1 DESCRIPTION OF THE SYSTEM 3

2 DIMENSIONS AND MATERIALS 4

2.1 Dimensions and tolerances 4

2.2 Materials and standards 5

3 MANUFACTURING 5

3.1 Manufacturing method 5

3.2 Manufacturing markings 5

3.3 Quality control 5

4 RESISTANCES ACCORDING TO ACI 6

4.1 Calculation principles 6

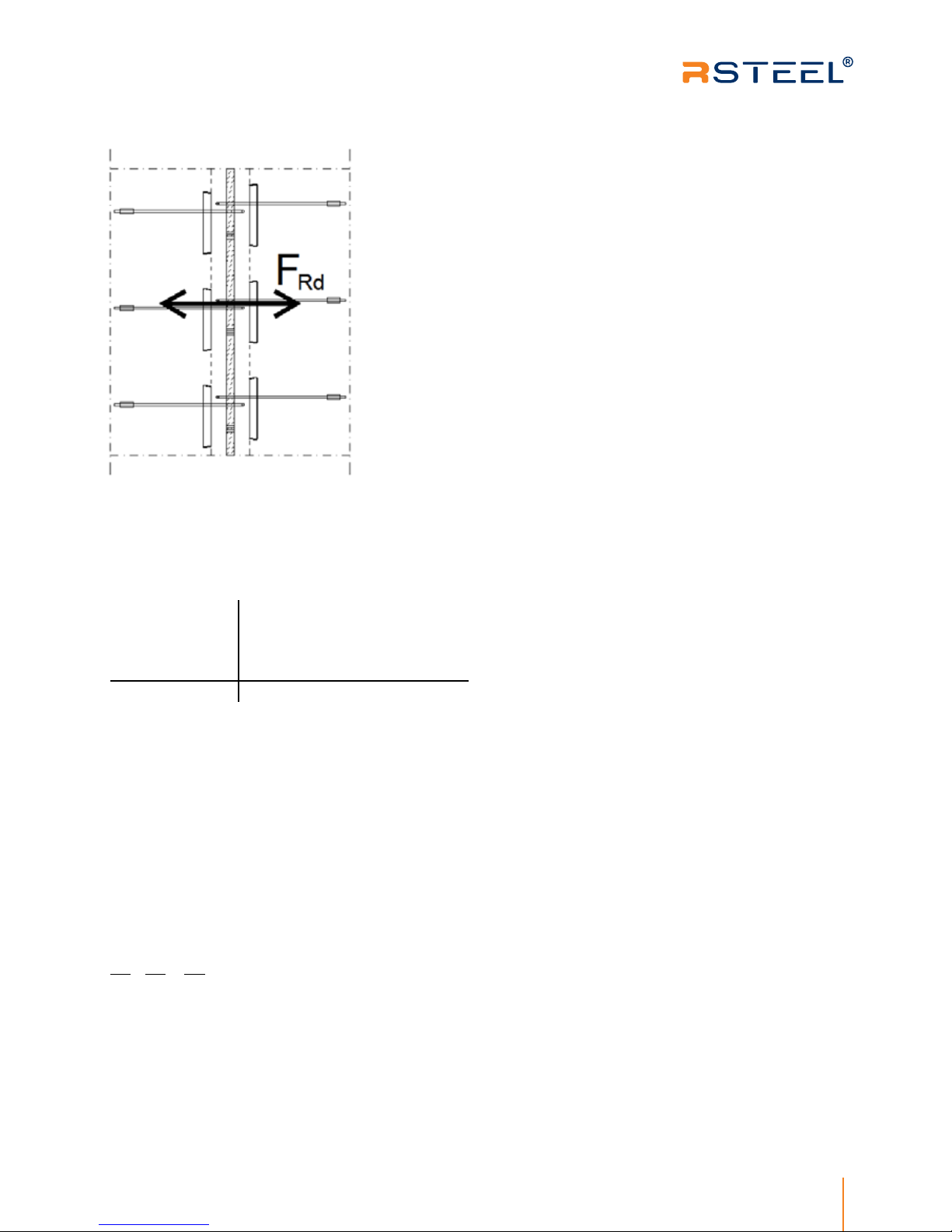

4.2 Design values of resistance for longitudinal shear force (ACI) 6

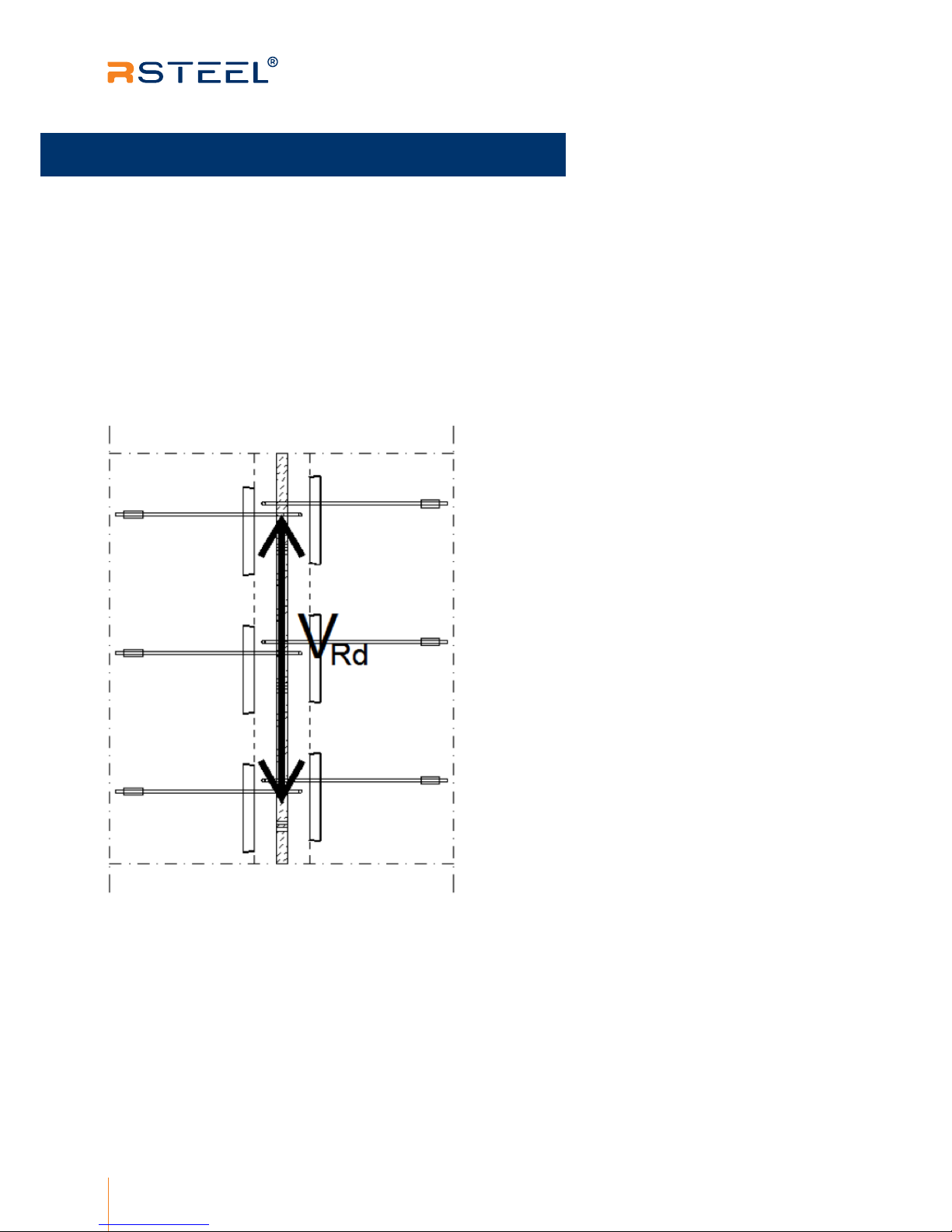

4.3 Design values of resistance for transversal shear force (ACI) 8

4.4 Design value for tensile force (ACI) 9

4.5 Resistances for combined forces (ACI) 9

5 RESISTANCES ACCORDING TO EC 10

5.1 Calculation principles 10

5.2 Design values of resistance for longitudinal shear force (EC) 10

5.3 Design values of resistance for transversal shear force (EC) 12

5.4 Design value for tensile force (EC) 13

5.5 Resistances for combined forces (EC) 13

6 APPLICATION 14

6.1 Limitations for application 14

6.1.1 Minimum edge and center distances 14

6.2 Reinforcement of the concrete 15

6.2.1 Reinforcement of the joint 15

6.2.2 Reinforcement of the concrete element 16

7 INSTALLATION 18

7.1 Attachment to formwork 18

8 SUPERVISION OF INSTALLATION 18

8.1 Installing the RVL wire rope loops 18

Table of Content