Before you start.. .

Check location where range will ALL OPENINGS IN THE WALL

be installed The location should OR FLOOR WHERE THE RANGE

Proper installation is your responsibility be away from strong draft areas.

Make sure you have everyihing necessoly such OS windows, doors. and TE;JC;; INSTALLED MUST BE

, -,

J venrs o( ram rne

for carrecr Insrallatlon. It ISme reSWn~lDll!N s?rcna neonnc

ofthe installer to compl,

clearance specified on the serial/rating

nhta The rtxinlirotina elate con be,,

ranae should be located for

con7enlent use In the kitchen.

Recessed inst allaticns must

Note: Clearances specified

are for combusiible walls and

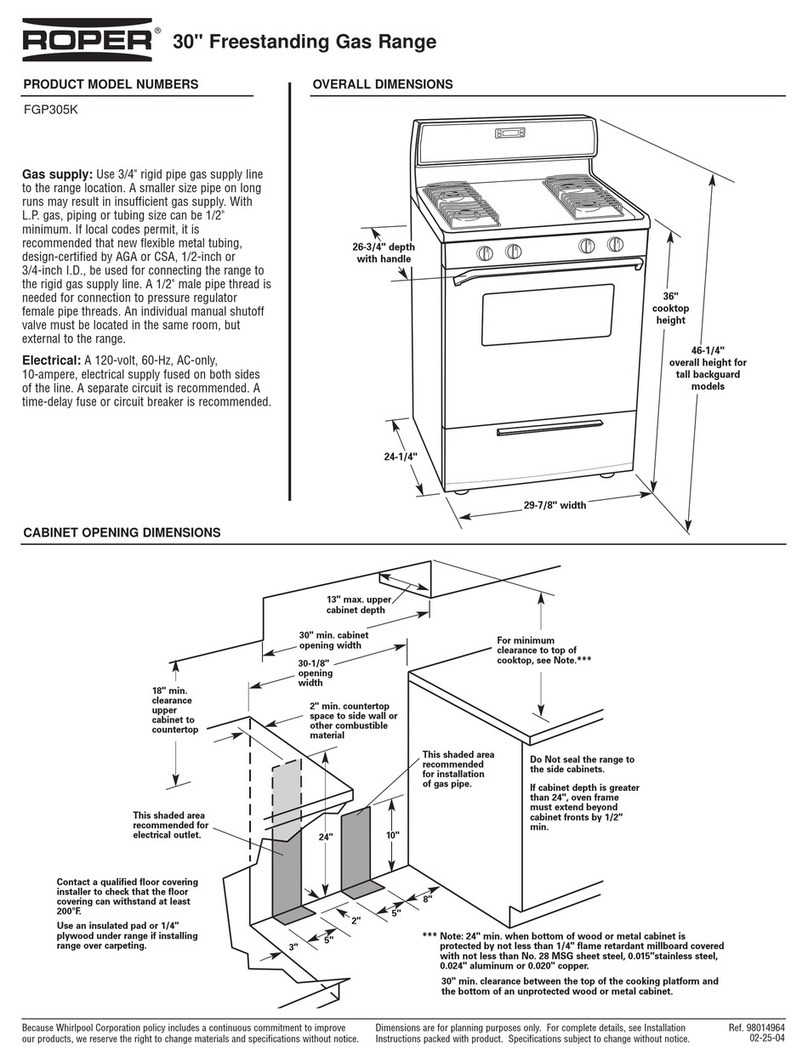

Cablnef ODenIna dlmsnslons

liquids in the vicinity df this

or any other appliance.

I

w,,.a,b orcupboa,~ Mot are, shown m&t be used.

r=d - Ib - Given dlmensicns provide

lopmudta4’mh

0” clearance.

.

surfaceburners cuuse5 ‘1

risk Of being burned.

To reduce risk, Itiallation

are alreaay provraea. /

reduce hazard by lns~alling a

range hood. l-lo& should extend 5

minimum beyond front of cabinets.

Tools needed for inskliioMon.

Gas Supply

Requirements

Observe all governing codes

and ordinances.

A

This ixstallatbn must confcfm

m W’WI kc01 CC&S and ordlnonces

In the absence of lccal codes, Installatbn

must oonfwm with American Natbnal

Standard, Natbnal Fuel Gas code ANSl

2223.1 -lotest edttbn.

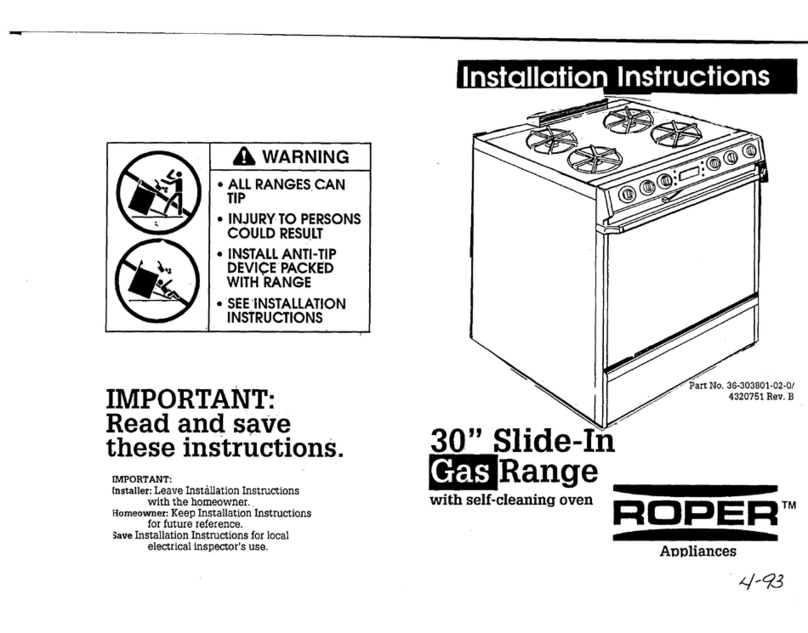

FOR YOUR SAFETY 1

if you smell gas:

1. Open windows.

2. Don’t touch electrical switches

3. Extinguish any open flame.

4. Immediately call your gas

supplier.

1FOR YOUR SAFETY t

Do not store or use gasoline

or other flammable vapors and

Gfouncled electrical

outtet:

is required See

Electrical Requirements.

B

I Input ratings shown on the

serial/rating plate are for

eleVOtim5 uo to 2.000 leet. For

elevations dbove 2.ooO feet. ratings

should be reduced at a rate of 4% lor

each KKKI feet above sea level

PANEL A

C

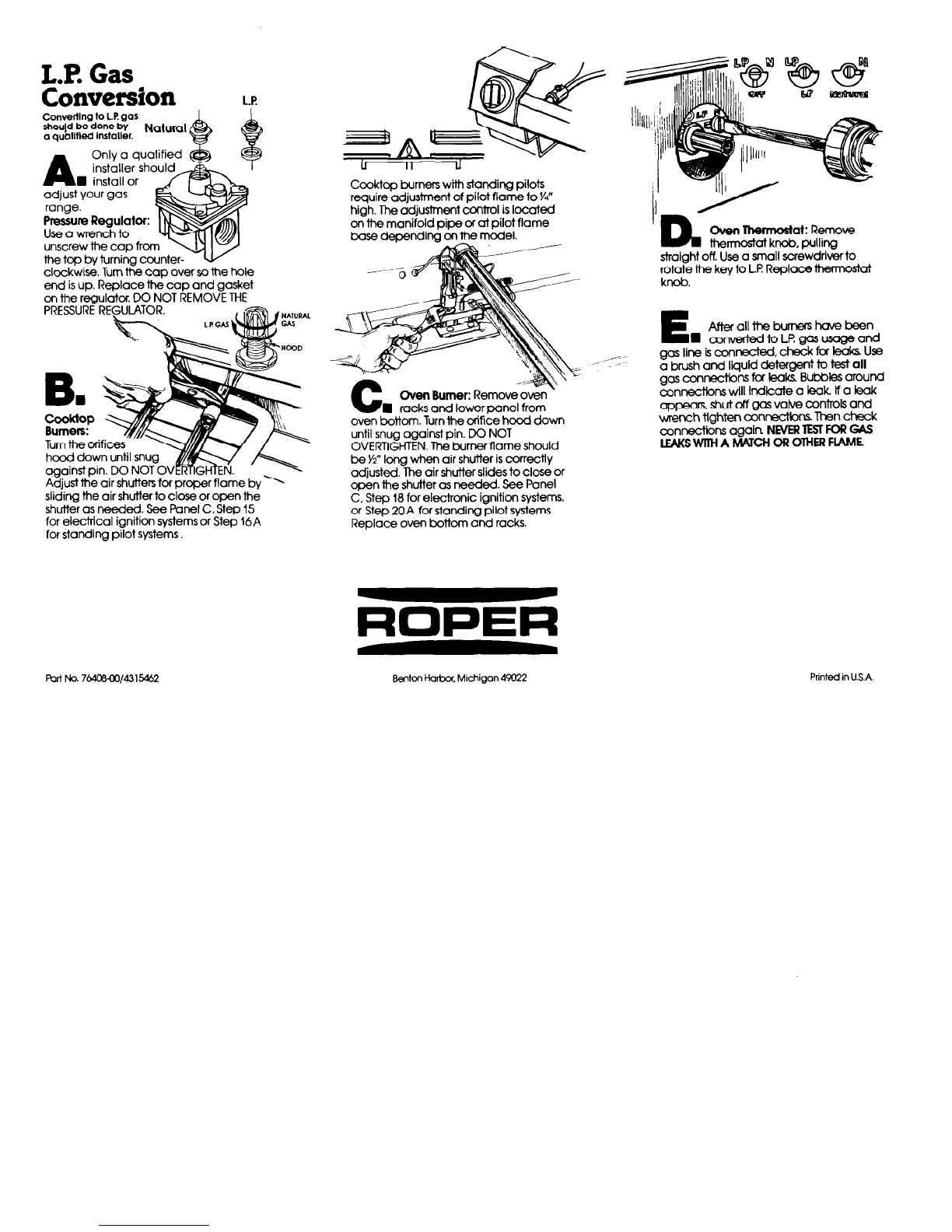

This range is equipped for use

n

wifh NATURAL gas. It is design-

certified bv A.G.A. for NATURAL and L.f?

gases wittiappmpriaie conversion, The

serial/rating plate located under the

cti~op

has information on the type of

gas that can be used. If this information

does fd agree wifh the type of gas

available. check with the local gas

supplier. See backcover for L.P gas

conversion instructions.

D

Provide a gas supply line of

n

%” rigid pipe to the range

location. Pipe

joint

compounds resistant

to the action of L.P. gas must be used.

With L.P gas, piping or tubing size can

be K” minimum. L.P gas suppliers usually

determine the size and malerials used

on their system

E

If local codes permit. A.G.A.

I cetiifred flexible metal tubina

(new) is recommended for connecting

this

range

to the gas supply line. Do not

kink of damage the flexible tubing when

moving the range. A Y9’ male pipe

thread is needed for connection to

The supply line shall be

6dPPed with an aPDrOVed

shutoff

valve

This valve should be

loabd in the same rcom as the ronae

and

should be in a location that allows

ease of opening and closing. Do not

block access to shutoff valve.

G

If rigld

m suo~lv line. o combindon of

pipe fittings h&t be used to obtain an

in-line connection to the range. All sfralns

must be removed from the supply and

fuel lines so range will be level and in

line.

(r

lmportanl: Observe all governing

codes and ordlnanceo.

Mobile Home instaiiation

The installation of this range must

conform to the Manufactured Home

Construction and Safety Standards,

Title 24 CFR. Part 3280 (formerly the

Federal Standard for Mobile Home

Construction and Safety, Title 24. HUD

(part

280).

When this range is installed In a mcbile

home, it must be secured to the flow

during transit. The procedure used in

steo 8.Panel I3 Isonemsthcdof

se&ring range to the mobile home.

Other p&edures are avallable and

adequate If they ccnfotm to the

standards listed above,

Copies of the standard listed above

may be obtaIned from:

‘Amedcan Gas ksoclatlon

15% Wilson Boulevard

Mlngton.Vlrglnla 22209

“National Flm ProtectIon Assoclallon

Battety March Park

Qulncy, Massachusetts 02169

H

n

The inlet pressure to the

regulator should be as follows

for both operation and checking

regulator setting:

NATURAL GAS:

Mlnlmum pressure 6 Inches

Maxlmum pressure 14 Inches

1.PGAS;

Mlnlmum pressure 11Inches

Maxlmum pressure 14 Inches

I

The range and its lndlvlduol shut-off

l

valve must be discmnected from

the gas supply piping system during any

presurre testing of that system at test

pressures in excess of k psig (3.5 kPa).

The range must be isolated from the

gas supply plp~ng system by closing 11s

indrvidual manual shut-oft valve during

any pressure testing of the gas supply

pIpIng system ai test pressures equal to

or less than % psig [3.5 kPa].