3RO_FFG_GUIDE (08/22)

CONTENTS

1. WARNINGS AND CAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

2. PLANNING AND INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.1. CLEARANCES ........................................................................................................ 4

2.2. AIR SUPPLY AND VENTILATION ....................................................................................... 4

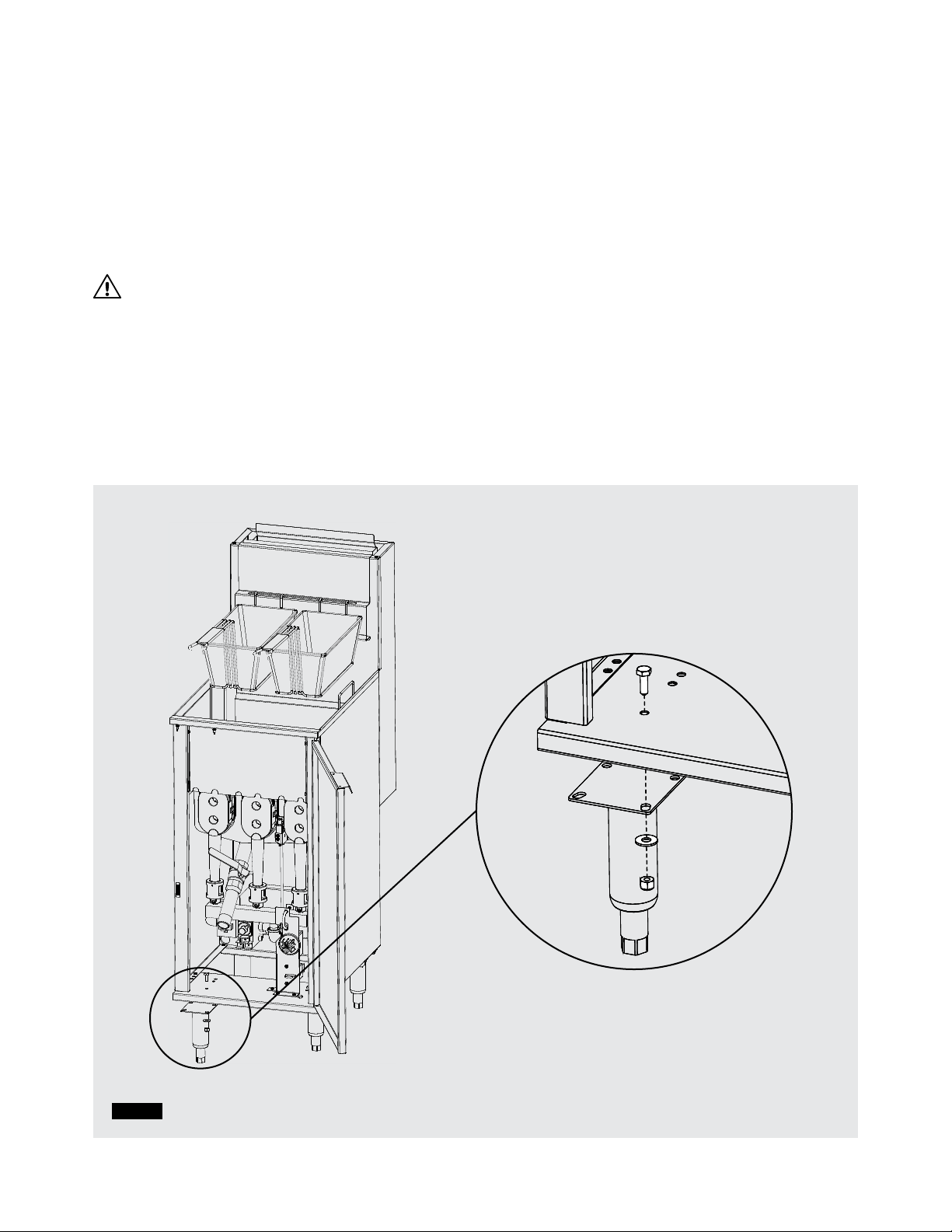

2.3. LEG INSTALLATION ................................................................................................... 6

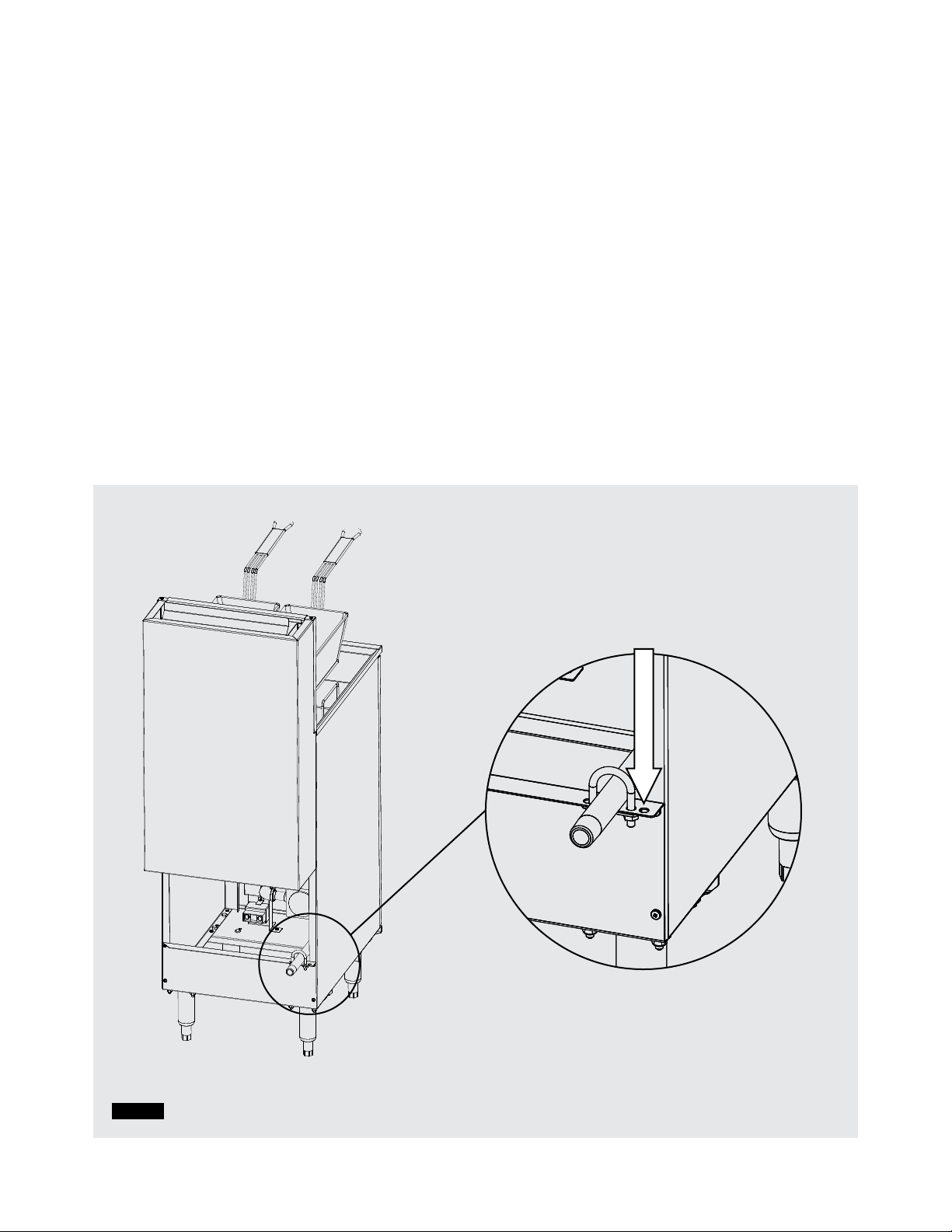

2.4. ATTACHMENT ........................................................................................................ 7

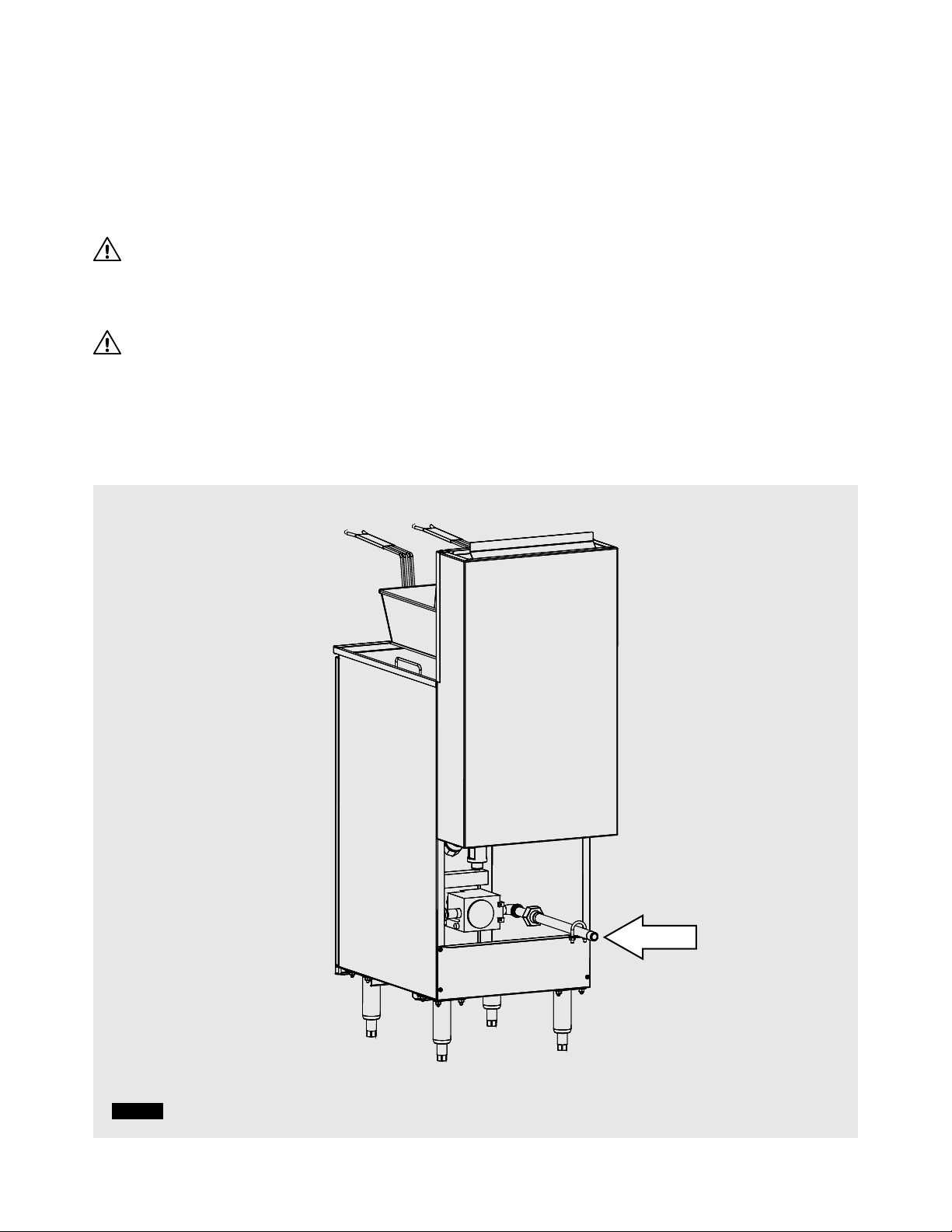

2.5. CONNECTION ........................................................................................................ 8

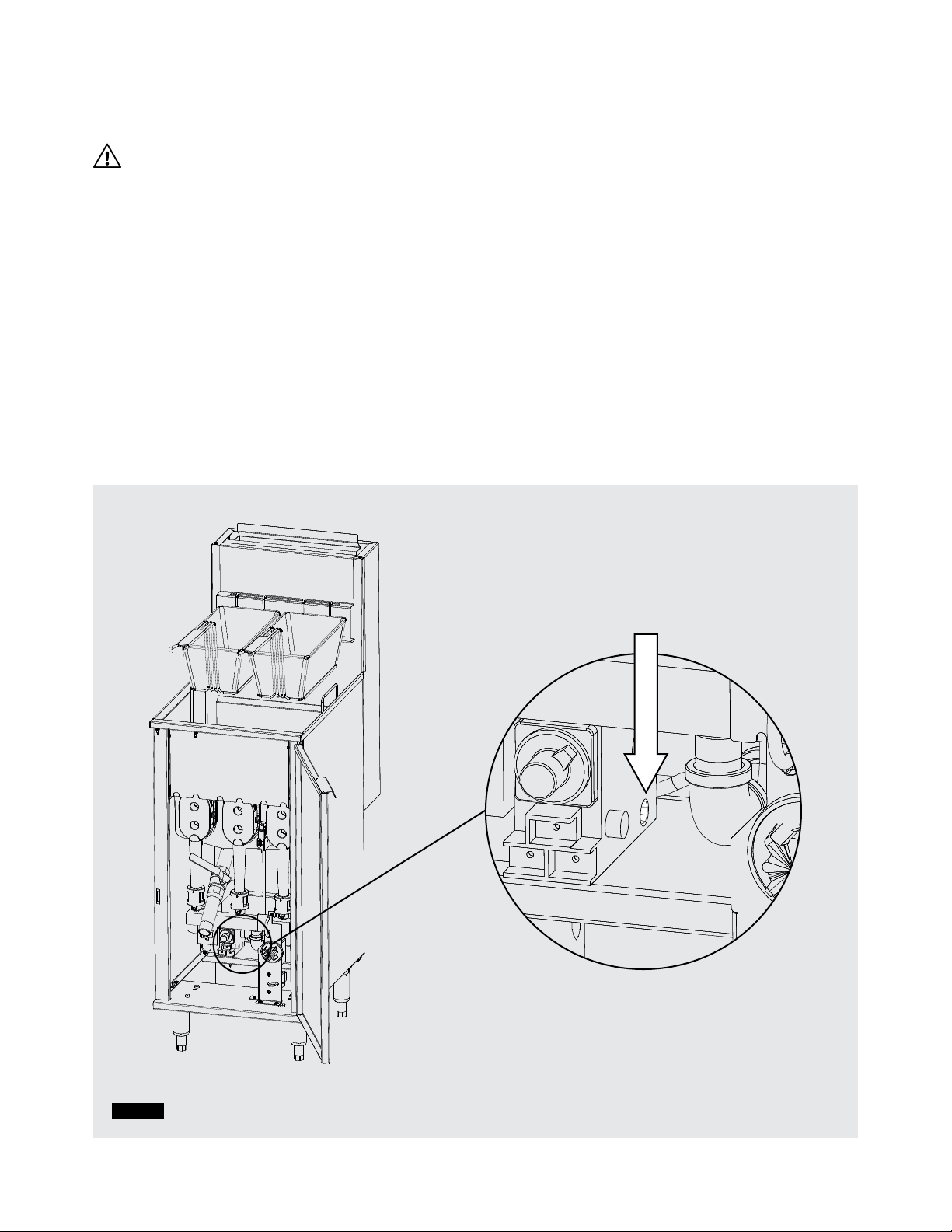

2.6. GAS PRESSURE CHECK .............................................................................................. 9

3. OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.1. FILLING .............................................................................................................. 10

3.2. IGNITION ............................................................................................................ 11

3.3. CLOSING ............................................................................................................ 12

3.4. DRAINAGE ........................................................................................................... 12

4. CLEANING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4.1. SURFACE CLEANING................................................................................................. 13

4.2. ACCESSORY CLEANING ............................................................................................. 13

4.3. FILTRATION .......................................................................................................... 13

4.4. TANK CLEANING ..................................................................................................... 14

5. PREVENTIVE MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

5.1. MINIMUM INSPECTION .............................................................................................. 15

5.2. PROFESSIONAL INSPECTION ....................................................................................... 15

6. TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

6.1. GENERAL TROUBLESHOOTING ..................................................................................... 16

6.2. TROUBLESHOOTING CHART ........................................................................................ 17

7. SERVICE PARTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

7.1. RO-FFG-115-N and RO-FFG-115-P .................................................................................. 18

7.2. RO-FFG-160-N and RO-FFG-160-P ................................................................................. 20

8. SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

9. ELECTRICAL DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

CONTACT US . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24