10

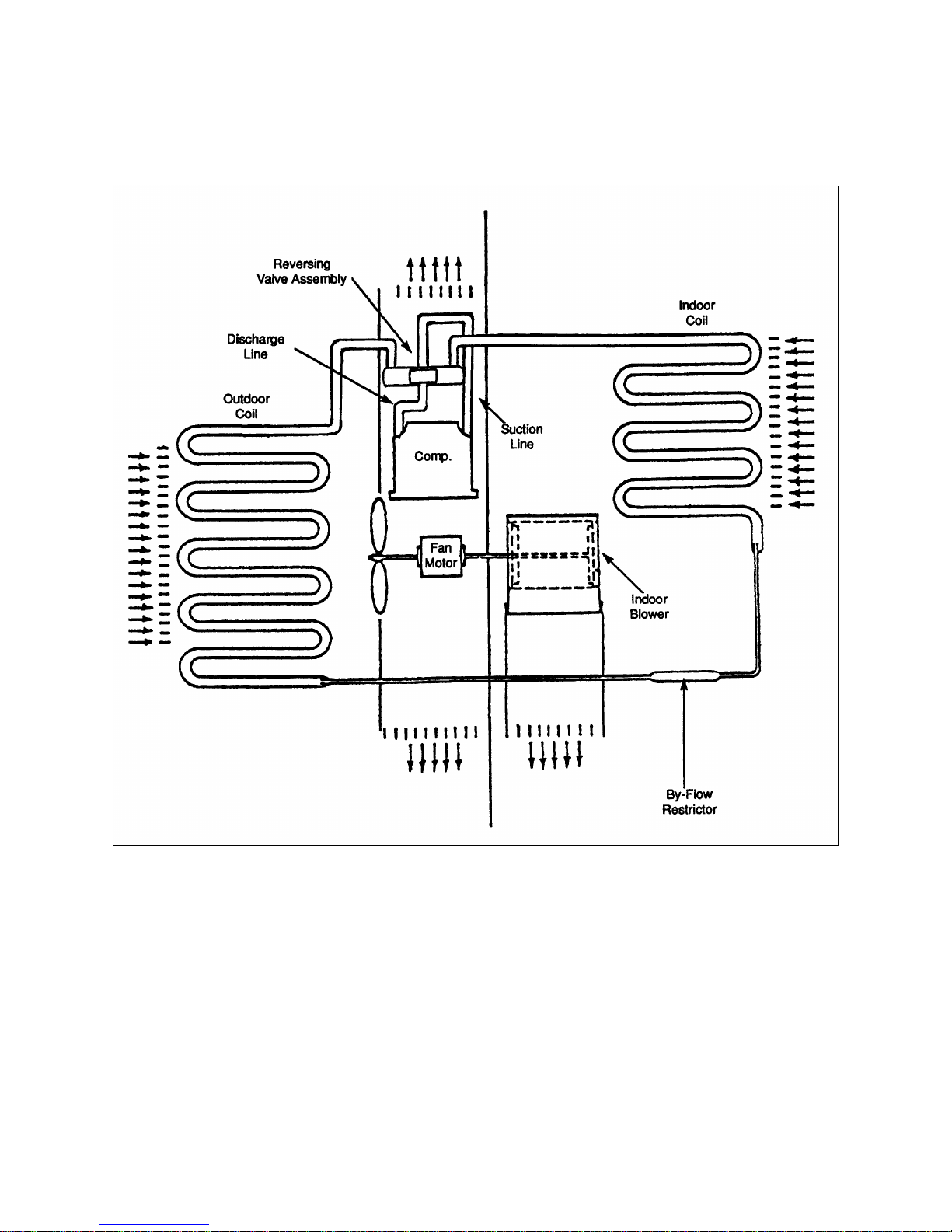

1. Indoor Coil (Cooling Mode)

The purpose of the finned evaporator coil is to transfer the

heat from the warm and moist indoor air to the cold low

pressure refrigerant.

As the heat leaves the air, the air temperature drops and some

of the moisture in the air condenses from a vapor to a liquid.

The liquid water (condensate) is drained onto the roof of the

recreational vehicle. As the heat enters the refrigerant in the

evaporator, it causes the refrigerant to evaporate (change from

a liquid to a vapor).

The refrigerant remains at nearly constant temperature (called

evaporator temperature or low side saturation temperature) in

the evaporator since there are both liquid and vapor together.

However, near the outlet of the evaporator coil, all of the liquid

has boiled (evaporated) away and from there on, the

temperature of the vapor rises (the vapor becomes

superheated). It is necessary that the vapor become

superheated because it is headed down the suction line to the

compressor, and the compressor can only pump superheated

vapor. Any vapor (which might be present if the vapor were

not superheated) could cause serious mechanical damage to

the compressor.

2. Suction Line

The suction line is the copper tube which carries the

superheated vapor refrigerant from the evaporator to the

compressor.

3. Compressor

The compressor is called a hermetic compressor which means

it is completed sealed (welded together). It is, therefore, not

internally field serviceable. Inside the compressor housing is

basically:

a) an electric motor which drives the compressor,

b) a pump which is designed to pump superheated

vapor,

c) a supply of special refrigerant oil. A small portion of

the oil will circulate out through the system with the

refrigerant, but will constantly return to the

compressor with the refrigerant, so the compressor

will not run out of oil.

4. Outdoor Coil (Cooling Mode)

The purpose of the finned condenser coil is to transfer heat

from the high pressure refrigerant to the warm outdoor air. As

the outdoor air passes over the coil, the heat transfer will

cause the air temperature to rise. Thus the condenser

discharge air will be several degrees warmer than the

condenser entering air.

As the refrigerant passes through the first few tubes of the

condenser, its temperature will be lowered or it will be de-

superheated. After the refrigerant is de-superheated, it will

begin to condense or change from a vapor to a liquid and will

remain at a nearly constant temperature throughout almost all

of the remainder of the coil. This temperature is called the

condensing temperature or high side saturation temperature

and will always be higher than the condenser entering air

temperature.

Near the bottom of the condenser, the refrigerant will all be

condensed to a liquid and from there on, its temperature will

drop to more nearly the temperature of the outdoor air. After

the temperature of the refrigerant drops below condensing or

saturation temperature, we call its condition sub-cooled liquid.

During all of the three processes in the condenser (de-

superheating, condensing, sub-cooling), the refrigerant gives

up heat; but most of the heat is given up during the

condensing process.

5. Reversing Valve

The reversing valves main function is to reverse the flow of

refrigerant. Internally, it is composed of two pistons on a

sliding block or cylinder with two openings. The operation of

the piston block is controlled by a solenoid valve. The

solenoid valve controls the flow of the refrigerant, which

produces a pressure difference in the valve itself. When the

solenoid valve is energized, it is in the heating mode. When it

is de-energized, it is in the cooling mode.

6. Discharge Line

The discharge line carries the refrigerant out of the compressor

and to the reversing valve. The reversing valve then

distributes this refrigerant to the outdoor coil during the

cooling mode, and to the indoor coil in the heating mode.

Remember that as the refrigerant entered the compressor, it

was superheated vapor. As the compressor works on the

refrigerant, it adds more heat and also compresses the

refrigerant into a smaller space. The refrigerant, therefore,

leaves the compressor highly superheated - so if the discharge

line is hot to the touch (burns), don’t be surprised - it should

be.

7. By-Flow Restrictor

The by-flow restrictor is the metering device for the heat

pump. The restrictor is made up of two orifices positioned

back to back. There is a space between the orifices. As the

system is either in the cooling or heating mode, it forces one of

the orifices to seat at one of the tapered ends and force the

other to break its seal. Refrigerant goes around one orifice and

through the other, establishing the pressure drop. The orifices