Important information

Rowlinson Heritage buildings come ready painted. To maintain the effective waterproofing of the treatment and

to VALIDATE the guarantee, the building must be properly treated with a recognised external wood preserver

EVERY TWO YEARS. The building MUST also be erected on pressure treated wooden 50mm x 50mm or similar

bearers (These are not supplied in the kit).

As timber is a natural material, there are certain weather conditions that may affect the materials properties. In times

of excessive dry spells the material may lose some of its internal moisture causing a certain degree of shrinkage on

a panel and in periods of excessive rain there will be a certain amount of swelling throughout the wooden panels.

This process can not be avoided. If you have problems with certain boards shrinking in dry spells try to decrease the

amount of direct sunlight on the building or the amount of air passing over the building. During hot spells spray water

directly onto the panels with the aid of a garden hose.

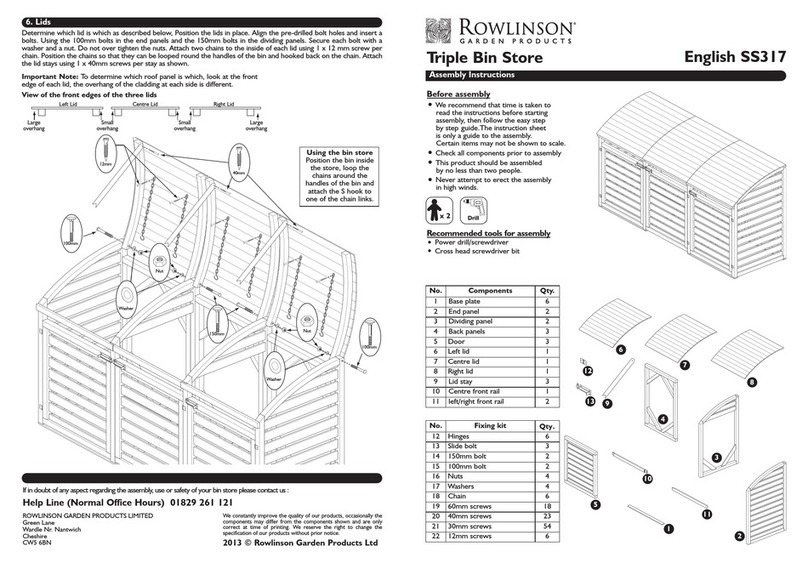

If in doubt of any aspect regarding the assembly, use or safety of your garden shed please contact us:

Help Line: (Normal Office Hours) 01829 261 121

Email: support@rowgar.co.uk

ROWLINSON GARDEN PRODUCTS LIMITED

Green Lane

Wardle Nr. Nantwich

Cheshire

CW5 6BN

www.rowgar.co.uk

We constantly improve the quality of our products,

occasionally the components may differ from the

components shown and are only correct at time

of printing. We reserve the right to change the

specification of our products without prior notice.

2017 © Rowlinson Garden Products Ltd

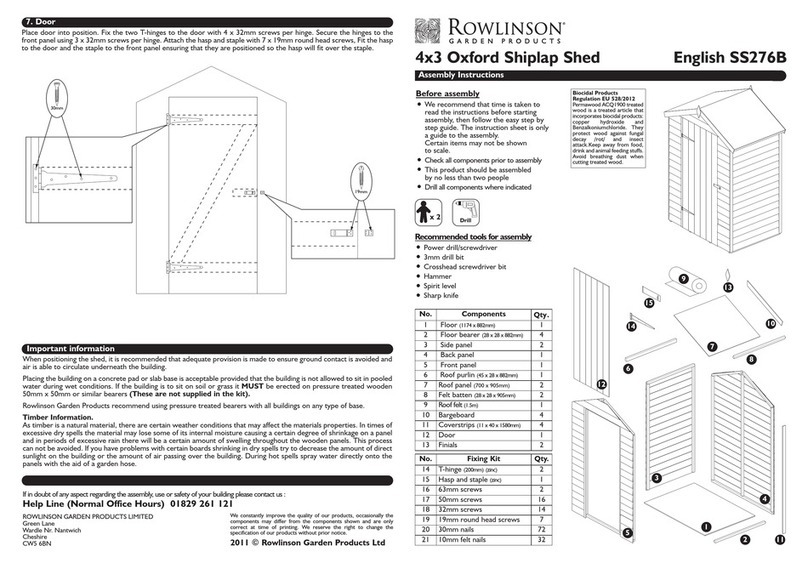

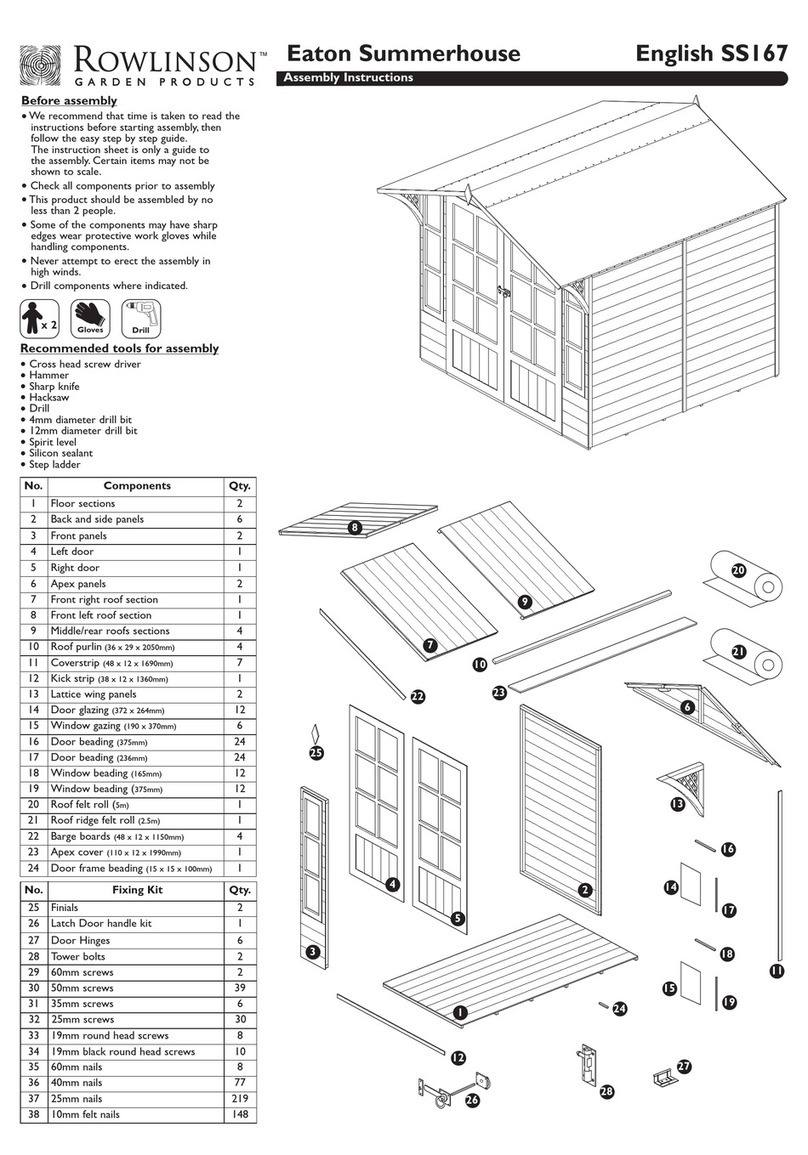

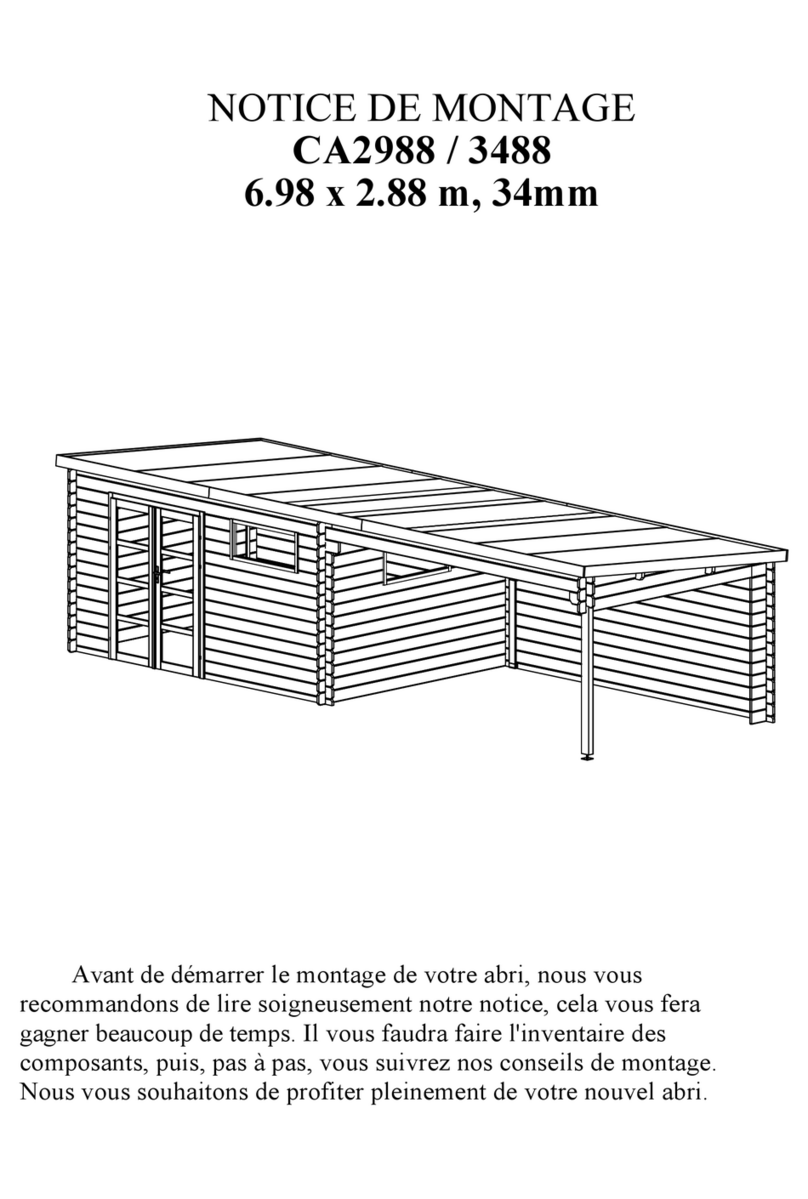

6. Coverstrips, bargeboards & finials

Fit a coverstrip into each corner, attach using 3 x 30mm nails per strip. To the front and rear of the shed, secure the

bargeboards so that the top edge is flush with the roof line and the two boards meet evenly at the apex. Secure using

3 x 30mm nails per board. At the front and rear of the assembly, attach the finials at the apex over the join between

the bargeboards using 2 x 30mm nails per finial.

30mm

30mm

30mm

30mm

30mm

30mm

30mm