/Links=2/Schieben

ation de la porte (

Gauche=2 / Coulissant = 3)

(Destra=1 / Sinistra=2 /

estraibile = 3) 2

Back door design (No=0 /

/ Left=2 / Sliding =3)

ign (Nein=0 /

Rechts=1 / Links=2 / Schieben

= 3)

Concept

(Non =0 / Droite=1 / Gauche=2 /

Coulissant = 3)

Design della porta posteriore

(No=0 / Destra=1 / Sinistra=2

estraibile = 3) 0

Distance from flammable

materials Abstand von

Brennstoffen Eloignement des Distanza da materiali

infiammabili

Side (mm)

Side with glass (mm) (mm)

Seitenglas (mm) (mm)

(mm) Laterali (mm)

Vetro laterale (mm) dS300

dS1 ---

Back (mm) Hinterwand (mm) (mm) Posteriore (mm) dR100

Front (mm) Frontwand (mm) Frontale (mm) Anteriore (mm) dP1200

From the ceiling (mm) Von der Decke (mm) Du plafond (mm) Dal soffitto (mm) dC750

Front to floor (mm) Front zum Boden (mm) De l'avant au sol (mm) Da fronte a terra (mm) dF670

Side - niche (mm) Seite - Nische (mm) - niche (mm) Laterali - nicchia (mm) dS2 100

Side - (mm) Seitliche Positionierung -

(mm) - (mm)

(mm) dS3 ---

Side radiation (mm) Seitliche Strahlung (mm) (mm) Radiazione laterale (mm) dL500

From the floor (mm) Von dem Boden (mm) Depuis le sol (mm) Dal pavimento (mm) dB195

Technical Sheet, Technisches Datenblatt, Fiche technique, Scheda tecnica Technical Sheet, Technisches Datenblatt, Fiche technique, Scheda tecnica