- 06 -

_check off as completed.

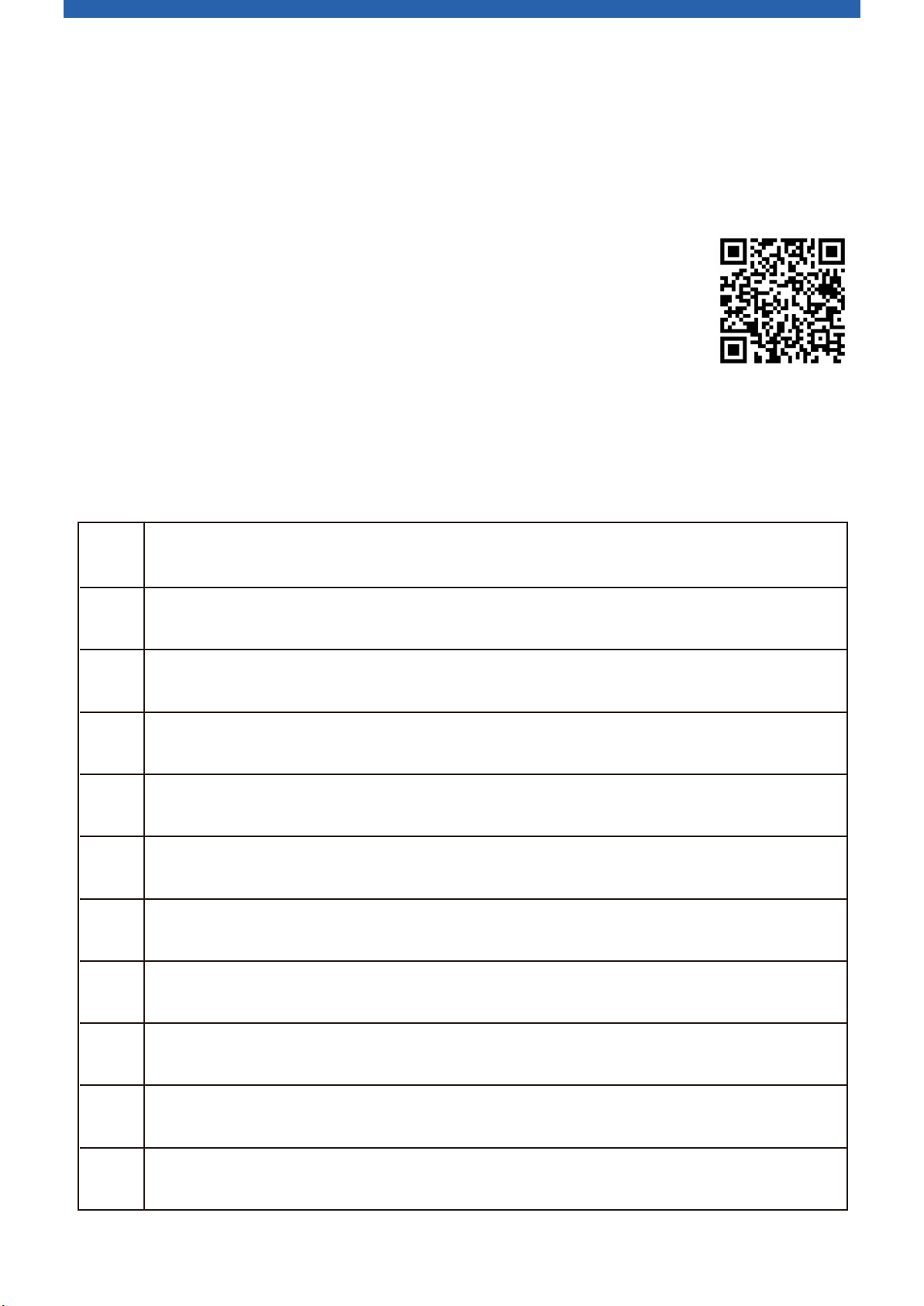

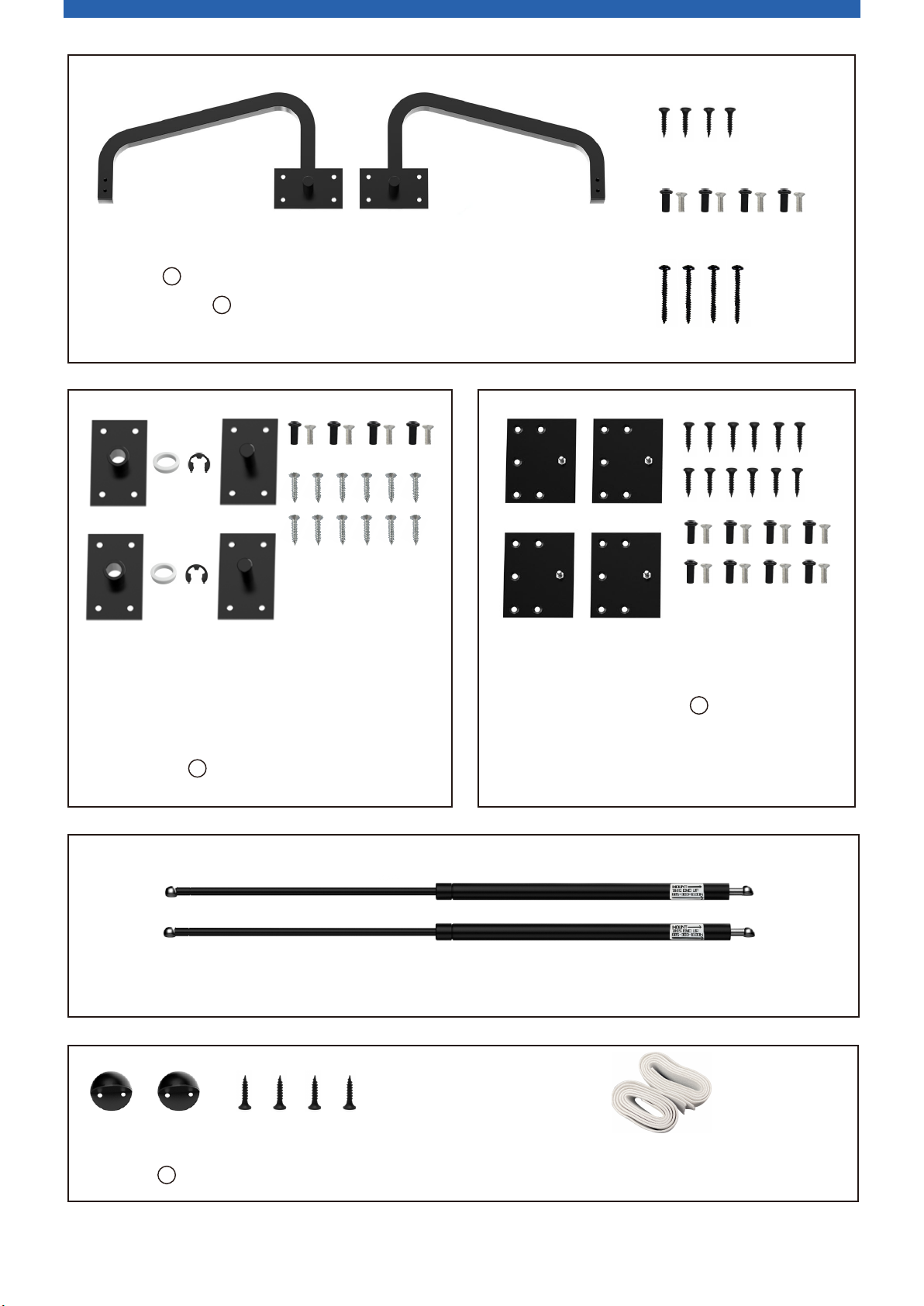

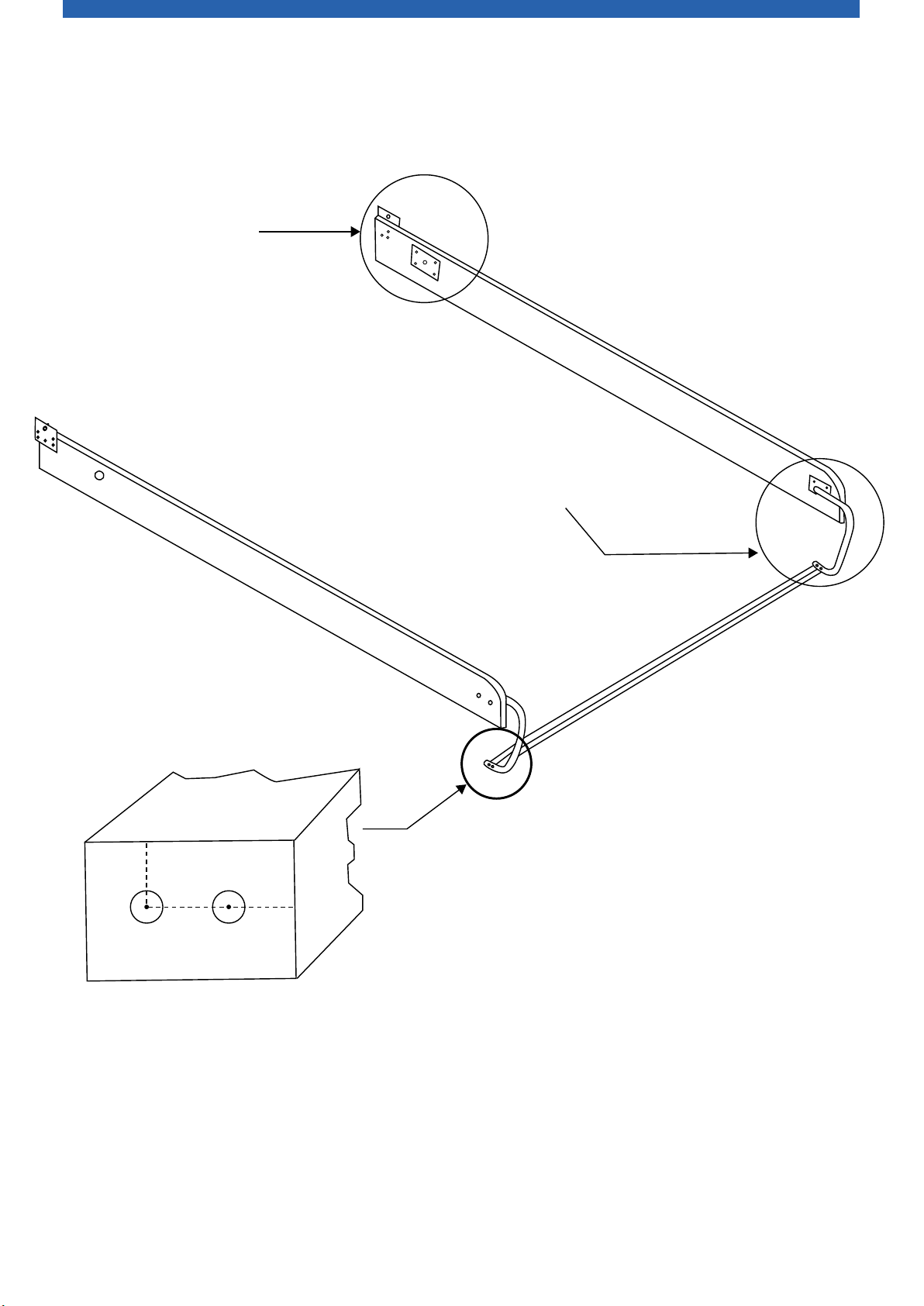

FRAME STRUTS: *SOLID WOOD* 3/4" X 1-1/2" X 60-1/2" 10 pieces

2 pieces

2 pieces

1 pieces

1 pieces

2 pieces

2 pieces

2 pieces

Box of 50

Box of 100

Box of 30

Box of 40

2 HANDLES

Box of 25

1 pieces

2 pieces

1 pieces

1 pieces

1 pieces

1 pieces

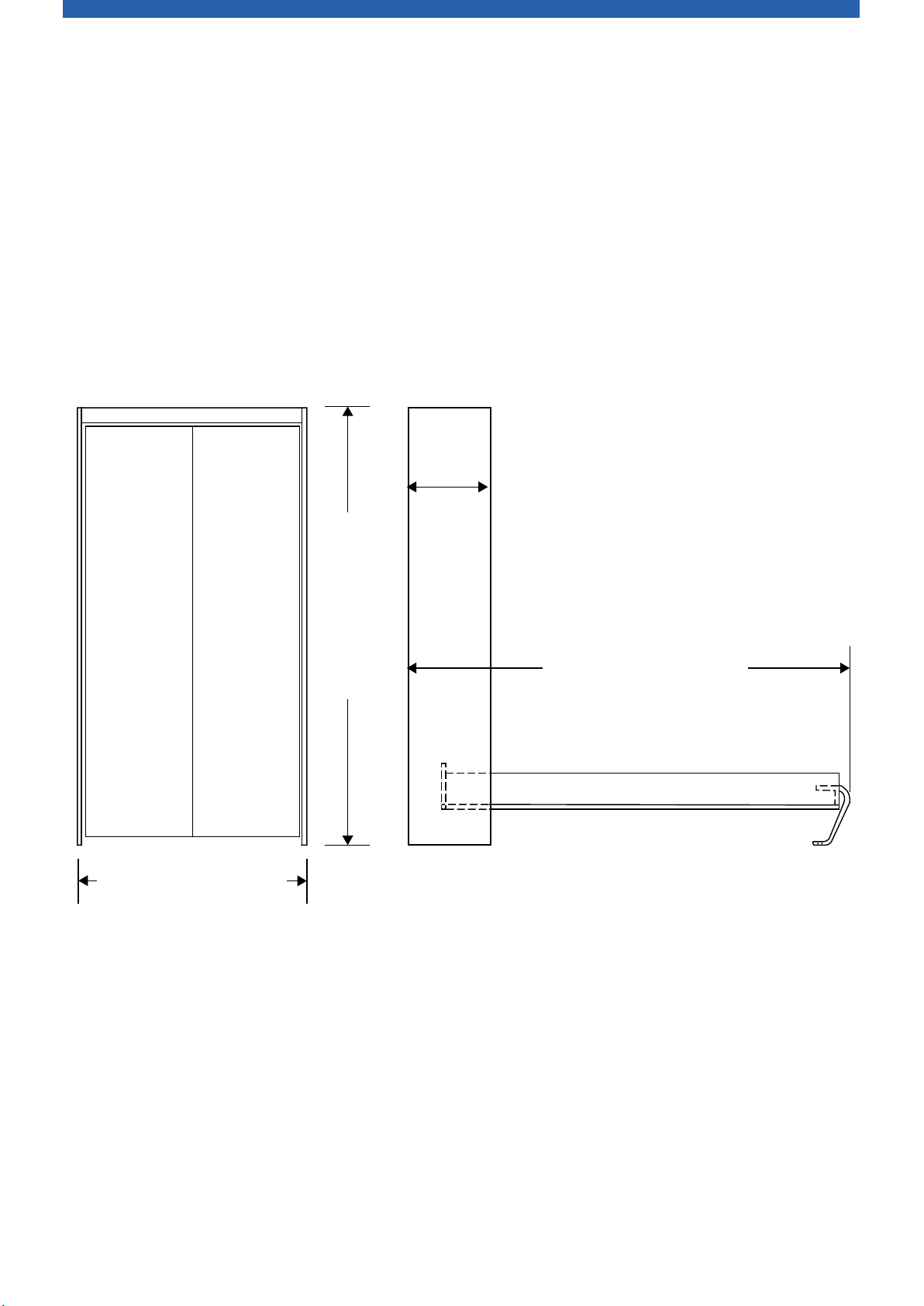

3/4" X 1-1/2" X 80"FRAME SIDES: *SOLID WOOD*

IMPORTANT: PLYWOOD MUST BE USED FOR THESE PIECES:

_B. SIDE RAILS: 3/4" X 5-7/8" X 81-1/2"

3/4" X 3" X 62"

3/4" X 7-7/8" X 62"

3/4" X 32" X 81-3/4"

3/4" X 15-7/8" X 64-3/8"

3/4" X 15-7/8" X 87-1/8"

3/4" X 14-3/8" X 64-3/8"

3/4" X 2-3/4" X 64-3/8"

3/4" X 2-3/4" X 64-3/8"

3/4" X 1-1/2" X 14-3/8"

3/4" X 1-2/5" X 60-1/4"

1/4" X 31" X 80"

13/16" X 80 feet

One 8 ounce bottle

1-1/2"

MUST weigh between 65 - 80 pounds

2"

#8 1-1/4" coarse thread

#8 1-1/2" coarse thread

#8 2" coarse thread

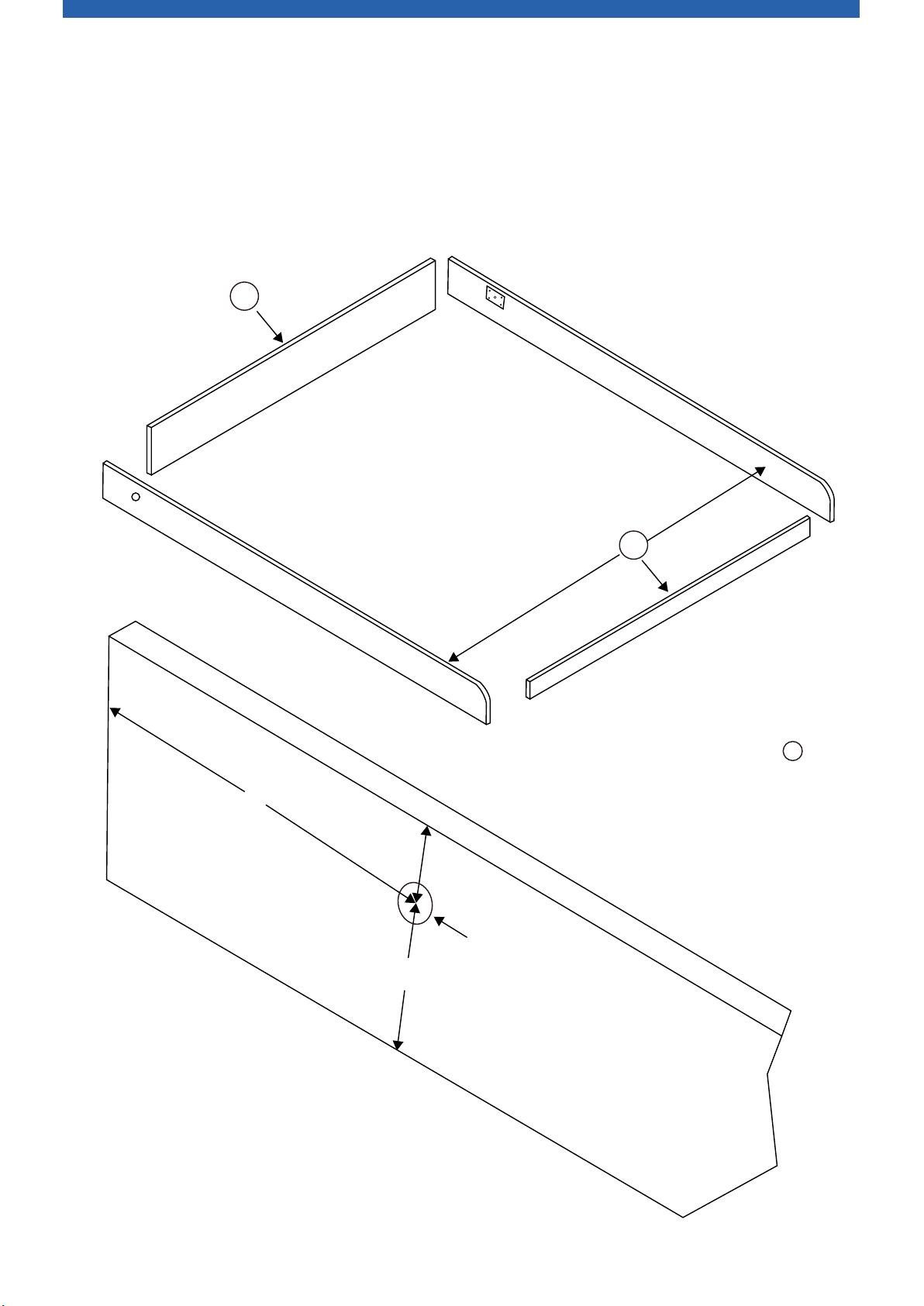

_C. FOOT RAIL:

_D. HEAD RAIL:

_E. BED FACE PANEL:

_F. BED HEADBOARD:

_G. BED CABINET VERTICALS:

_H. BED HEADER:

_l. Leg Support Rail:*SOLID WOOD*

_J. 1/4" PLYWOOD mattress support:

_K. VENEER or MELAMINE TAPE:

_L. WOOD GLUE:

_M. FINISH NAILS:

_N. SCREWS:

_O. DESIRED CABINET HANDLES OR PULLS

_P. MATTRESS

HEADERBOARD:

FRONT RAIL:

REAR RAIL:

MOUNTING CLEATS:*SOLID WOOD*

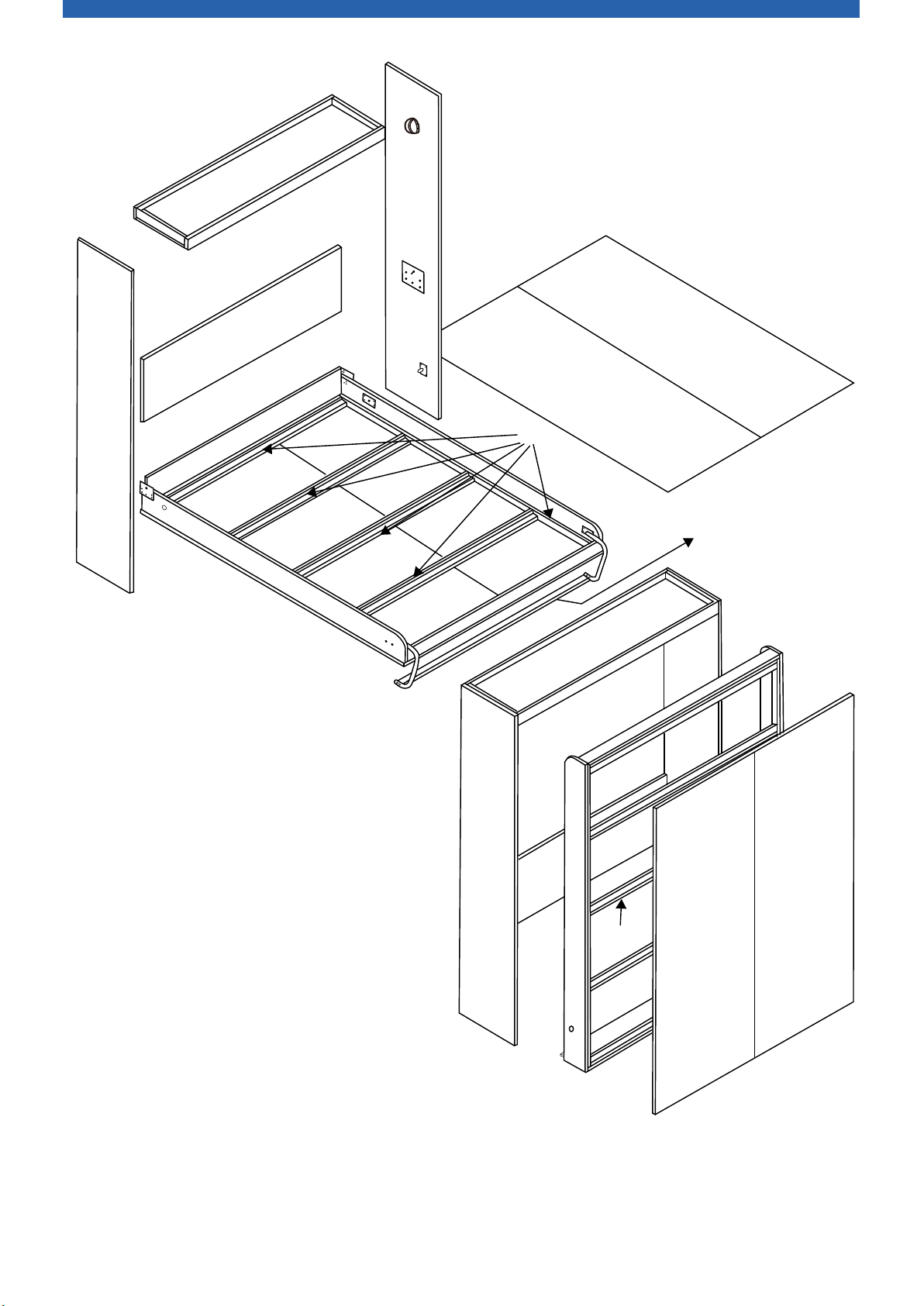

_A. INNER WOOD BED FRAME:*To be constructed of solid wood: poplar, clear pine, maple, etc.*

QUEEN SIZE DELUXE KIT VERTICAL BED WITH 3/4"

PLYWOOD FACE PANEL BILL OF MATERIALS / CUT SHEET

Note: Do not substitute other materials.