•

•

•

•

•

•

Installation,maintenanceandcommissioningmustbecarriedout

by qualified technical personnel.

For devices to use in Hazardous Locations ATEX1/3 D (zone

20/22) the requirements of the EN 50281-1-2 (e. g. regarding dust

deposits and temperatures) must be observed.

Switch off the supply voltage before opening the housing.

Dangerous voltage!

Operateonlywithclosedlidofthehousing.

Useafuseforthesupplyvoltage(max.4A).

A voltage disconnecting switch must be provided near the switch.

A RCCB protection switch is necessary.

•

•

•

•

•

•

Compare the mains voltage applied with the specifications given on

the label before switching the device on.

Forterminalconnectionofthedevice,thelocalregulationsorVDE

0100 (regulations of German electrotechnical engineers) must be

observed.

Inthecaseofincorrecthandlingorhandlingmalpractice,theelectric

safety of the device cannot be guaranteed.

For devices to use in Hazardous Locations ATEX 1/3D (zone 20/22)

the respectively valid installation regulations must be observed.

Isolatingsignaloutput-mainsvoltage:3kV~

Provide protection for relay contacts to protect the device against

spikes,ifinductiveloadsareconnected.

Safety items

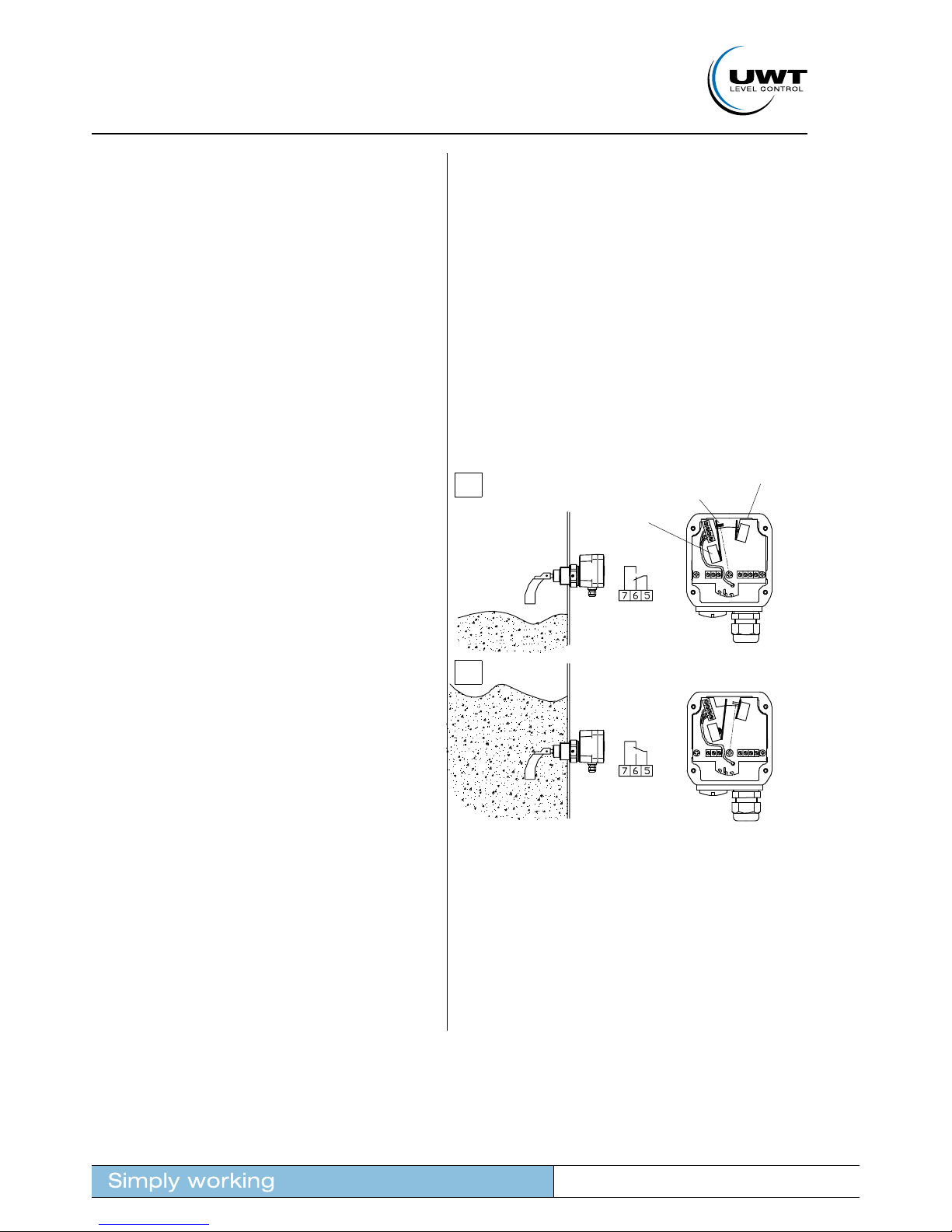

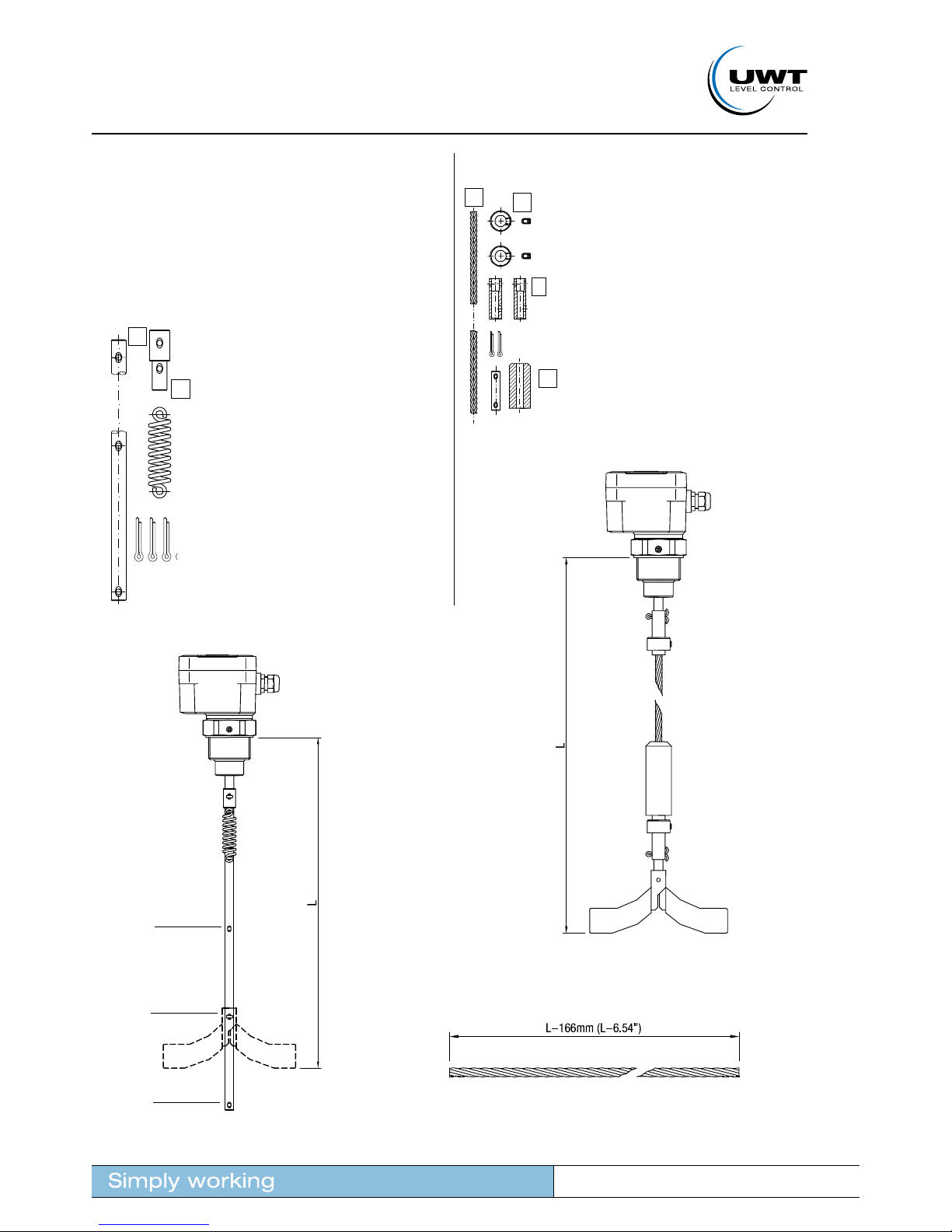

The unit must be mounted with the thread or the flange on the container.

Mounting may be vertical, oblique or horizontal. For the individual

mountingoftheseveralROTONIVO-modelsseepricelist.

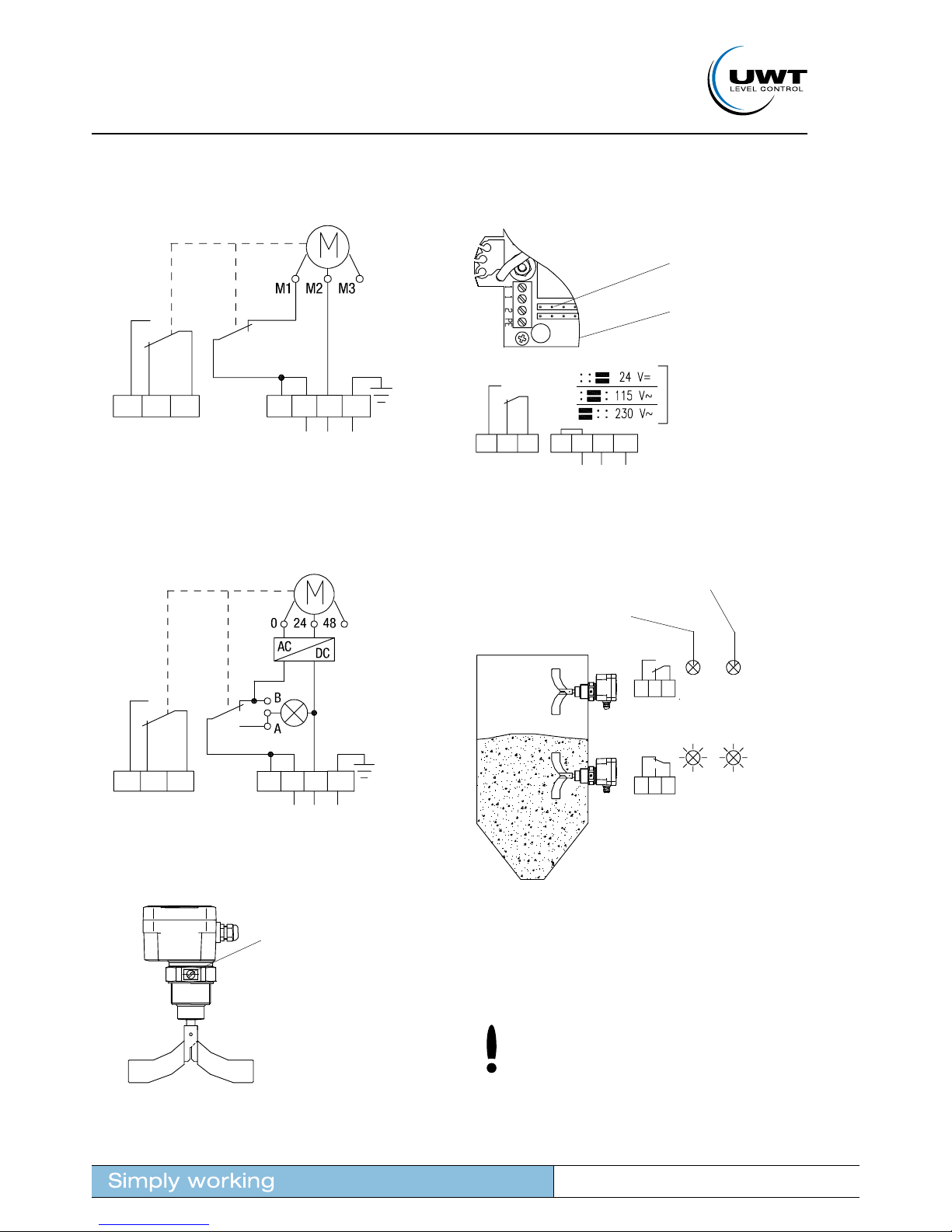

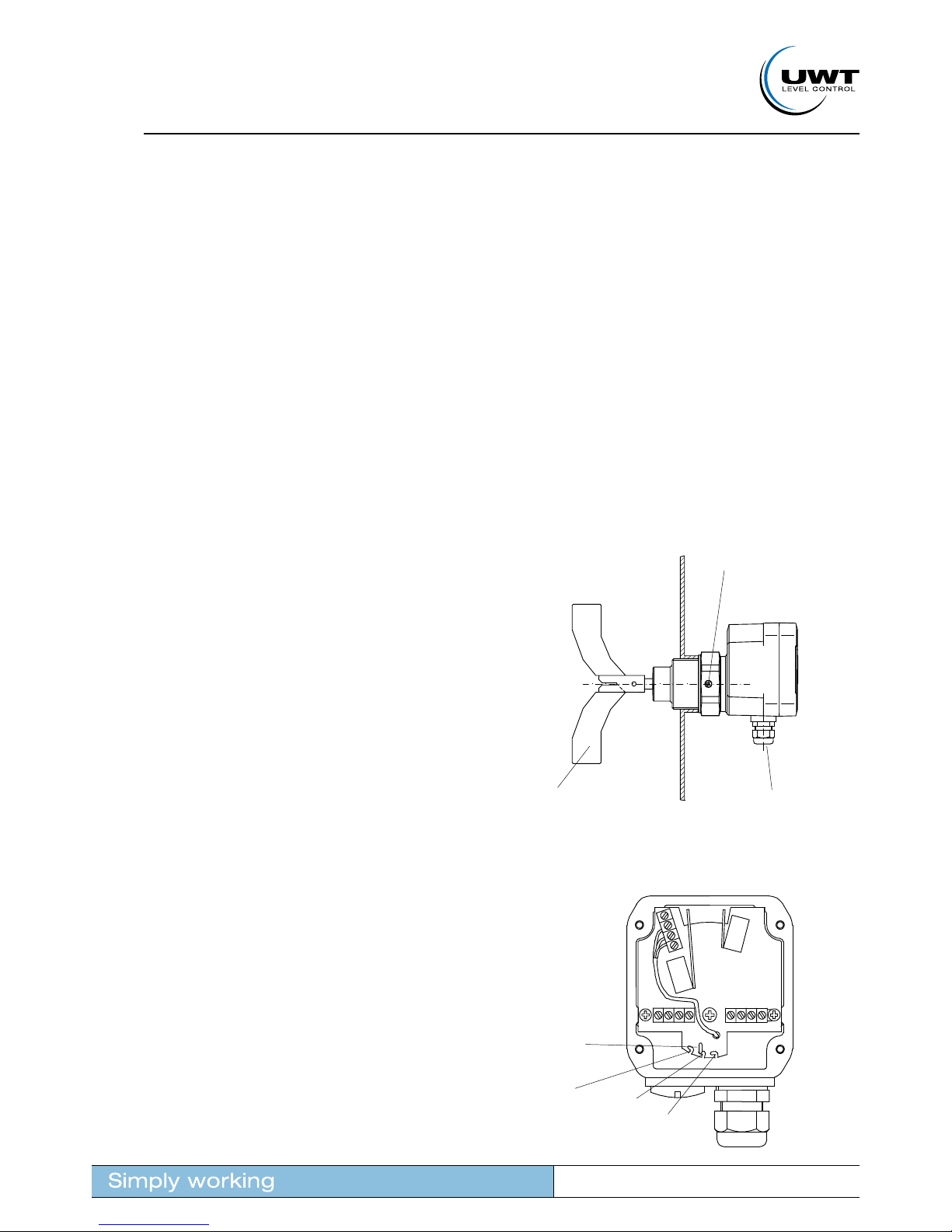

The electrical connections are made in accordance with the connection

diagram.Makesure,thatthecableinthescrewedcableglandisseated

tightly without fail. For models according to ATEX 1/3D a pull relief must

be provided for the connection cables.

Aftermounting,turnthehousingintherightdirection.Thescrewedcable

glandmustshowdownwards(seedrawingrighthand).Thismakessure,

thattheunitworksneandprotects,thatwaterentersintothehousing

through the screwed cable gland.

When the unit is used outside, we recommend to use the weather-

protection-cover. It protects the unit against moisture, heat, cold and

prevents the formation of condensation water in the interior of the

housing.

Adjusting the unit onsite is not required.

Mounting

The spring is adjustable in 3 positions. It should be changed only if

necessary.

„Fine“: for light material;

„Medium“: suitable for nearly every material;

„Coarse“: for very sticky material;

Factory setting is „medium“.

The spring can be changed via small pliers.

Adjustment of the spring

Cut one side of the

universal vane:

- in case of empty or demand

detector at any rate;

- to feed the vane through

the mounting hole;

Correct mounting:

Screwed cable gland

points down

Fixthescrewafter

turning the housing in

the right direction

spring

fine

medium

coarse