ED

E

TI

-

P-E

5 -

WARNING

Do not o

erate this machine around

uels, solvents,

mAMMABLEmOORlNISHESTHINNERSWOODDUSTORAN

mAMMABLEMATERIALS#IGARETTELIGHTERSPILOTLIGHTS

lectrical sparks and all other sources of ignition

s

ou

e ext

ngu

s

e

or avo

e

.

or

areas s

ou

e we

vent

ate

WARNING

Always wear safety

o

les when operatin

this ma

hine to avoid e

e injur

from debris projected from the

osc

at

n

a

WARNING

To avoid electrical shock, do not use this machine if it

has been rained on or spra

ed with water.

WARNING

To avoid electrical shock, unplug the power cord be

ore

a

ust

ng t

e

an

e

ar

e

g

t or rep

ac

ng t

e

a

WARNING

Always turn o

this machine and unplug the power

ord be

ore leaving it unattended. Do not allow u

trained

ersons to o

erate this machine

WARNING

Always wear a dust mask when operatin

this machine

to avoid inhalin

dust created by the oscillatin

Pad. In

a

n

ust create

y t

s mac

ne can cause ser

ous

resp

rator

n

ur

.

WARNING

o avo

e

ectr

ca

s

oc

,

o not

u

on t

e

ower cor

o move the machine or unplu

the power cord from

e e

ectr

ca

out

et

WARNING

o not remove, paint over or destroy warnin

decals. I

arnin

decals become dama

ed, call 1-262-681-3583

or free re

lacements.

WARNING

o avo

e

ectr

ca

s

oc

,

o not operate t

s mac

ne

VERELECTRICALmOOROUTLETS

WARNING

ress safely. Keep hands, feet and loose clothing away

rom moving parts on this machine

WARNING

o avoid electrical shock, always keep the power cord

lear o

the oscillating Pad and in good condition. A

ays li

t the power cord over the machine

WARNING

EVERO

ERATETHISMACHINEUNDERTHEIN

UENCEO

lcohol or dru

s. Do not allow anyone under the a

e o

8 to o

erate this machine

WARNING

his machine wei

hs over 130 pounds. Do not attempt

o li

t this machine alone. Two persons are required to li

t

s mac

ne.

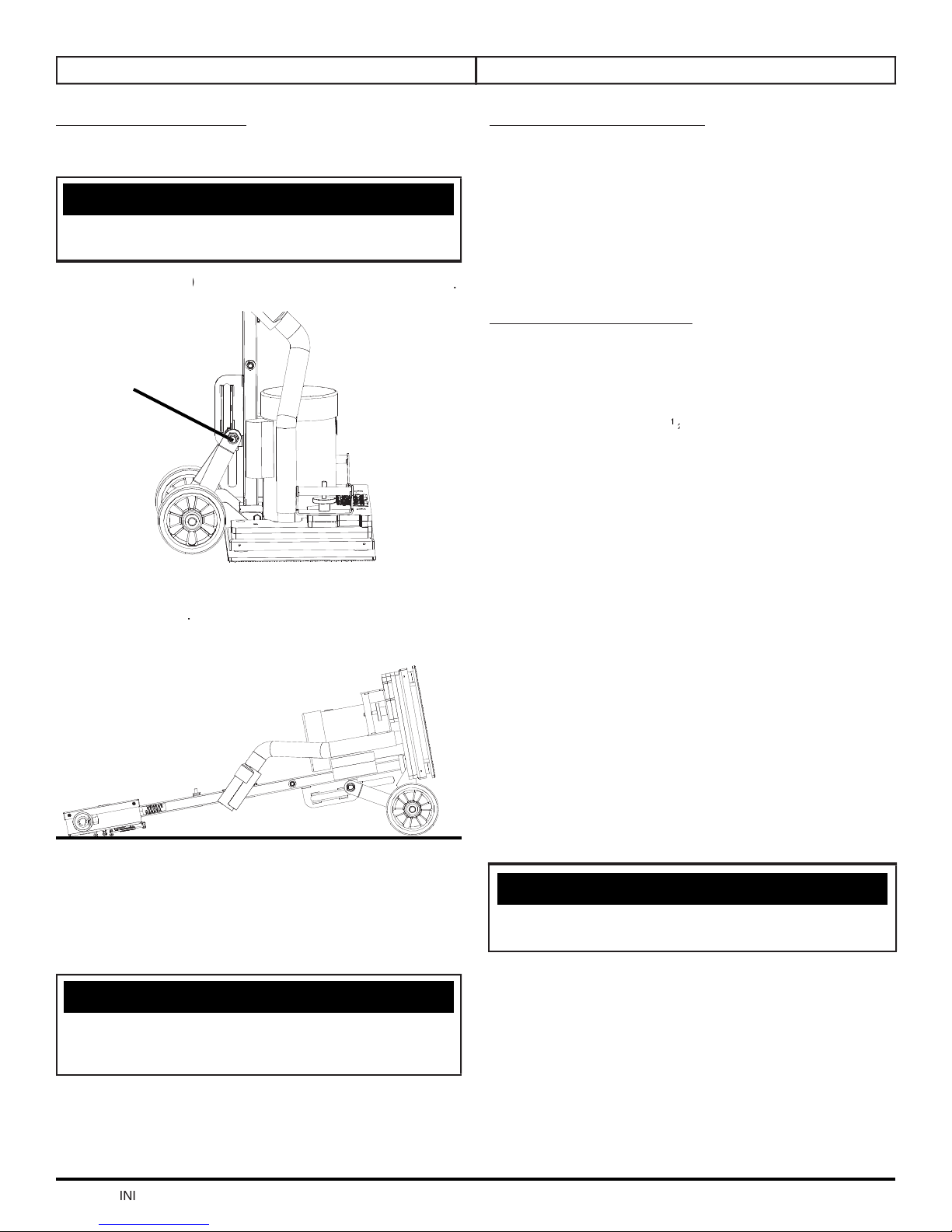

CAUTION

To avoid personal injury and

or damage to this ma

chine, the persons li

ting the machine should grasp the

li

ting bars on the base o

the machine with one hand,

and the handle with the other.

CAUTION

Always unplug the power cord and wrap the cord on

the cord wrap and handle be

ore attemptin

to li

t this

machine

CAUTION

lways raise and lock the handle into position be

ore

attempting to li

t this machine. Always leave the pad on

he machine be

ore transporting the machine to avoid

amage to the pad

ace.

CAUTION

ilt the machine onto its wheels and transport it slowly

and care

ully. Do not operate this machine i

any parts

ave been damaged or removed.

CAUTION

lterations to this machine ma

result in personal injur

r property

amage, an

vo

t

e warranty