Cobalt Filterpump 400R Range Instruction Manual V.1.0 www.rotorflush.com

Page 2 of 14

Contents

1. MAN FACT RER & PROD CT IDENTIFICATION DATA (as per EEC98/37 p.1.7.4a).......................................3

1.1. Manufacturer Data ............................................................................................................................ 3

1.2. Filterpump Data.................................................................................................................................3

2. TECHNICAL ASSISTANCE INFORMATION .......................................................................................................3

3. INTROD CTION ............................................................................................................................................. 3

4. GENERAL SAFETY WARNINGS........................................................................................................................4

4.1. Preventive Measures to be taken by the ser ..................................................................................4

4.2. Significant Protection and Precautions (as per EEC 98/37 p. 1.1.2 and 1.7.2; EN 292-2 p.5). ........... 4

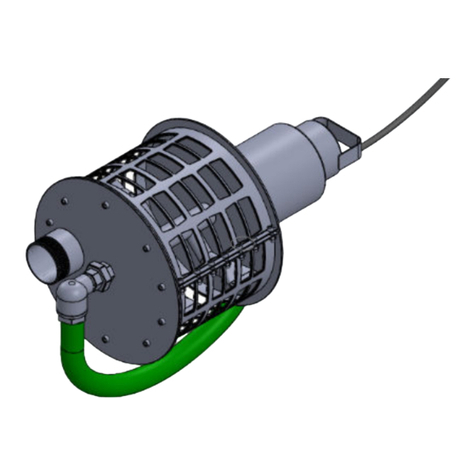

5. DESCRIPTION .................................................................................................................................................5

5.1. General Description ........................................................................................................................... 5

5.2. Technical and Construction Characteristics .......................................................................................5

6. TECHNICAL DATA CARD (as per EEC 98/37 p.1.1.2 and 1.7.2; EN 292-2 p................................................... 5

6.1. Pump Technical Data .........................................................................................................................5

6.2. Self-cleaning Filter Technical Data.....................................................................................................5

7. CONTEMPLATED AND NON-CONTEMPLATED SE ........................................................................................ 6

7.1. Contemplated Conditions of se.......................................................................................................6

7.2. Non-Contemplated Conditions of se ...............................................................................................6

8. HANDLING AND TRANSPORT (as per EEC 98/37 p. 1.7.4.a; EN 292-2 p.5 1.1.a) ...................................... 6

8.1. npacking ..........................................................................................................................................6

8.2. Handling and De-installing.................................................................................................................6

8.3. Transport ........................................................................................................................................... 7

9. PREPARATION FOR SE (as per EEC 98/37 p.1.7.4.a, EN 292-2 p.5.1.3)..................................................... 7

9.1. General information ..........................................................................................................................7

9.2. Electrical Connections........................................................................................................................7

9.3. Checking the Direction of Rotation....................................................................................................7

10. INSTALLATION (as per EEC 98/37 p. 1.7.4.a; EN 292-2 p.5.1.1b) ................................................................7

10.1. Fixed Installation...........................................................................................................................8

10.2. Temporary Installation (for Temporary se) ................................................................................9

11. ASSEMBLY AND DISASSEMBLY

12. ADJ STING AND REGISTERING

(as per EEC 98/37 p.1.7.4.a)....................................................................... 9

(as per EEC 98/37 p.1.7.4.a; EN 292-2 p.5.5.1.d)......................................9

13. SE AND START- P (as per EEC 98/37 p.1.7.4.a; EN 292-2 p. 5.5.1.d) .................................................... 10

13.1. Starting........................................................................................................................................10

14. MAINTENANCE AND REPAIRS (as per EEC 98/37 p.1.6; EN 292-2 p.5.5.1.e) ............................................ 10

14.1. Troubleshooting..........................................................................................................................11

15. TECHNICAL INFORMATION..........................................................................................................................12

15.1. Diagram of Filterpump Dimensions and Weights .......................................................................12

15.2. Diagram for Installation with Minimum Functional Distances....................................................12

15.3. Rating Plate Example ..................................................................................................................13

16. INFORMATION ON AIR-BORNE NOISE (as per EEC 89/392 p. 1.7.4.f)..........................................................14

17. WASTE DISPOSAL......................................................................................................................................... 14

18. DECLARATION OF CONFORMITY .................................................................................................................14