10

7. OPERATION NOTICES

•7.1. Installation

(1) Welding environmental temperature should be between -10℃to 40℃.

(2) Welding should be done in relatively dry environments, the air humidity of not more than

90%.

(3) To avoid areas containing dust or corrosive gas welding operation environment.

(4) To avoid sunlight or rain, welding, do not le water or rain water infiltrated the welding

machine.

(5) To avoid the strong air flow environment for gas welding operations.

•7.2. Safety

Welding machine has been installed in over-voltage, over current and over temperature

protection circuit, when the grid voltage, output current and the internal temperature exceeds the

set temperature, the welding machine will automatically stop working; but excessive use will

result in welding damage, so you need to note the following:

(1) To ensure good ventilation!

The welder at work have a greater current flow through the cooling of natural ventilation van not

meet the requirements of welding, it is equipped with cooling fans to help the welder. Before

using, please check the vents to make sure it has not been blocked or covered the distance

between the object and the surrounding welding should not be less than 0.3 meters, welding

machines should have been so good ventilation, to ensure the normal operation of welding

machine extending welder life.

(2) Prohibit the overload!

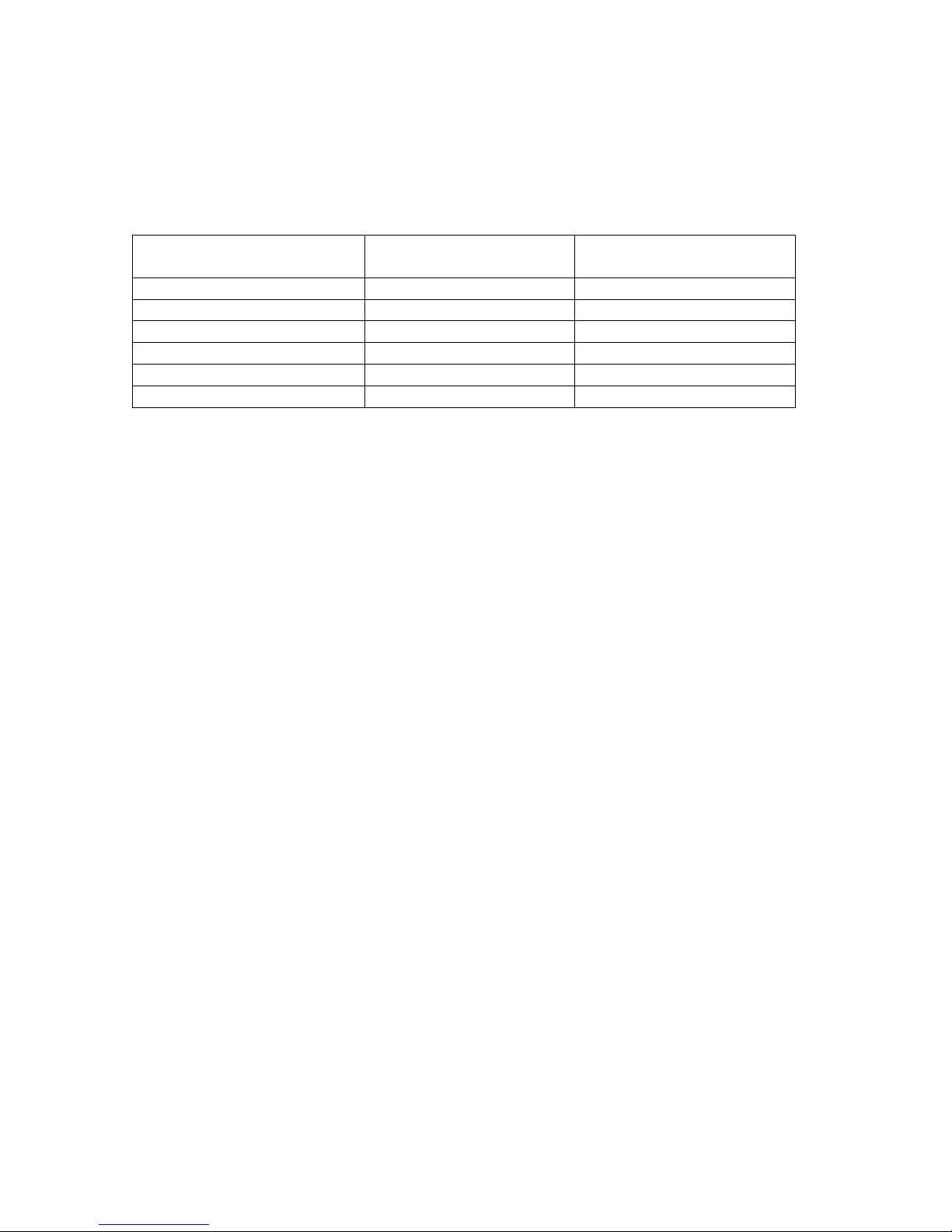

By welding machine operators should ensure that the duty cycle to allow use of welding (see

technical data table), keeping the welding current within the normal range, if the current overload

will shorten the life of welding machine welding machine and may even burn.

(3) Prohibits the over-voltage!

Supply voltage listed in the “Technical Data Sheet”, the general case, the welding voltage within

the circuit will automatically compensate to ensure that the welding current in the permitted

range. If the voltage exceeds the allowable value, will damage the welder, the user should be fully

aware of this situation, take appropriate preventive measures.

(4) After each welding machine comes with grounding screw, and marked with ground markers.

Before use, use a larger than 2.5mm cable, in the welding chassis ground to discharge any

static electricity or to prevent leakage accidents.

(5) If the welding work over the standard loading time, the welding machine may suddenly stop

working into the protected status, which means that the load beyond the standard rate of

welding, excessive heat triggered a temperature control switch, the welding machine to stop

working, while front panel alarm indicator lights up. In this case, you do not unplug the power

plug, to maintain the cooling fan rotation. The red light goes out, the temperature dropped to

a reasonable extent, and then you can restart welding.