VALVE INSTALLATION GUIDELINES AND COMPLIANCE

The valve must be installed so that it is readily accessible for commissioning and maintenance in accordance with the

TMV2 scheme. The valve must be installed with isolation valves on both the hot and cold water systems as close as

possible to the valve; so as to allow the valve to be commissioned and tested correctly. The valve is fitted with integral

check valve cartridges which command the water supply, therefore the thermostatic valve is protected against

cross-flow due to unbalanced line pressures as required by the Water Supply (Water Fittings) Regulations 1999.

Most problems associated with the operation of thermostatic shower valves are caused by debris in the new pipe work

getting into the thermostat. These problems are easily avoided by thoroughly flushing the pipe work BEFORE the shower

valve is fitted.

WATER SUPPLY - (WATER FITTINGS) REGULATIONS 1999

This valve complies with the requirements of the above regulations and installation should be carried out in strict

compliance with them.

MOUNTING BAR SHOWER VALVES

TEMPERATURE

This valve is factory set to a maximum outlet temperature of 42˚C/ 107.6 F

COMMISSIONING

It is important that incoming water supplies conform to the requirements specified for pressure and temperature.

Assure that supply water conditions satisfy any guidance information for the control of bacteria and that the

designation of the supplied valve suits the application. Do not continue commissioning until supplies are correct and

stable considering variation caused by other service users.

Use a calibrated thermometer for testing incoming and mixed water.

1. Record temperature of the incoming hot and cold supply.

2. Record temperature of mixed discharge at maximum draw off rate.

3. Record temperature of mixed discharge at minimum draw off rate.

4. Isolate the cold water supply and measure the mixed water temperature as the cold water failure device reacts.

This should deviate by no more than + 2°C of the initial maximum set point. Restore the cold supply and measure the

stabilised mixed water temperature. This must not deviate by more than + / - 2°C of the initial set recorded result.

Record these findings.

5. Record the measuring equipment used for the measurements.

The above records must be retained and updated during the service life of the TMV.

If there is a residual flow during the commissioning or the annual verification (cold water supply isolation test),

then this is acceptable providing the temperature of the water seeping from the valve is no more than 2oC

above the designated maximum mixed water outlet temperature setting of the valve.

Temperature readings should be taken at the normal flow rate after allowing for the system to stabilise.

The sensing part of the thermometer probe must be fully submerged in the water that is to be tested.

Any TMV that has been adjusted or serviced must be re-commissioned and re-tested in accordance with the

manufacturers' instructions.

The installation of thermostatic mixing valves must comply with the requirements of the Water Supply (Water

Fittings) Regulations 1999.

IN SERVICE TESTING & MAINTENANCE

The continuing performance of the TMV must be assured. In service validation testing must be conducted at

appropriate intervals. The following method is recommended.

First service: Between 6 to 8 weeks after commissioning repeat the initial tests.

That is 1, 2 & 3 as above.

If the stabilised mixed water temperature has changed by > 1ºK *, from the initial recorded setting, check the following

before re setting the mixed water temperature.

a) Check inline filters washers are clear

b) Check non return valves are clear and operational.

c) Any isolating valves are fully open.

If the reset temperature is acceptable < 1ºK from initial reading repeat the recording routine as 1 to 5 above.

Second service: Between 12 & 15 weeks after commissioning repeat the tests and check measures of the First service.

If no significant drift from the initial settings are noted, that is < 1ºK record findings accept the tests and expand service

interval as indicated on the following page.

If the test results have drifted repeat recovery methods of the first service and conduct the second service again after 6

to 8 weeks.

*ºK = Kelvin, a unit of thermodynamic measurement used to represent a difference of Celsius ( ºC ). Kelvin and Celsius

units are equivalent.

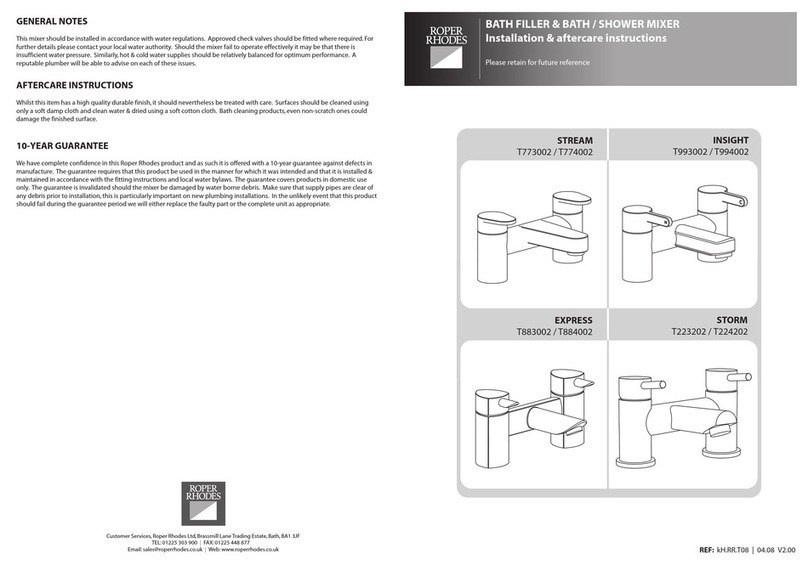

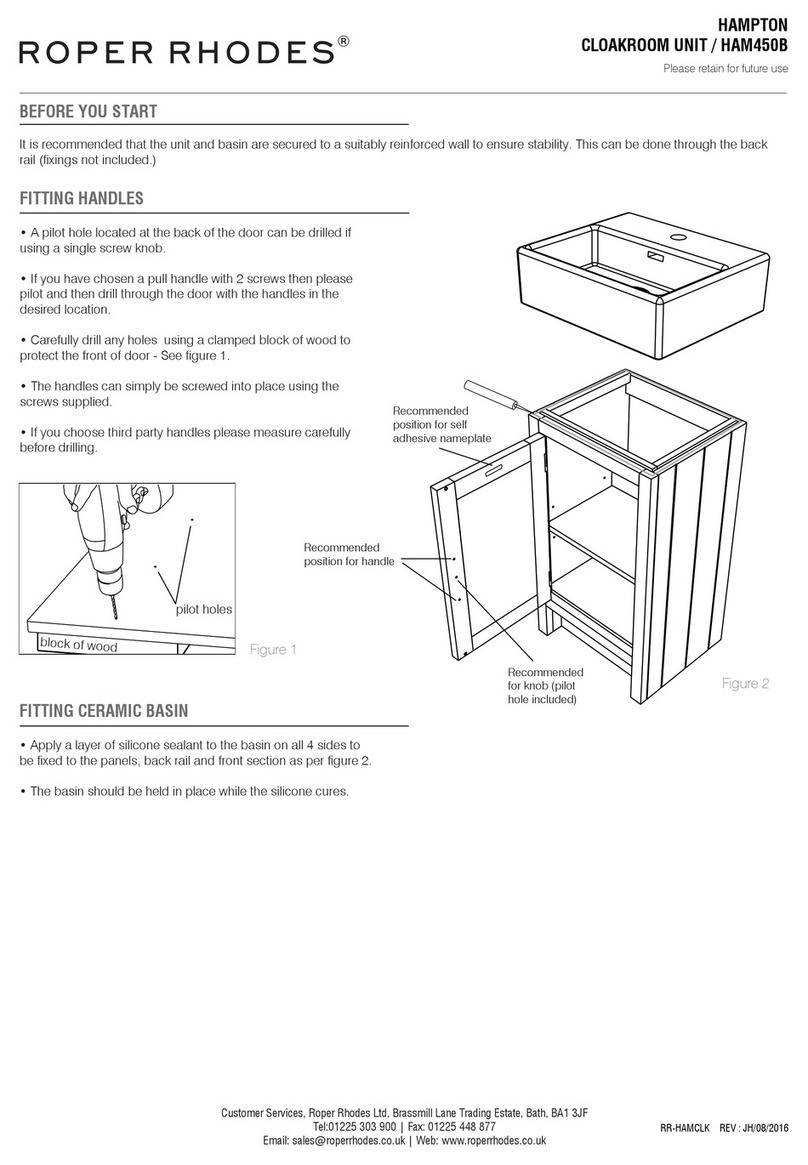

297mm

G1/2" BSP

110mm

150mm

STORM BOTTOM OUTLET BAR VALVE SHOWN