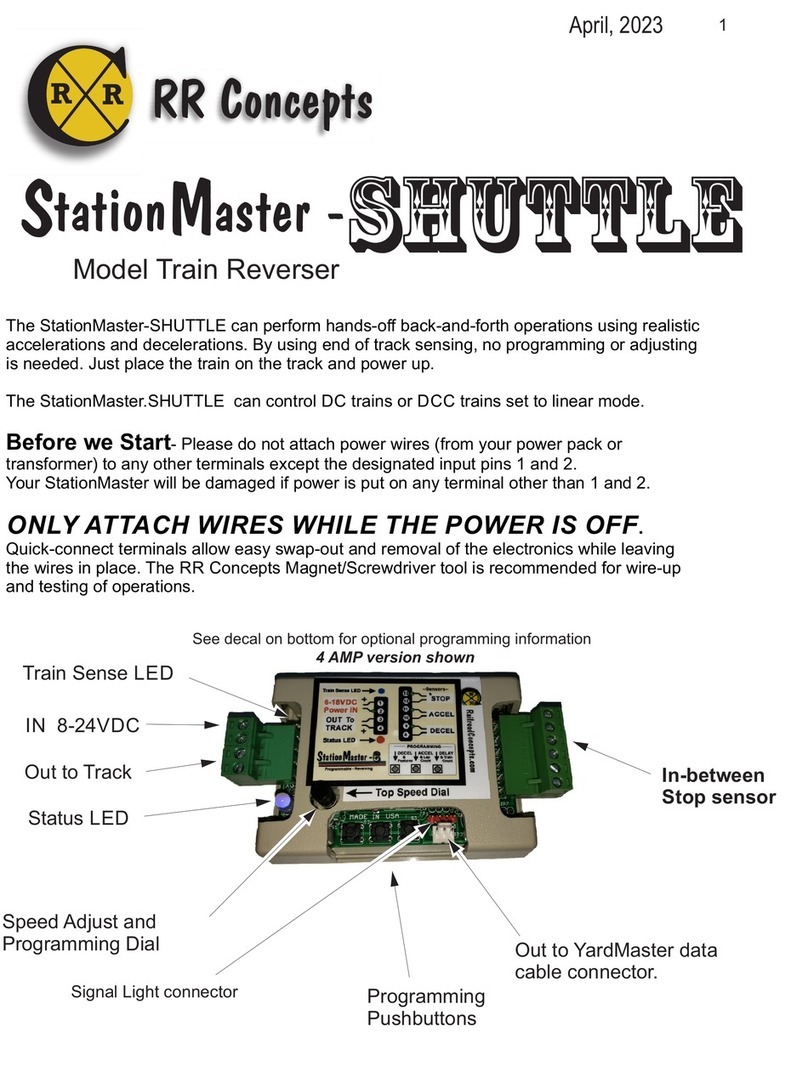

2

Train Detected LED Bypass Jumper

Top Speed Adjust and

Programming Dial “Out to YardMaster” data

cable connector for siding

control hookups.

IN 8-22VDC

Out to Track

See the label on the bottom for programming and additional information.

Sensor LED

Programming

Pushbuttons

Sensor Inputs:

DECEL

ACCEL

STOP

tation aster -

Quick Hookup Instructions

SM6

How to do

Realistic Station Stops &

Realisitic Reversing (More details in manual)

The StationMaster works with DC (out of the box)

or DCC trains set to linear mode. (N, HO, G, etc.)

AC trains cannot be controlled.

sensor

Stopping

Position

To

Power Pack

TRACK

Terminals

To

Power Pack

TRACK

Terminals

Attach to

TRACK.

Swap these

wires to go the

opposite direction

1

2

3

4

8

9

10

11

12

13

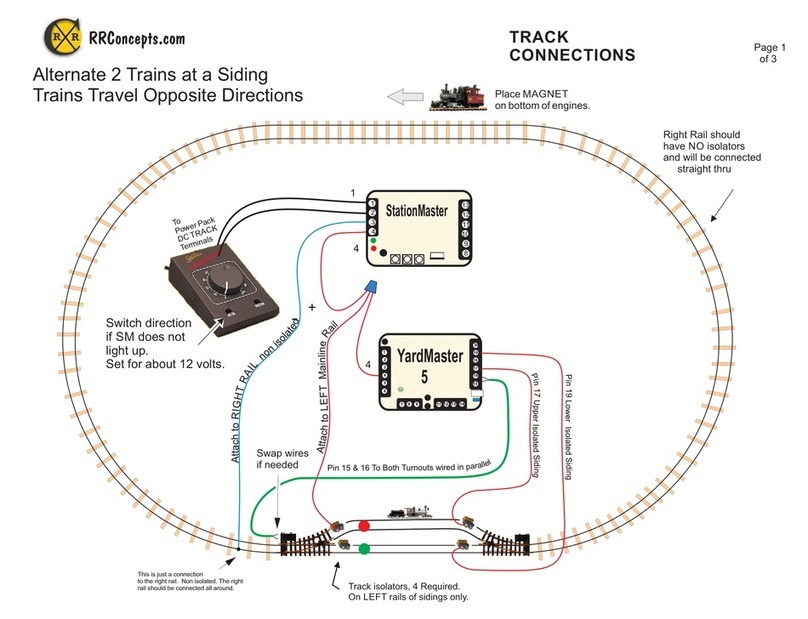

StationMaster

Accelerate + Decelerate Station Stop Hookup

1) Attach terminals 1 & 2 to the transformer.

2) Attach terminals 3 & 4 to the track.

3) Attach terminals 8 & 9 to a train sensor. (No polarity)

4) Mount a magnet on an engine or car.

Set the transformer to the desired top speed. That’s it!

See the online manual for optional additional features:

* Change acceleration rate,

* Change deceleration rate,

* Add additional station stops,

* Do multiple laps before stopping,

* Run 2 trains on the same track.

* Change station stop pause duration, (Default 10 seconds)

* Perform “Self-Adjusting” deceleration. (Requires STOP

sensor to stop at an exact location)

To

TRACK

1

2

3

4

8

9

10

11

12

13

StationMaster

SCAN FOR INFO

4 AMP Version shown, Also available in 10 AMP configuration.

StationMaster CONNECTIONS and CONTROLS

Go to StationMaster.net (bottom of page) and download the 25 page user manual for more info.

Visit RailroadConcepts.com for more fun, advanced hookups, and ordering parts.

Un-modified track!

No diodes, no breaks, no additional track connections.

Reversing Hookup

Station Stop Hookup

RR Concepts

C

RR

Un-modified trains.

No sensors, no

magnets.

It just works!

Accelerate + Decelerate Reversing Hookup

1) Attach terminals 1 & 2 to the transformer.

2) Attach terminals 3 & 4 to the track.

3) Program the StationMaster for “Reversing Mode”

(see below for programming)

See the online manual for additional in-between stops,

self adjusting exact stopping using STOP sensors,

delay times, etc,

One time programming for No Sensor Reversing mode”:

1. Turn the top speed dial fully counter-clockwise. 4. When train starts to run, press button #3 about

2. Simultaneously press buttons 1 and 2. 3 feet from the end. Repeat for both directions.

3. Turn the top speed dial fully clockwise. 5. Turn dial to desired creep speed into the ends.