2A

New Rowse

Agricultural and Industrial Machines

Rowse Hydraulic Rakes Co., Inc., (hereinafter“Rowse”).

Warrants each new agricultural and industrial machine

or equipment, (hereinafter “Product”) to be free from

defects in materials and workmanship under normal use

for which it was intended for a period of one year from

the date of purchase. The obligation of Rowse under this

warranty is limited to repairing or at its option, replacing

F.O.B. factory any part or parts which is reported in

writing to Rowse within 30 days from the date of

failure thereof and specifying the nature of the defect

or failure and which Rowse inspections shall disclose

to have been defective. It is the responsibility of buyer

to transport at his own expense the product to the

dealers service shop or Rowse factory. When requested

by Rowse, part or parts shall be returned for inspection,

transportation prepaid, to Rowse or a place designated

by Rowse. In no event shall Rowse be obligated for inci-

dental or consequential damages caused by such failure

or defect, including, but not limited to, the loss of crops,

inconvenience, rental of replacement equipment, loss of

prots, or other commercial loss.

There is no warranty with respect to used products

or new products that have been improperly assembled

by one other than an authorized dealer, modied or

altered, repaired, neglected, or used for purposes other

than those for which it was intended.

EXCEPT AS SPECIFICALLY WARRANTED HEREIN,

ROWSE DISCLAIMS ANY OTHER WARRANTY OF

MERCHANTABILITY, IMPLIED OR EXPRESSED, AND

FITNESS FOR PURPOSE. THERE ARE NO WARRANTIES

WHICH EXTEND BEYOND THAT FACE HEREOF.

Limited Warranty

Safety and Special Information

Safety Information

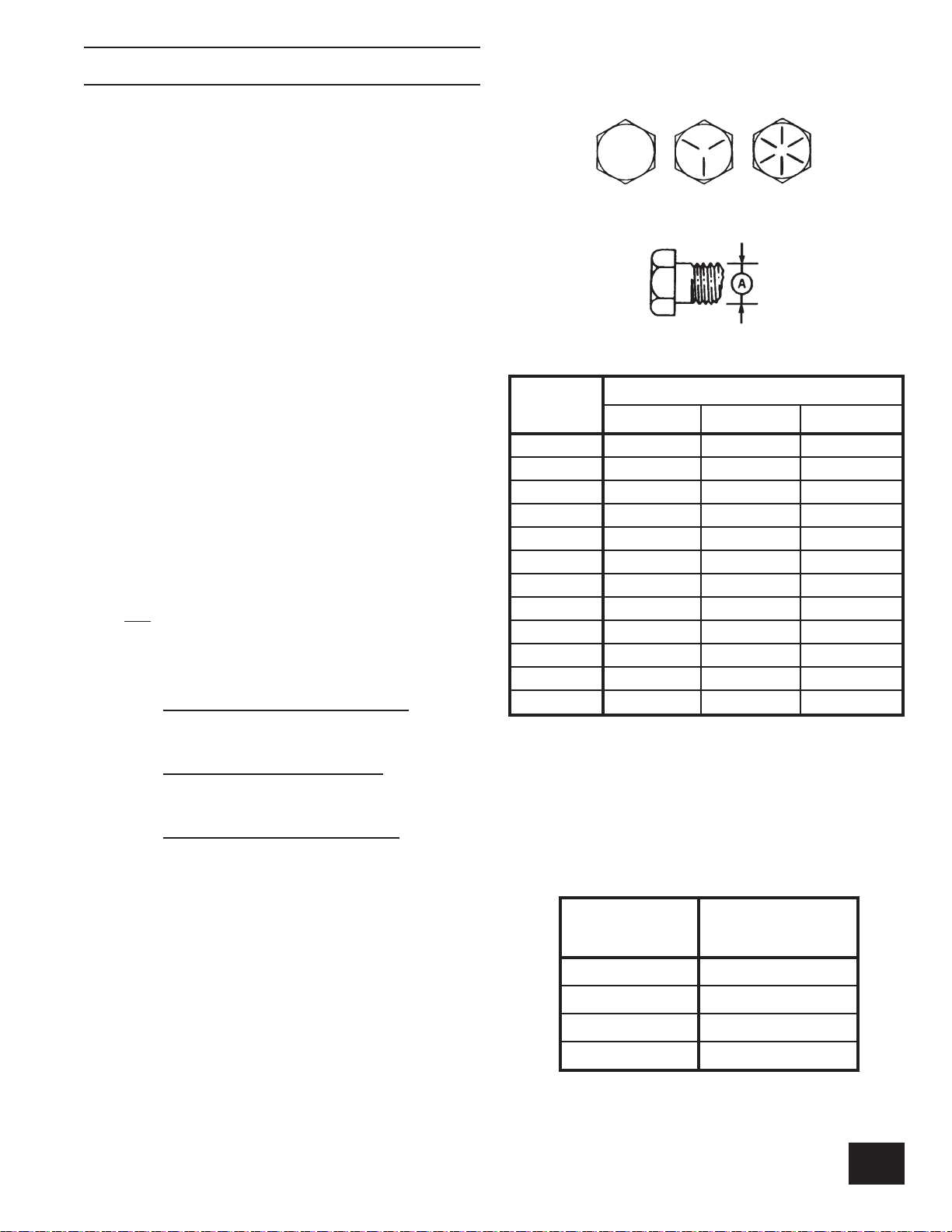

1. Throughout this manual and on machine decals im-

portant safety information appears with:

a) The Safety-Alert Symbol:

b) And one of the three signal words:

CAUTION, WARNING, or DANGER

2. Use of these three signal words is limited to safety

messages only.

3. The denition of each of these signal words follows:

CAUTION

Indicates a potentially hazardous situation which, if

not avoided, may result in minor or moderate injury.

It may also be used to alert against unsafe practices.

WARNING

Indicates a potentially hazardous situation

which, if not avoided, could result in death

or serious injury, and includes hazards that

are exposed when guards are removed. It

may also be used to alert against unsafe

practices.

DANGER

Indicates an imminently hazardous

situation which, it not avoided, will

result in death or serious injury. This

signal word is to be limited to the most

extremesituations,typicallyformachine

components which, for functional

purposes, cannot be guarded.

!

!

!

! !

4. For additional safety information, refer to Section D:

Safety.

Special Information

Messages that pertain to operational instructions,

maintenance messages, lubrication instructions, etc.,

use signal words such as: Note, Notice, Important, or

Attention. The signal word is set o in bold and all caps as

shown in the example below:

NOTE: Indicates a special point of information.