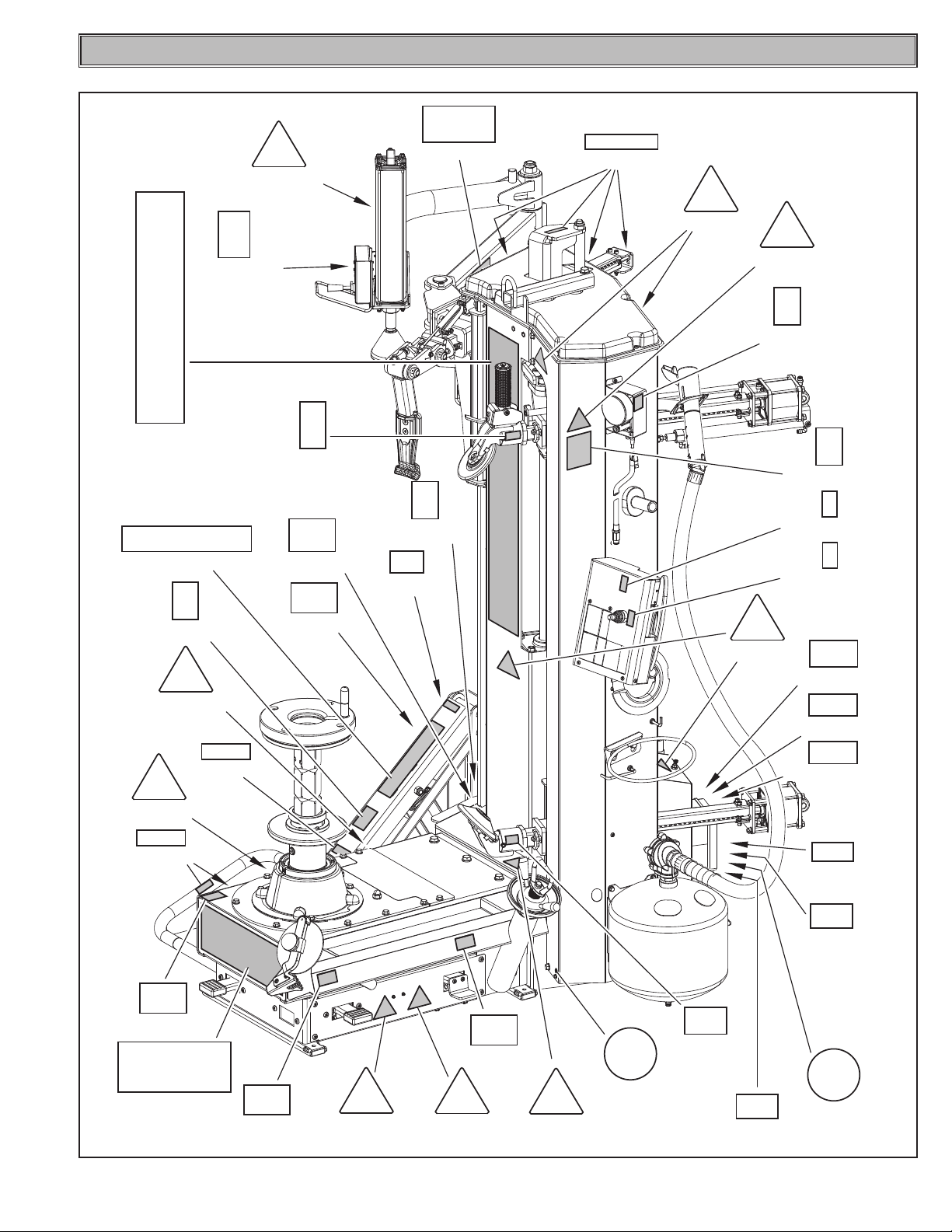

4.1 General safety rules

• Anytamperingwithor modication tothemachinenot previ-

ously authorized by the manufacturer exempts the latter from all

responsibility for damage caused by or derived from said actions.

• Removingofortampering with thesafetydevicesorwith the

warning signals placed on the machine leads to serious dangers

and represents a transgression of OSHA safety standards.

• Useofthemachineisonlypermittedinplacesfreefromexplosion

or fire hazard and in dry places under cover.

• Originalsparepartsandaccessoriesshouldbeused.

THE MANUFACTURER DENIES ANY RESPON-

SIBILITY IN CASE OF DAMAGES CAUSED BY

UNAUTHORIZED MODIFICATIONS OR BY THE

USE OF NON ORIGINAL COMPONENTS OR

EQUIPMENT.

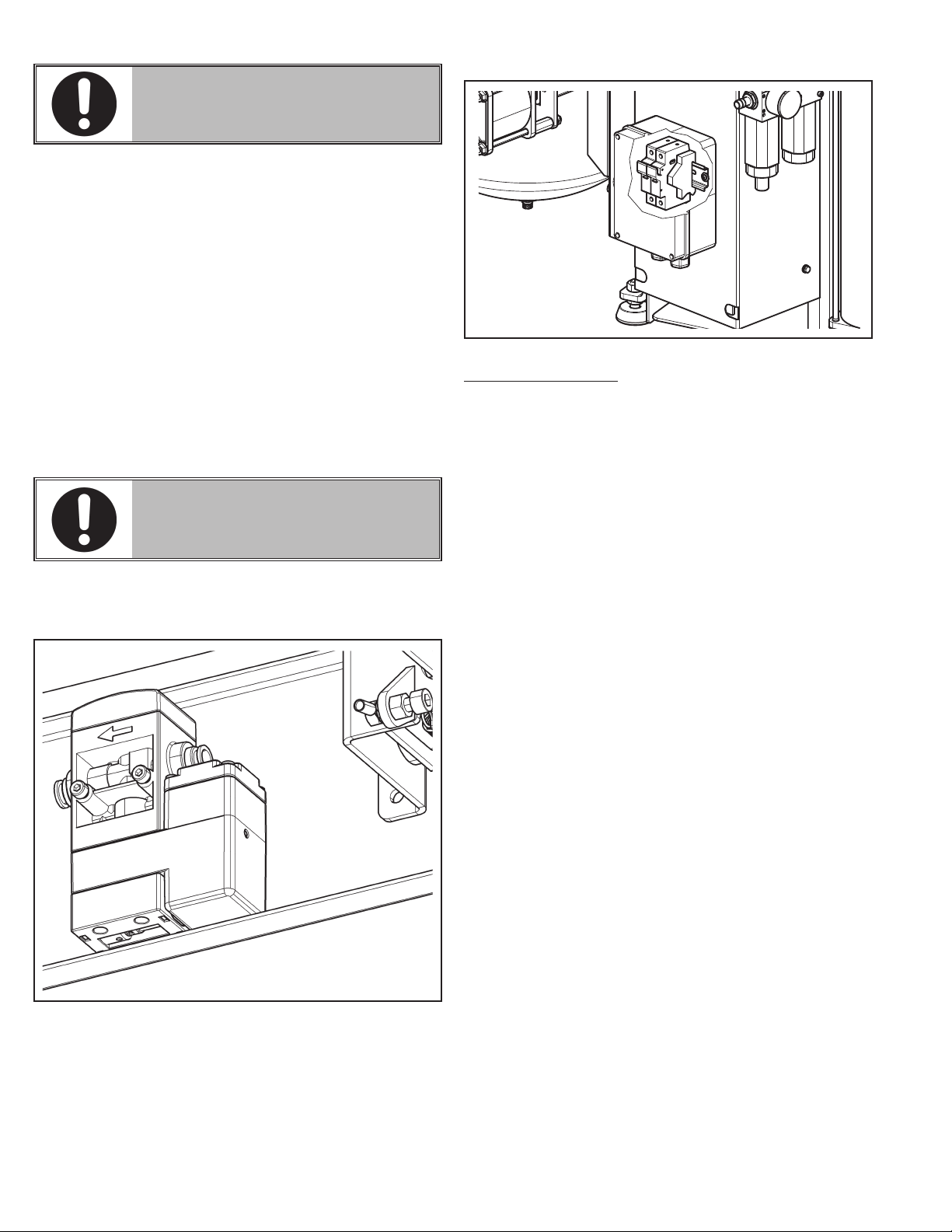

• Theinstallationmustbeperformedbyqualiedandauthorized

personnel in full compliance with the instructions given below.

• Ensurethattherearenodangeroussituationsduringthemachine

operating manoeuvres. Immediately stop the machine if it miss-

functions and contact the customer service of an authorized

dealer.

• Inemergencysituationsandbeforecarryingoutanymaintenance

or repairs, disconnect all supplies to the machine by using the

main switch.

• Themachinepowersupplysystemmustbeequippedwithanap-

propriate earthing, to which the yellow-green machine protection

wire must be connected.

• Ensurethattheworkareaaroundthemachineisfreeofpotentially

dangerous objects and that there is no oil since this could damage

the tire. Oil on the floor is also a potential danger for the operator.

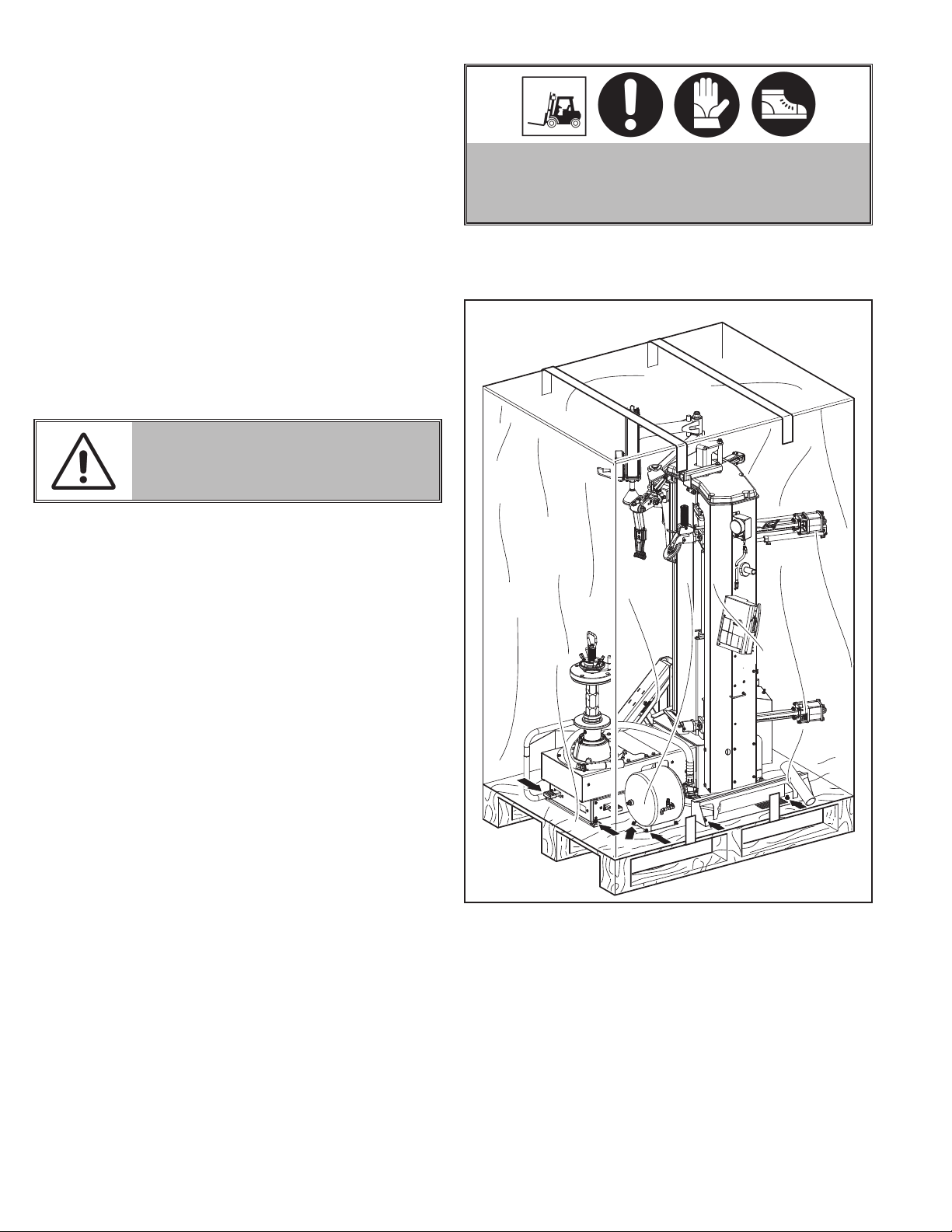

OPERATORS MUST WEAR SUITABLE WORK

CLOTHES, PROTECTIVE GLASSES AND GLOVES,

AGAINST THE DANGER FROM THE SPRAYING

OF DANGEROUS DUST, AND POSSIBLY LOWER

BACK SUPPORTS FOR THE LIFTING OF HEAVY

PARTS. DANGLING OBJECTS LIKE BRACELETS

MUST NOT BE WORN, AND LONG HAIR MUST

BE TIED UP. FOOTWEAR SHOULD BE ADEQUATE

FOR THE TYPE OF OPERATIONS TO BE CAR-

RIED OUT.

4.0 IMPORTANT SAFETY INSTRUCTIONS

When using your garage equipment, basic safety precautions should

always be followed, including the following:

1. Read all instructions.

2. Care must be taken as burns can occur from touching hot parts.

3. Do not operate equipment with a damaged cord or if the equip-

ment has been dropped or damaged – until it has been examined

by a qualified service person.

4. Do not let a cord hang over the edge of the table, bench, or

counter or come in contact with hot manifolds or moving fan

blades.

5. If an extension cord is necessary, a cord with a current rating

equal to or more than that of the equipment should be used.

Cords rated for less current than the equipment may overheat.

Care should be taken to arrange the cord so that it will not be

tripped over or pulled.

6. Always unplug equipment from electrical outlet when not in use.

Never use the cord to pull the plug from the outlet. Grasp plug

and pull to disconnect.

7. Let equipment cool completely before putting away. Loop cord

loosely around equipment when storing.

8. To reduce the risk of fire, do not operate equipment in the vicinity

of open containers of flammable liquids (gasoline).

9. Adequate ventilation should be provided when working on

operating internal combustion engines.

10. Keep hair, loose clothing, fingers, and all parts of body away

from moving parts.

11. To reduce the risk of electric shock, do not use on wet surfaces

or expose to rain.

12. Use only as described in this manual. Use only manufacturer’s

recommended attachments.

13. ALWAYS WEAR SAFETY GLASSES. Everyday eyeglasses only

have impact resistant lenses, they are not safety glasses.

SAVE THESE INSTRUCTIONS

9