Pompe orizzontali monostadio e multistadio

Horizontal single-stage and multistage pumps

Pompes horizontales monocellulaires et multicellulaires

+RUL]RQWDOHHLVWX¿JKHXQGPHKUVWX¿JH.UHLVHOSXPSHQ

Bombas horizontales monocelulares y multicelulares

Manuale d’uso e manutenzione

Instructions for use and maintenance

Manuel d’utilisation et d’entretien

Betriebs-und Wartungsanleitung

Manual de uso y mantenimiento

Possibili aggiornamenti senza preavviso - Revision possible without prior notice - Mises à jour éventuelles sans préavis - Techn. Änderungen vorbehalten - Posibles actualizaciones sin preaviso

15

MGPOS155R0

EN

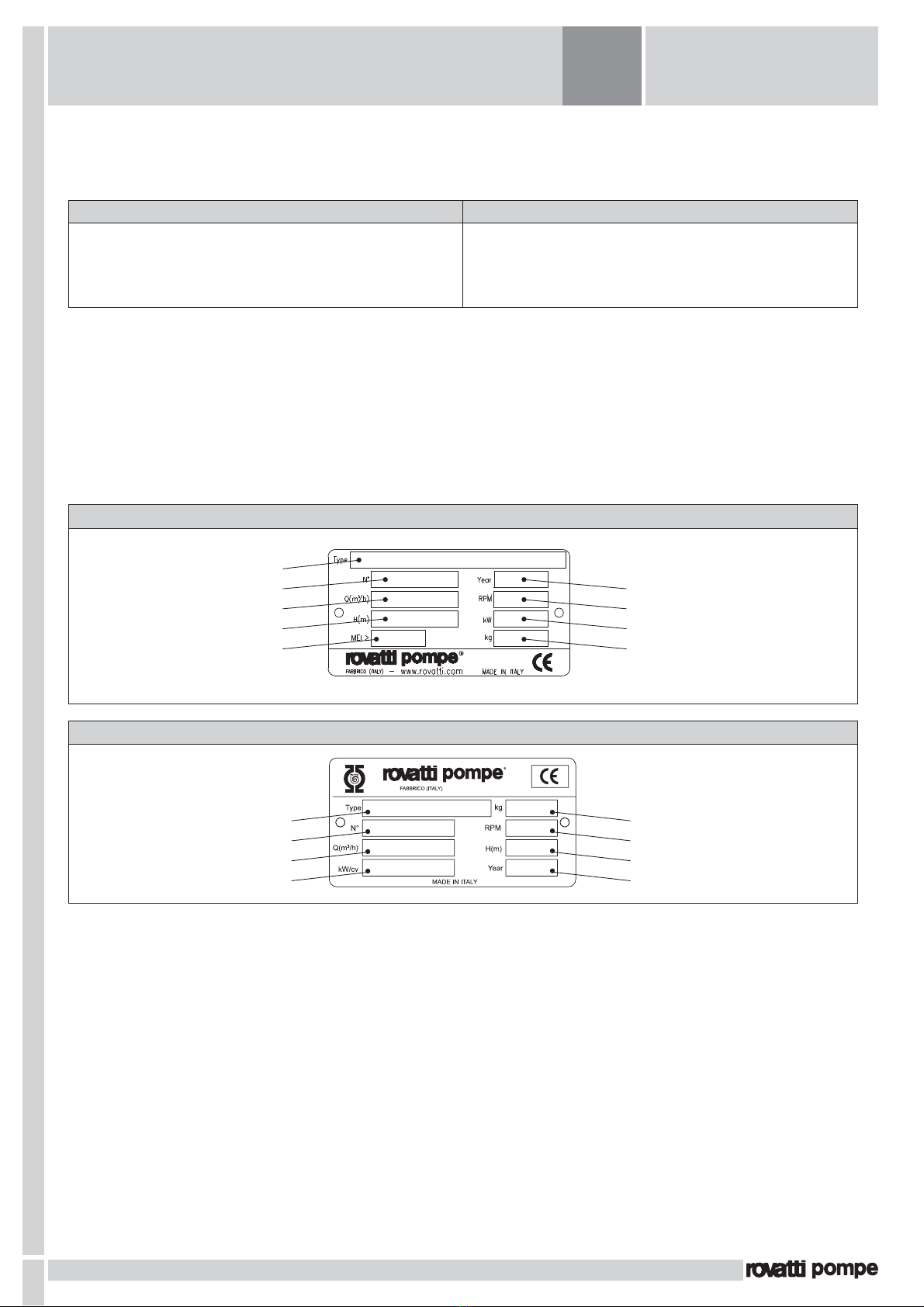

0DFKLQHLGHQWL¿FDWLRQ ........................................................................................................................... 16

1.1 ManuIacturer’s identi¿cation..................................................................................................................................................16

1.2 Identi¿cation..........................................................................................................................................................................16

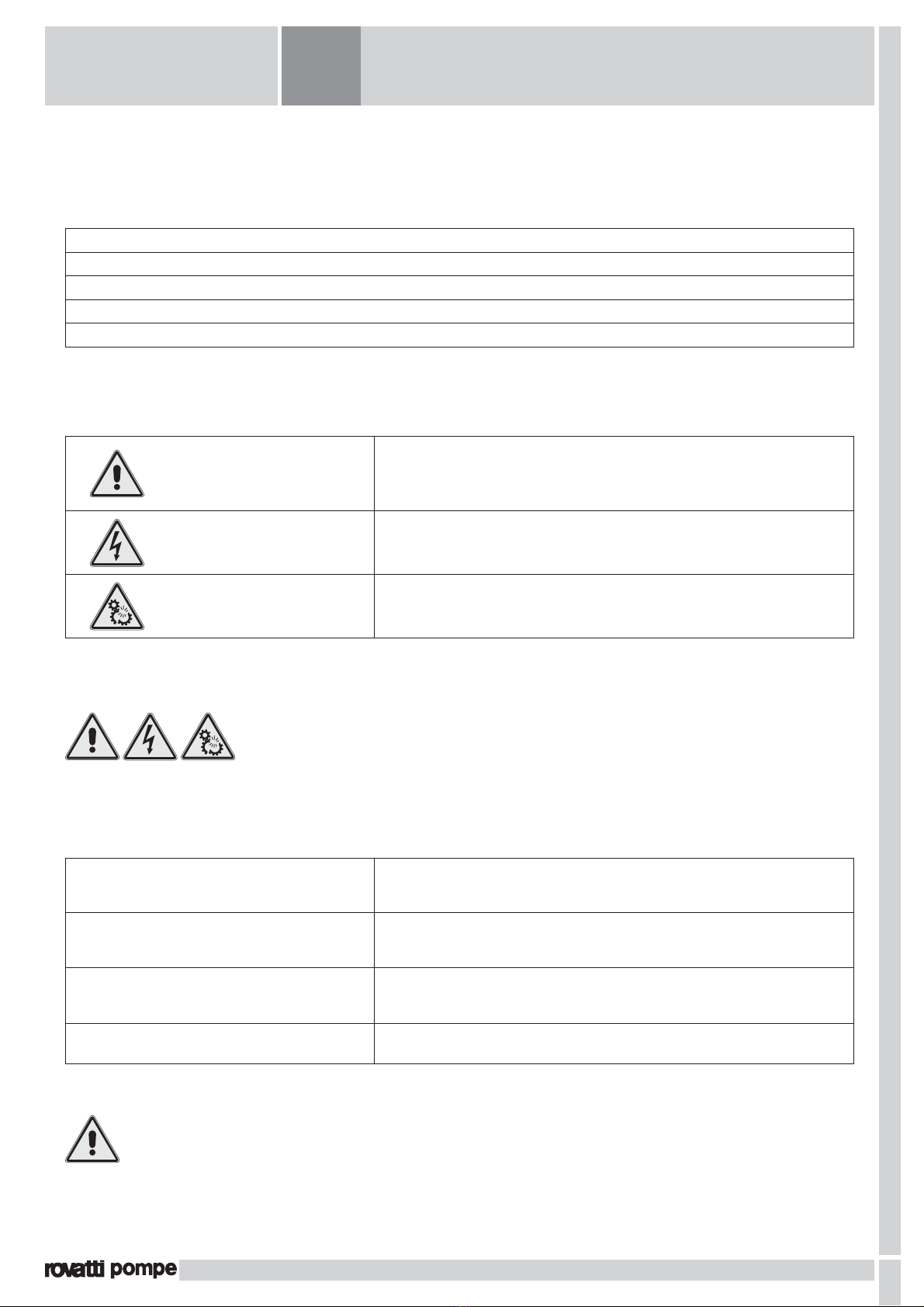

1.3 Identi¿cation plate .................................................................................................................................................................16

2. Description of the manual..................................................................................................................... 16

2.1 Introduction ...........................................................................................................................................................................16

2.2 Purpose oIthe manual .........................................................................................................................................................16

2.3 Update procedure .................................................................................................................................................................16

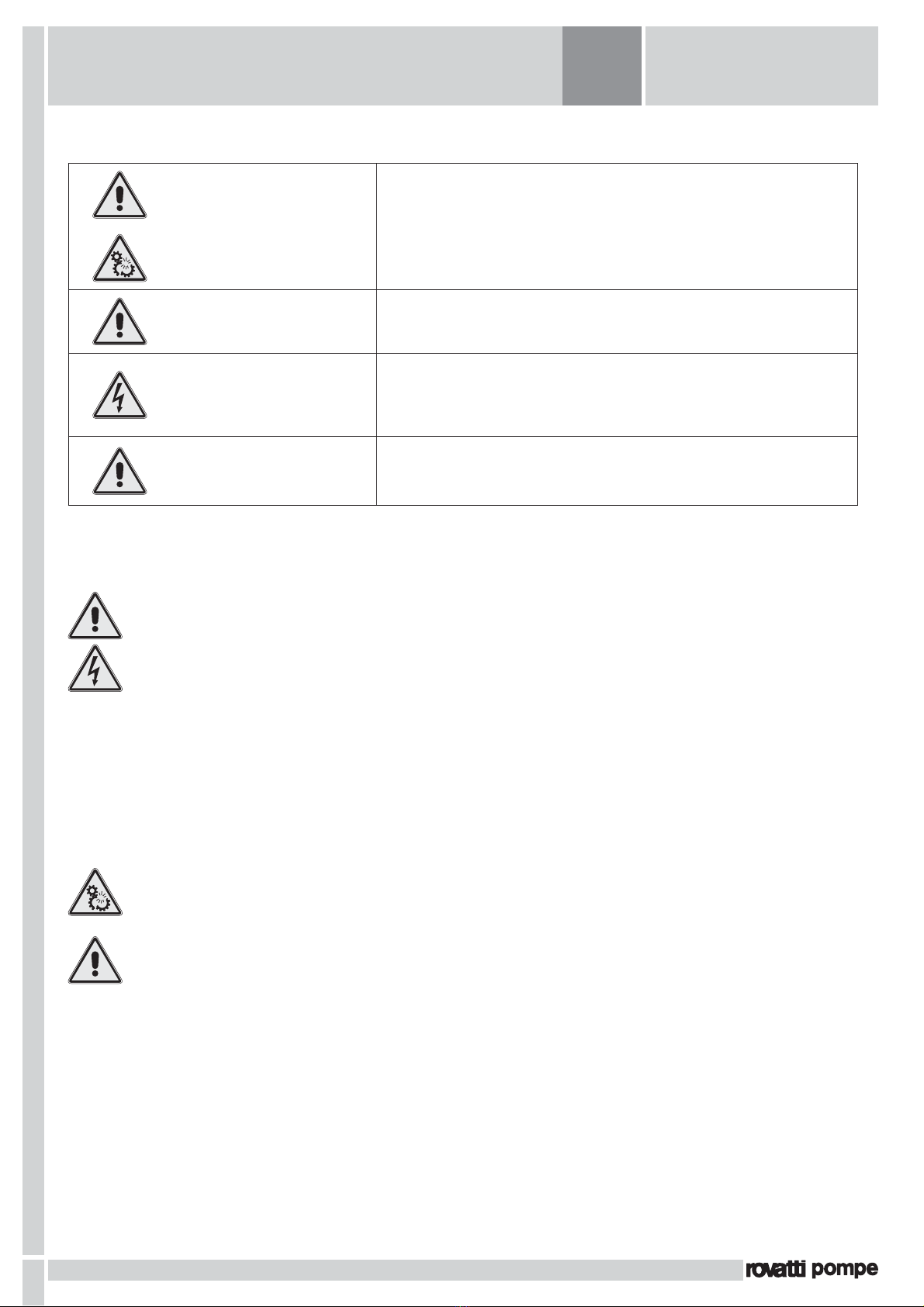

3. Preliminary information......................................................................................................................... 17

3.1 Standard reIerences..............................................................................................................................................................17

3.2 Simbology..............................................................................................................................................................................17

3.3 General warnigs....................................................................................................................................................................17

3.4 Operators skills......................................................................................................................................................................17

3.5 ProtectiYe eTuipment reTuired ..............................................................................................................................................17

3.6 Risidual risks.........................................................................................................................................................................18

3.7 Prohibitions............................................................................................................................................................................18

3.8 Noise leYel.............................................................................................................................................................................18

3.9 Unintented andor improper uses..........................................................................................................................................18

3.10 Warranty................................................................................................................................................................................18

4. Description of the machine................................................................................................................... 19

4.1 Purpose oIthe machine ........................................................................................................................................................19

4.2 Use conditions.......................................................................................................................................................................19

4.3 General characteristics..........................................................................................................................................................20

4.4 Pumps identi¿cation..............................................................................................................................................................21

5. Transport, handling and storage.......................................................................................................... 21

5.1 Transport and handling .........................................................................................................................................................21

5.2 Storage..................................................................................................................................................................................21

5.3 Packing disposal ...................................................................................................................................................................21

6. Installation.............................................................................................................................................. 22

6.1 Inspections beIore installation...............................................................................................................................................22

6.2 Installation ............................................................................................................................................................................23

7. Starting ................................................................................................................................................... 23

7.1 Preliminary inIormation beIore starting..................................................................................................................................23

7.2 Bearings lubrication...............................................................................................................................................................23

7.3 Starting..................................................................................................................................................................................23

8. Maintenance .......................................................................................................................................... 25

8.1 Bearings lubrication...............................................................................................................................................................25

9. Off service and demolition.................................................................................................................... 25

10. Spare parts ............................................................................................................................................. 25

11. Troubleshooting..................................................................................................................................... 26

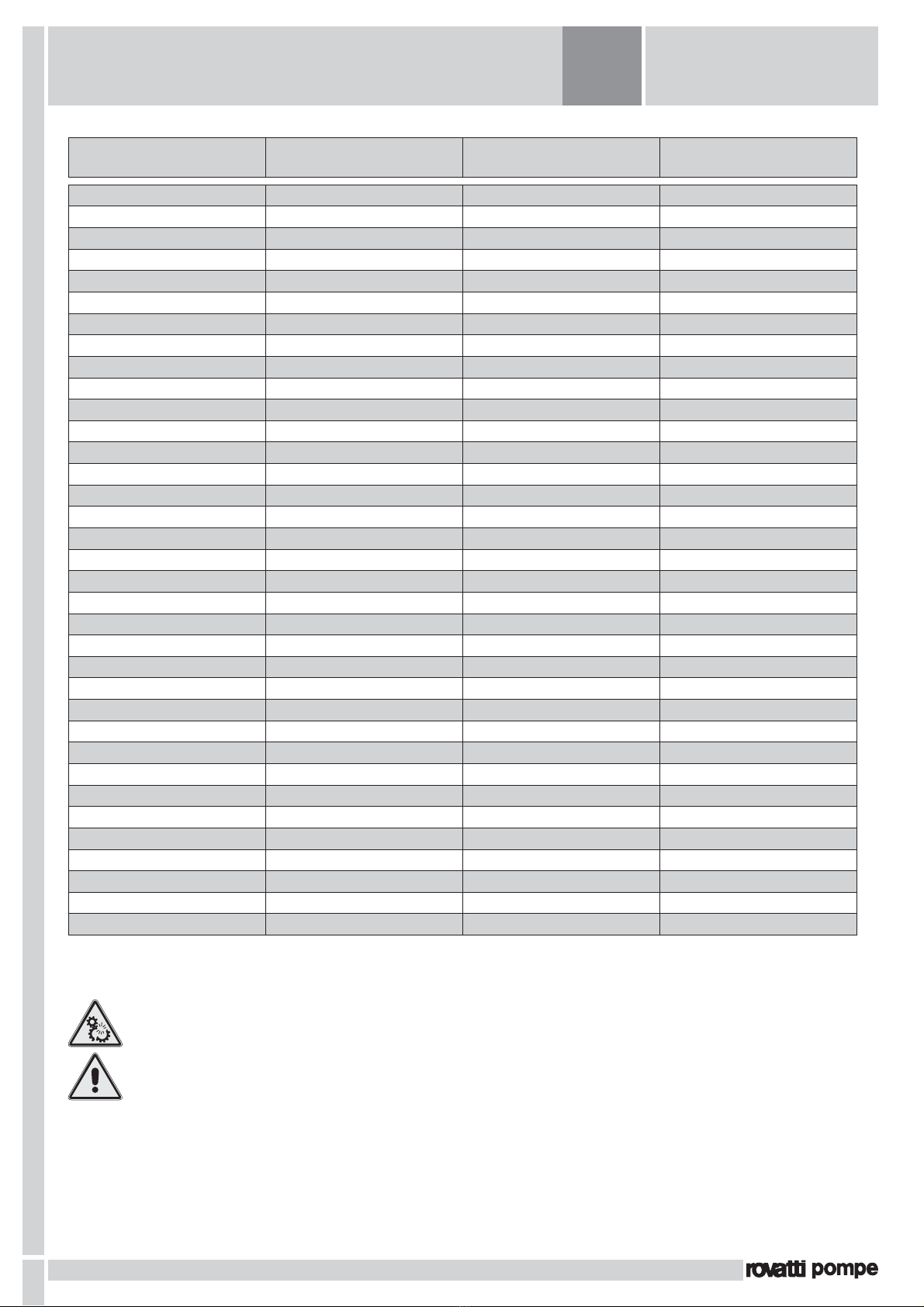

Index