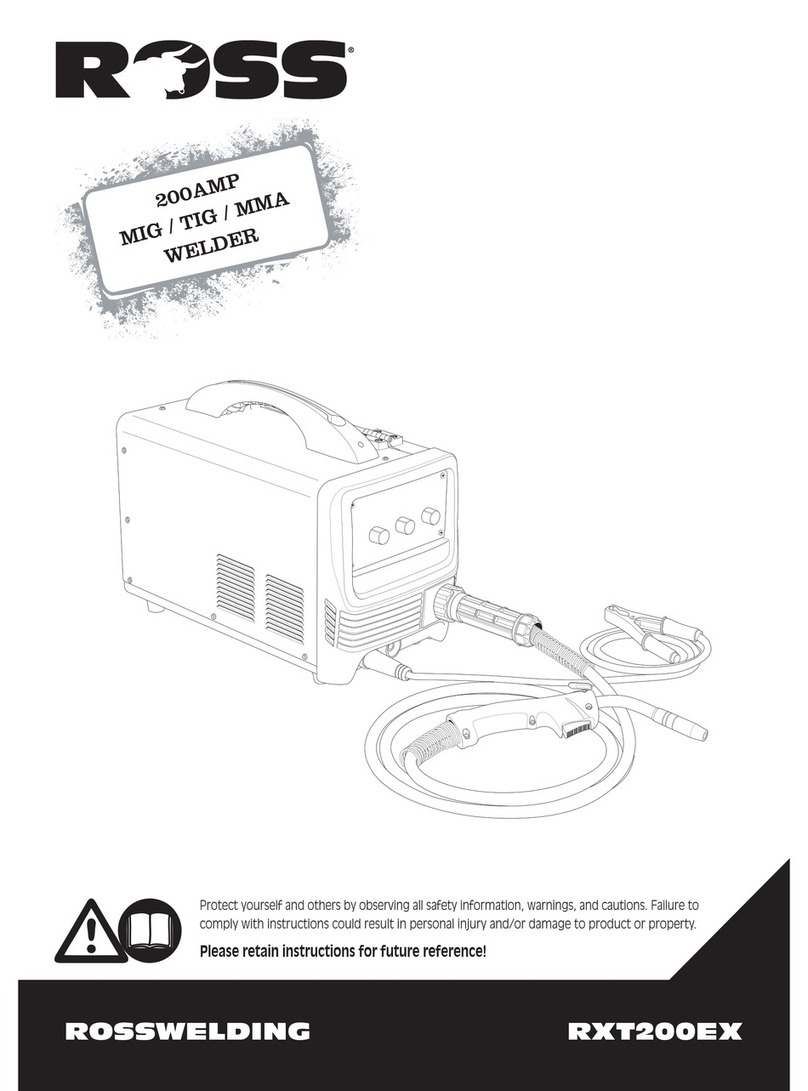

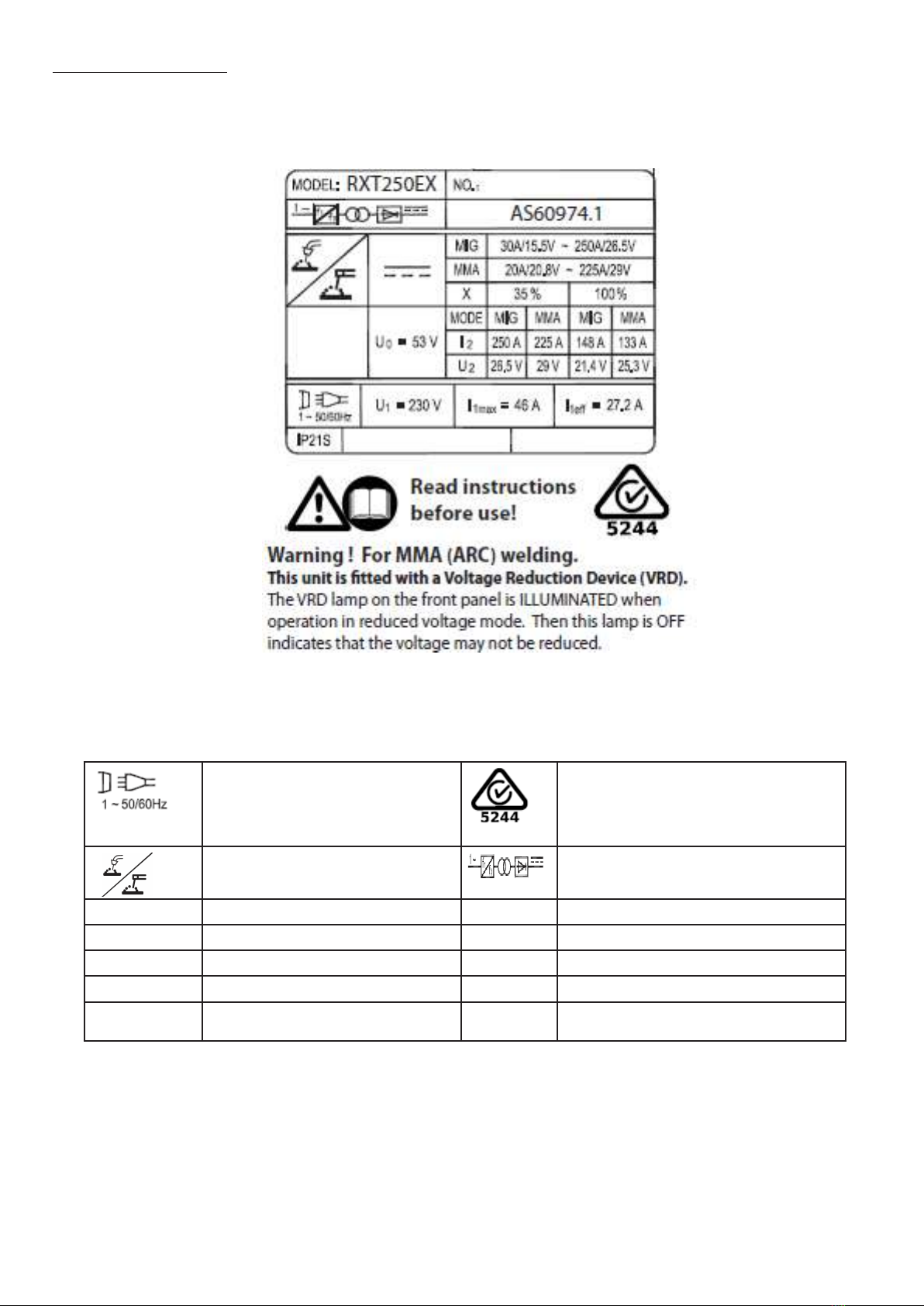

[1] Mode switch MIG /MMA

[2] GREEN Power lamp

[3] ORANGE Alarm/ Temperature lamp

[4] GREEN VRD indicator (MMA mode)

[5] 2 STEP / 4 STEP selector switch (MIG

MODE)

[6] Manual Wire feed. (MIG MODE)

[7] Welding power (MIG MODE)

[8] Wire feed speed control (MIG MODE)

[9] Negative output terminal.

[10] Tool Draw

11 Euro torch connector

12 Positive output terminal

[13] Welding current control (MMA MODE)

[14] Mains input

[15] Power switch

[16] Gas input.

[17] ARC Characteristics

[18] Burn Back control

[19] Positive output terminal

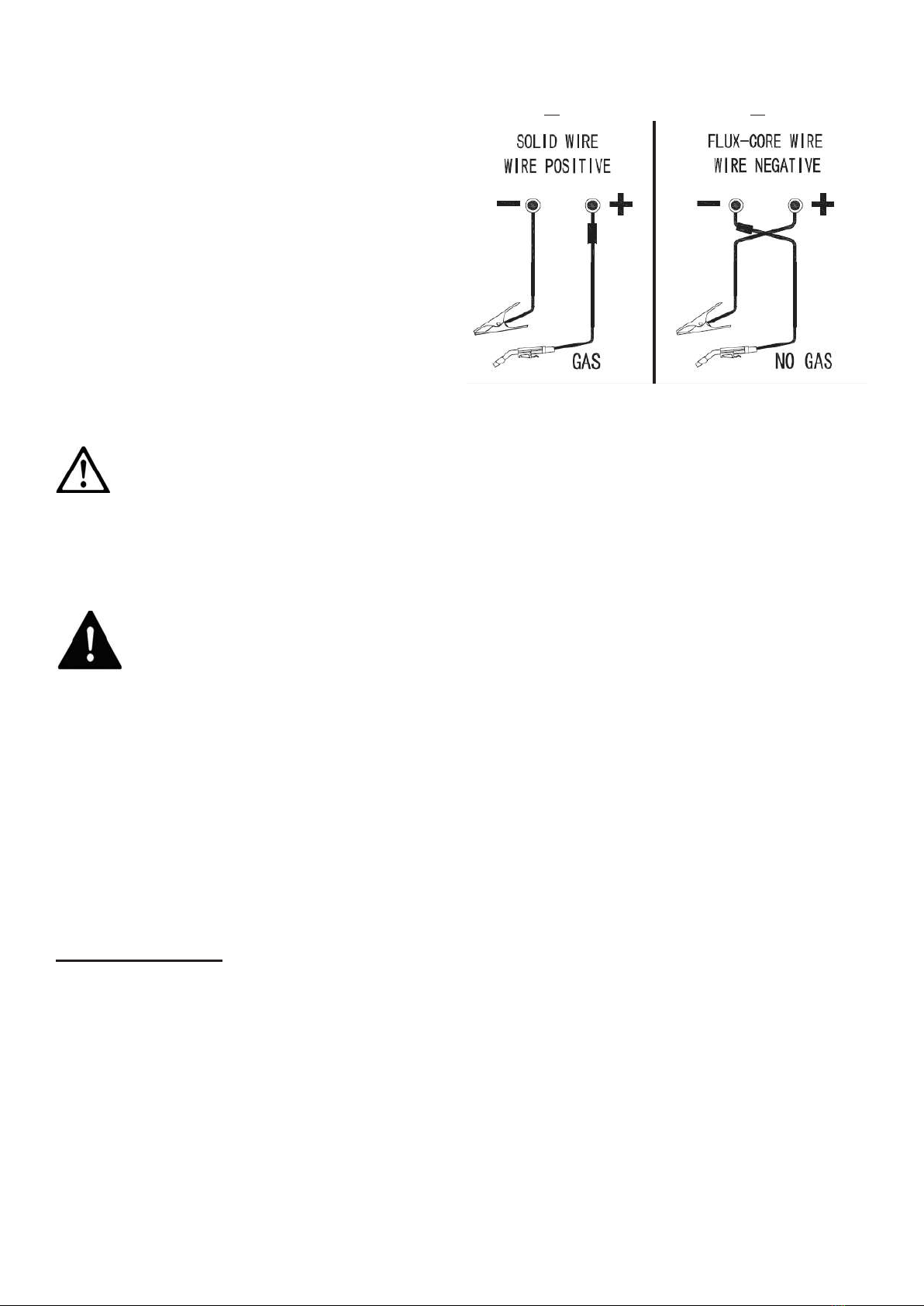

[20] MIG welding polarity selection cable.

[21] Tension screw

[22] Wire feed roller

[23] Guide tube

[24] Reel Holder

[25] Negative output terminal.

LOADING THE WIRE

• SelectMIGmodewiththemodeswitchonthefrontpanel.

• Setthe2 STEP / 4 STEP selector switch [5] to 2 Touch

• Fitthetorchtotheeurotting[11]andrmlytighten.

• Openthesidecoveroftheunit

• Removetheknobfromthewirereelholder[24]andtthewirespoolontothewirereelsothatthewirewill

exitthespoolfromthebottom

• Rettheknob[24].

• Release the tension screw [21] and open the upper roller arm.

• Without letting the wire un-spool, cut the end of the wire of cleanly leaving no kinks the feed

about 30cm of the wire through the guide tube and into the wire liner by hand.

• Thewirefeedroller[22]hastwodifferentsizegroves.Checkthatthewireisalignedwiththecorrectsize

groveinthewirefeedrollerforthetypeofwireandthencarefulclosetheupperrollerandtensionscrew.If

necessaryremovethewirefeedrollerandturnitovertoaccesstheothergroveandret.

At the end of the torch

• Twistthenozzleclockwiseandpulltoremove.

• Unscrew the contact tip counterclockwise and remove. Check that the correct tip size is being

used for the wire being tted.

• Lay the torch sheath out in a straight line so that the wire move through it easily

WARNING! The following steps require applying power to the welder. Do not touch anything with the

torch or wire as it may result in accidental arcing.

• Plugthepowercord[14]intoitselectricaloutlet,setthewirefeedspeedcontrol[8]midwayandturnthe

welderON[15].

• Pressthewirefeedbutton[6]orliftthetorchhandleandcontinuepressingthetrigger

untilthewirefeedsthroughtheendofthetorchabout50mm

Note:Ifthewiredoesnotfeedthrough,viewthewirefeedunitandseeifthewireisbeingpushed.Ifitis

not,turnthewelderOFFandaddmoretensiontothewirefeedadjustingspringandtryagain.

• Oncethewireisexposed,releasethewirefeedbutton[6]orthetrigger

• Slidethecontacttipoverthewireandscrewitintotorchhandle

• Replacethenozzleandcutoffanyexcesswireover10mm

MIG MODE