4

2. SUMMARY

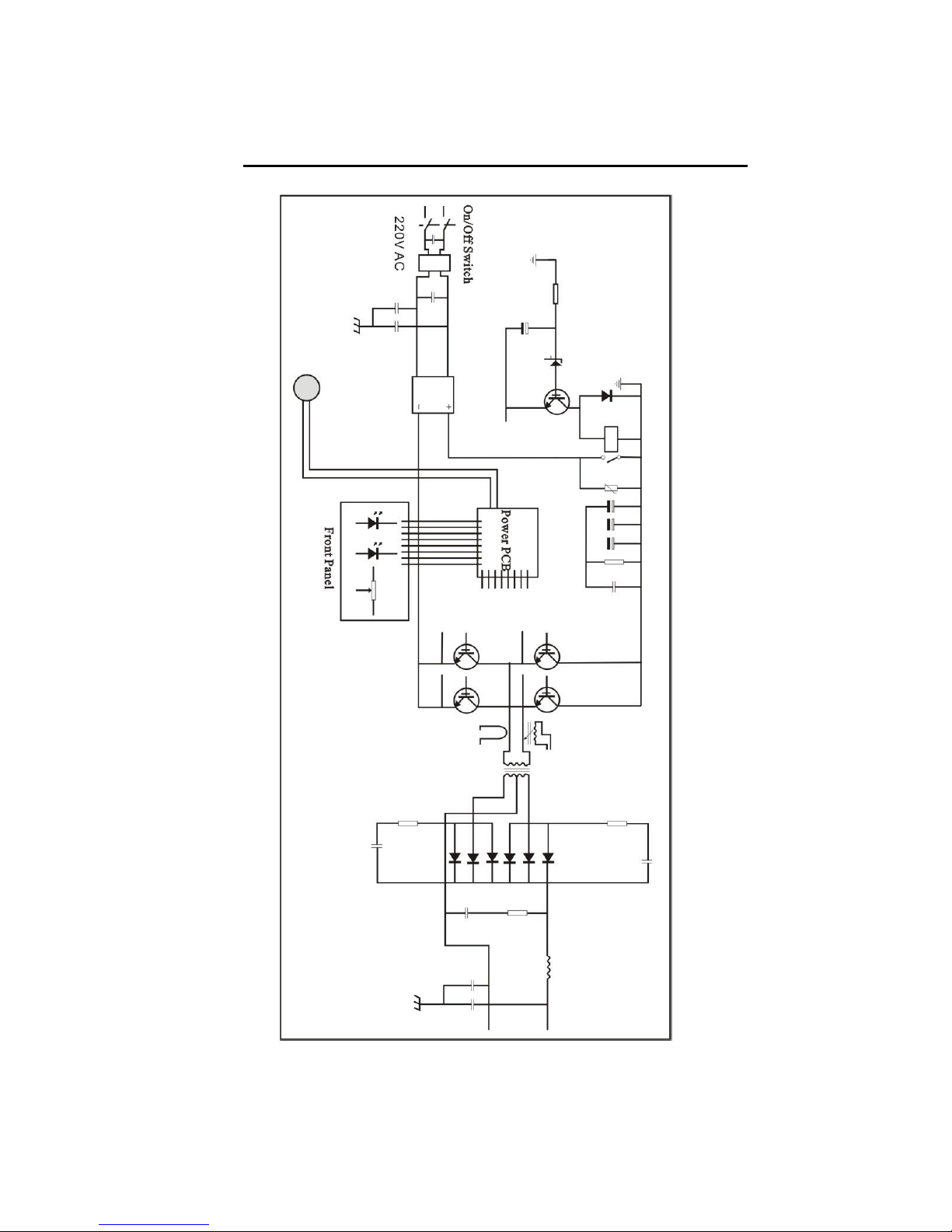

TIG series welder is a TIG welder which adopts the insulated gate bipolar transistor (IGBT) power

module. It can change work frequency to medium frequency so as to replace the traditional

hulking work frequency transformer with the cabinet medium frequency transformer. Thus, it is

characterized with portable, small size, light weight, low consumption and noise etc.

Excellent welding performance

TIG series has excellent performance: constant current output makes welding arc more stable; fast

dynamic response speed reduces the impact from the arc length fluctuation to the current.

There are also some automatic protection functions for over voltage, over current, over heat, etc.

inside the welders, when the problems listed before occurred, the alarm on the front panel is light

and at the same time the output current will be cut off. It can self-protect and prolong the using

life and greatly improve the reliability and practicability of the welders.

TIG series can be ignited easily and with good weld bead.

TIG series has wide range of applications. Given its small size, light weight, easy and flexible

operation, it can be used in various kinds of environment, such as working aloft, field work,

interior decoration,etc.

High duty cycle. In 40℃environment, TIG series’duty cycle can reach 40%, so that can keep

continuous operation.

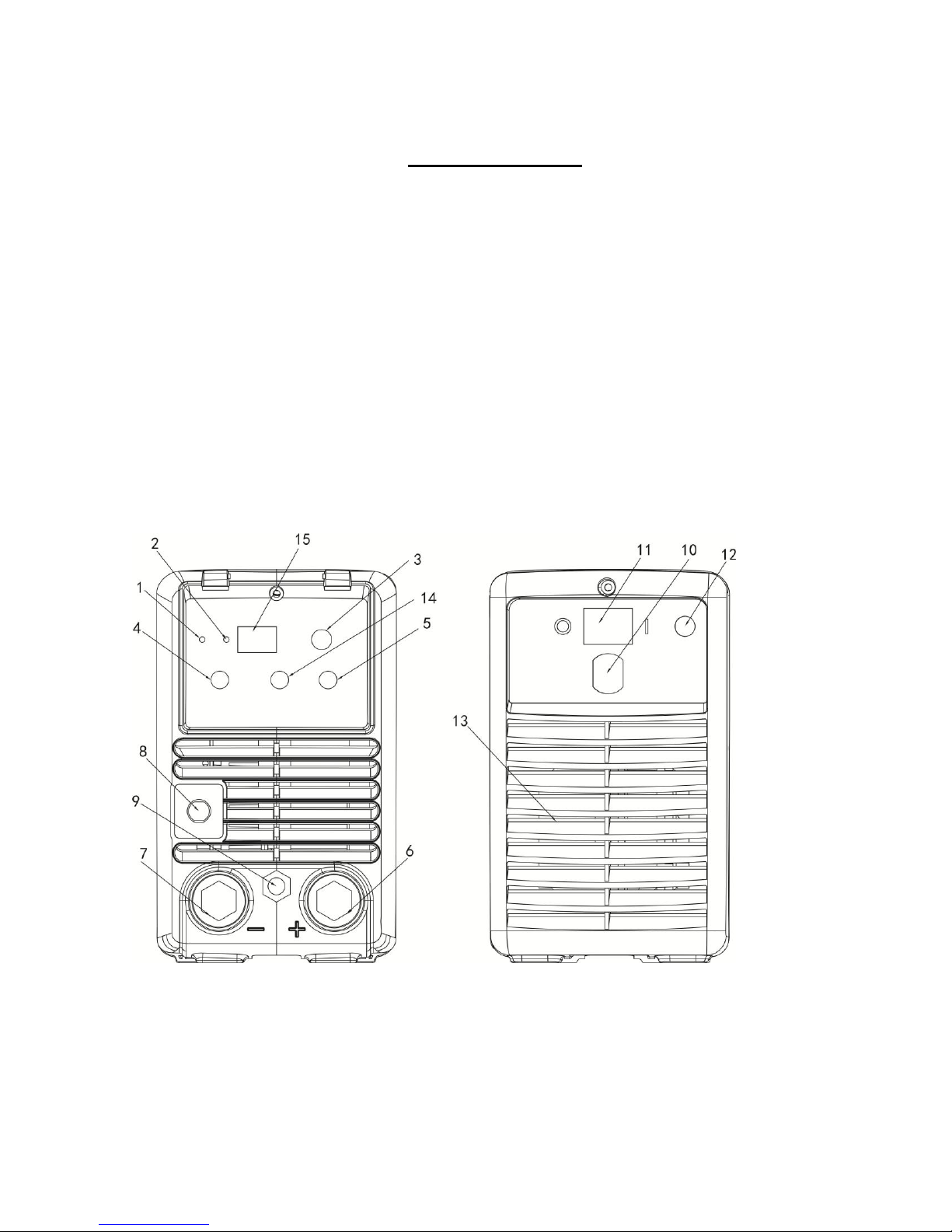

Stable structures

The front and rear panel are made of engineering plastic, that have features of heat-resistant,

corrosion-resistant, to ensure the welder keep normal work even under bad environments.