Pompe con moltiplicatore

Pumps with overgear

Pompes avec multiplicateur

Pumpen mit Multiplikator

Bombas con multiplicador

Manuale d’uso e manutenzione

Instructions for use and maintenance

Manuel d’utilisation et d’entretien

Betriebs-und Wartungsanleitung

Manual de uso y mantenimiento

Possibili aggiornamenti senza preavviso - Revision possible without prior notice - Mises à jour éventuelles sans préavis - Techn. Änderungen vorbehalten - Posibles actualizaciones sin preaviso

13

MGPT205R2

EN

1. Machineidentication ........................................................................................................................... 14

1.1 Manufacturer’sidentication..................................................................................................................................................14

1.2 Identicazione ......................................................................................................................................................................14

1.3 Identicationplate .................................................................................................................................................................14

2. Description of the manual..................................................................................................................... 14

2.1 Introduction ...........................................................................................................................................................................14

2.2 Purposeofthemanual .........................................................................................................................................................14

2.3 Update procedure .................................................................................................................................................................14

3. Preliminary information......................................................................................................................... 15

3.1 Standardreferences..............................................................................................................................................................15

3.2 Simbology..............................................................................................................................................................................15

3.3 General warnings ..................................................................................................................................................................15

3.4 Operators skills......................................................................................................................................................................15

3.5 Protectiveequipmentrequired ..............................................................................................................................................15

3.6 Residual risks........................................................................................................................................................................16

3.7 Prohibitions............................................................................................................................................................................16

3.8 Noise level.............................................................................................................................................................................16

3.9 Unintended and/or improper uses.........................................................................................................................................16

3.10 Warranty................................................................................................................................................................................16

4. Description of the machine................................................................................................................... 17

4.1 Purposeofthemachine ........................................................................................................................................................17

4.2 Use conditions.......................................................................................................................................................................17

4.3 General characteristics..........................................................................................................................................................17

4.4 Pumpsidentication ..............................................................................................................................................................17

5. Transport, handling and storage.......................................................................................................... 18

5.1 Transport and handling .........................................................................................................................................................18

5.2 Storage..................................................................................................................................................................................18

5.3 Packing disposal ...................................................................................................................................................................18

6. Installation .............................................................................................................................................. 18

6.1 Inspectionsbeforeinstallation...............................................................................................................................................18

6.2 InstallationofT,TK,MBpumpseries ...................................................................................................................................18

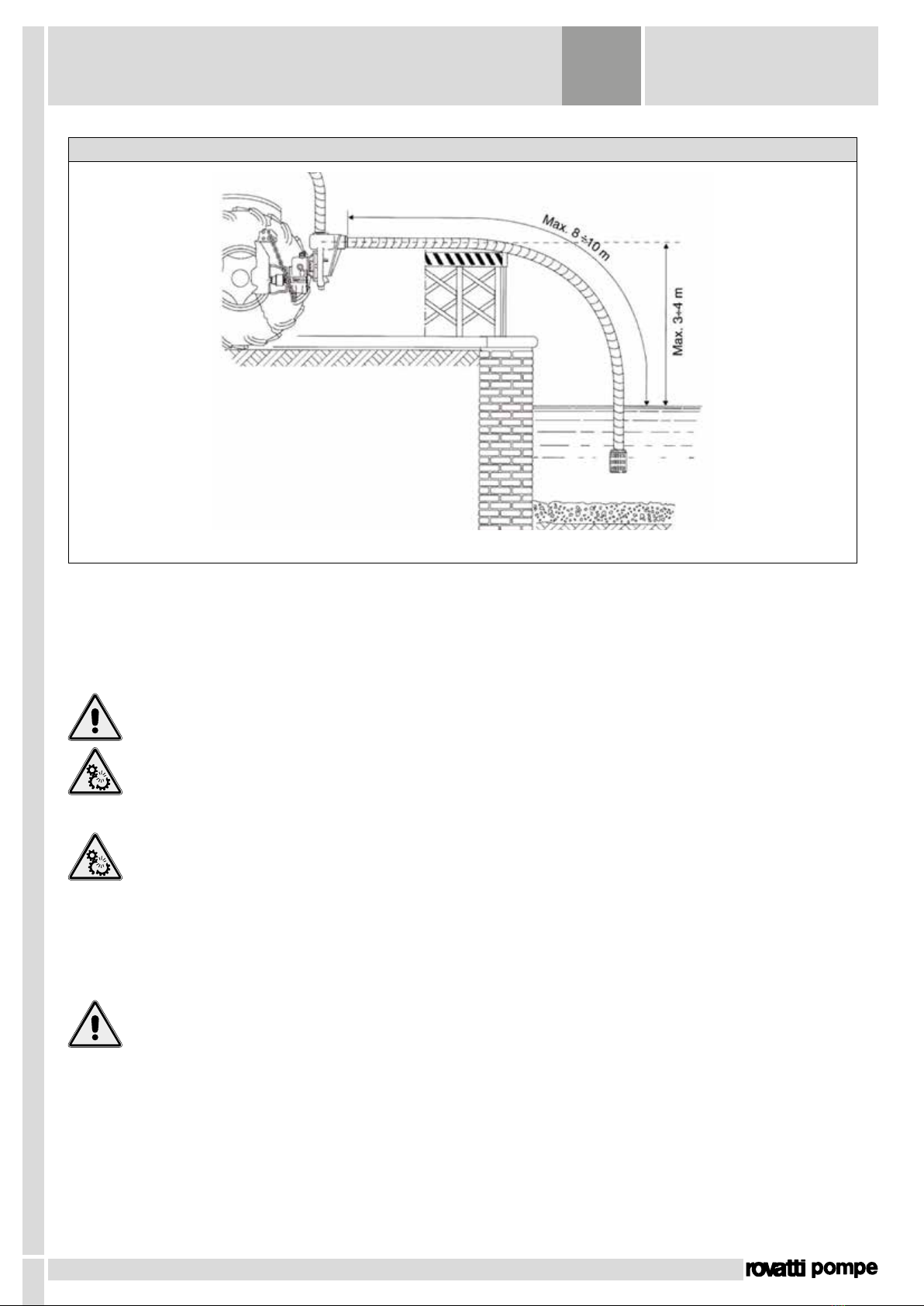

6.3 InstallationofT0,T0Apumpseries.......................................................................................................................................19

7. Starting ................................................................................................................................................... 20

7.1 Preliminaryinformationbeforestarting..................................................................................................................................20

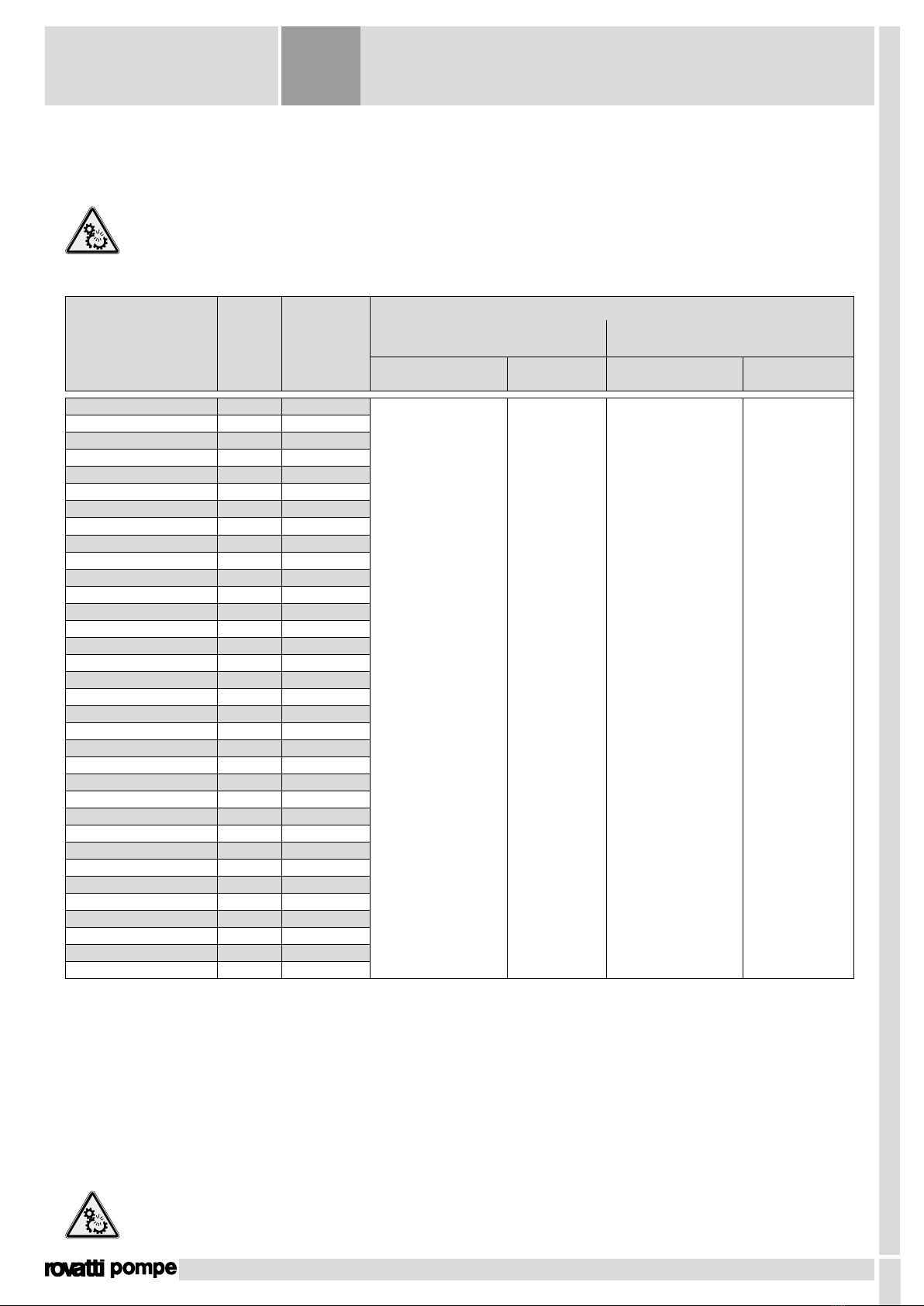

7.2 Lubrication.............................................................................................................................................................................20

7.3 StartingofT,TK,MBpumpseries ........................................................................................................................................20

7.4 StartingofT0pumpseries ....................................................................................................................................................20

7.5 StartingofT0Apumpseries..................................................................................................................................................20

8. Maintenance .......................................................................................................................................... 21

8.1 Lubrication.............................................................................................................................................................................21

9. Off service and demolition.................................................................................................................... 22

10. Spare parts ............................................................................................................................................. 22

11. Troubleshooting..................................................................................................................................... 22

Index