1RYCO CLEAN KIT OPERATION MANUAL

RYCO CLEAN KIT

1.INTRODUCTION

Contaminants that enter a hydraulic system such as dust, debris and dirt can cause system failure and, in some

cases, serious damage to its components. Fluid contamination is a critical factor inuencing the safety of hydraulic

systems and therefore, minimising the presence of any particles and impurities within the hydraulic hose

assembly, tubing and components is of paramount importance.

The RYCO CLEAN Kit is an easy to use, low-cost solution to eliminate hydraulic contamination from the inside of

hose, tube, and pipe. It is designed to clean the internal surfaces of hose, tube, and pipe eectively and eciently.

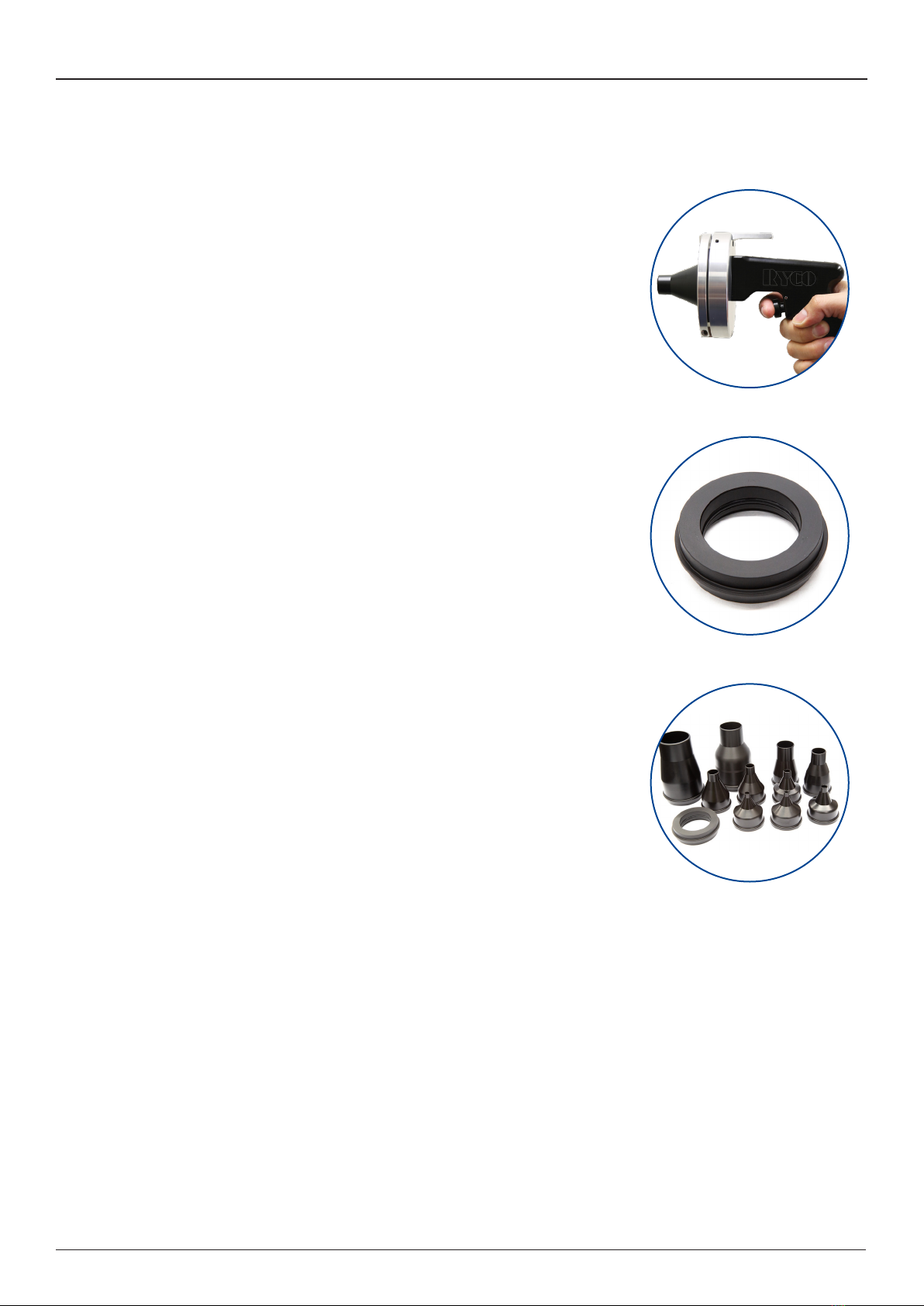

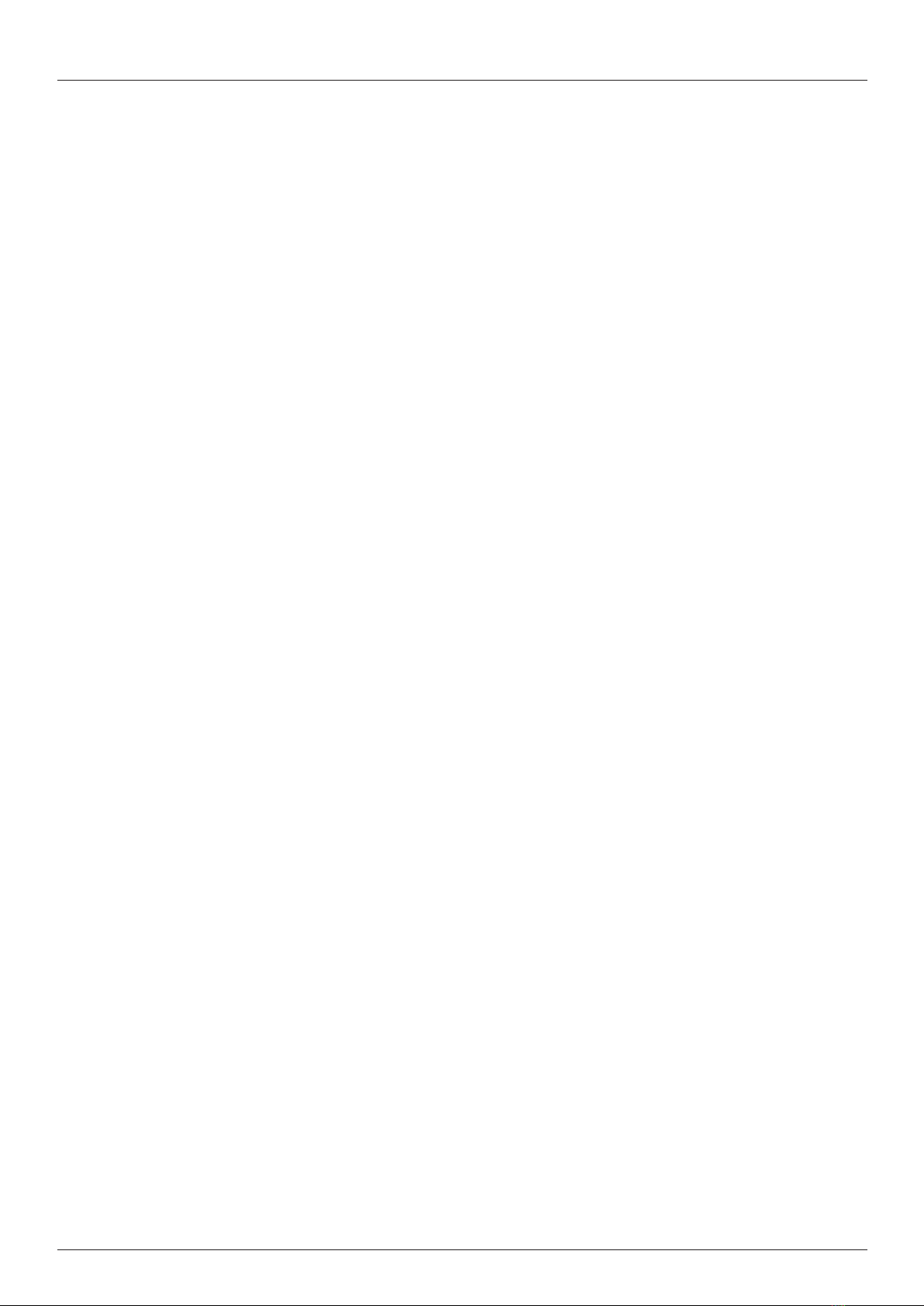

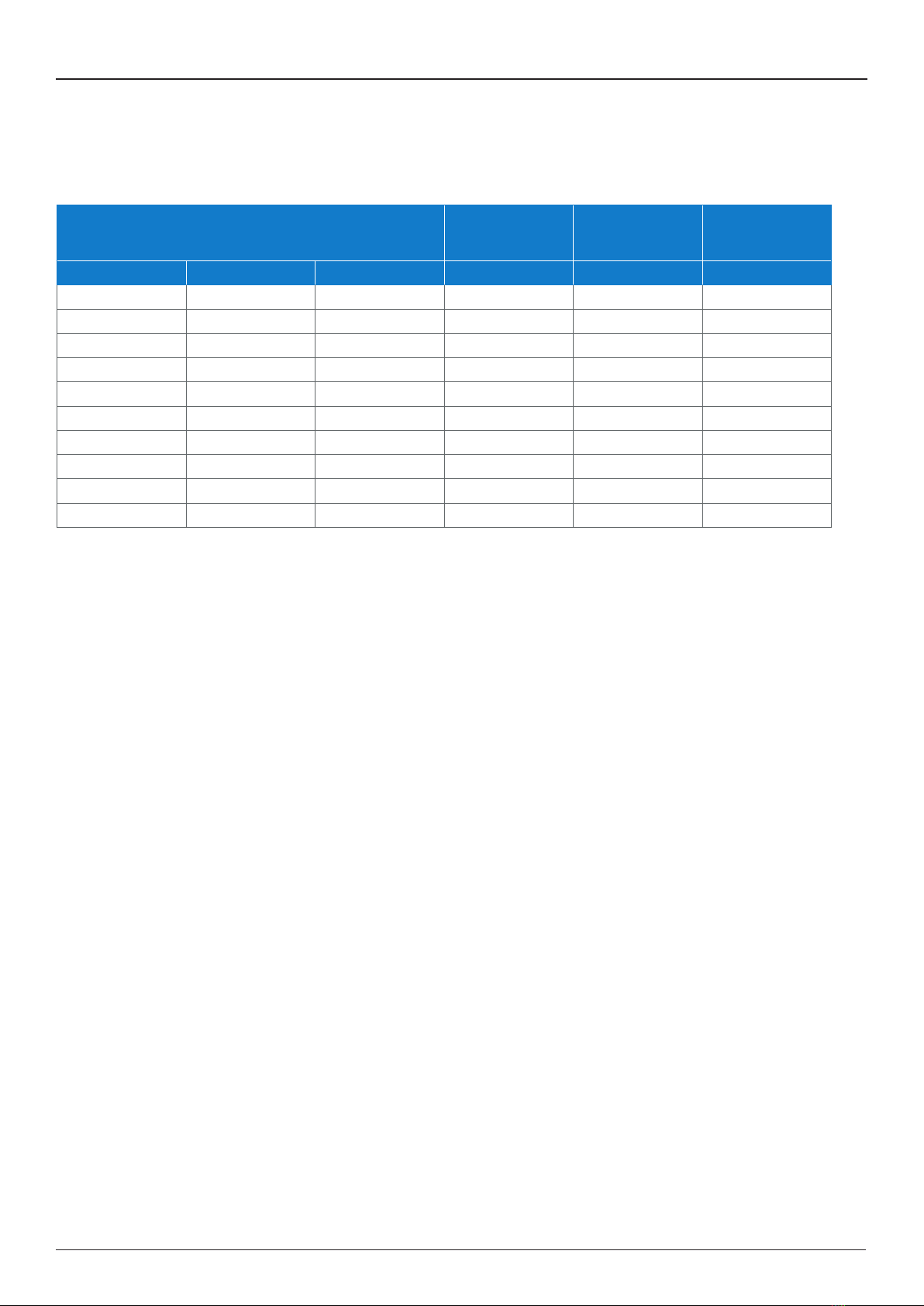

It comprises of a pneumatic Hand Launcher, an adaptor ring, and a range of specially designed nozzles to

accommodate dierent sizes of hose, tube, and pipe.

The optimum air input pressure range for the RYCO CLEAN Hand Launcher to operate eectively is between 87 psi

(6 bar) and 110 psi (7,5 bar).

2.SAFETY INSTRUCTIONS

1. Read this manual carefully and understand the content before using the RYCO CLEAN Kit.

2. Keep this manual with the RYCO CLEAN Kit for future reference.

3. Always wear appropriate PPE in accordance with industry, job site and OHS requirements when using the

RYCO CLEAN Hand Launcher. RYCO recommends the wearing of suitable safety glasses, ear protection

and a face mask as minimum PPE requirements for operators and bystanders.

4. Refer to the Projectile Selection Chart to ensure you select the correct nozzle for your application.

5. Bleed the air pressure from the hose before connecting or disconnecting the Hand Launcher gun.

6. The discharging end of the hose, tube or pipe must always be pointed towards a catcher bucket or

cloth to avoid possible injury to personnel by the projectile exiting at high speed.

7. To achieve the desired level of cleanliness the process should be repeated until the projectile emerges

free of contamination. Do NOT reuse projectiles.

8. It must be ensured that the projectiles travel all the way through the hose, tube or pipe and do not get

stuck inside.

9. If any component within the kit does not operate to your required performance level or have been

damaged or worn discontinue use and contact your nearest RYCO representative for guidance.

10. Pressure range - do NOT exceed input pressure of 110 psi (7,5 bar). Compressed air is recommended as a

gas to power the RYCO CLEAN Hand Launcher. Do NOT use oxygen or other volatile gases.

11. If the instructions in this manual are unclear or if you require further technical advice or additional

information, contact your nearest RYCO representative.