WE'r:"':"S::E"::e'"

'C

a

0

s amount of kindling into

or on the grate (#2 C/W) and

0 -

ling is burning vigorously, add

els full of coal, spreading it out to

nition. Wait for several minutes

is ignited and add two or three more

soovets

0

coal. Repeat this process until

V

of the

coal capacity of your stove is reached. If too much

coal is added too quickly, the fire could be lost. With

the fire established, fill the coal holding area to

capacity. Care should be taken to keep all coal in

the

#

1 C/W basket and within the refractory area

of the #2 C/W.

coals down. It is not necessary to shake all the

ashes out of the basket. Shake until glowing

embers begin to fall into the ash drawer. Use the

tool provided to reset the draft regulator to the

desired setting. It will be necessary to refuel and

shake ashes at least two or three times daily.

Another method of improving the draft is by poking

the coals around the sides of the basket with the

Handy Tool.

If the fire dies out, it is not necessary to remove the

unburned coal. Thoroughly shake down all ashes

and poke the corners with the Handy Tool to insure

removal of dead clinkers and ashes. Start a fire as

described previously on top of the unburned coal.

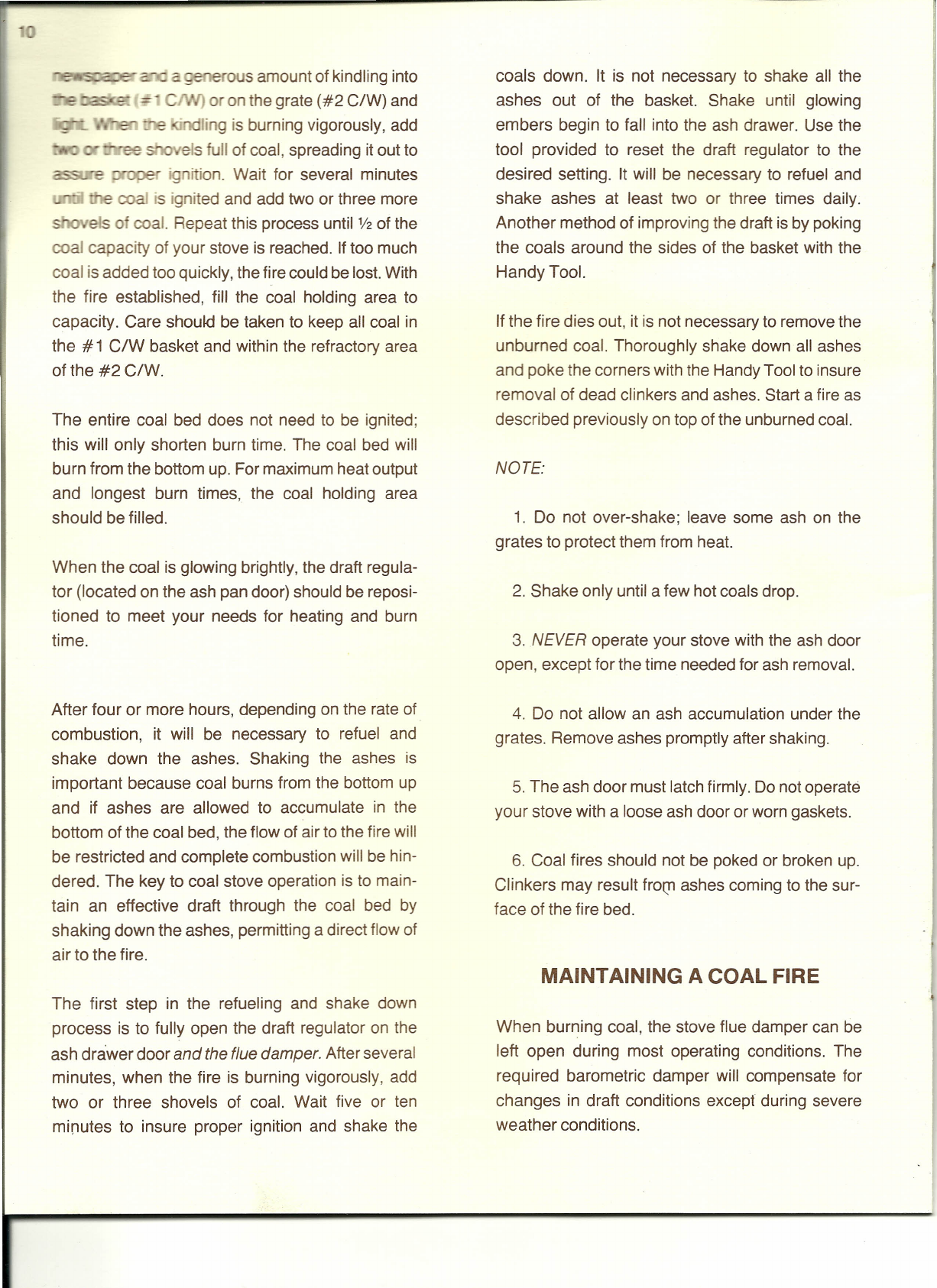

The entire coal bed does not need to be ignited;

this will only shorten burn time. The coal bed will

burn from the bottom up. For maximum heat output

and longest burn times, the coal holding area

should be filled.

NOTE:

1. Do not over-shake; leave some ash on the

grates to protect them from heat.

When the coal is glowing brightly, the draft regula-

tor (located on the ash pan door) should be reposi-

tioned to meet your needs for heating and burn

time.

2. Shake only until a few hot coals drop.

3 NEVER operate your stove with the ash door

open, except for the time needed for ash removal.

After four or more hours, depending on the rate of

combustion, it will be necessary to refuel and

shake down the ashes. Shaking the ashes is

important because coal burns from the bottom up

and if ashes are allowed to accumulate in the

bottom of the coal bed, the flow of air to the fire will

be restricted and complete combustion will be hin-

dered. The key to coal stove operation is to main-

tain an effective draft through the coal bed by

shaking down the ashes, permitting a direct flow of

air to the fire.

4. Do not allow an ash accumulation under the

grates. Remove ashes promptly after shaking.

5. The ash door must latch firmly. Do not operate

your stove with a loose ash door or worn gaskets.

6. Coal fires should not be poked or broken up.

Clinkers may result from ashes coming to the sur-

face of the fire bed.

M INT INING CO L FIRE

The first step in the refueling and shake down

process is to fully open the draft regulator on the

ash drawer door and the flue damper After several

minutes, when the fire is burning vigorously, add

two or three shovels of coal. Wait five or ten

minutes to insure proper ignition and shake the

When burning coal, the stove flue damper can be

left open during most operating conditions. The

required barometric damper will compensate for

changes in draft conditions except during severe

weather conditions.