Operation Specifications

R80 600S Design Pressure: 600 PSI / 4.1Mpa / 41 Bar

R80 1000S Design Pressure: 1000PSI / 6.9Mpa / 69 Bar

R80 1200S Design Pressure: 1200PSI / 8.3Mpa / 83 Bar

Max. Permeate Pressure: 125PSI / 0.86Mpa / 8.6 Bar

Min. Operating Temp.: 14⁰F / -10⁰C

Max. Operating Temp.: 150⁰F / 66⁰C

Factory Test Pressure: ASME: 1.1x Design Pressure

Standard: 1.5x Design Pressure

Operating pH Range: 3 – 11

Cleaning pH Range: 2 – 12 (less than 30 minutes)

Vessel Use and Precautions

Do not allow the vessel to fall or impact on the ground or other object.

Use padding to protect the vessels during handling to prevent damage.

Pressure up to the design pressure (PSI) of the specific model being used.

Vacuum conditions should be avoided with vacuum breakers.

Accommodates standard 8” nominal diameter spiral-wound elements.

Read and follow the membrane manufacturer installation instructions along with this

manual.

The required vessel/element interface hardware is supplied with the vessel. Ensure that

an element adapter is installed at each end of the vessel before use.

Vessel expands under pressure and careful consideration must be taken when installing

straps/saddles and system connection piping.

Installation with the straps/saddles provided is strongly recommended

Vessel should not support any other system components. Connections must be non-load

bearing.

Mount vessel using strap/saddle hardware provided and span recommended in the

engineering drawing.

Do not over tighten the straps – vessel must be allowed to expand under operation.

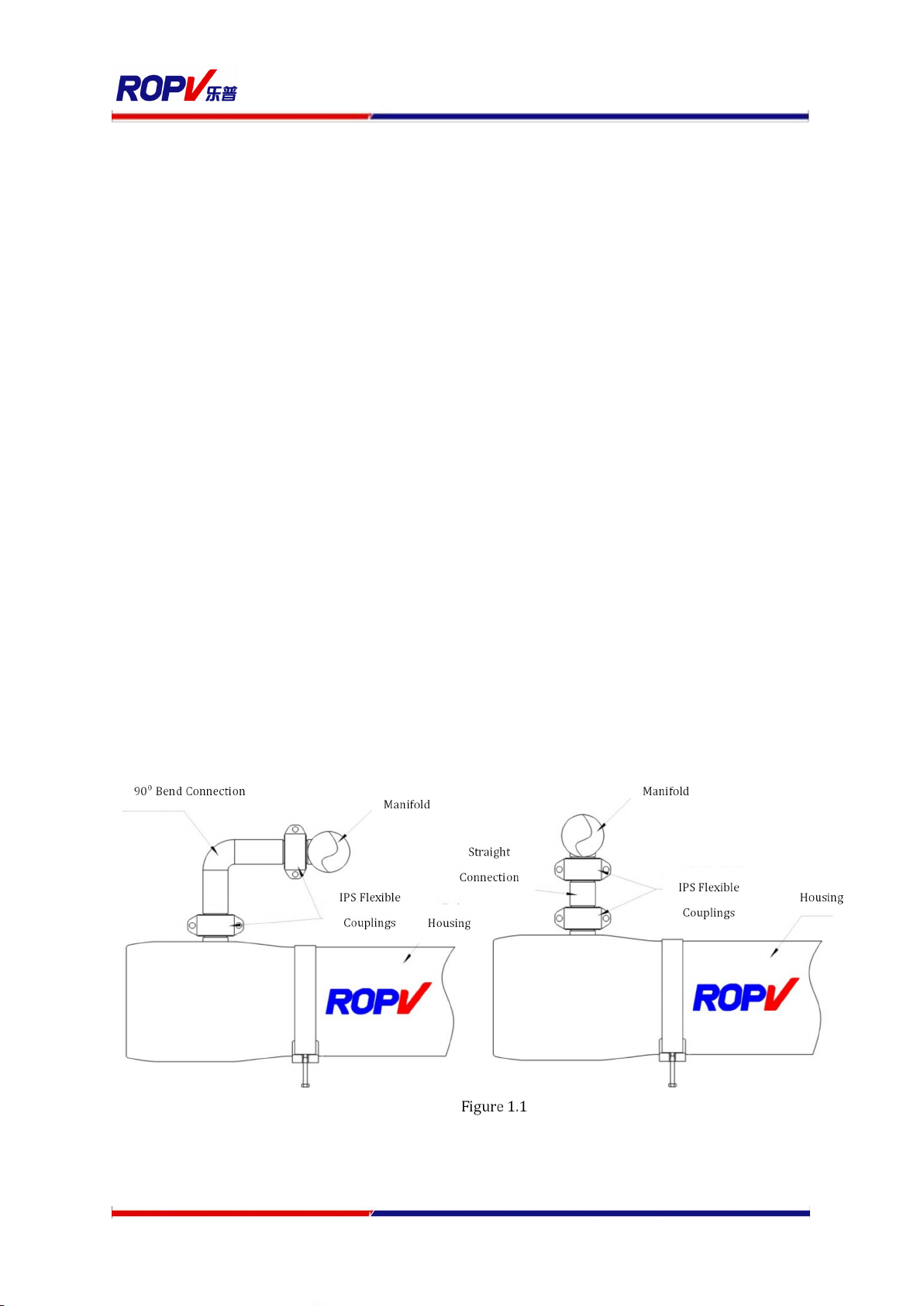

Maximize the connection flexibility to allow for vessel growth under pressure.

Align the side ports with the system manifold, correcting any misalignment before final

installation.

Provide overpressure protection in the system safety devices.

Inspect end closures regularly for signs of corrosion. Immediate corrective action

and/or replacement are suggested in case of corrosion.

Thrust Ring must be installed at the downstream end of the vessel.