Operation

A. Remove all shipping plugs from the hoses and fittings.

B. Ensure that a suitable element is fitted and that the element

housing cover is fitted with its ‘O’ ring and that the cover is

correctly screwed into place.

Excessive force is not required.

C. Ensure that the hoses are correctly fitted to the filter unit

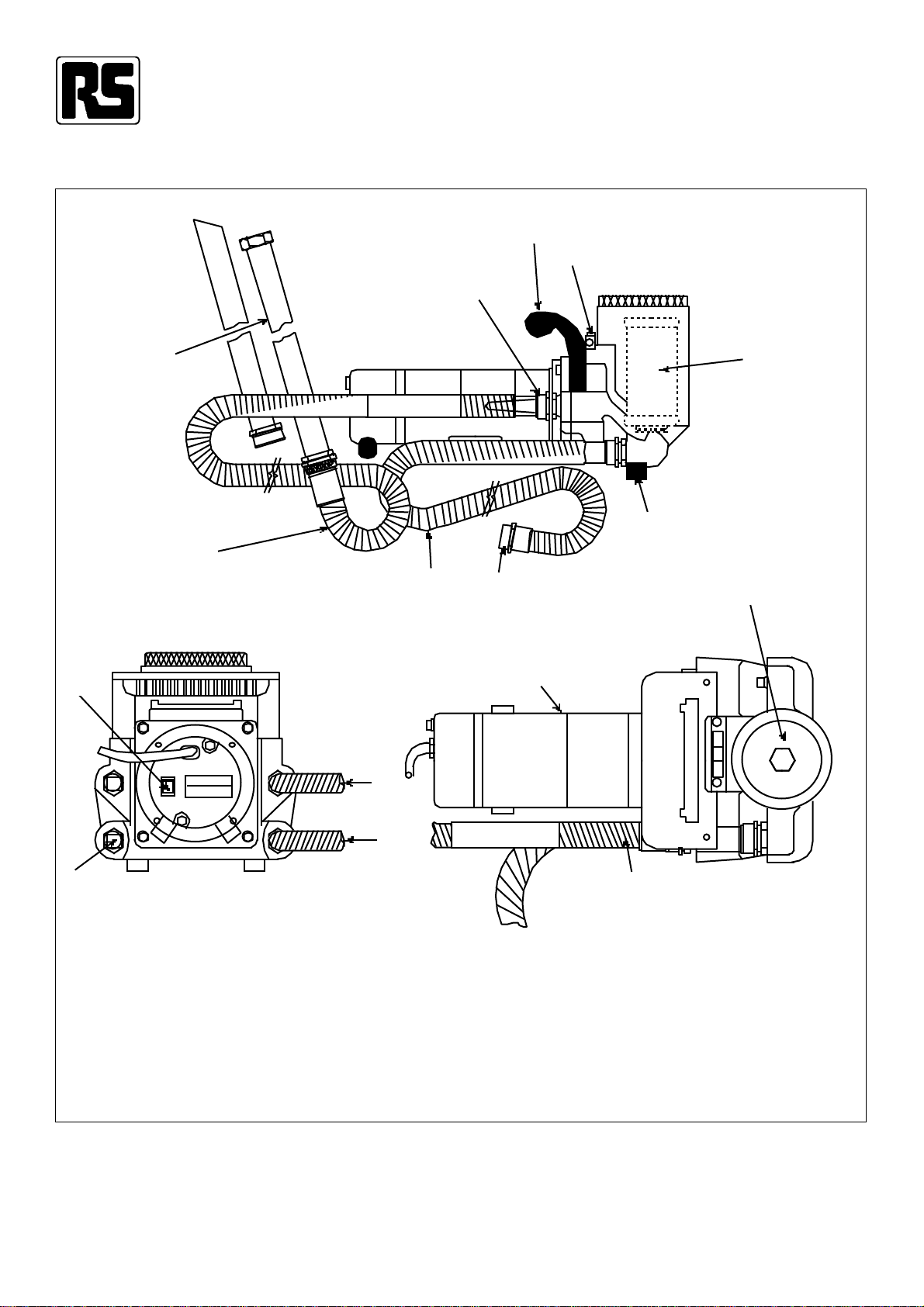

(see Figure 1).

The inlet, or suction hose should be fitted to the port

nearest to the motor, marked with arrow

The outlet hose should be fitted to the port furthest from the

motor, marked with arrow

D. Connect the wand assemblies if required.

E. Place the inlet hose/wand assembly into the fluid to be

filtered and/or transferred. Place the outlet hose/wand

assembly into a suitable fluid discharge container.

F. Connect the filter unit to the appropriate power supply and

switch on the filter unit utilising the on/off switch at the rear

of the unit (Figure 1).

G. If, during operation the 1.7 bar differential visual indicator

(element condition monitor) Figure 1, moves into the red

area, switch off the unit and change the element. (See

element servicing section).

Please note: That if the filter unit is being used to pump fluid to

a height of more than 2 metres, the indicator may

move into the red area immediately. This is

caused by the extra pressure generated and

does not necessarily indicate that the element

needs changing.

H. Upon completion of the operation, switch the filter unit off

and disconnect from the power supply.

I. Withdraw the hoses from their respective fluid containers

and drain them into a waste fluid vessel. To ensure ‘No-

mess’ transportation, the inlet and outlet hose assemblies

can be screwed together by removing the wand assembly.

Element servicing

A. Switch off the filter unit and isolate from the power supply.

B. Rotate the element housing cover anti-clockwise and

remove.

C. Remove the dirty/contaminated element from the housing

and dispose of. (Elements are non-cleanable). Ensure

element housing is clean.

D. Place the new element in the housing, fitting the ‘O’ ring

seal into the lower location hole.

E. Inspect the housing cover ‘O’ ring and replace if necessary.

F. Replace the housing cover and hand-tighten.

Note: It is recommended the filter unit is cleaned and flushed

between uses.

Technical specification

Maximum allowable

operating pressure 3.5 bar

Flow capacity Up to 15 litres/min

Visual element

condition indicator Differential pressure type set at 1.7

bar

Fluid compatibility Petroleum based and water

emulsions

Integral relief valve Set at 3.5 bar for motor protection

Operating temperatures Filter unit -20°C to +82°C

Hose/wand -4°C to +50°C

Weight 10.6 kg

Electrical motor 1/4 hp at 2500 rpm 3A maximum

110V single phase

50 Hz