Page 4 of 9

•Do not exceed the rated capacity 1000lbs.

•Before moving the load, assure that the load is centered and a load-restraining device is

recommended to secure the load. DO NOT move unstable loads.

•Do not use on sloping ground.

•Do not move the cart when loading in a raised position of height above 11.8in.

•Do not randomly regulate the safety valve.

•Do not allow people to sit or ride on the cart.

•Do not transport the loads during the lifting process.

•All maintenance is to be performed by professional personnel strictly in accordance to the

related information in this manual.

•Make sure all persons stay clear of the supported load.

•Keep feet and hands away from under the lowering table. Safety shoes should be worn during

operation.

•Make sure that all nuts, bolts and split pins are sufficiently fastened.

OPERATION INSTRUCTIONS

WARNING: Before use, check any broken or loose parts.

(1) Before operating, be sure the load is centered and stable on the platform.

(2) To lift the load on the cart, continue stepping on the foot pedal as the platform rises to the required

height.

(3) To lower the load on the cart, turn the Star Handle slowly and gently until the platform is lowered to

the desired height.

WARNING:

People will be seriously hurt or the cart will be damaged if turning the Star Handle quickly when

lowering the load.

Never shut off the oil return valve sharply, or the cart and/ or loads can be damaged.

Leaving the cart: Whenever the operator leaves the cart, the platform must be fully lowered.

Visibility: The operator must always have a clear view of the path in the direction of travel.

Load handling: Only stable and safely arranged loads within the rated capacity of the cart should be

handled. Operators are not to pick up and move loads that are too heavy. If, upon attempting to lift the

load, the rear wheels of the cart begin to rise, set the load down immediately and obtain proper

equipment to lift a load of that size.

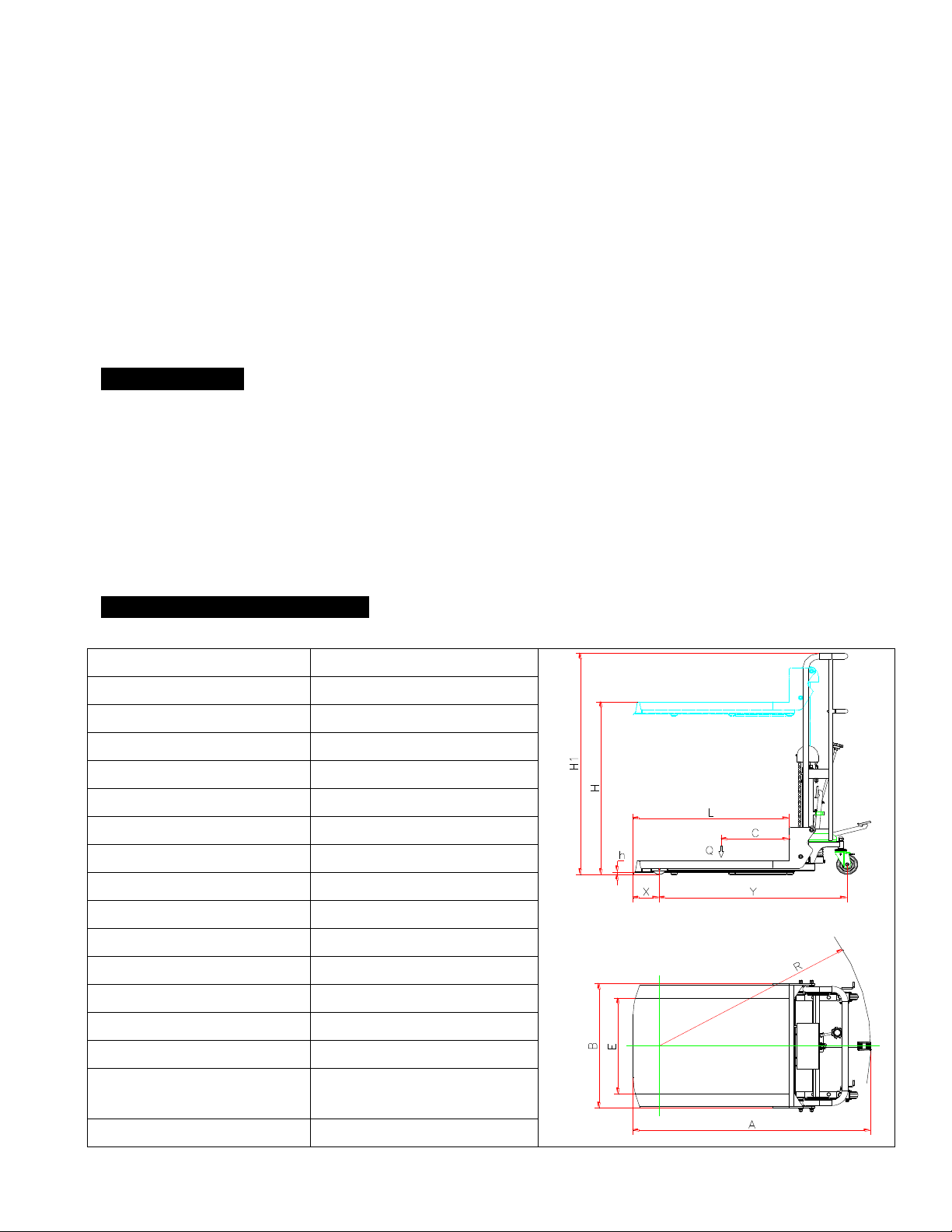

When picking up a load, center the load evenly on the platform, (The load center position is showed in

TECHNICALSPECIFICATION section), and engage loads securely and stably.

Loads can be of many sizes and descriptions, such as boxes, bags, packages, or other small objects.

All loads should be made stable by either interlocking the objects, or strapping or shrink-wrapping the

load, to prevent individual objects from falling off the cart.

Long loads reduce the stability of a cart. Long, wide, or high loads require more room, so watch the

clearance. The load may be very secure until something is run into that shifts the cart’s center of gravity.

This creates the potential for a lateral overturn. Lifting long loads that extend directly in front changes

the weight center of the cart and reduces the lifting capacity of the cart. When right angle stacking or

moving with a low raised load to clear low objects, move very slowly and avoid sharp turns.

WARNING:

The length of cargos handled must be less than 35”, while width less than 36”.

Do not move with loads raised higher than 11.8”, and move with a low raised load just for short

distance.

Move very slowly and avoid any turns when moving with a raised load.