Page 2

RULES FOR SAFE OPERATION (Continued)

7. DONOTMAKEADJUSTMENTSUNTILCUTTERORBLADEHASCOMETOACOMPLETESTOPANDTOOLHAS

BEEN DISCONNECTED FROM POWER SOURCE.

8. FEED WORKPIECE AGAINST ROTATION OF CUTTER.

9. DO NOT USE AWKWARD HAND POSITIONS.

10. KEEP FINGERS AWAY FROM REVOLVING CUTTER, USE FIXTURES WHEN NECESSARY.

11. WHENEVER POSSIBLE, ALWAYS USE DUST COVER FOR OVERHEAD GUARDING.

12. DONOTREMOVEJAMMEDCUTOFFPIECESUNTIL CUTTERORBLADEHASSTOPPEDANDTOOL HASBEEN

DISCONNECTED FROM POWER SOURCE.

13. HOLD WORKPIECE FIRMLY AGAINST THE TABLE.

14. UNUSED SAW MAY CAUSE PERSONAL INJURY. DISCONNECT MOTOR CORD FROM THE RECEPTACLE ON

YOUR SAW AND PLUG ACCESSORY POWER CORD INTO THE RECEPTACLE. ALWAYS USE THE SAW'S

MASTER SWITCH TO TURN THE ACCESSORY "ON" AND "OFF".

WARNING:

Unplug the power supply cord of your BT3000 from

electrical outlet before you begin mounting this kit. It

shouldremaindisconnecteduntilthemountingoperation

is complete, all attachments are installed properly, and

they have been checked to make sure they are secure.

Failure to unplug your saw could result in accidental

starting causing possible serious personal injury.

INTRODUCTION

As mentioned previously, this kit gives you the capability of

mounting a router or jig saw on the accessory table of your

BT3000. A router mounted on the accessory table will pro-

vide expanded capabilities for making rabbets, grooves,

chamfers,dovetails,andmortiseandtenonjoints. A jig saw

mounted on the accessory table will provide expanded

capabilities for cutting curves, scrollwork, and intricate pat-

terns.

The circle cutting jig included in this kit enables you to easily

cut circular patterns in both large and small stock with either

a router or jig saw.

The additional versatility gained from use of this kit will turn

your BT3000 table saw into a remarkable woodshaping

center. IMPORTANT NOTE

Thisrouterkithasbeenspecificallydesignedforusewiththe

Ryobi Model RE600 Electronic Router Only. The hole

pattern on the mounting plate has not been drilled to

accommodate other routers on the market.

This jig saw kit is used to mount a jig saw on the accessory

table of your BT3000 table saw. Ryobi jig saws plus many

otherbrands canbemountedusingthepartssuppliedinthis

kit. Beforeoperatingthejigsaw,makesurethefrontandrear

clamping brackets properly secure the jig saw base to the

mountingplate. Caremustbetakentoinsurethatthejigsaw

bladedoesnotcomeincontactwiththethroatplate,accessory

table, or any part of the assembly during operation. Visually

inspect all areas of moving parts prior to connecting the jig

saw to power supply.

UNPACKING

Your new router and jig saw mounting kit includes two

separate mounting plates, two guide fences with guide

blocks, a dust cover assembly, a throat plate, plus the

necessary brackets and connecting hardware required to

mount a Ryobi Model RE600 Electronic Router to the

accessory table of your BT3000 table saw. It also includes

connectinghardwarerequiredtomountRyobijigsawstothe

accessory table of your BT3000 table saw .

CHECKING PARTS

Separate all parts from packing materials. Check your parts

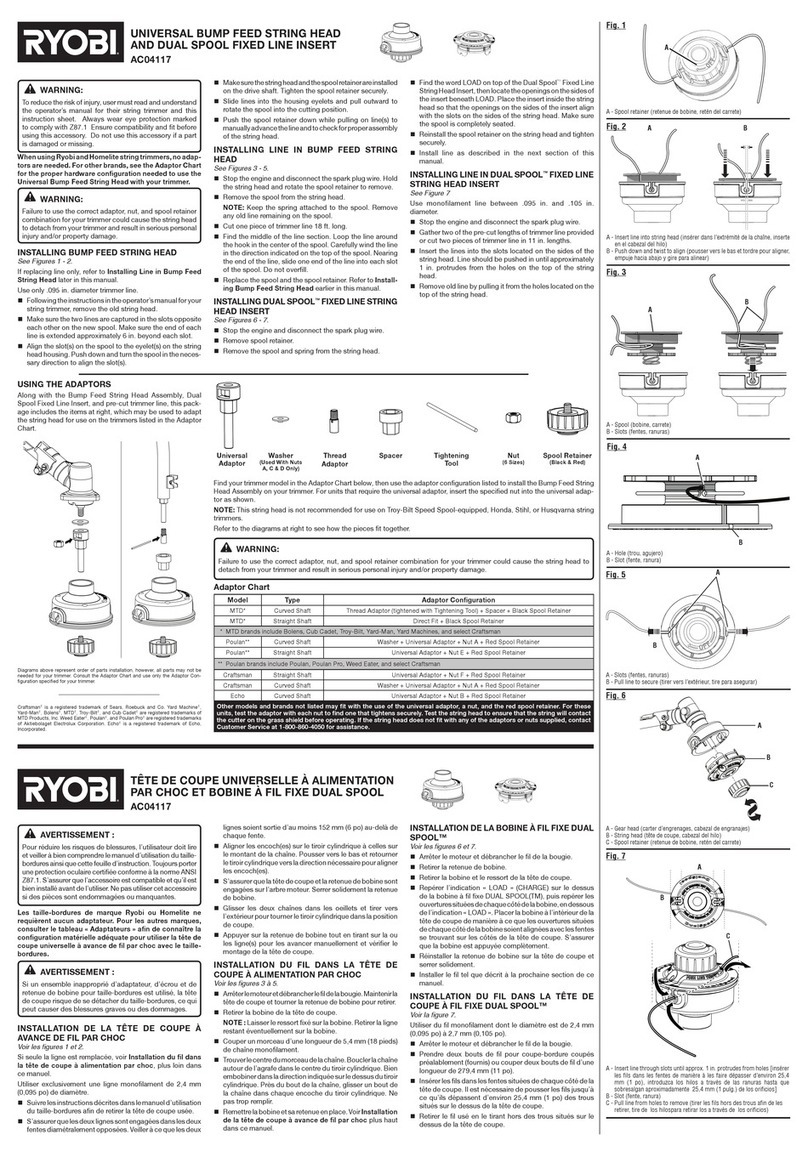

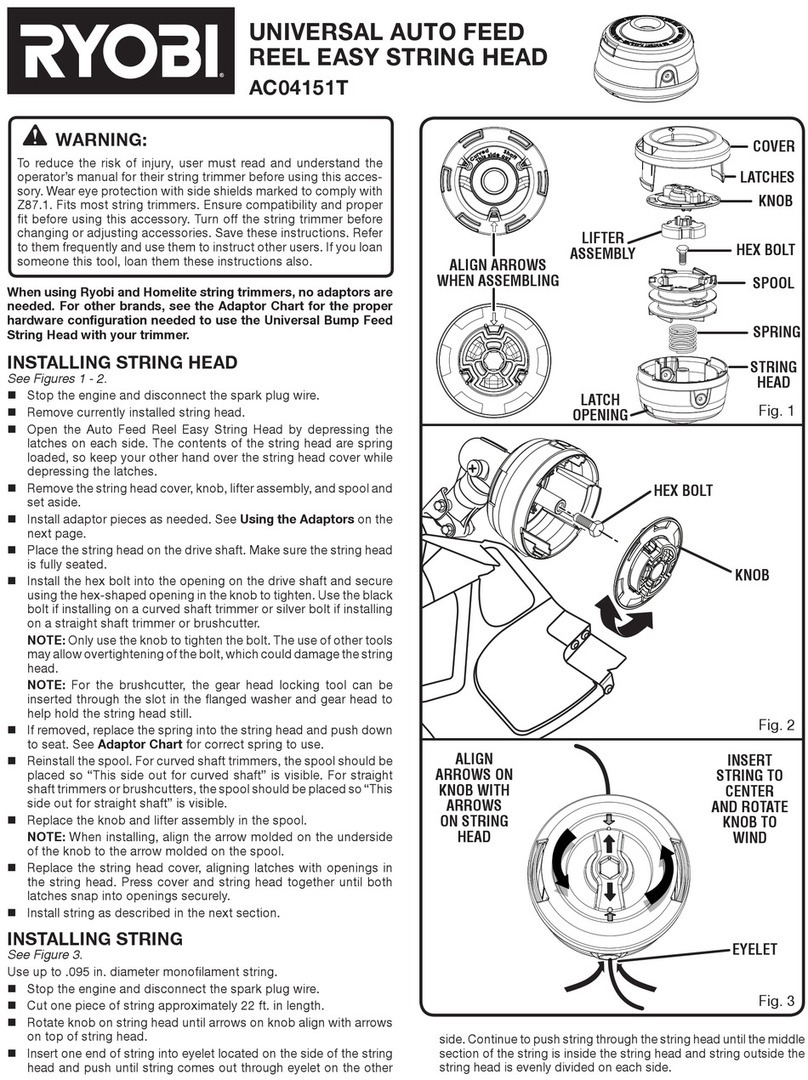

with the parts list on page 3. Refer to Figure 1 if you are

unsure about the description of any part. If any parts are

missing, delay assembly of this kit until you have obtained

the missing part(s).

WARNING:

Attempting to assemble the Router and Jig Saw

Mounting kit or to use in any way without obtaining any

missingparts andinstallingthemcorrectly,couldresult

in an accident resulting in possible serious injury.

TOOLS NEEDED

Tools needed for assembly of this kit are a phillips screw-

driver, two slotted screwdrivers, and an adjustable wrench.

Note: Adjustable wrench will be used to tighten threaded

post into the special 5/16 in. T-nut provided.