This installation guide provides basic guidelines for the Rosemount 2120. It does not provide

instructions for detailed configuration, diagnostics, maintenance, service, troubleshooting,

or installations. Refer to the Rosemount 2120 Reference Manual (Document Number

00809-0100-4030) for more instruction. Manuals are available electronically on

www.rosemount.com.

Failure to follow these installation guidelines could result in death or serious injury

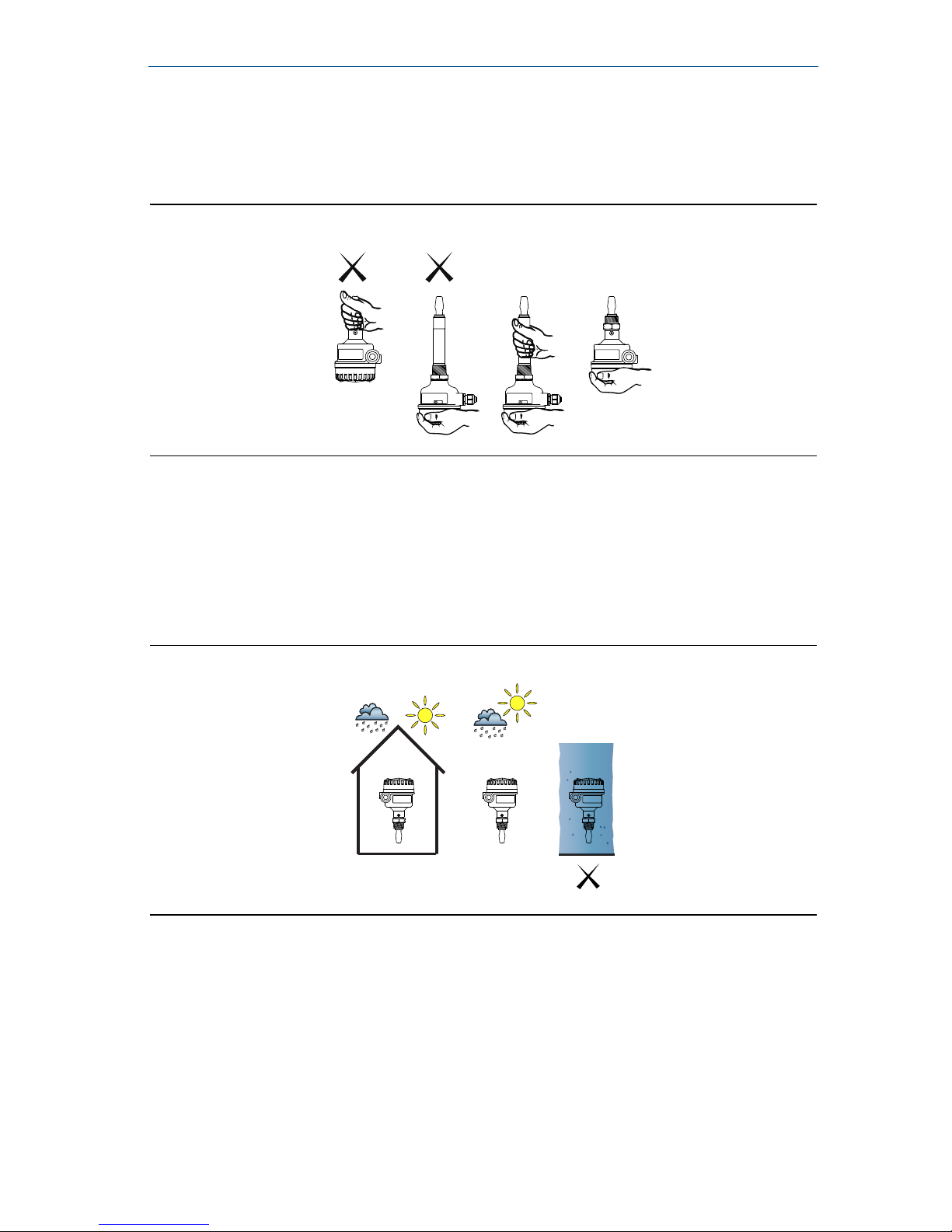

The Rosemount 2120 is a liquid level switch. It must be installed, connected, commissioned,

operated, and maintained by suitably qualified personnel only, observing any national and

local requirements that may apply

Ensure the wiring is suitable for the electrical current and the insulation is suitable for the

voltage, temperature, and environment

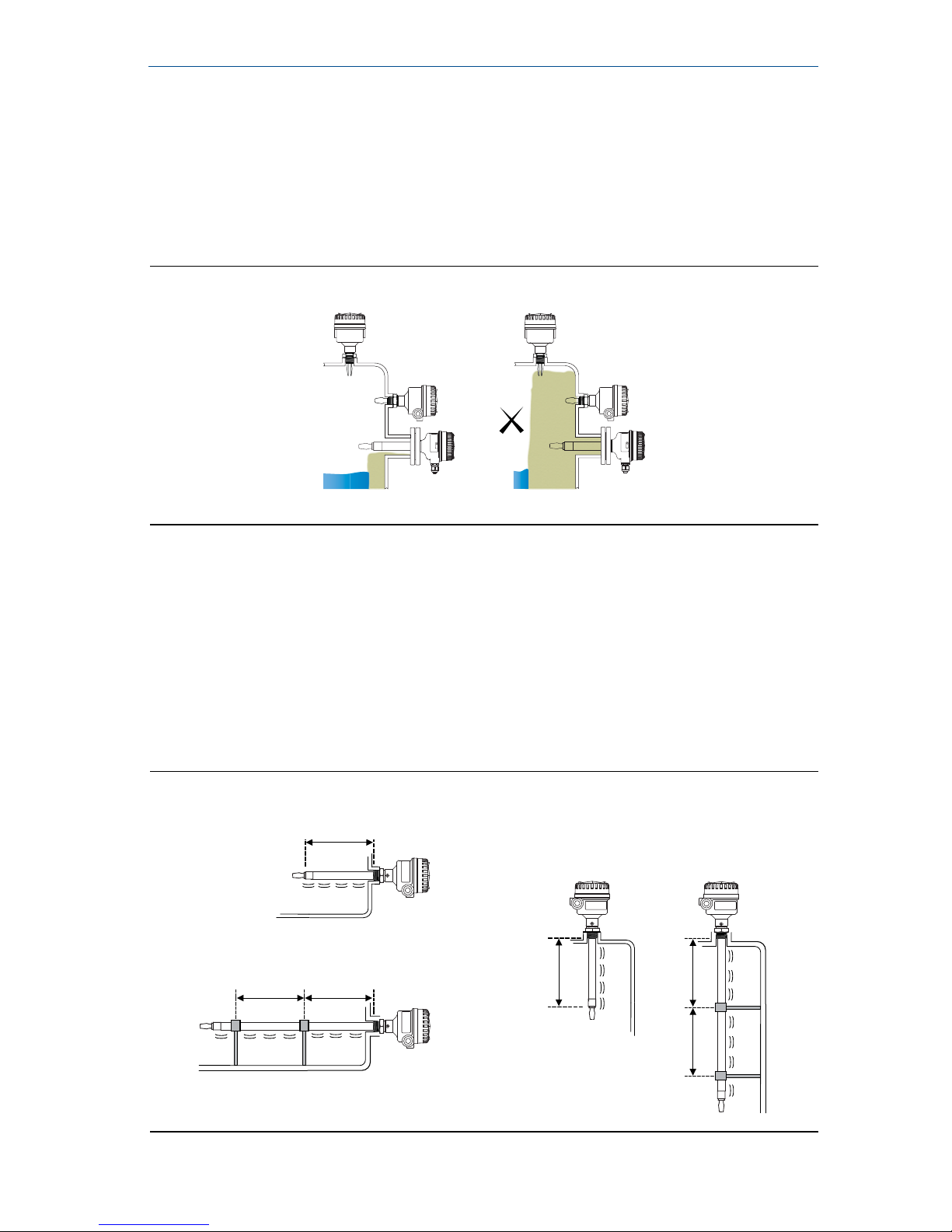

Use the equipment only as specified. Failure to do so may impair the protection provided by

the equipment

Any substitution of non-recognized parts may jeopardize safety and is under no

circumstances allowed

Explosions could result in death or serious injury

Installation of the 2120 in a hazardous environment must be in accordance with the

appropriate local, national, and international standards, codes, and practices. Please review

the Product Certifications section for any restrictions associated with a safe installation

Verify that the operating atmosphere of the 2120 is consistent with the appropriate

hazardous locations certifications

External surface may be hot

Care must be taken to avoid possible burns

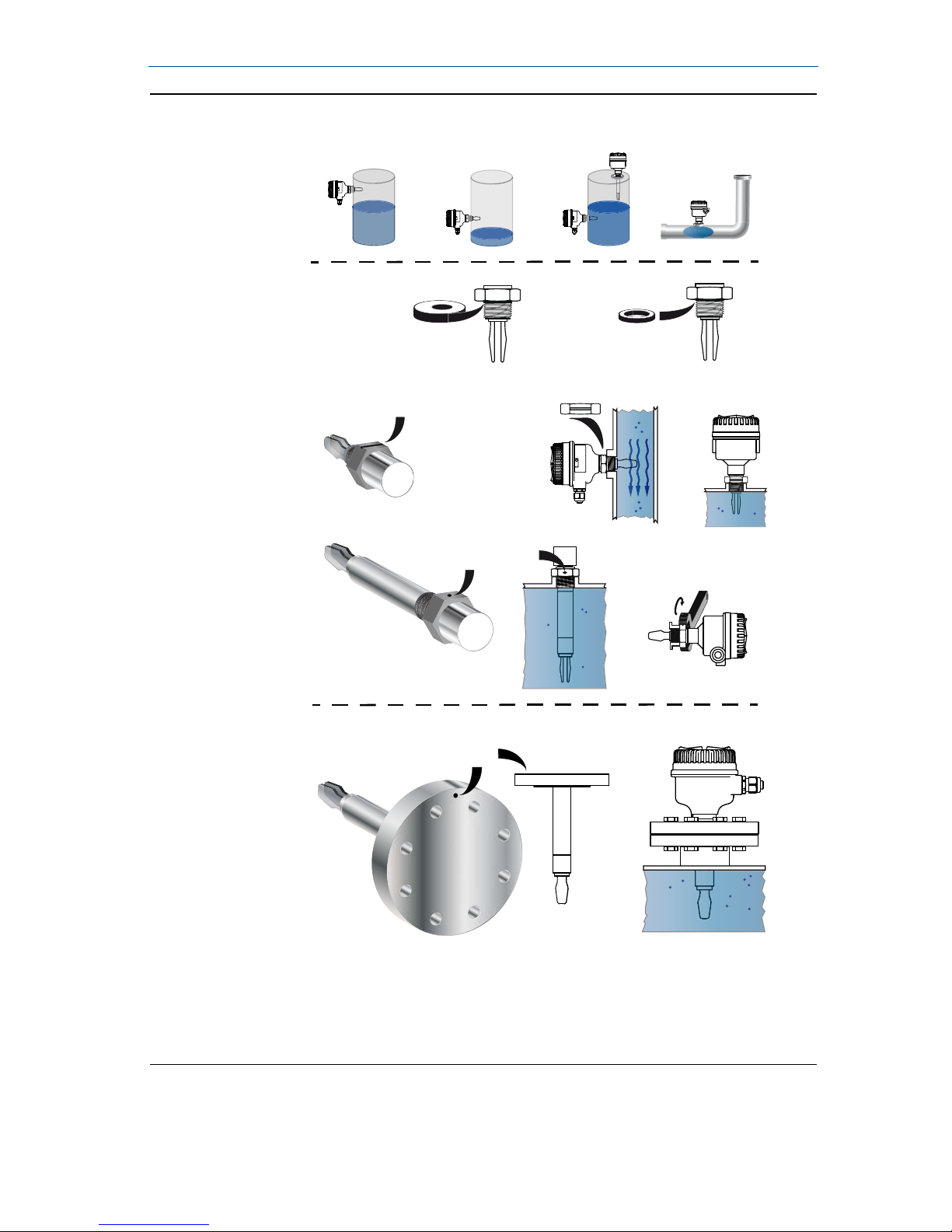

Process leaks could result in death or serious injury

Install and tighten process connectors before applying pressure

Do not attempt to loosen or remove process connectors while the 2120 is in service

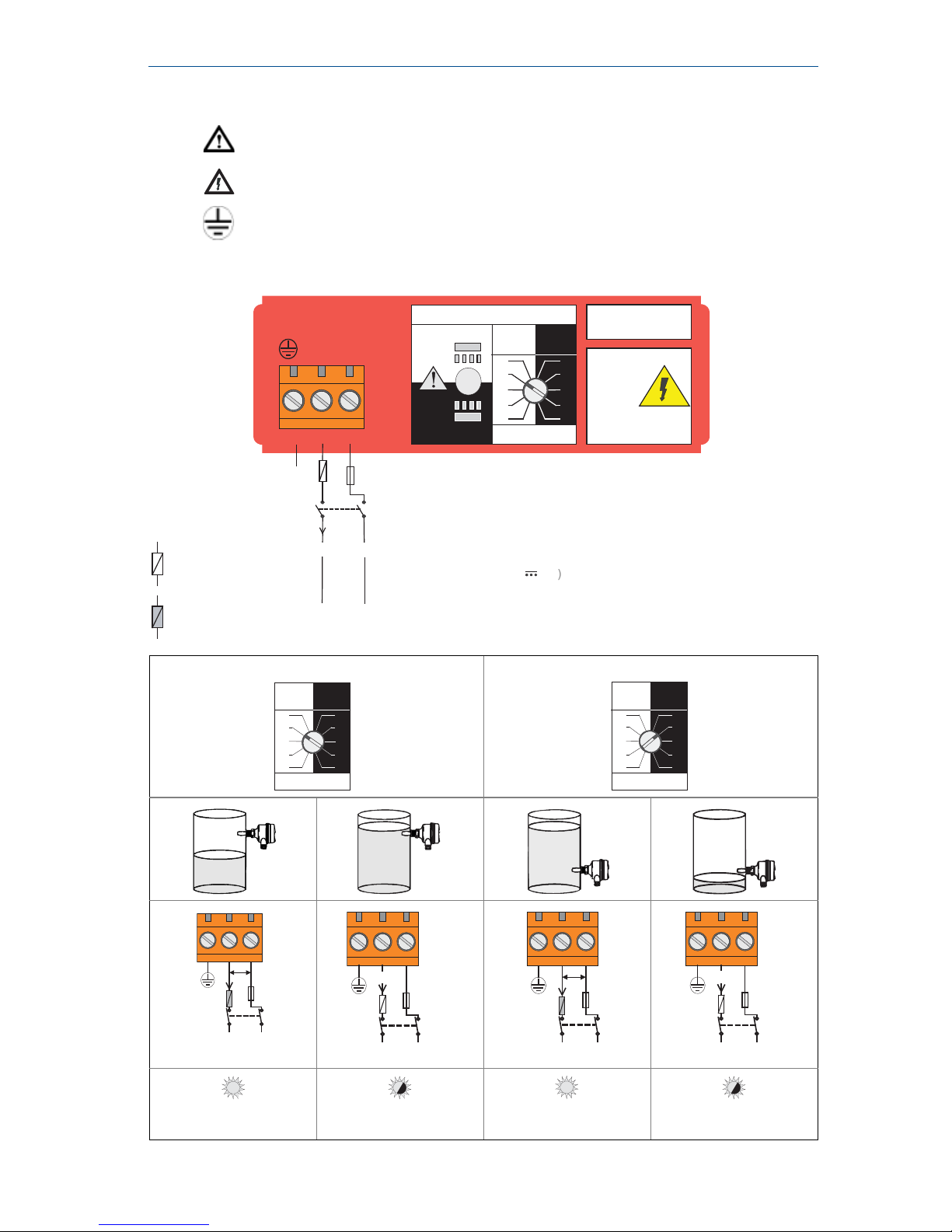

Electrical shock could cause death or serious injury

If the liquid level switch is installed in a high voltage environment and a fault condition or

installation error occurs, high voltage may be present on leads and terminals

Use extreme caution when making contact with the leads and terminals

Make sure that power to the 2120 is off while making connections