SAFETY INSTRUCTIONS … cont

DRESS PROPERLY

Use protective gloves and re resistant protective clothing when using the welder. Avoid exposing

skin to the ultraviolet rays produced by the arc.

ALWAYS USE THE WELDING MASK

Under no circumstances should the welder be operated unless the welding mask is protecting

the eyes and face. There is a serious risk of eye damage if the mask is not used. The sparks and

metal projectiles can cause serious damage to the eyes and face. The light radiation produced

by the arc can cause damage to eyesight and burns on the skin. Never remove the welding mask

whilst welding. Move the torch away from the work piece and release the trigger switch before

removing the welding mask.

SAFETY GLASSES

After welding use safety glasses when brushing, chipping grinding the slag from the weld.

OTHER PERSONS

Ensure that other persons are screened from the welding arc and are at least 15 metres away

from the work piece. Always ensure that the welding arc is screened from onlookers, or people

just passing by. Use screens if necessary, or non reecting curtains.

KEEP CHILDREN AND ANIMALS AWAY

Do not let children or animals have access to the welding equipment or to the work area.

SWITCHING OFF

When you have nished welding switch off the welder. Do not put the torch down with the welder

switch On and with the wire tted. When leaving the welder unattended, move the On/Off switch

to the Off position and disconnect the welder from the mains supply. Do not leave hot material

unattended after welding.

WELDING CABLES

Keep the welding cables, earth clamp and torch in good condition. Failure to can result in poor

welding quality and could be dangerous in structural situations.

CHECK DAMAGED PARTS

Before further use of the welder, any part that is damaged should be carefully checked to deter-

mine that it will operate properly and perform its intended function. Check for breakage of parts

and any other conditions that may affect its operation. Any part that is damaged should be prop-

erly repaired, or replaced, by an authorised service centre.

IMPROPER USE

Do not use this welder for pipe thawing.

HANDLING

Ensure the handle is correctly tted and always use safe lifting practices when lifting.

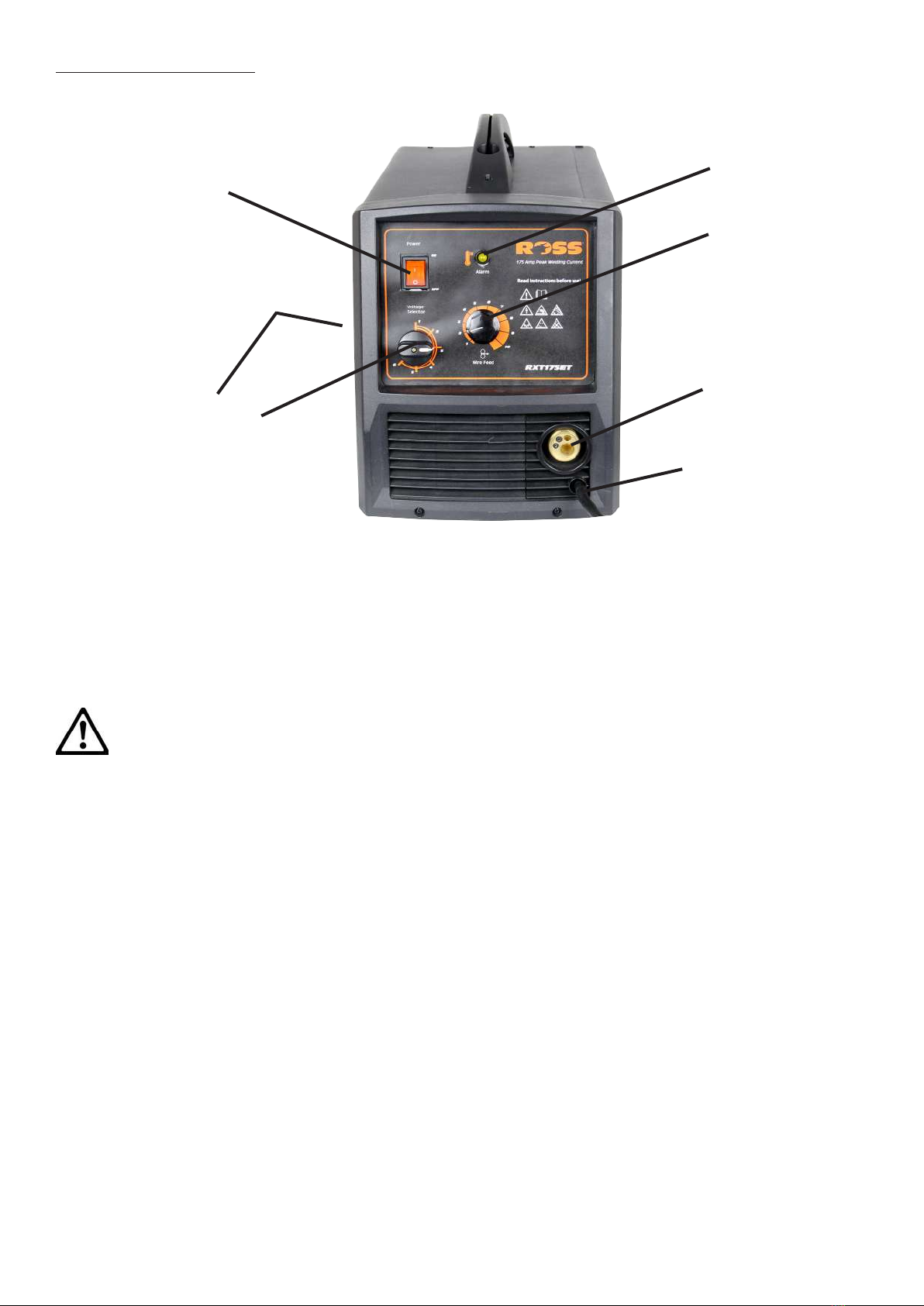

CAUTION! - VENTILATE THE WELDER

THERE must always be a sufcient air passage around the welder to allow for the cooling

of the transformer. If the cooling process is obstructed the welder will overheat and the overload

cut out protector will activate and cut off the welding current. If the overload cut out protector activates leave

the welder for at least 15 minutes to cool down before further use.